The estimating of volumes is a routine practice in an open pit-heap leaching operation. Until recently, the conventional cross-section manual method has been used at Wharf Resources’ South Dakota operation for the estimate of material mined from the pits, crushed ore delivered to the heaps, unload spent ore, ore and topsoil stockpiles, waste dumps and other earthwork projects.

MINE-SURVEY is a general mine surveying and mapping computer system designed for IBM and IBM-compatible personal computers. It consists of several integrated program modules for data entry, reduction, volume calculation, plotting of survey data and database management. MINE-SURVEY treats all topographic surfaces as lines of three-dimensional points and stores them in separate status maps or working periods representing different configuration as a function of time.

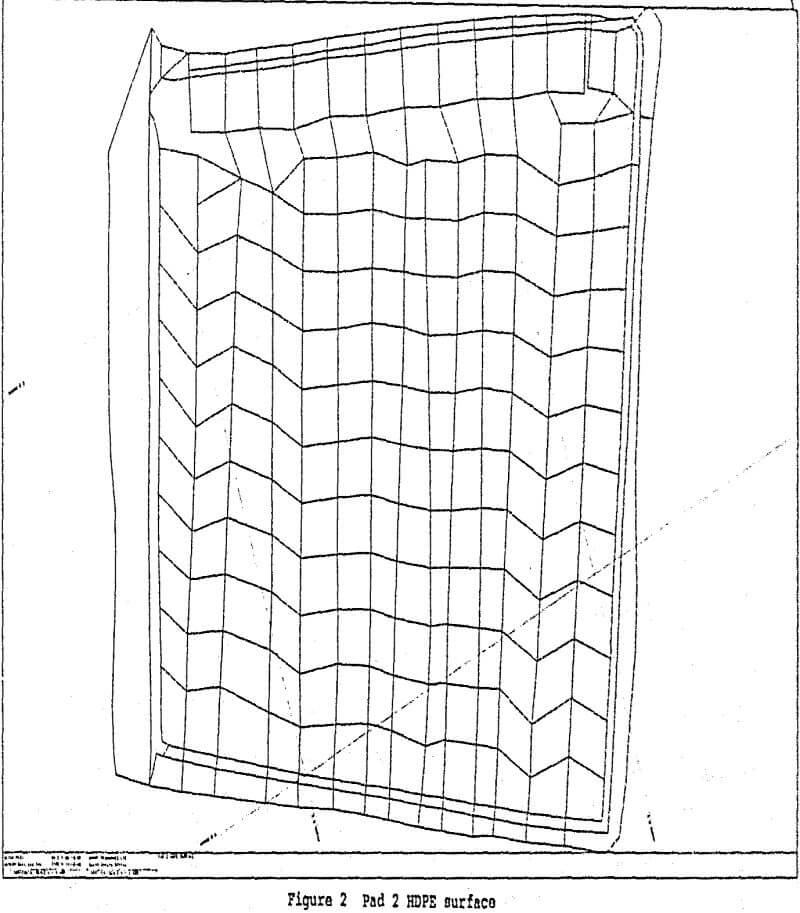

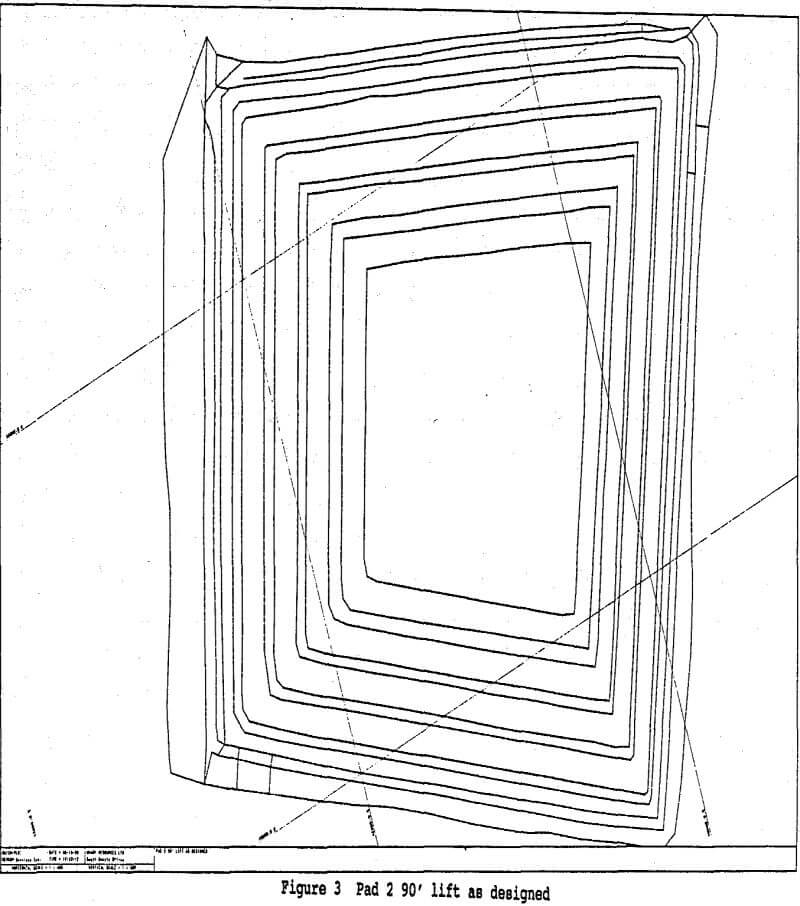

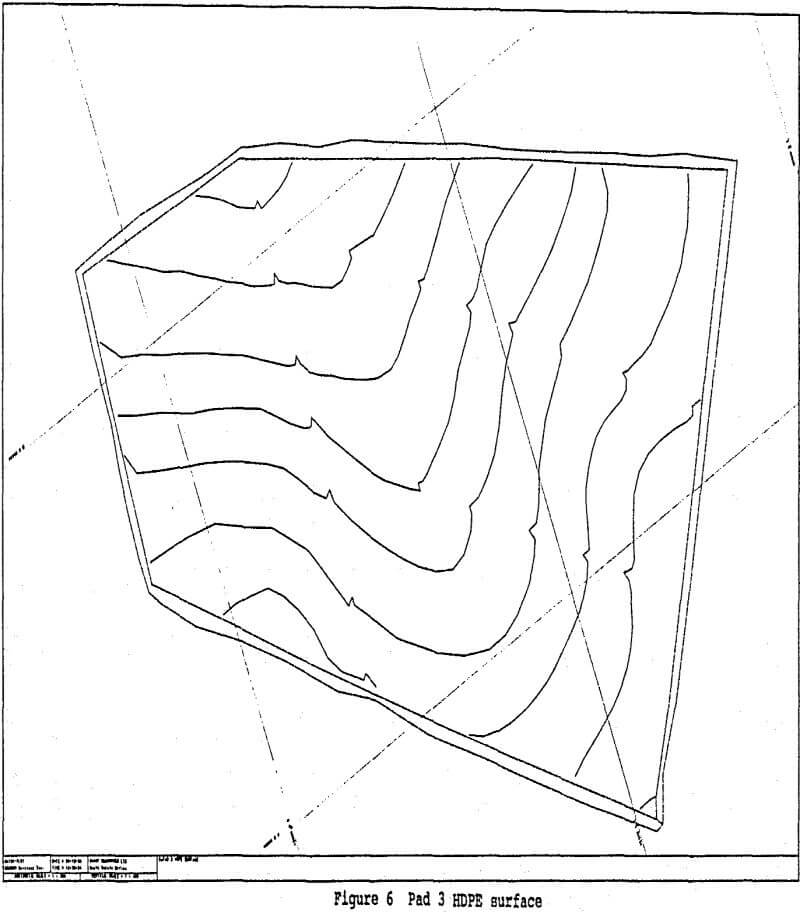

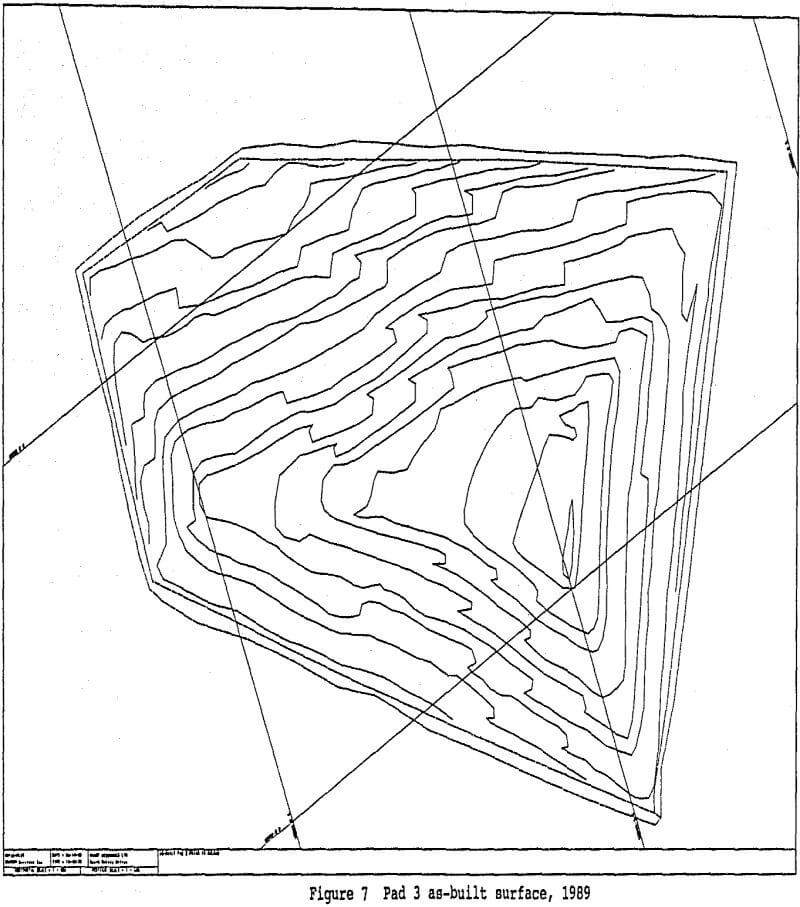

The general practice consists of shooting a tight grid for the primary HDPE liner and berms. This process is repeated when the ten-foot cushion layer is completed. These two surfaces constitute the key elements for the loading/unloading of pads. The toe and crest of subsequent ore lifts are surveyed on a weekly basis and at the end of the month for volume reconciliation.

A working period can be defined as a surface representation of the pads as a function of time. It can be an as-built surface or a designed surface. The first working period to be created is the pad base or primary liner surface. The surveyed grid is tied using one of the line types previously defined. The berm around the pad is connected to the grid and forms the base surface upon which subsequent lifts are added.

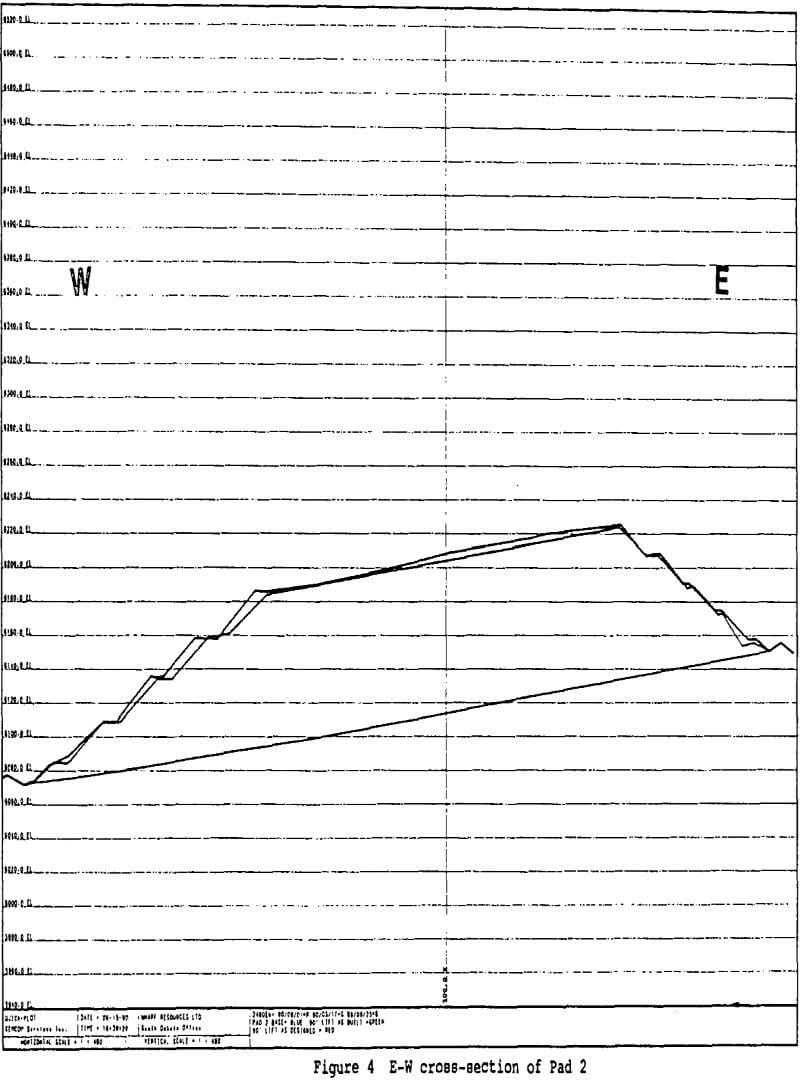

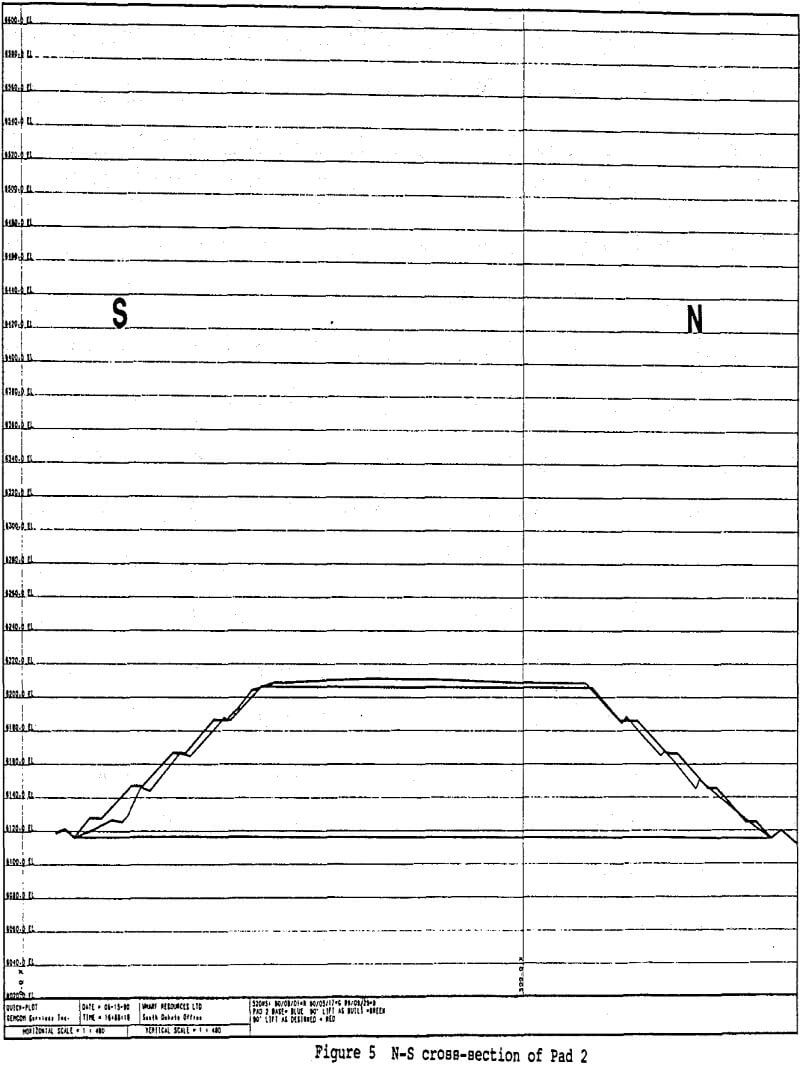

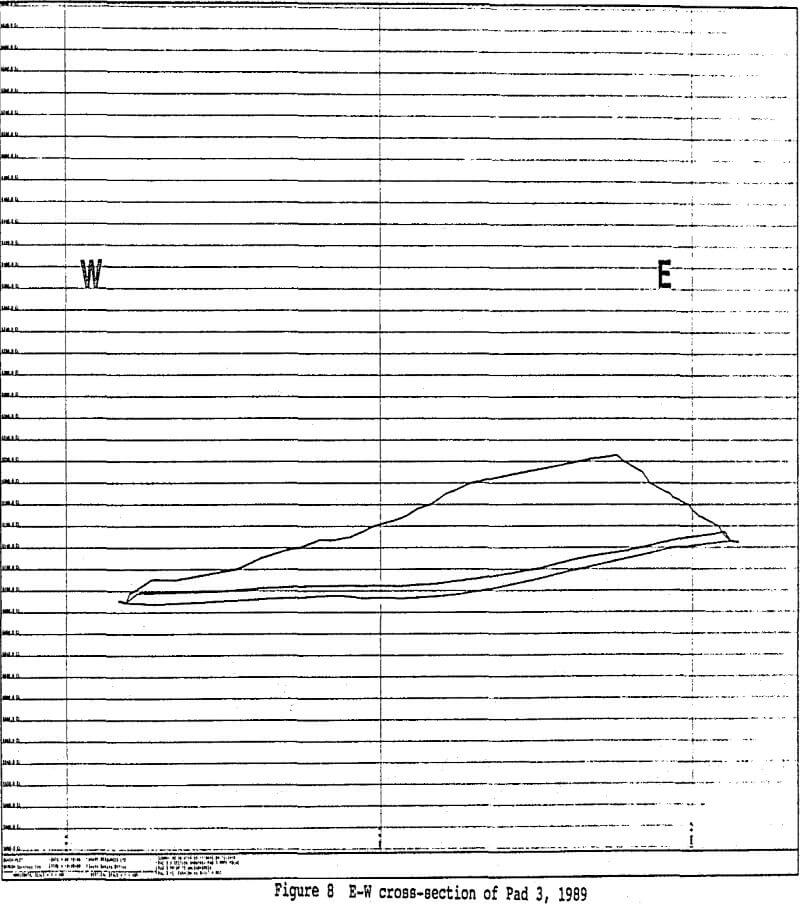

The “Average End Area Method” is used to compute volumes between two working periods; normally two sets of cross-sections perpendicular to the slopes are defined for volume estimation; the spacing between cross- sections depends on the accuracy required.

MINE-SURVEY has the option to generate cross-sections automatically. This is a neat feature when numerous parallel sections are required as the user needs to define only the coordinates of one cross-section together with the desired spacing and total number of sections.

A more reliable, accurate, and timely estimate of crushed ore delivered to the pads and spent ore unloaded from the pads. The tedious and time-consuming manual estimation has been completely eliminated from the process. The estimates are now available within minutes, as opposed to hours or days. The validation of ore densities, truck factors, and the reconciliation of pit production has been substantially improved.