Table of Contents

Microscopic evaluation of trace quantities of metalliferous phases in flotation products requires counting large numbers of particles. Particle counts of many thousands may be required for precision, but not “obtained practically by conventional microscopic techniques. A less tedious microscopic method for evaluating trace sulfides in mill tailings was developed for the O’okiep Mining Company in South Africa. Hundreds of thousands of particles were evaluated by this method called “gross-counting.”

Sample Preparation

Of prime importance in quantitative microscopy is (1) representative sampling, (2) careful screening or sizing of loose incoherent materials, and (3) random mixing and distribution of particles in microscopic mounts. For this reason, procedures are described for the preparation of polished mounts, as used at Newmont Exploration Limited in Danbury, Connecticut.

Representative samples are carefully split and screened initially for most microscopic examinations. Polished lucite mounts are prepared from individual screen fractions. Screen fractions coarser than 400 mesh (>37µ) are mixed thoroughly and sampled randomly for mount preparation. A two-gram sample is weighed from each screen fraction, and thoroughly mixed with lucite powder (150 mesh) in a 2 to 1 ratio by volume of lucite to sample. The mix is poured into a 1 inch stainless steel mold and 10 more grams of lucite added slowly on top of the mix. The mold is placed into a lucite press and heated to 135°C at a pressure of 10,000 lbs per square inch. The mold is then cooled to about 50°C while maintaining pressure at 10,000 lbs.

Advantages and Limitations of Point-Counting

The purpose of this paper is to describe the analysis of trace particle constituents of flotation products by a new microscopic technique called “gross-counting.” Point-count procedures used by Newmont are also described in order to compare the advantages as well as limitations of both methods in solving problems in mineral dressing. The two methods are complementary to each other in all phases of quantitative mineragraphy. Point-counting is similar to particle counting, but differing in the concept of integrating intersecting points of a random grid rather than tallying numbers of particles. Volume percentages are obtained by either method, but point-count data are statistically more valid, and should be obtained whenever practical in preference to particle counts from either microscopic fields or linear traverse.

Point-counting is most applicable in quantifying particles in higher concentration ranges above 2 or 3 percent, becoming less precise and more time consuming in lower concentration ranges below one percent, especially below 0.1 percent. Gross-counting is most useful in quantifying particles below 0.1 percent, with limited application up to several percent.

The point-counter has greatly expanded the use of quantitative microscopy to geologic and metallurgical problems. At Newmont, microscopic point-counting has been especially useful in the evaluation of flotation products. Samples are screened and prepared into polished lucite mounts for microscopic examination. Polished mounts are traversed under the microscope and the particles tallied by conventional point-counting techniques.

Concepts of Gross-Counting

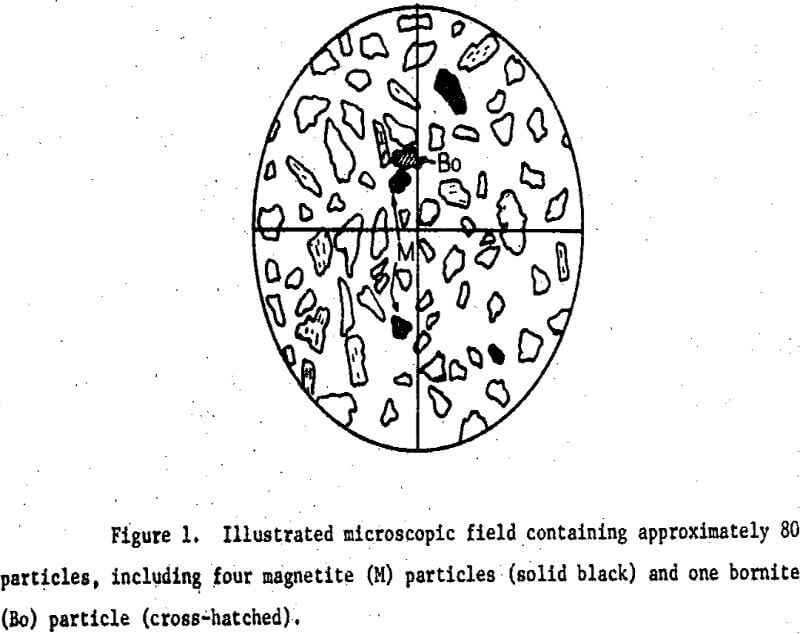

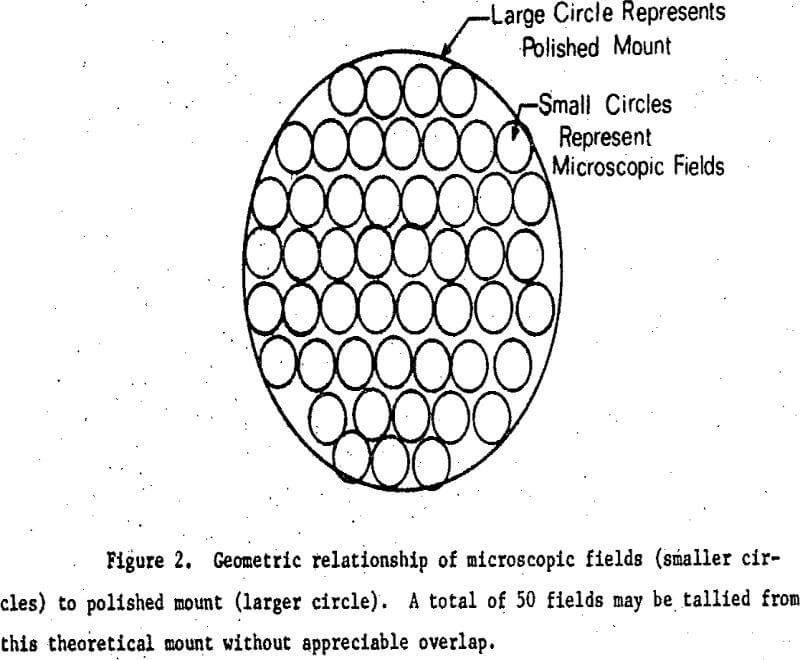

Depending on magnification and mesh size of particles, a microscopic field may contain from several dozen to several hundred or more particles. The field represented by Figure 1 contains one bornite and four magnetite particles in addition to many gangue particles. Most sulfide particles, e.g., chalcopyrite, bornite, pyrite, sphalerite, galena, etc., are highly reflective and recognized readily in a field of many particles. Sulfides and other metallic phases of interest are tallied accordingly on any standard point-count recorder, along with a field count. Each time a field is inspected for sulfide particles, it is recorded on the same recorder and scanning continues to the next field. The number of fields examined per mount may range from about 100 to nearly 500 fields, depending on magnification.

The average particle count per field is ordinarily estimated by particle counts from about 5 or 6 fields randomly selected at widely spaced intervals across the mount. Estimations can be facilitated by selecting optimum magnification .(where total particles per field usually fall in range from 50 to 200) and by counting particles in one quadrant of cross hairs (multiplying by 4 to obtain total field counts). A difference greater than 40% between highest and lowest numbers of particles per field would be considered excessive for accurate gross-count evaluation, and a more homogeneous mount should be prepared.

After averaging the particle counts from five or six fields, the total particle count (C) is estimated from the product of total fields (F) and average total per field, (a).

C = Fa

The number of particles of a given mineral type divided by the total number of scanned particles then gives an approximation of volume percentage, similar to data obtained from point-counting.

Volume % mineral “A” = Number particles Mineral “A”/Total particle count (C) x 100

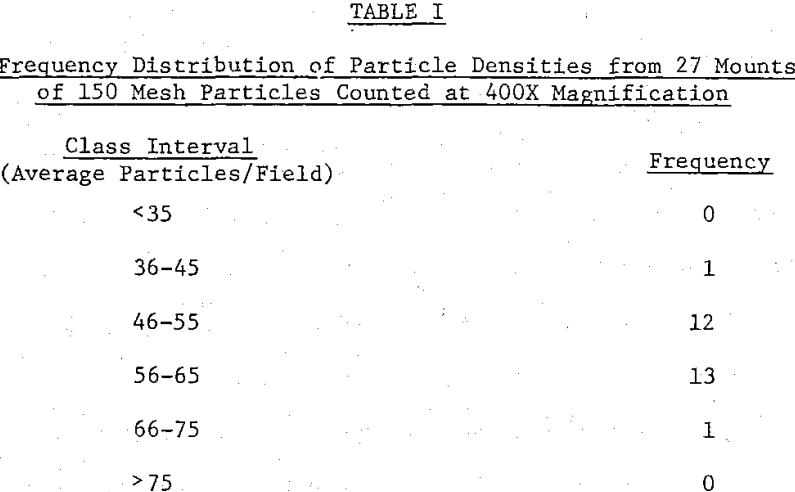

Particle densities for 27 different mounts containing 150 mesh particles were measured at a magnification of 400X, to measure the variation between different mounts. Count data are compared and an overall average of 55.2 particles/field and a standard deviation of 6.3 were calculated. In view of the small standard deviation and the apparent reproducibility of particle densities from mount to mount, use of an overall average can be justified in some cases where equivalent and homogeneous mounts are examined.

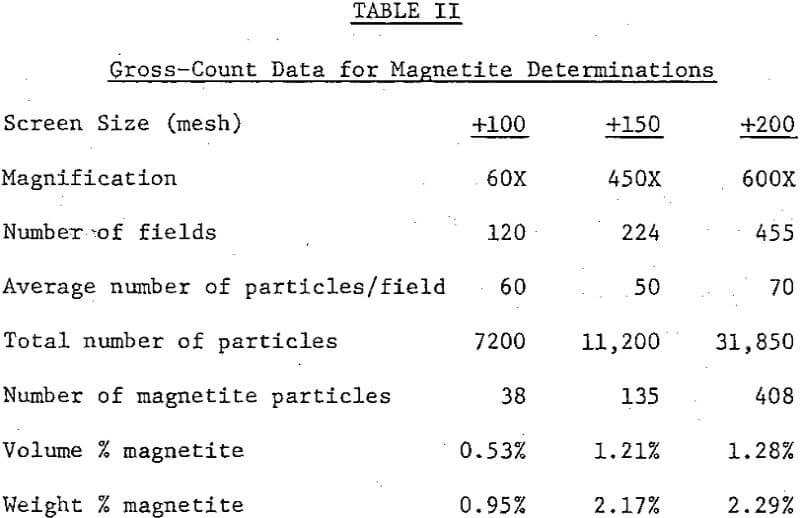

An example of the application of the gross-count method where particles of magnetite are counted in successive fields. A sample containing about one percent magnetite was screened on 100, 150, and 200 mesh Tyler screens. Magnifications are listed for each screen fraction. The total number of fields traversed and total number of magnetite particles observed in all the fields were recorded. For example, a total of 38 particles of magnetite were counted in a total of 120 fields that were inspected in the mount containing plus 100 mesh particles.