Union Carbide began looking seriously at heap leaching in 1971- At that time some 1.6 million tons of mineral averaging 0.040% U3O8 were stockpiled at various sites around the Gas Hills, Wyoming, uranium facility. Several alternatives for economically exploiting these reserves were considered and heap leaching seemed the most attractive. At the time, Western Nuclear Inc. was operating a heap leach project nearby in which the low-grade ore was leached with sulfuric acid, the product liquor treated in an on-site solvent extraction circuit, and the stripped product liquor re-acidified and recycled.

Pilot Test Program

Prior to the pilot heap test, samples of the various mineral piles were evaluated in bench-scale testing. The objectives of this study were to determine (1) the acid requirement, (2) permeability of the ore, (3) ultimate U3O8 recovery, (4) probable product liquor grade, and (5) an estimate of heap economics. These tests were conducted on small samples, usually 100 grams or less. The laboratory data on these samples indicated that the liquor would flow readily through the ore with an anticipated flow rate of 10-20 gallons per square foot per day (400-800 l/m²) compared to about 3-6 gallons per square foot (129-240 l/m²) of pond area observed by Western Nuclear. The tests indicated that 20 pounds of H2SO4 per ton of ore (10 kg/t) were required for leaching and that only 100-150 gallons of leaching solution (400-600 l/t) per wetted ton would be required for uranium recoveries of 90% and that the liquor grade could reach as high as 2.0 grams U3O8 per liter.

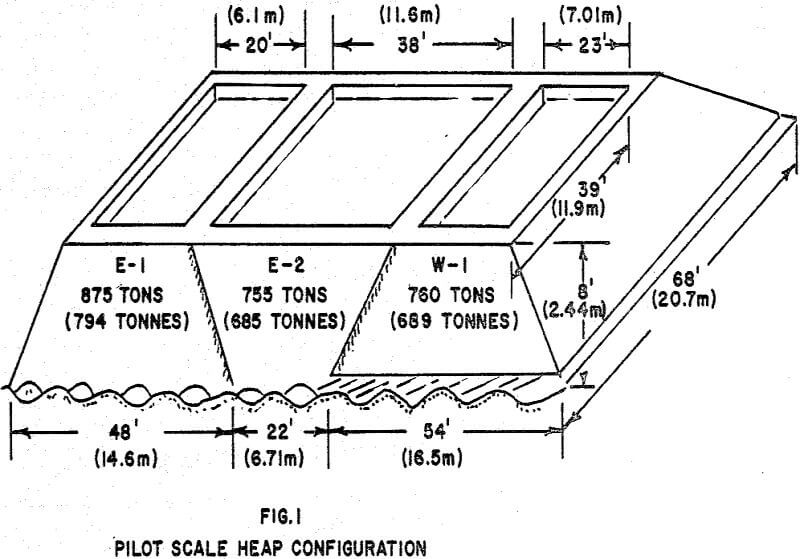

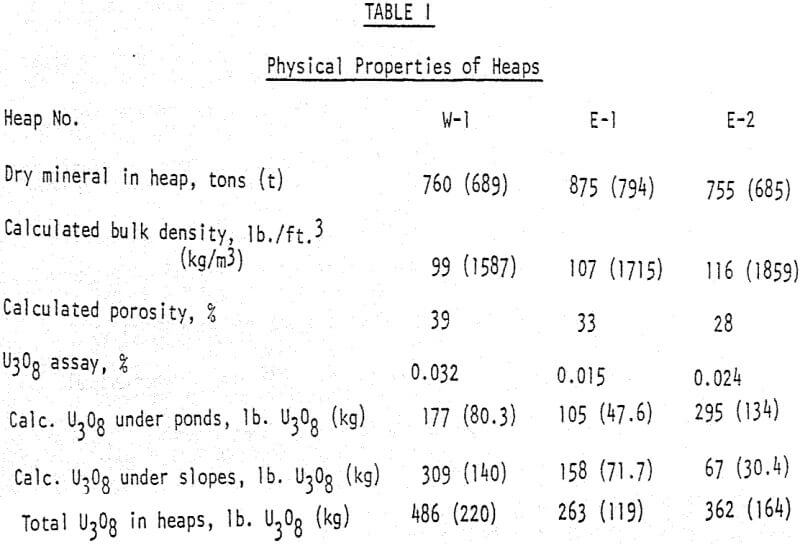

Three test heaps, employing various sources of low-grade mineral, were planned. The stockpiles were essentially unconsolidated sands and required no crushing.

Full-Scale Pilot Heap Operation

In the early spring of 1973, construction of a 225,000-ton (204,000 t) full-scale pilot heap was begun at Gas Hills. The heap base was limited to the area of the old tailing pond and this determined the size of the heap. While leaching operations would start in 1973, the heap construction would not be completed until 1974. This was accomplished by starting the base at one end of the heap area and progressing lengthwise. As soon as the base was laid and compacted, the perforated pipe was laid down with a covering of gravel. This operation was followed by a 5-foot protective covering of ore, and lastly the heap itself was constructed to elevation in a single lift. About 125,000 tons (113,000 t) were placed on the base in 1973 with the remaining 100,000 tons (91,000 t) added in 1974. All the construction operations were carried out simultaneously.

The construction of the clay base was carried out under the guidance of Dames and Moore. Their field engineers sampled and tested local clays and conducted the laboratory tests to determine the suitability of the available clays. Placement of the 12-inch (0.3m) clay liner was accomplished in two 6-inch (0.15m) lifts compacted with a sheepsfoot roller. The moisture content of the clay was adjusted and each lift was compacted to 85-90% of maximum dry density. Seepage rate through the clay liner was calculated to be less than one foot per year.

The operating scheme was to leach the individual ponds in a staged sequence. Two ponds were to be on the leaching cycle while the third was being washed. In effect, 2/3 of the heap production was to be processed for uranium recovery with the low-grade wash liquor on recycle. Figure 8 is a schematic plan of the operating procedure. Upon completion of the 200-gallons-per-ton (840 l/t) leach and the 100-gallon-per-ton (425 l/t) wash, the Stage 3 pond would be shut down and Ponds 4a and 4b would be flooded. Ponds 3A and 3B would continue as Stage 2 leach while Ponds 2A and 2B would be converted to a washing stage. The objective, of course, was to optimize liquor grade to the processing facilities without sacrificing uranium recovery.

Maybell Heap Leach Experience

Construction of the Maybell heap base was started in June 1975. The entire base for the planned 1976 operation was constructed prior to the placing of ore and mineral (average length 670 feet (204 m) and width 485 feet (148m)). Ore and mineral haulage were started the first week in August and completed by the end of November. Base construction was from local clays following the procedures developed at Gas Hills. The entire heap was constructed to 21 feet (6.4 m) in a single lift.

The completed heap was left dormant during the winter months without apparent ill effects. In the spring of 1976, the pond berms were built, the pond bottoms ripped, and construction of the processing plant was begun. The processing plant consisted of three 120-gpm (7.6 l/s) skid-mounted, continuous IX columns and three elution columns with the attendant solution makeup facilities. Yellow cake precipitation tanks with a filter press for recovery of the yellow cake were installed.

The water for leaching was obtained from an abandoned pit, acidified with H2SO4, and pumped to the appropriate ponds. Once the operation was underway all solutions were recycled and only the necessary makeup water was required from the pit. Pond size and flooding schedules were designed at levels to provide full flow of product liquor to the IX column and maintain recycle of wash liquor.

Minimal maintenance of the heap ponds is required and can be handled during day shift only. Adequate pumping capacity is installed so that pond flooding is limited to day shift only. Experience shows that a properly designed plant can be operated with two operators per shift. An auxiliary, gasoline-powered pump is recommended on the heap product liquor pond for solution recycle in the event of an extended power outage. Once a heap is in operation, there is no way of shutting it off, and an emergency means of handling the liquor must be provided.