The source, amount, and delivered cost of water are important elements in a placer operation. In many cases they determine the type of equipment or mining method used. Water estimates for new or proposed operations are generally based on experience or working data obtained from comparable operations.

The water required for various working methods varies widely and depends on many factors. Examples that follow are intended only to show the possible range.

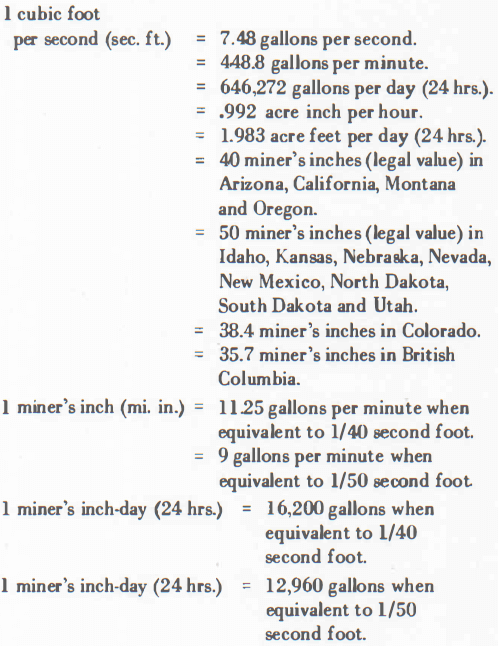

Rockers: A steady flow of 4 or 5 gallons per minute is sufficient to operate a small (1’x 4′) rocker. Water can be dipped from a barrel where steady flow is not available. Net water consumption may be as low as 50 to 100 gallons per cubic yard, if carefully saved and reused.

Small-scale hand mining: Where material is loosened by picking, and shoveled into a sluice box by one or two men, 170 to 225 g.p.m. are required for a 12-inch box with steep grade.

Ground sluicing: Water duty varies widely but may range between 1/10 and ¾ cubic yard per miners’ inch-day at small mines. This would be equivalent to about 22,000 to 162,000 gallons per cubic yard.

Hydraulicking: Water duty varies widely and reflects the coarseness of gravel, degree of cementing, height, of bank, grade of bedrock, available head, etc., and is commonly between ½ and 7 cubic yards per miner’s inch-day. This would be equivalent to about 2,000 to 32,000 gallons per cubic yard. The better efficiencies are obtained at large, well-equipped mines. Small, 1 or 2- monitor mines operated by individual owners or lessees, usually have a water duty of less than 1 cubic yard per miner’s inch-day.

Stationary washing plants: These are typically owner-operated plants, fed by a dragline or a small power shovel. Most employ a trommel or other screening device ahead of the sluice. Incomplete figures indicate a range of 650 to 2,000 gallons per cubic yard.

Moveable washing plants and dryland dredges: In same category as stationary plants and same remarks apply. Water requirements ranging from 480 to 3200 gallons per cubic yard have been noted. Plants equipped with Ainlay bowls (in place of sluices) generally have good water economy.

Dragline dredges: Net water required for washing gravel and maintaining the pond is governed by the amount of clay , porosity of the gravel, and other factors. Wash water which is commonly supplied by an 8-inch centrifugal pump working against a 40-foot pressure head, may range between 570 to 2,500 gallons per cubic yard.

Bucket–line dredges: Water in circulation aboard a dredge may range from 3,500 g.p.m. to over 10,000 g.p.m. depending on digging capacity of dredge and type of material being washed. Dredges are usually provided with independent high pressure and low pressure water systems, the high pressure being used for screen sprays and bucket nozzles, and the low pressure for the gold-saving tables and general service. When working in land-locked ponds, a fresh water input of 1,000 g.p.m. to more than 2,000 g.p.m. will be needed to replace muddy water which must be pumped out of the pond (to prevent excessive mud build-up) and to maintain pond level.