Table of Contents

High-pressure grinding rolls (HPGRs) have struggled for acceptance into the hard-rock mining sector.

CRITICAL HPGR PARAMETERS

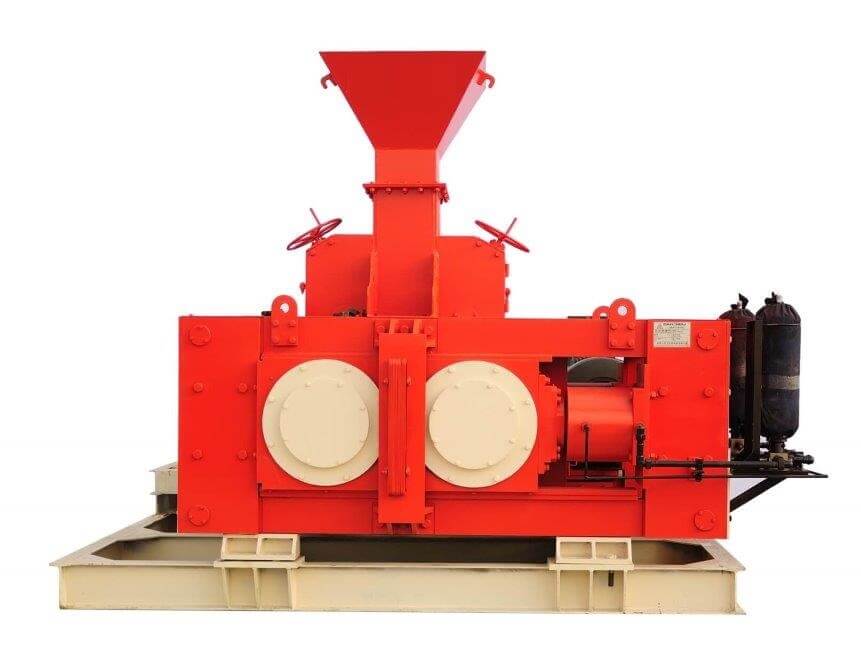

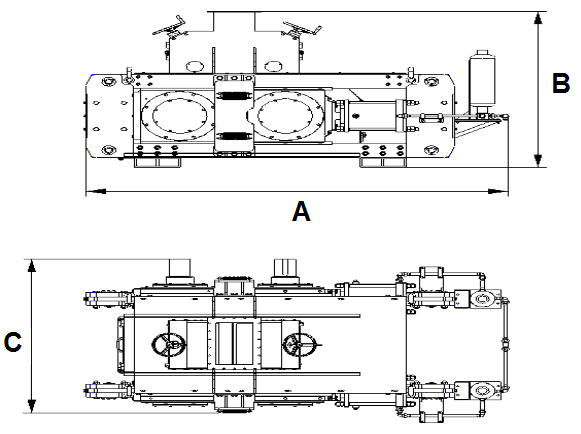

HPGR roll diameters typically range from 0.5 m to 2.8 m, depending on the supplies, and roll widths vary from 0.2 m to 1.8 m. The aspect ratio of the rolls also varies as a function of manufacturer. Typical HPGR throughput rates range from 20 to 3,000 tph, with installed motor power as high as 3,000 kW per roll. The roll surface is protected with wear-resistant materials, and it has been these that have traditionally stymied HPGR acceptance, but solutions are now in place.

When operating an HPGR, the two most important operating parameters are

- Operating pressure

- Roll speed

The two key operating parameters are inherently linked to the following:

- Specific throughput

- Specific pressing force

- Maximum pressure between the rolls

- Specific energy input

Detailed descriptions of the derivation and formulation of the parameters are given in numerous texts, and as such, the following section provides only a precis of the critical formulas, with some examples of actual relationships from testwork.

When a plant design (with or without High Pressure Grinding Rolls) is being assembled, every well-equipped engineer will be able to turn to numerous rules of thumb associated with these crushers-even without reference to textbooks or suppliers.

The types of rules referenced above include:

- Product-size distribution will be approximately 80% passing the closed-side setting— with poor applications dropping to 50%.

- Centralised and circumferentially distributed feed is required to extract the best performance.

- Profile and condition of the crushing liners is critical to deliver the best distribution of energy into the crushing chamber.

- Low-bulk-density feeds reduce throughput.

- Maximum product bulk density is 1.9 to 2.1 t/m3 for average limestone feed-stock.

- Secondary applications are power driven, whilst tertiary duties are pressure driven.

- Mostly 5°/o-10% of the feed-size distribution is the maximum less than the closed side setting—except with modern cones that are trying to generate interparticle crushing.

- Maximum feed size should not exceed 80% of the open-side feed opening.

- Feed moistures >4% should be avoided.

|

|

HPGR comminution provides considerable benefits to the heap leaching:

- Even under the compaction caused by haulage trucks, HPGR-treated ore exhibits better solution percolation than conventionally crushed feed.

- Dump leach ores or coarsely crushed heap feeds still are subject to problems of insufficient oxygen availability. Current HPGR tests indicate improvements in oxygen availability at the leachate-copper mineral contact of up to 30%. Oxygen diffusion paths are significantly reduced and surface coatings are fractured resulting in acceleration of surface oxidation for sulfides.

- Microfracturmg of up to 60% of the coarse (i.e. +100 mesh) particles shortens the diffusion paths to copper minerals and leads to dramatic increases in copper extraction rates.

- Microfracturmg is particulary important to overall kinetics in ores with notoriously slow penetration rates. It also reduces another metallurgical problem, i.e. the presence of trapped air between particles and within the pore space. In a conventionally crushed ore, trapped air can significantly retard leaching by blocking solution penetration.

- Hold-up of leach solutions enriched in iron salts, particularly in the coarse sand fractions of dumps/heaps may retard oxidation of sulfides and solution drainage. Our results indicate that HPGR shortens the drainage cycles in the coarse particle size range (+100 mesh) and enhances salt-rich lixiviant flow.

- In many conventionally crushed ores, sulfide particles are blocking leaching channels. Microscopic work indicates that HPGR minimizes this problem by providing considerably more alternative leaching space.

- HPGR reduces acid consumption by providing better accessability for the lixiviant to copper minerals through microfractures without excessive increases of reagent-consuming slimes.

Other beneficial aspects indicated by the bench-scale HPGR testwork are:

- Potential for cost-efficient haulage to distant leach sites.

- Optimizes solution application during flooding, trickling or sprinkling.

- May shorten acid curing periods.

- Strongly enhances leaching of both fracture- located and disseminated copper.

- Improves bacterial access to sulfides and accelerates bioleach kinetics.

- Substantial (up to 15%) increases of copper extraction rates.

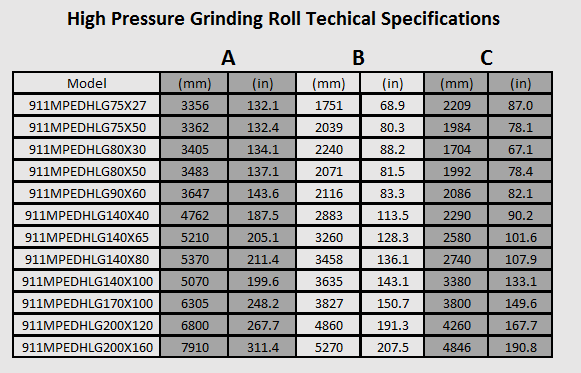

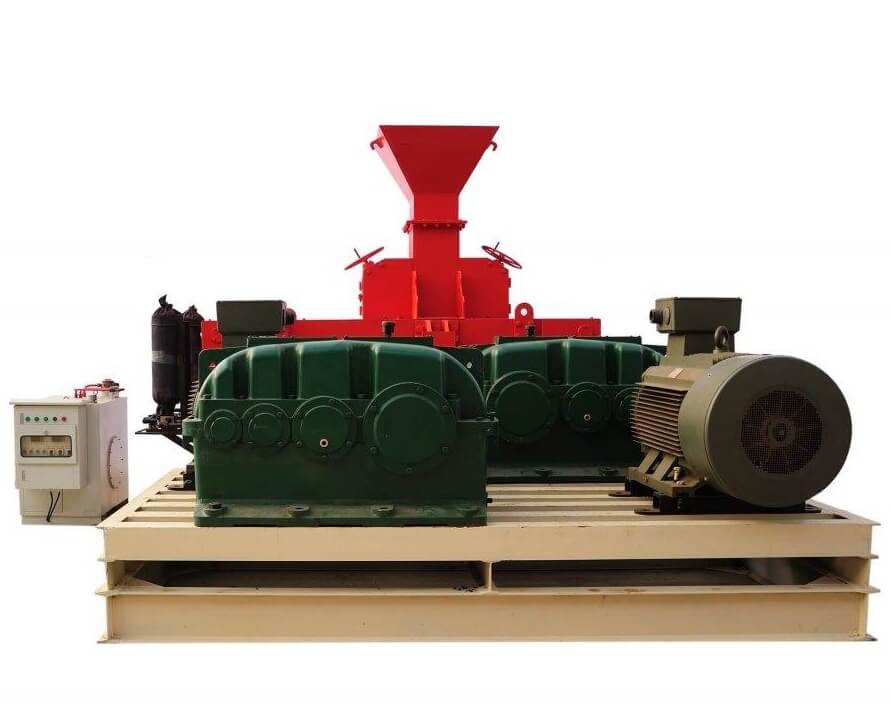

High Pressure Grinding Roll Features & Performance

The high pressure grinding roll has established itself in various industries. High pressure grinding rolls has been leading the way for the use of HPGR in the non-ferrous metals mining industry. In comminution circuits of the cement and diamond industry, HPGR has become a standard grinding tool. HPGR has demonstrated economic and technical benefits that are nothing short of spectacular.

HPGR offers operational features such as low wear, high availability, push button control for fineness of grind and throughput, compact size, proven technology and performance guarantees will become pivotal for plant optimization and expansion. The key features of HPGR, the cost-efficient operation due to reduction of power and the even more significant decreases of steel wear cost, have been unchallenged by any other available comminution technology.

HPGR Comminution

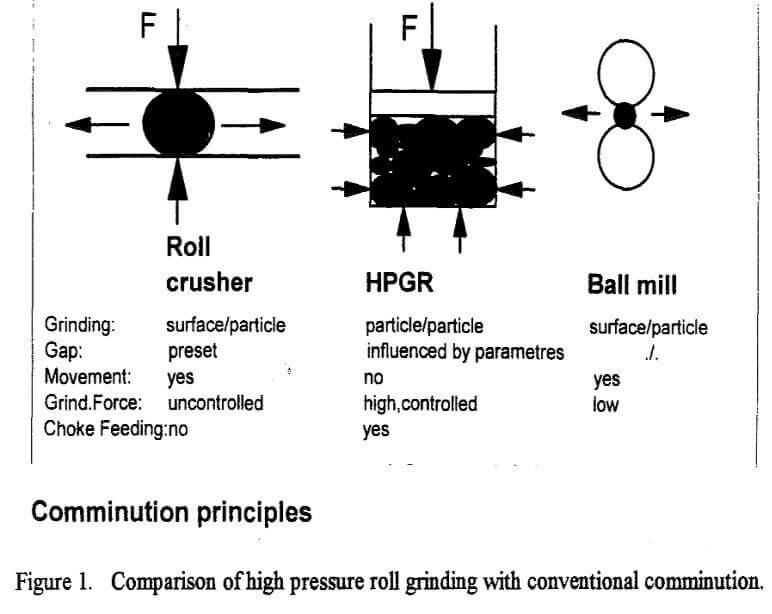

Unfortunately, high pressure grinding rolls continue to be confused with conventional roll crushers. HPGR comminution is substantially different from impact, attrition and abrasion comminution as it occurs in crushers, SAG and ball mills. The HPGR comminution occurs in a bed of particles between two counter-rotating rolls where only a limited amount of the ore is in contact with the rolls. The particles are breaking each other in a restricted space with no opportunity to move or escape. Therefore, the comminution efficiency is significantly higher than in conventional crushing and ball mill grinding. The HPGR comminution exhibits two extremely important features in regard to hydrometallurgical dump, heap, thin layer, vat or agitation leach operations:

- large amounts of micro-fracturing in the coarse (i.e. +100 mesh) material and

- substantially more fine product without the adverse effects of conventional fine grinding such as over-grinding and slimes.

Figure 1 illustrates the principles of high pressure roll grinding and compares it to conventional comminution.

Operating Experience With HPGR in the Minerals Industry

Operating Experience With HPGR in the Minerals Industry

High-pressure grinding rolls were first applied in the minerals industry in 1985 in cement plants. The main objective for the use of HPGR was the significant energy savings achievable. Today, they are also being used by diamond mines and for the communition of coal as well as for the grinding of slag, iron and chromium concentrates (Figure 4).

If ball milling was completely replaced by HPGR, up to 50% of the energy needed for the dry grinding mill could be saved. In wet grinding, the energy savings are lower, yet still noticeable. Further to the reduction in energy costs, the HPGR also proved to produce higher quality grinding products and/or a better recovery. At present, 165 HPGR Polycom units have been sold worldwide; about 11% of them are operating in the mining industry.

Gold mining operations have, thus far, not utilized the considerable metallurgical and economic benefits offered by HPGR grinding. As is the case with any new processing equipment, a certain acceptance time is required before operators recognize the potential and are willing to modify conventional circuits. Also, while the priority in many grinding operations has been on energy and throughput, gold processing plants, especially, have not recognized the dramatic beneficial effects high-pressure roll grinding has on the gold metallurgy.

A few early problems with the HPGR may have contributed to the reluctance of gold mining to use this equipment. These problems included:

- Older HPGR could not provide an adequate wear protection system for high-wear applications. The fact that hard rock applications caused wear rates of about 25 g/mt initiated the development of a segmented wear protection system (see Figure 5) which provides a sufficiently high amount of wear mass and a fast and easy replacement for a high availability.

- The other major problem was “shoulder formation.” Due to the occurrence of the highest pressure in the center of the roll, the wear is also the strongest in this area causing a deeper profile. This problem has been solved through an automatic roll dressing unit which removes the shoulders during the ongoing operation of the HPGR.

Today, HPGR grinding can handle soft and hard rock feeds without operational downtime until the high equipment availability factor of well over 90% has been reached.

Through these recent optimizations and the simplicity of the unit, today’s HPGR designs provide high reliability and cost-efficient operations. Coupled with the Polycom HPGR small space requirements, they are ideally suited for comminution plant modifications and upgrades. HPGR Polycom grinding is now being considered for several gold operations in the western United States as well as for refractory gold plants in Australia (Grier, 1992). Judging from other technology improvements and operating practices in gold processing which have come from the cement industry (Marsden et al. 1993), it is almost certain that the remarkable impact high-pressure grinding rolls have made in cement plants will also find its way into gold operations.

Even though there are definitely local preferences to the use of comminution technology, the selection of a cost-efficient, high-recovery crushing and grinding circuit depends predominantly on the compositional characteristics of the gold ore. Therefore, many of the subsequent gold recovery problems are directly related to results of the comminution.

Gold Ore Treatment Problems

Although considerable progress has been made with optimized conventional and/or innovative gold ore treatment, significant processing problems remain with many ores. They are primarily related to the mineralogy of the ore feed. Further, the mode of occurrence of the gold is essential for the precious metals recovery after comminution (Baum, 1990).

These findings are supported by Mintek (1993) in an evaluation of gold ores from the Pacific Rim which points out that because of the variability and mineralogical complexity of many ores from the southwest Pacific, very careful control of the comminution process is required for optimum results.

The following listing highlights pertinent gold ore treatment and recovery problems inherent to conventional comminution.

- The plant throughput in most gold operations by far exceeds the initial design, especially when lower ore grades are encountered. This will inevitably result in extended operating hours, lower throughput, poor grinding size, and escalating operating costs (Chadwick, 1991).

- Larger fragments (“clasts”) of harder ore frequently limit the throughput of the grinding circuit.

- Optimization of gold recovery by gravity, flotation or cyanidation is still being hampered in many operations by the limitations conventional comminution circuits show in regard to fine particle liberation without generating excessive fines due to overgrinding.

- High circulating loads will result in fine grinding SAG mills leading to slimes coatings on coarse gold or gold-bearing sulfide surfaces. This causes gold losses in conventional grinding circuits (e.g., gold buildup in the classifier underflow).

- The increased use of whole ore roasting will depend on better liberation and minimization of bottlenecks in the dry grinding and classification circuits.

- Conventional grinding does not permit treatment of large tonnages of very low-grade, ultrafine gold mineralizations, oxide and refractory alike.

- Considerable amounts of coarse gold-gangue middlings are still being lost in many milling operations.

- Conventional fine ball mill (over)grinding is generally the reason for increased leachability of both metallurgically and environmentally troublesome heavy metals such as arsenic, thallium, etc.

- Poor fracturing of the gangue matrix.

- Slimes coatings and agglomerations in ball mills.

- Large amounts of detrimental tramp iron in the pulp. Conventional grinding circuits typically generate 0.5 to 2.5 kg of tramp iron per ton of ore milled (Marsden and House, 1992). Plants with mill throughputs of over 3000 t/d can lose up to $500,000 per year in gold and silver due to the effects of tramp iron.

- Flattening and surface contamination of coarse gold.