Table of Contents

The ore milled from start-up until January, 1968, was mainly massive sulphides, consisting of a complex mixture of iron, copper, zinc and minor amounts of lead sulphides with important associated values in gold, silver and cadmium (average specific gravity 3.8).

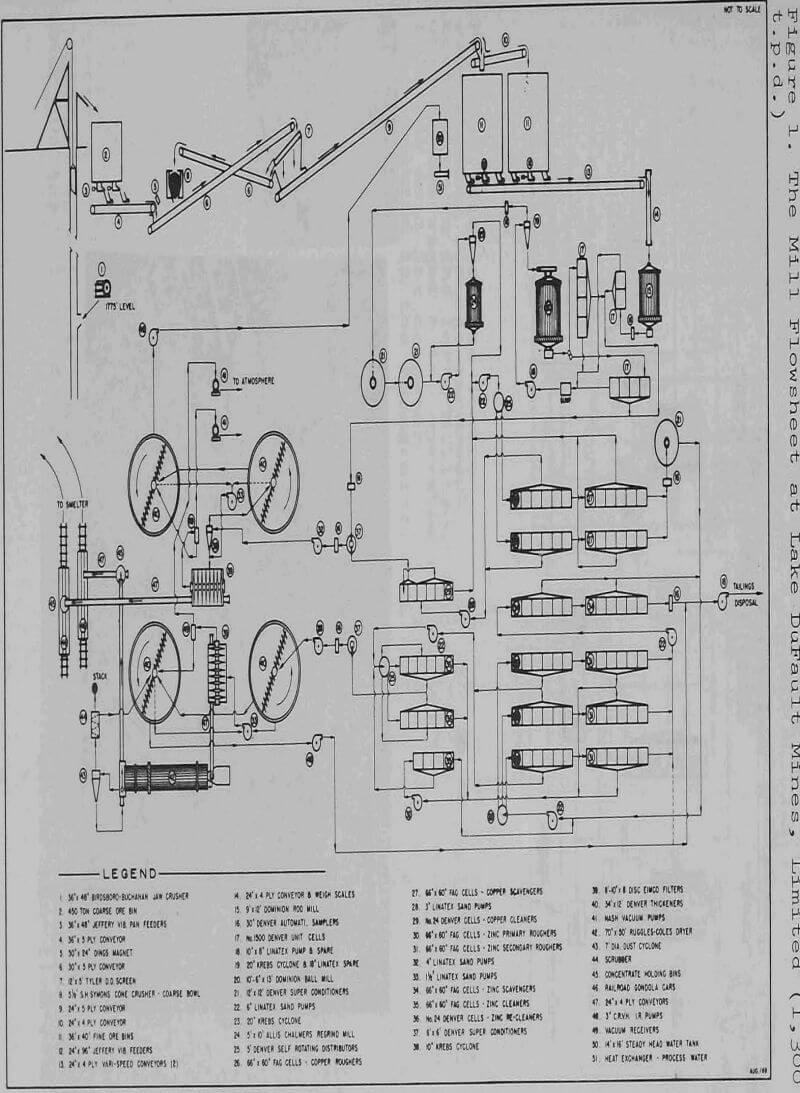

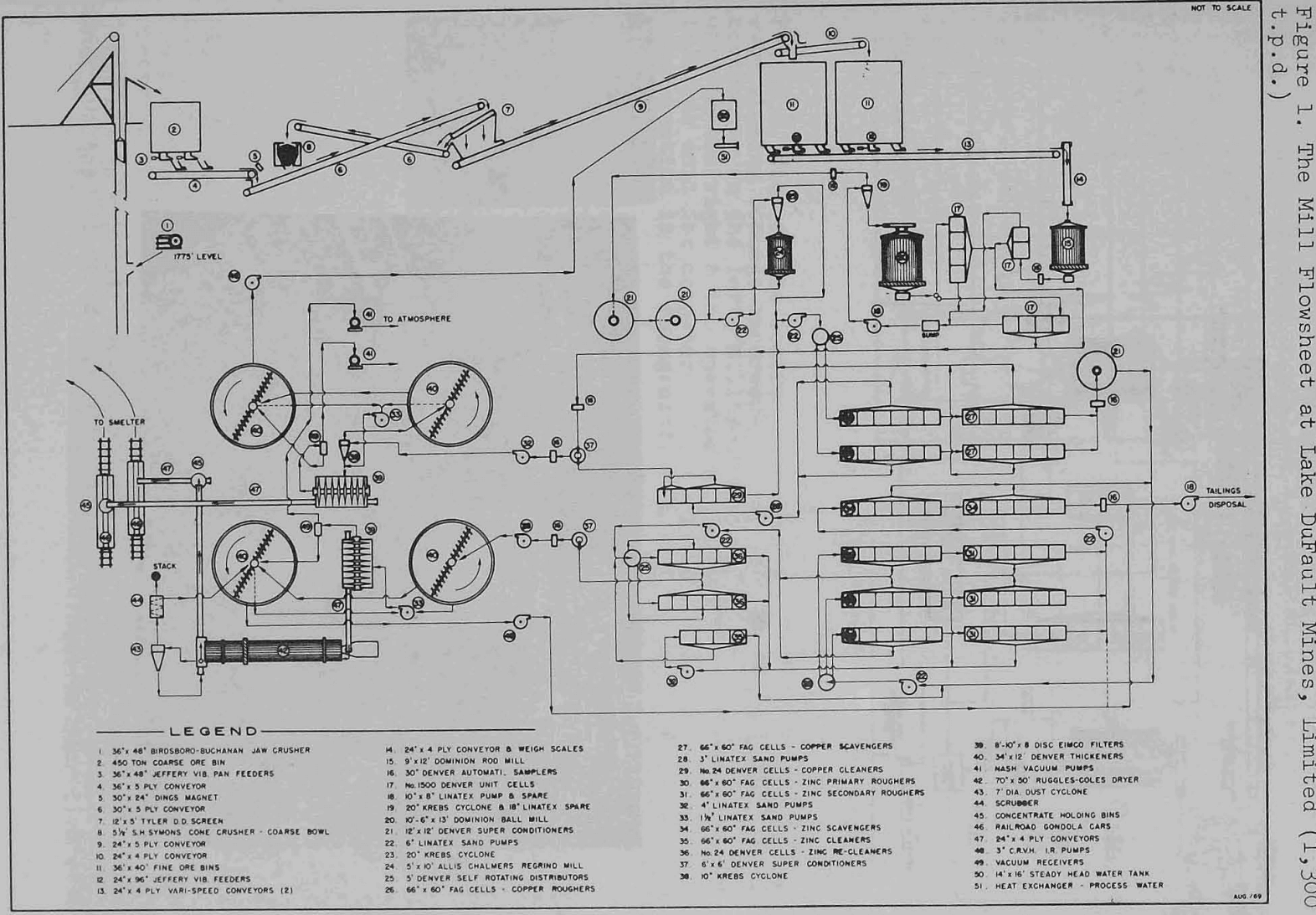

Description of the Grinding-Classification Circuit

The crushing plant product (presently -14 mm) is stored in two circular flat-bottomed woodstave ore bins of 1,600 tons live load capacity each. To improve blending of the ore and reduce variations in the head values, hardness and specific gravity, feed is alternated between the bins every 10 minutes by means of a timer and moveable gate. Ore from the screen house can discharge directly into the 1 bin or, by means of the gate, drop onto a 24-inch cross conveyor feeding the 2 bin.

The ore removed from the bins is weighed on the rod mill feed-belt, then discharged into a 9 ft. x 12 ft. rod mill operating in open circuit. The rod mill is driven by a 450 h.p. motor through a speed reducer and an air-operated clutch. The mill originally operated at 16 r.p.m., or 62%, of critical speed, which gave sufficient grinding capacity for the massive sulphide ore.

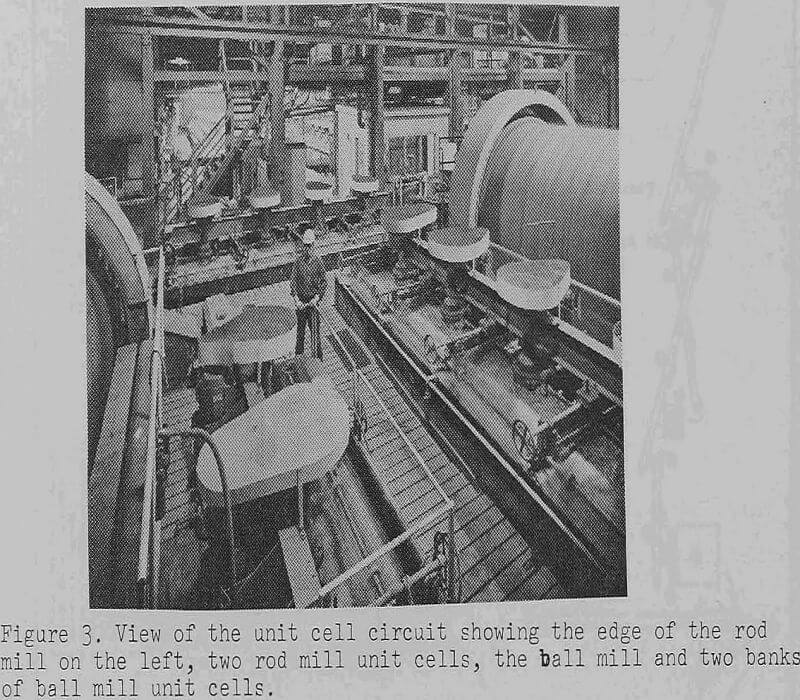

The rod-mill discharge flows to a two-cell bank of rod mill unit cells, where approximately 30.0%, of the total copper in the ore is removed as final grade concentrate. Tailings from the rod mill unit cells and the ball mill unit cells flow by gravity to a dual sump and pumping installation, one acting as a standby.

A 10-ft. 6-in. by 13-ft. ball mill, equipped with a scoop feeder, receives the underflow from the cyclone. The mill, rotating at 18 r.p.m. or 77.0% of critical speed and handling a circulating load of approximately 300%, is driven by an 800 h.p. motor through a fluid drive clutch and speed reducer. The grinding media presently consisting of 2-in. forged steel balls, is added each shift to maintain the ball charge at 35% of mill volume. Grinding media consumption is 2.50 lbs. per ton of mill feed.

Instrumentation in the Grinding-Classification Circuit

Control of ore addition to the rod mill was initially accomplished using a 0-80 ton-per-hour weigh scale located on the belt feeding the rod mill in conjunction with a recorder-controller. Tonnage variations were accomplished by varying the gate positions on the chutes and the speed of the cross conveyors. When using the vibrating feeders, both cross conveyors are maintained at maximum speed. Tonnage variation is accomplished by varying the vibration of the feeders. The ratio of ore being pulled from each bin can be changed through the use of auto/manual switches and ratio controllers.

After installing the sonic unit, it was found that, with some ore conditions, more ore could be ground in the mills than could be handled by the equipment further on in the process. Also, such conditions could have caused problems in supplying mill feed. Therefore, a switching device was designed and installed by the Lake Dufault instrumentation department to limit the maximum throughput to levels which were acceptable. This was accomplished by switching between the two possible modes of grinding control; i.e. sonic and fixed set-point.

With the X-ray analyzer assaying the mill heads for copper, zinc and iron, a very accurate estimate of the specific gravity can be calculated along with the desired water ratio. The desired water ratio is now automatically being set by the computer as dictated by ore changes in order to maintain a constant percentage of solids by volume rather than by weight.

Results of Incorporation of Instrumentation

At Lake Dufault the addition of sophisticated instrumentation to the grinding circuit has resulted in definite economic returns and in ease of operation.

The economic returns have been realized by increased tonnage throughput. This has been made possible through the optimum use of the grinding circuit capacity, which could only be achieved by varying the tonnage processed to compensate for the variations in the mill feed. This has been done while maintaining the most favourable grind to yield the best metallurgical results.

The ease of operation is also very noticeable. Prior to the installation of this equipment, the mill crew (concentrator leader and helper) was fully occupied trying to make appropriate tonnage, density and reagent changes while striving for peak performance.