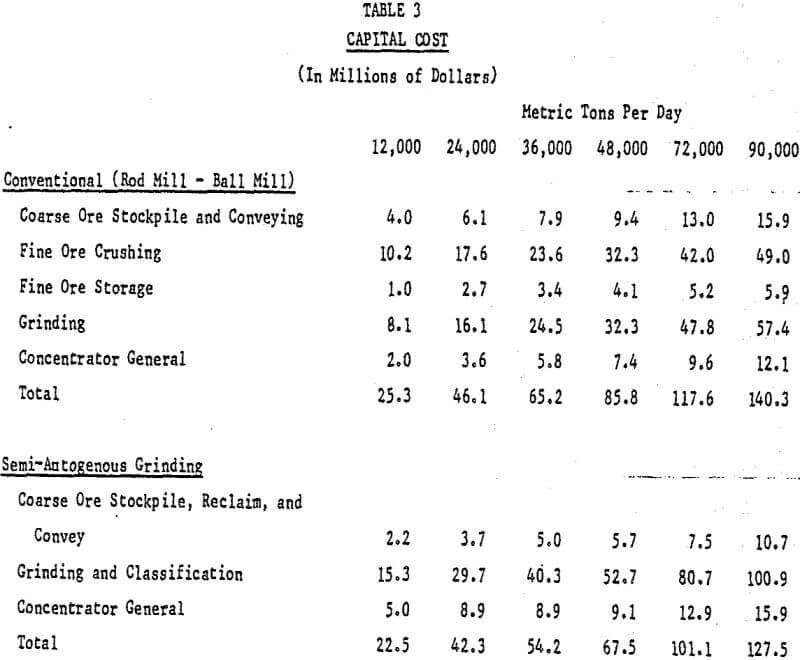

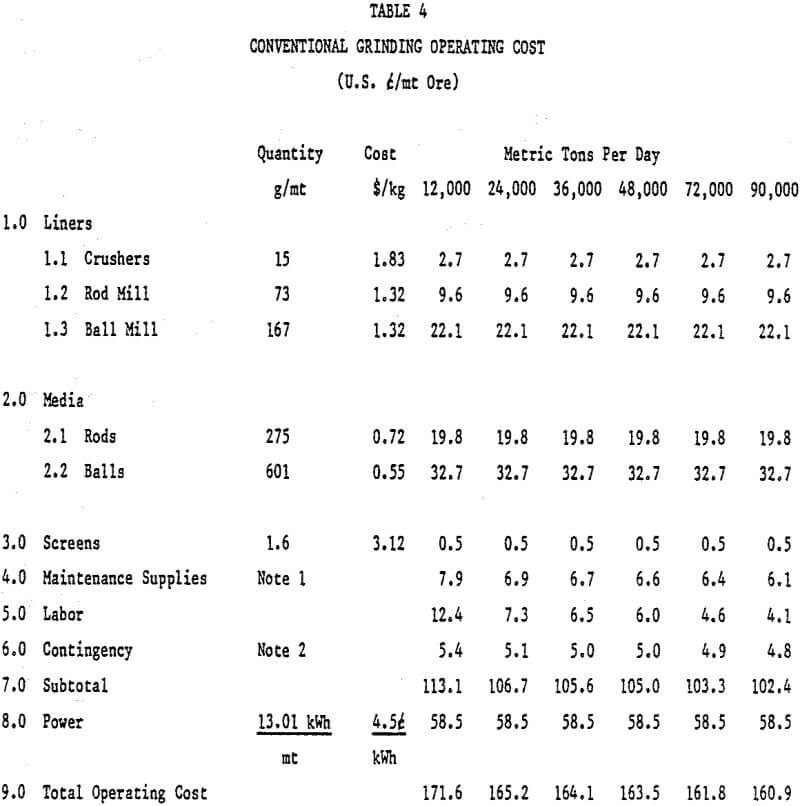

A comminution circuit is an important integral part of a mineral processing plant. Nearly 40% of the capital cost and 30 to 40% of the operating cost are taken up by the crushing and grinding circuit. Therefore, considerable care should be given to the design and selection of this circuit.

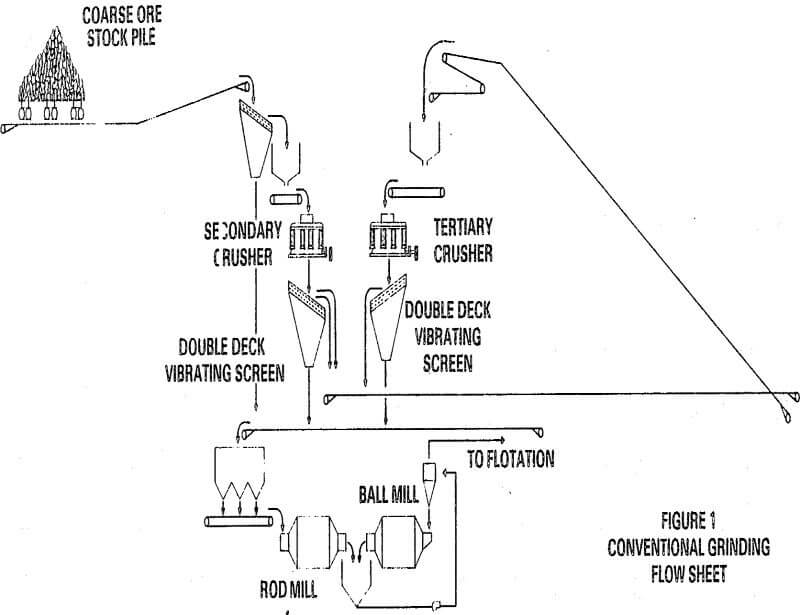

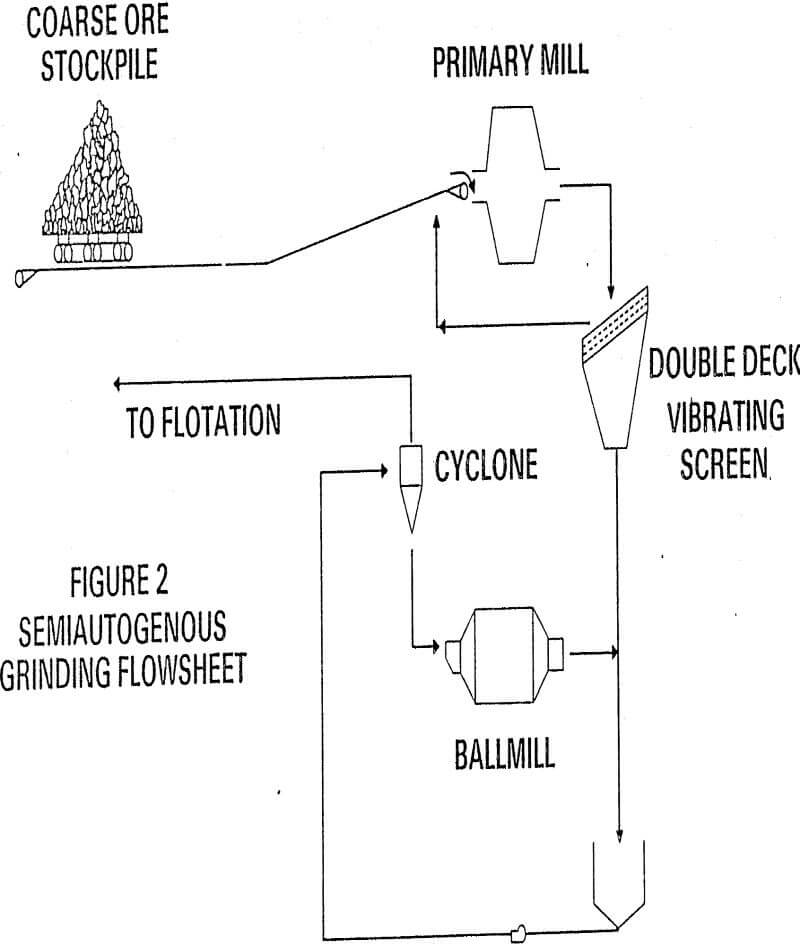

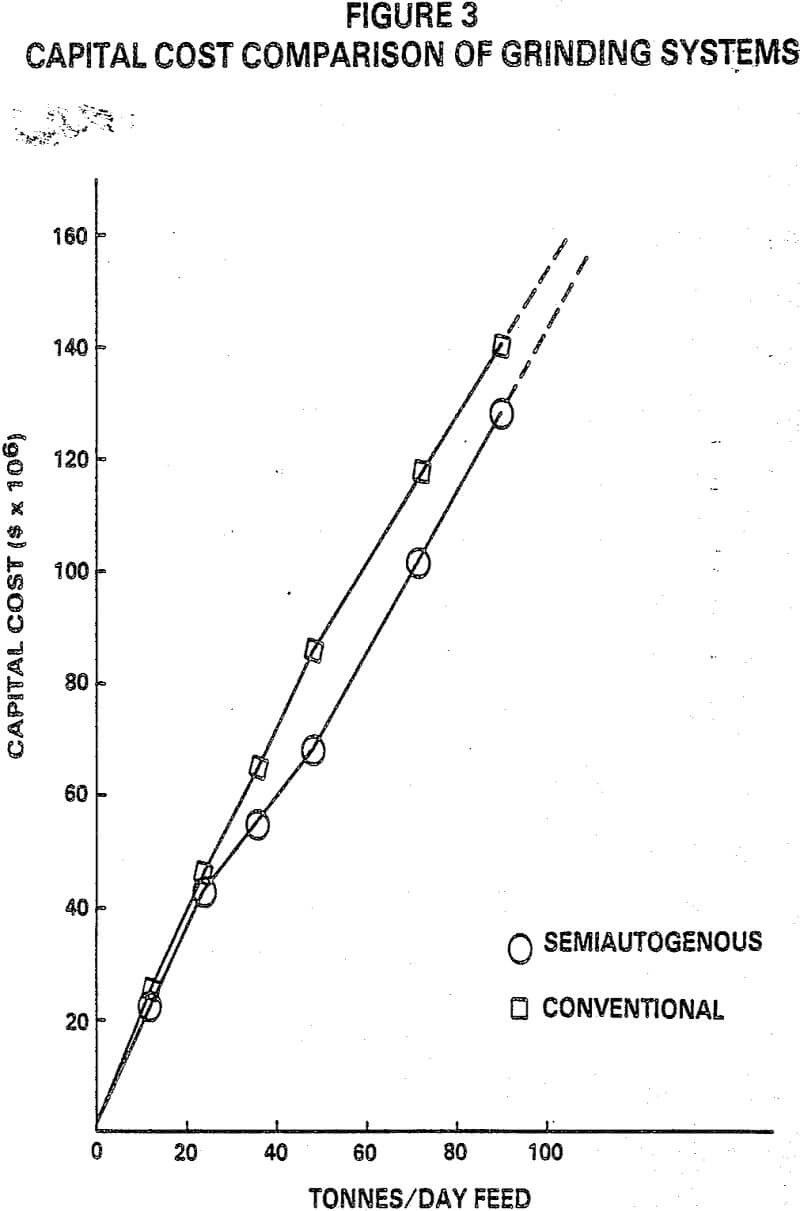

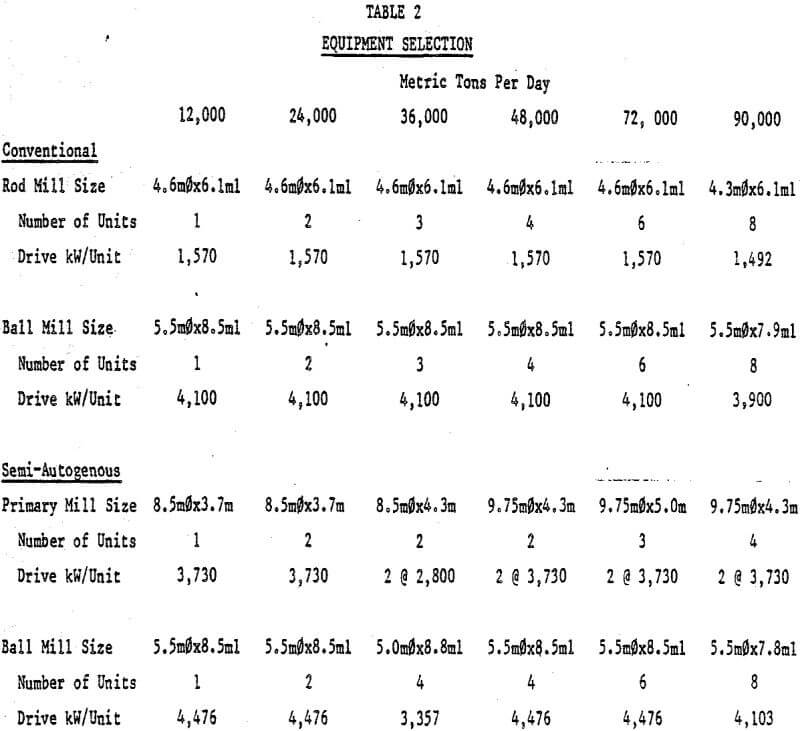

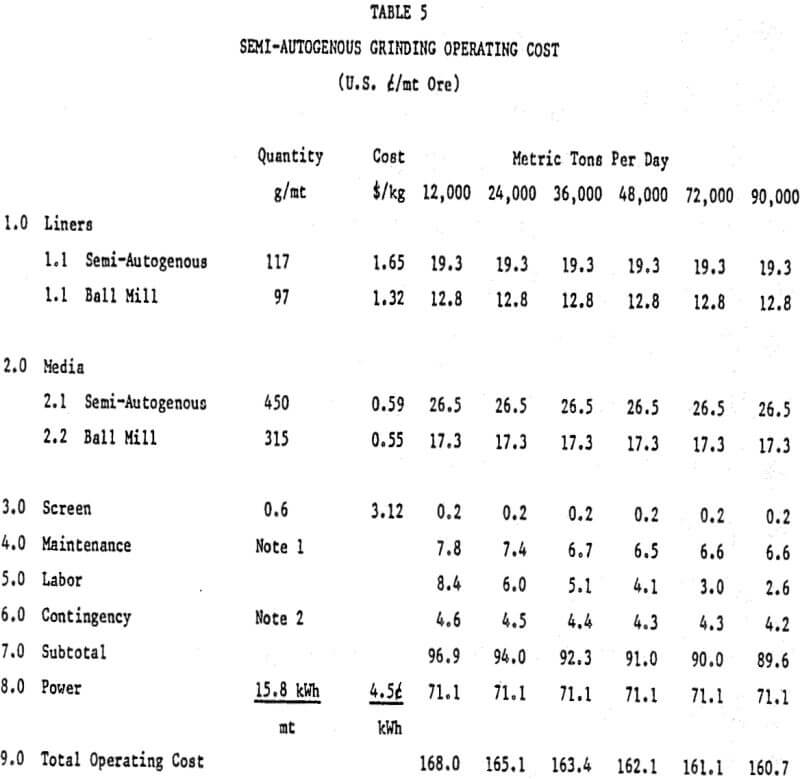

Autogenous, semi-autogenous, and conventional grinding circuits have all been used for processing copper ores. The emphasis lately has been towards the use of autogenous or semi-autogenous grinding systems. The reason is obvious. For a given tonnage, the initial investment required for an autogeneous and semi-autogenous system is generally lower. However, the operating cost may not be lower. Autogenous grinding has a definite advantage over the others in that no media are used in grinding. Semi-autogenous grinding does use media; consequently, the operating cost may not be lower. The operating cost of a given grinding circuit is basically a function of the ore type.

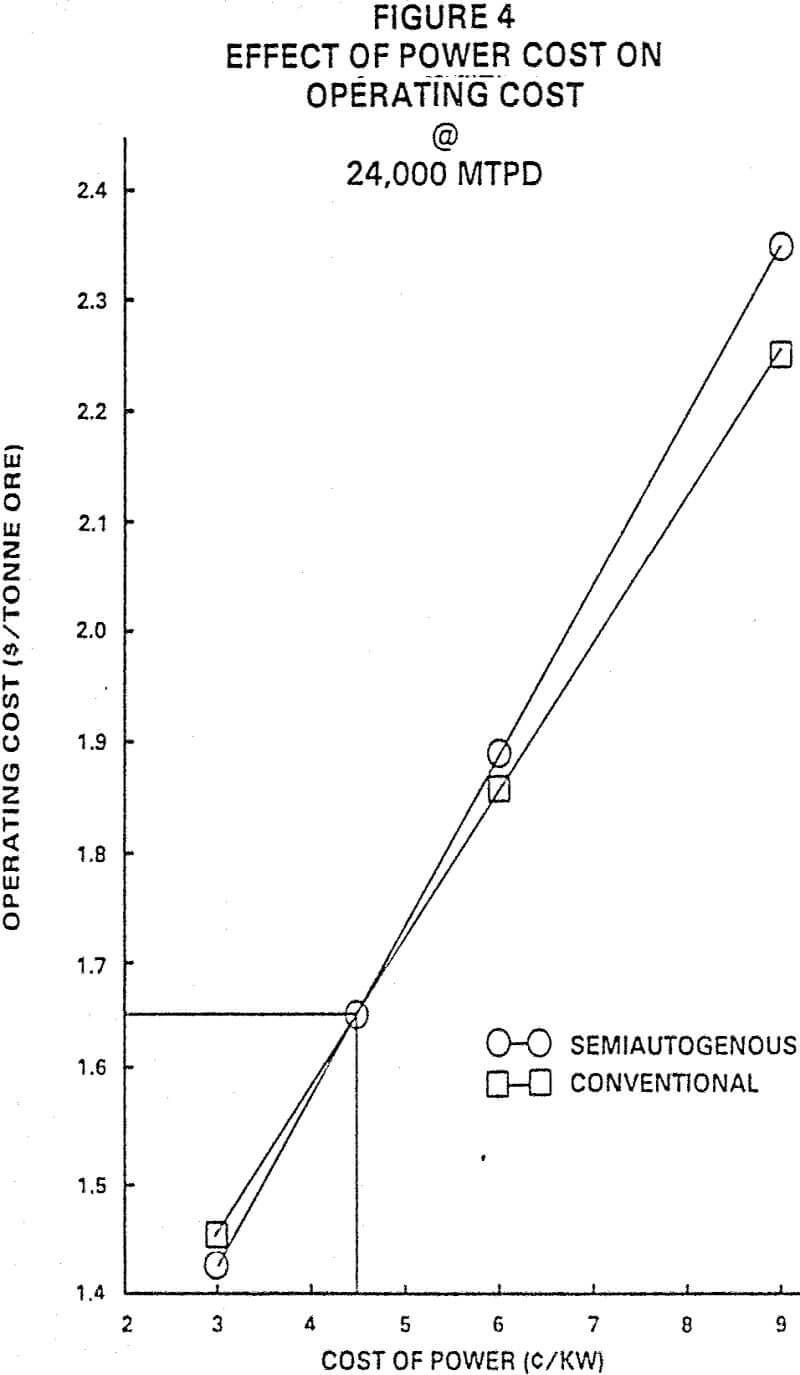

Energy is no longer a cheap commodity. While some British Colombia operations are fortunate to obtain energy at a very low cost (1.5¢ to 2¢/kWh), some of the Southwestern U.S. operations are already paying approximately 4¢/kWh. In some developing countries, cost of power exceeds 8¢/kWh. According to a General Electric Company survey, the cost of electricity will continue to rise.

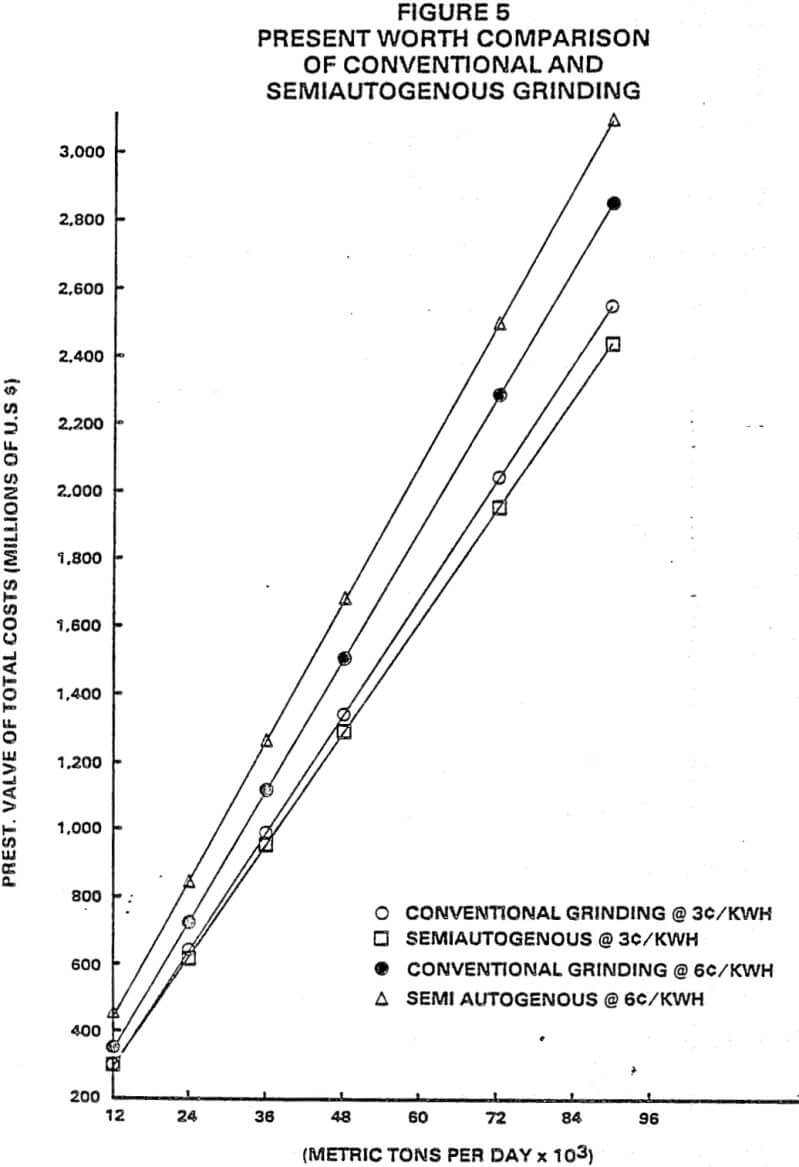

Present worth of the invested capital and operating expenses of the two systems for a 20-year operation were calculated. In this calculation, the following assumptions were made:

- The power coat will increase at 20 percent per year for the next 5 years and 15 percent per year for the following 15 years.

- The labor and maintenance coat will escalate at 10 percent per year.

A comminution system should not be selected on the basis of its initial capital cost alone. The system should be technically capable of delivering the expected performance. There is no single system that is optimal for every ore. The comminution system should be site-specific for each ore body on the basis of the rock characteristics, ore minerology, and metallurgical yield to give optimal results.

Each grinding process has its own merits and demerits. Fully autogenous grinding has the advantage of minimum equipment, lower capital and operating costs (due to zero media consumption), and the ability to handle wet or sticky ores. The capital advantages sometimes are minimal when lower availability is taken into consideration. The disadvantage is the higher energy consumption.

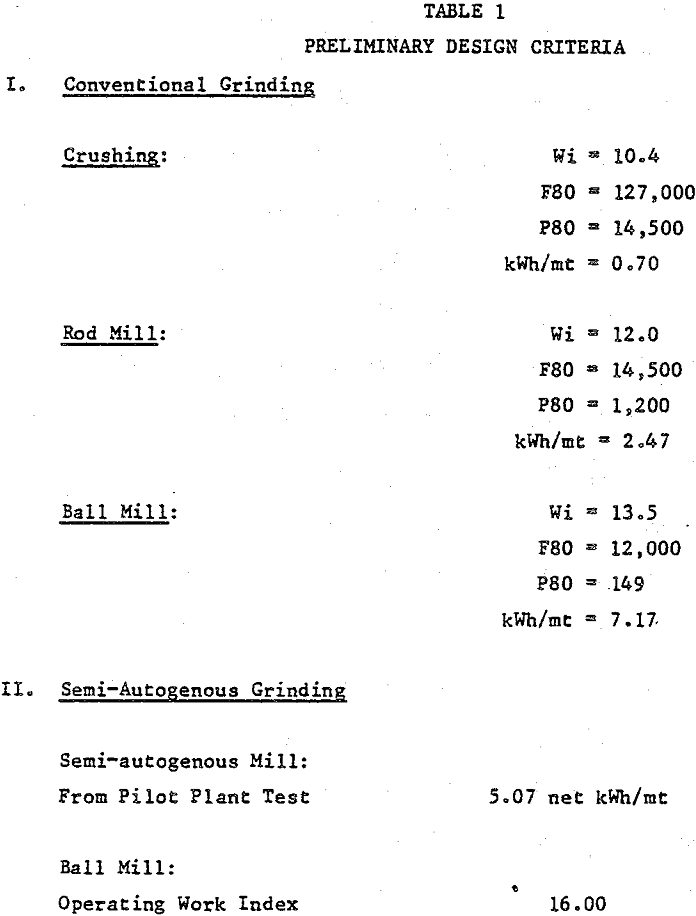

Note 1: Five percent of equipment cost

Note 2: Five percent of operating cost