Tailings disposal has been a problem for the mining engineer since the beginning of the metal milling process. Disposal systems in common use have evolved as the most economic method for the disposal of an unwanted waste material within the disposal restrictions in force at the time of construction. As restrictions are constantly being expanded, the design requirements for tailings disposal systems are also being enlarged.

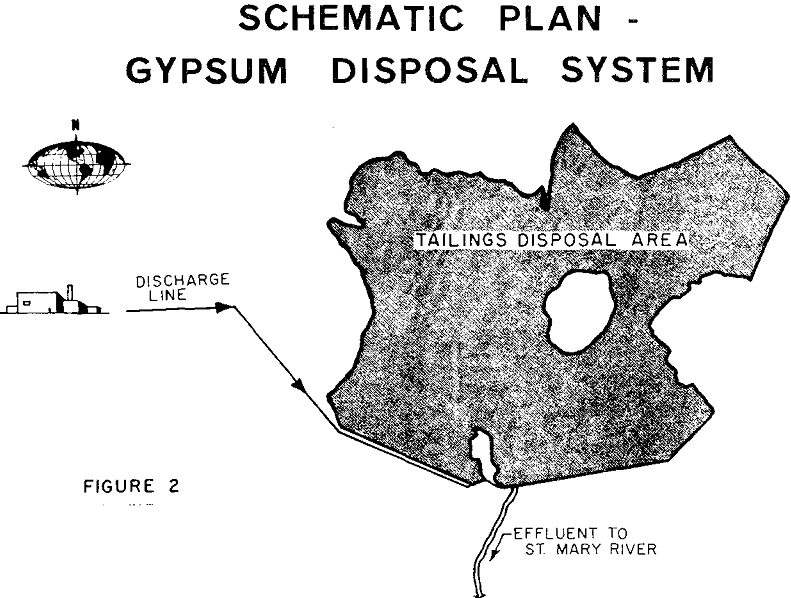

In selecting the location of the tailings disposal area the main consideration should be to obtain maximum disposal with a minimum of embankment construction cost. Also, to reduce transporting costs, an area downgrade from the mill is preferable.

Most tailings disposal systems use hydraulic systems to transport the tailings to the disposal area. This is basically for two reasons. First the milling process creates a tailings slurry, and second, hydraulic transportation provides a more economic method of moving the material. Tailings slurries usually range from 10 to 20 percent solids by weight at the mill discharge and can be thickened to 30 to 50 percent solids for more economic placement.

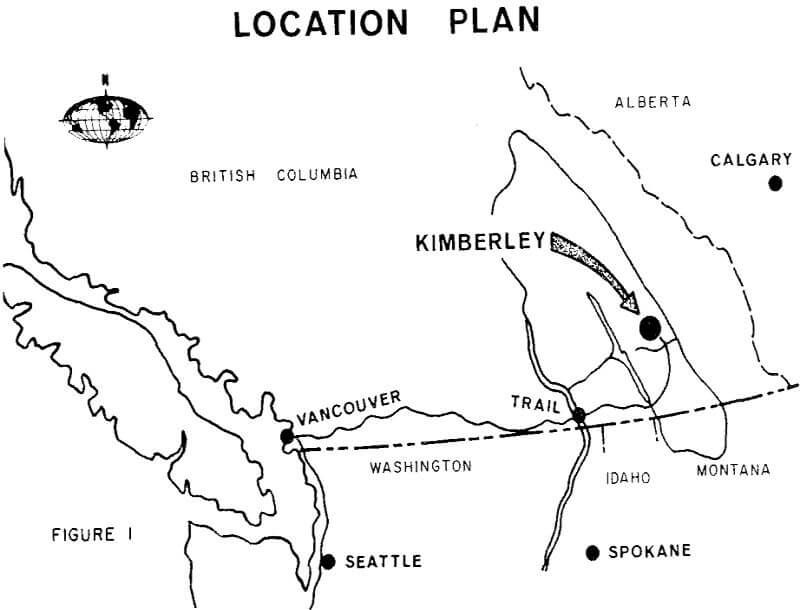

The gypsum tailings pond, which is the subject of this paper, is located in the southeast portion of British Columbia. The site in relation to adjacent provinces, states and major cities is shown on Figure 1. The history of Cominco’s operations at Kimberley dates back to their purchase of the Sullivan Mine in 1910. The Sullivan concentrator at Kimberley has been enlarged over the years to its present capacity of 10,000 tons per day, producing 500 tons per day of lead concentrates, 750 tons per day of zinc concentrates and 1,700 tons per day of iron concentrates.

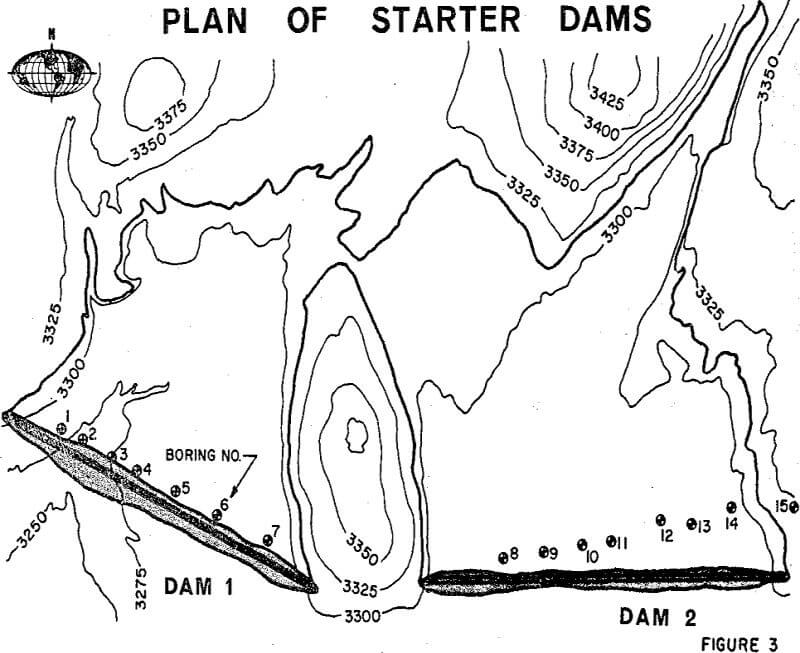

After the approximate location of the two starter dams had been established, the area was investigated by drilling 15 test borings.

All soils encountered in our exploration program were of glacial origin. Granular materials were the predominant type, with particle sizes ranging from sands to cobbles. However, areas of gravelly clay till were encountered in higher areas near the starter dam abutment. Both undisturbed and bulk samples of the natural soils, along with bulk samples of the gypsum tailings, were obtained for laboratory testing.

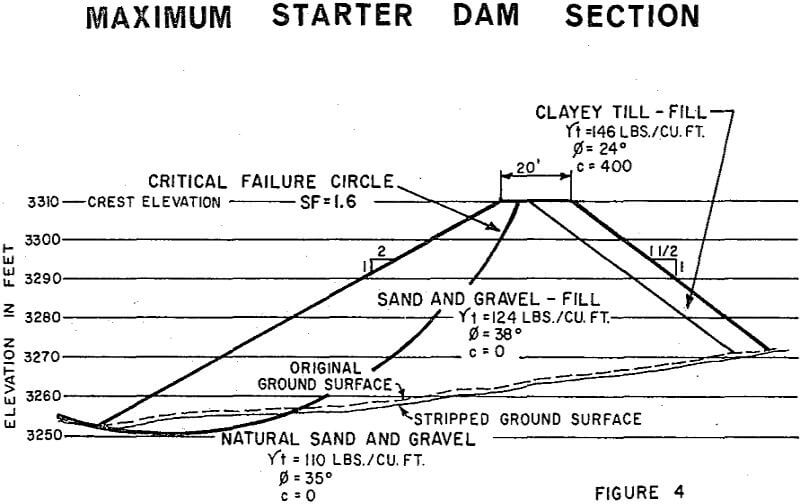

From direct shear and triaxial tests and associated moisture density determinations, the following parameters were developed:

Natural soils below starter dam

∅ = 35 degrees

c = 0

√t = 110 lbs per cubic foot

The embankment design for the starter dam utilized the natural materials available at the site for construction. The bulk portion of the starter dam consists of sand and gravel obtained from the basin area upstream from the starter dam. The impervious clay section was obtained from borrow pits on the higher ground near the starter dam abutments.

In the design criteria for the tailings disposal area a maximum depth of 90 feet was selected as the ultimate tailings height. To define the expected life of the disposal area and to determine the rate at which future embankment construction should proceed, we developed a time-versus-surface-elevation-of-embankment graph.