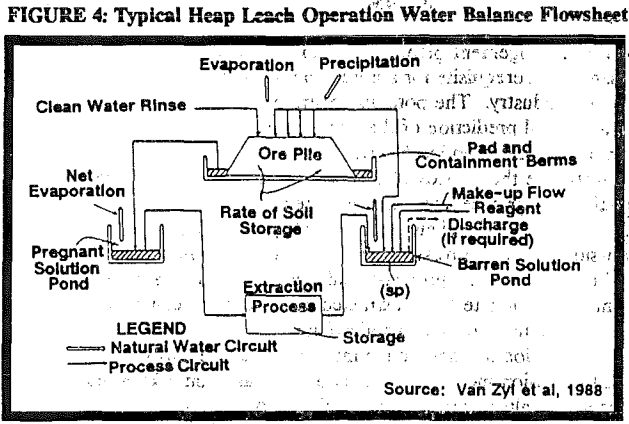

Column testwork on run of pad ore composites has shown that varying the solution application rate from .005 gpm/ft² to .001 gpm/ft² has no effect on the overall silver or gold extraction after a short period of time of 2-3 weeks. The pregnant solution grade is inversely proportional to application rate leading to like extraction values. In other words, the same number of ounces per day can be obtained by lowering the application rate which increases the pregnant solution grade.

It is also known that the operating per-cent moisture in a heap is proportional to the application rate. Higher application rates lead to higher retained solution inventories within the pad and vice-versa. Because a volume of ore drains out to a final moisture independent of leach solution application rate, a lower application rate allows for more volume of ore to be under irrigation without incurring excess solution draindown volumes.

The flowrate decrease is accomplished by turning down the application rate on any pads over 2-3 weeks old. Initial application rates of .005 to .010 gpm/ft² are used on new material to quicken the rate of saturation and eventual solution breakthrough. As soon as a new pad area is available for leach solution, older pads are gradually turned down to obtain the required flowrate for the new pad. One of the keys to this program is the use of drip emitters rather than sprinklers for applying leach solution. The use of emitters enables the heap operator to turn down the flow-rate to a given section of pad without decreasing the application area. This is due to the fact that the area leached with drip emitters is independent of flowrate while decreasing flow to a sprinkling device cuts down the radius of coverage with that device. With an initial operating flowrate of 5600 gpm, it is expected that a final flowrate of 3000-3500 gpm can be reached within 6 months. The overall flowrate is being turned down gradually to give time for solution evaporation and to avoid sudden changes in the circuit.

Heap Leach Solution Management – Decommissioning

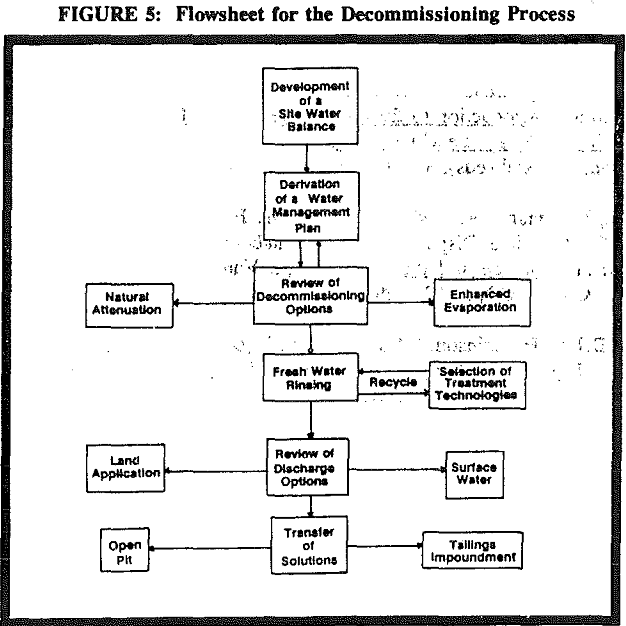

The principal objectives of solution management in decommissioning spent heap leach pads are to meet all operative environmental regulations in a cost-effective manner and to leave the pads in a condition where they do not present a long-term liability either to the operator or to the environment. This involves the reduction in volume of the residual process solutions and/or treatment of these solutions to where they meet applicable water quality criteria.

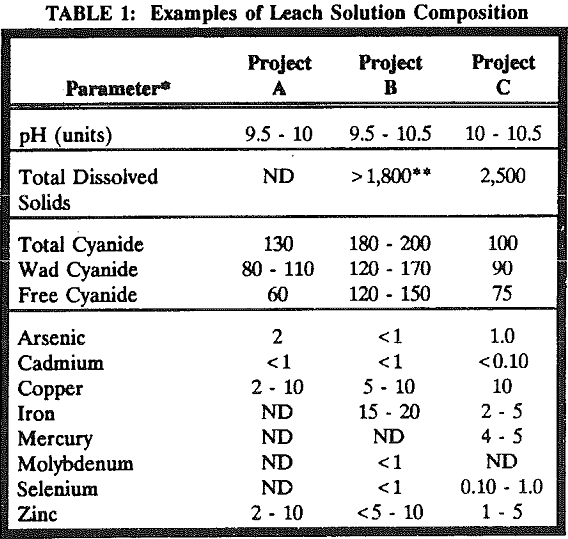

Leach and Process Solution Chemistry

While solution management encompasses consideration of aspects of process solution quantity and quality, it is advantageous to have a general appreciation of process solution quality prior to consideration of overall management strategies and approaches, as it is the quality of the process solutions which ultimately determine their disposition.

4Au + 8NaCN + O2 + 2H2O = 4NaAu(CN)2 = 2NaOH

Irrespective of the preferential formation of a strong complex between gold and cyanide, other reactions taken place between the ore and the process solution during leaching. These include the formation of other metallo-cyanide complexes and the solution of other species from the ore soluble under high pH conditions.

Decommissioning Objectives and Criteria

In order to attain the goal of decommissioning a state agency usually has numerical or narrative standards which must be attained to protect the beneficial uses associated with the surface and groundwaters. The beneficial use classifications may include potable water, agriculture, stock watering, aquatic life, industrial, or recreation. The standards vary widely from state to state as do the controlling agency or agencies. Since the regulations are changing rapidly the first step in the decommissioning process is to contact the appropriate state agency and personnel and obtain a current set of water quality and mining regulations.

Decommissioning standards (or heap leach pads vary between jurisdictions and from state to state, both in terms of the parameters regulated and the numeric standards used. Such regulation can be generic, e.g., state-wide or set on a site-specific basis.

Solution Management Options

There are five primary alternatives for attaining regulatory compliance and handling post-operational process solutions from a spent heap leach facility, although not all may be available for consideration at one particular site:

- Natural attenuation.

- Fresh or treated water rinsing.

- Transfer of solution to another facility or into a tailings impoundment.

- Evaporation of excess solution.

- Treatment and discharge of rinse solutions to meet applicable water quality criteria.

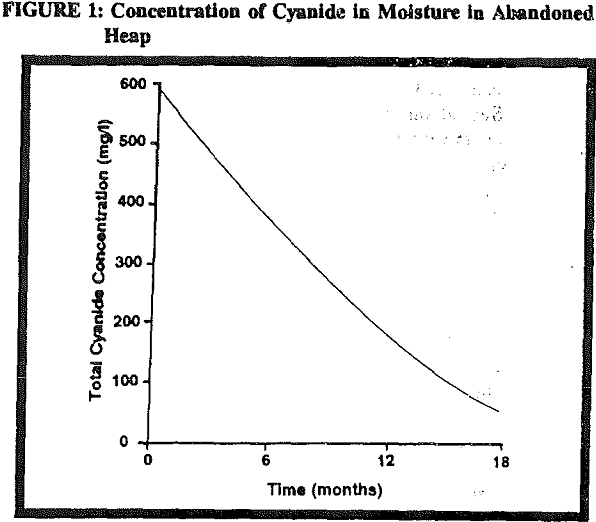

However the time dependency of the process means that the control of the process is out of the operator’s hands. The operator is forced to monitor the system and collect any runoff or seepage from the spent ore which fails to meet regulatory discharge criteria, then wait until the heap leach can be decommissioned. Both the time monitoring requirement and the possibility of handling/treating large volumes of non-dischargeable runoff can be fiscal and practical disincentives to the use of natural degradation.

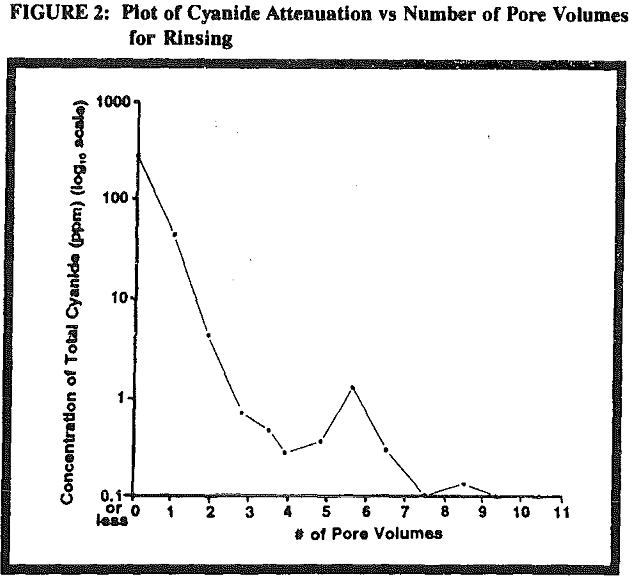

Fresh or Treated Water Rinsing

In the case where a heap leach operation utilizes a number of pads either on a once through basis or load/unload, the transfer of process solution represents a temporary expedient as, on final decommissioning, ” the disposal solutions will need addressing ultimately! However, judicious transfer of process solution within the operation can have the effect on minimizing the total amount of fluid the operation requires, leading to a smaller ultimate management concern.

Intuitively and probably economically, the evaporation alternative is normally preferred where natural attenuation is unlikely or feasible and there are no other mine facilities, such as other operational pads or tailings impoundments, which can accept the redundant process solutions.

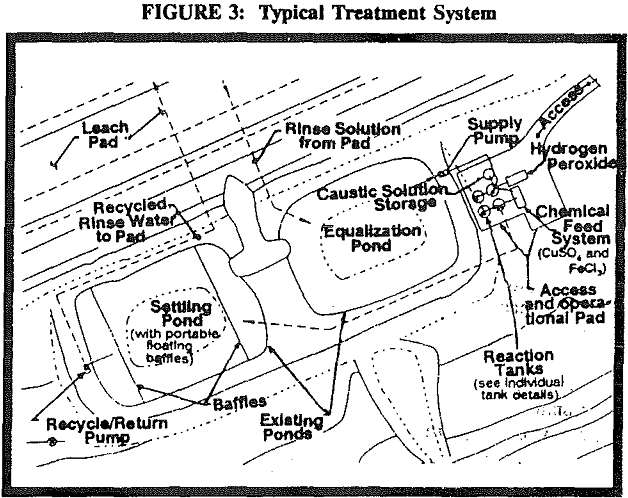

In the event fresh water rinsing and/or natural attenuation are not successful in attaining a desired effluent quality, treatment of the solutions may be required. The goal of rinse solution treatment is to reduce the pH, metals, and/or wad cyanide to levels acceptable for discharge into surface water or land application.

If treatment is required, the identical processes are available as would be applied in either discharge option. Wad cyanide will be parameter of primary concern due to potential for impacts to wildlife. However, the levels of wad cyanide are readily reduced through rinsing, natural attenuation, or treatment to acceptable levels.

Another chemical treatment option employed at less frequently involves addition of ferrous sulfate to either barren or rinse solutions to precipitate cyanide and to form a relatively stable iron cyanide. The addition of ferrous sulfate to a solution with a pH below about 8.5 would quantitatively precipitate the free cyanide from solution.

Site Water Balance and Management Plan

There are two fundamental aspects associated with decommissioning of a spent leach pad. The first involves chemical reclamation during which the constituent concentrations in solution are reduced to acceptable levels either through continuous rinsing with fresh or treated solution, either alone or in combination with natural attenuation.

The second aspect of decommissioning involves physical reclamation which includes an evaluation of the need for capping a spent pad and the options available for reducing the generation of solution entering and exiting the pad. The capping options include compaction alone, compaction with addition of low permeability natural materials, and synthetic covers.