The conglomerate ore analyzed approximately 1.2% copper. The specific gravity of the ore was 2.72 and the bulk density was 108 pounds per cubic foot (determined on “as is” ore). The Bond laboratory ball mill work index was determined as 22.0 at 65 mesh.

Autogenous Grinding Tests

Crude ore was fed manually to the mill, wet ground, and discharged through slotted grates and five pebble slots near the periphery of the grate. The pebble slots had approximately 2½-inch openings. A trommel on the mill trunnion equipped with a 3/16-inch screen, separated the minus 2½-inch discharge product into two size fractions. Trommel oversize was then screened to make 2 ½ by 1-inch and 1 by 3/16-inch fractions. Liberated copper in the 2½ by 1-inch product was removed by handpicking.

Liberated native copper was removed from the 1 by 3/16-inch fraction by jigging, and the jig tailings were returned to the mill. Minus 3/16-inch material from the trommel was also jigged to remove liberated copper.

Although no attempt was made to optimize the flotation circuit, 87.5% of the copper was recovered in a 46.9% Cu total concentrate during test A and 87.7% of the copper was recovered in a 60.5% Cu total concentrate during test B. More than half of the copper in the ore was recovered by jigging in each test. Relatively large pieces of native copper were not present in this ore, as jig concentrates contained only 0.2% by weight plus 5/8-inch material. The Mineral jig yielded a concentrate assaying 74.6% Cu in test B and a concentrate assaying 65.5% Cu in test A.

Comminution by Crushing and Rod Mill-Ball Mill Grinding

Approximately 30 tons of Kingston conglomerate were processed in the pilot plant. The ore was crushed through ½-inch prior to grinding. Pieces of +½-inch copper were removed from the circuit by handpicking from the +½-inch return belt in the crushing circuit. Because of the small amount of coarse copper in the ore, no problems were experienced in crushing. Only 0.005% of the feed was removed by handpicking, representing 0.4% of the copper in the ore.

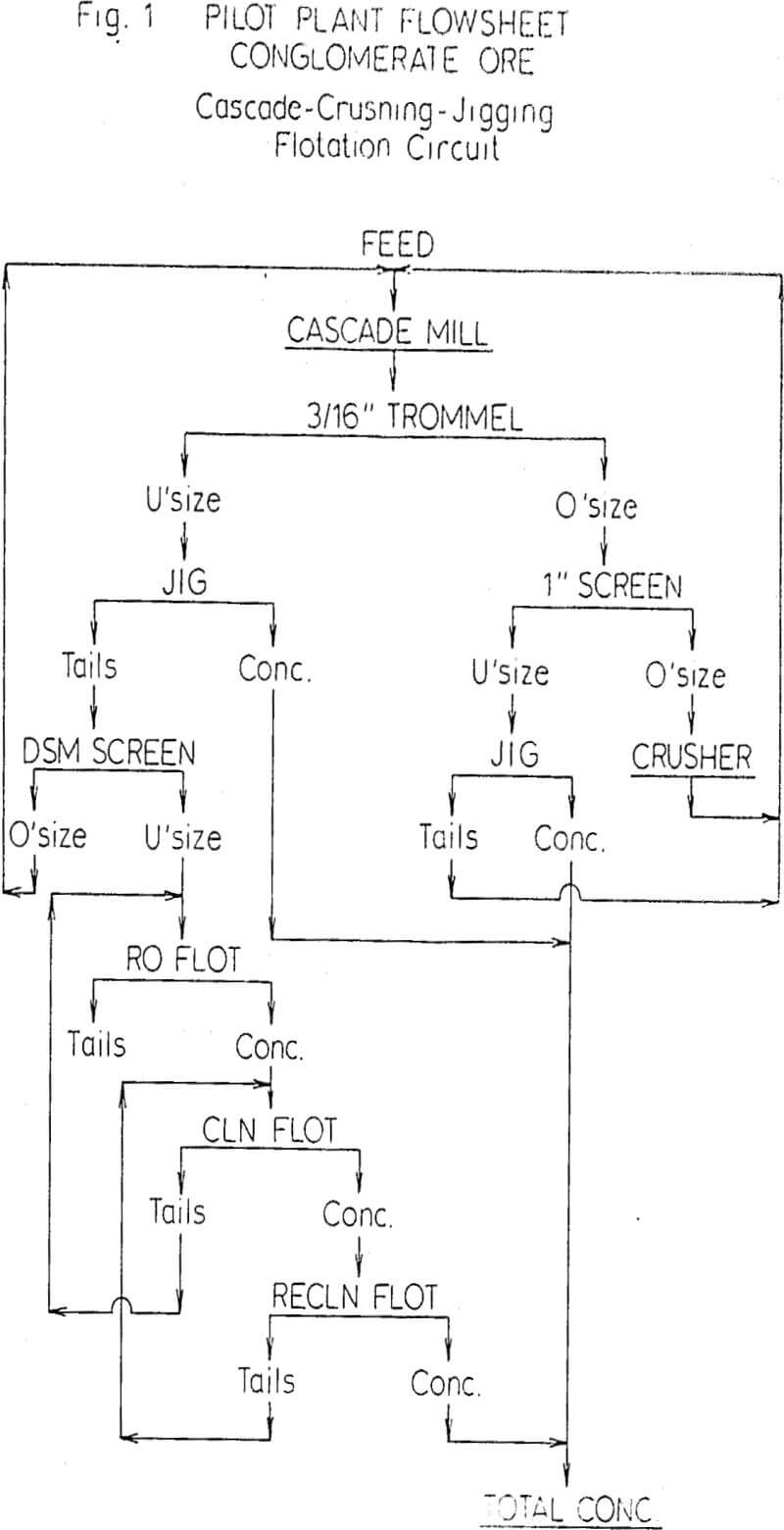

The -½-inch crusher product was blended and fed to a hopper which was discharged by a constant weight feeder to a 2′ x 3′ rod mill. Rod mill discharge was fed to a Mineral jig; the hutch product was drawn off as a final concentrate and the jig tailings pumped to a DSM screen.

Although the operation was not optimized in terms of concentrate grade, 87.1% of the copper was recovered as a 58.4% Cu concentrate in test C and 87.2% of the copper was recovered as a 60.7% Cu concentrate in test D. The ore is quite hard and abrasive. The average rod wear was 1.73 lb./ST and the average ball wear was 1.37 lb./ST.