When supplies of high pressure mercury or other liquids are required in analytical work, it is convenient to have the source of supply at a relatively constant pressure and available in sufficient volume to satisfy the requirements of the apparatus in use.

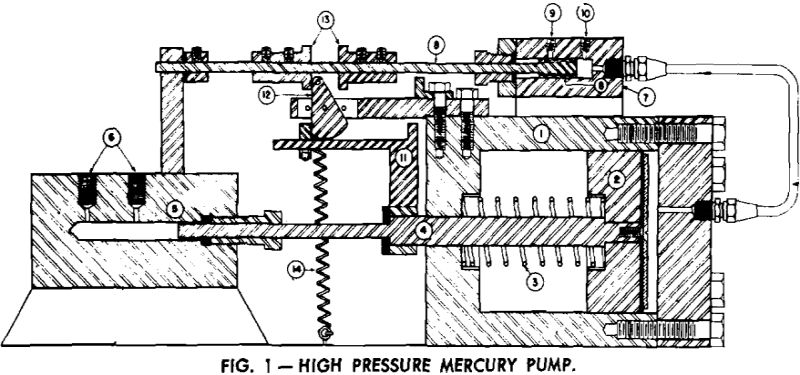

Air enters the pump through the inlet port into the valve cylinder passes through the connecting tubing and main cylinder head and acts on the piston. Pressure in the air cylinder increases until the pressure in the mercury end is sufficient to open the discharge check valve, one of the ports indicated at. When this critical pressure is reached the piston moves forward and the mercury end of the shaft displaces mercury through the check valve.

Although the pump as installed is used intermittantly by hand control of the air supply it could easily be made automatic by the installation of a variable pressure regulator in the air supply line. The internal friction resulting from inaccurate machining and alignment of the component parts sometimes causes the pump to stall during slow operation at maximum discharge pressures above 5,000 psi.