There is much interest in the automation of entire comminution circuits. At the present technological level it is possible to automate a circuit but to date it has not been done. To successfully automate a circuity a number of problems must be solved. Not all of them are engineering problems. The purpose of this paper is to discuss some of these problems, ascertain the implications of these problems and indicate solutions to them.

Objectives

Suppose one is given a valid model, the critical parameters of the mills and the ore, one still is not in a position to automate a plant. One must perform a very important management function and that is to determine what are the objectives of the automation process. One would say blithely to “optimize the circuit.” This is not satisfactory. When one speaks in precise mathematical terms, one cannot say “optimize,” one must say optimize with respect to what. You might say that you want to have the lowest cost per ton of ore ground. You would specify a bookkeeping system of overhead, maintenance, capital investment and direct charges. The circuit could be optimized, but is this what you want? Suppose you’re running a copper plant and the price rises 4, 5, 10 cents a pound. You may want to take advantage of this market and increase your profits by increasing production and gladly accept the increase in production cost. What objective are you trying for now? Maximum output, maximum profit, maximum return on investment? How many of these questions are now answered? How many of those decisions are made by default?

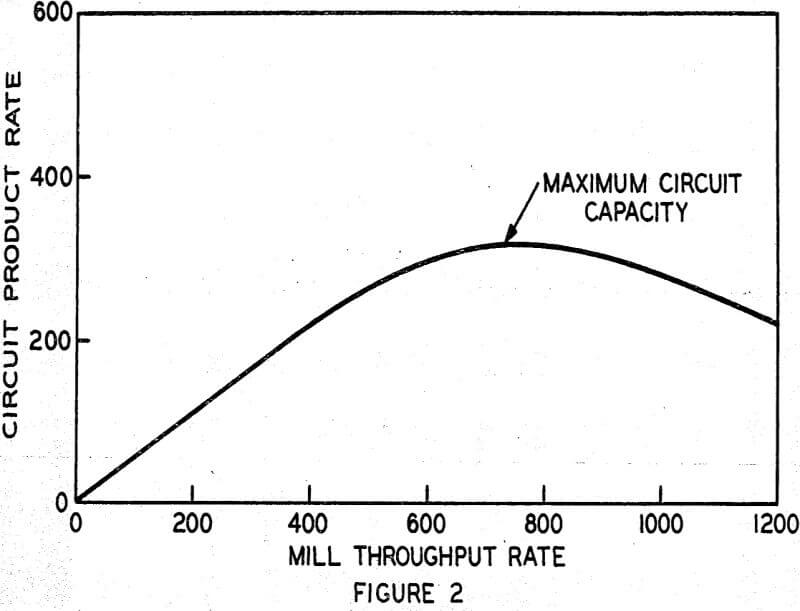

For example, suppose from data logging you’ve learned to stabilize the mill through-put rate. From this you’ve obtained your cost per ton at various through-put rates. The objective is set to operate at minimum cost per ton. The mill is run at this rate and the preliminary cost figures are correct. Now you are making maximum profit per ton of ore comminuted.

Personnel

One of the key ingredients to a successfully automated plant is personnel. That automation reduces the number of jobs in a factory has been well documented. Much of the work that is dull and routine is taken over by the computer because this is the type of work most easily automated. However, new problems arise. These problems are for example related to the objectives and type of mathematical model used.

A new breed of personnel is required. These individuals must be familiar with the modern mathematics used by computers. They must know the interaction of computers and the measuring instruments, or the controlling devices. Consequently, many managers and engineers—in the field today are obsolete. You may be technically obsolete. Many of you can remedy this problem by reading. More useful would be a sabbatical leave in which you would attend a university for a semester or two.

New people hired by the company should be examined, not, so much on the basis of their intimate knowledge of current processes but for their knowledge of the basic sciences. Personnel knowledgeable in the basic sciences can always be trained in the nuances of unit operations, present or future. The reverse is not true. Automation brings new problems and the people that are being hired today must have the skills to solve the problems of tomorrow.

Hardware

The hardware required for automation is divided into three classes: the instruments, the computer and the process equipment. It is in these areas that most of the money will be spent but, interestingly enough, the choice and amount spent is governed by the adequacy of the mathematical model involved.

In comminution circuits the variables of primary importance are the tonnage of material in a stream and the size distribution of the particles. If one is able to measure these two variables accurately and reliably much of the model work done to date would be applicable. While a great deal of instrumentation work is being done, there is no adequate method of measuring the size distribution of particles. What is needed is a rapid in situ measurement of particle size vs. cumulative fraction finer.

The lack of instrumentation for continuously measuring particle size makes control a difficult but not impossible job. A reasonably good mathematical model will give a surprisingly accurate estimate of the size distribution, knowing the characteristics of the mill and measuring such variables as mill power consumption, speed and feed rate.

Computer

The nerve center of any automated plant is obviously the computer. Here information is received, assessed, computed, manipulated and commands sent out for changes in the circuit operation. In the early stages of automation the computer may simply receive the information on routine computations and then log the results. The size and speed of the computer is dictated by the instrumentation, the mathematical model, the objectives and the amount of control desired. The amount of information that is needed to perform the operation is an important consideration in choice of the computer.

A large number of instruments with a high input rate will require many channels and higher speeds. A sophisticated model with a long program and many calculations will require a larger memory and a short cycle time. On the other hand sluggish circuits like those in comminution can use slower computers. Parts of a model often can be simulated by an analog computer which would be cheaper and faster. A good math model will yield accurate predictions and hence fewer changes in the circuit need be made. This would mean a slower computer. A poor or empirical model would require that more data be taken and more changes be made and thus a larger, faster computer should be used. When buying a computer always err on the size of a larger, faster computer.

The problem of what to control in a comminution circuit has not been fully explored. Part of the question, is what can be controlled. For example, in a large crusher the feed rate and setting of the crusher are typical variables. In a ball mill the classifier oversize, the feed rate and the circulating load are variables that can be controlled.

Planning

When the decision has been made to automate a circuit it is best, whether starting with a new circuit or an existing circuit, to go up in a series of steps. The application of control to any operation is an evolutionary process starting from the simple and going to the complex. Though it would be nice to say that one would simply design a whole automated comminution circuit from scratch, this is not possible at the present time nor in the forseeable future.

One should start by controlling individual unit operations. Having learned the subtleties and intricacies of a unit operation one then can attempt to link two of these together into a single unit and then three and four until the whole circuit is automated. The complexities and dynamics of comminution circuits, like other circuits, and their interactions with the measuring instrument are not sufficiently well known at this time for any other but a step by step approach to be recommended.