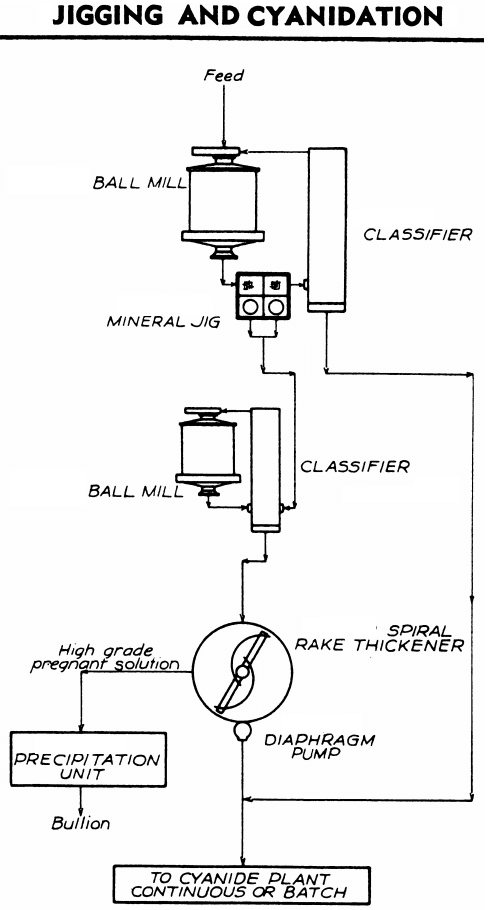

PROCESS FLOWSHEET DESCRIPTION: Jig gold concentrates reground and cyanide leached. Mineral Jig in ball mill-classifier circuit for removing sulphides for fine grinding and subsequent cyanidation leach.

ORE TREATED: Sulphide gold or silver ores where fine grinding of the sulphides is necessary to expose the gold or silver to the cyanide solution and where it is not necessary to grind the gangue to the same degree of fineness.

ADVANTAGES: The Jig in this flowsheet recovers a bulk concentrate containing practically all of the sulphides as well as the free gold. This fraction of the ore may be ground to any fine mesh necessary for maximum recovery and strong solution if necessary can be used in this circuit. Both classifier overflows from primary and regrinding circuits go to the cyanide treatment plant. This only necessitates grinding the bulk tonnage to free the minerals from the gangue, and the fine grinding needed for gold extraction from sulphides is confined to the small tonnage of gold bearing minerals contained in the Jig concentrate.

PROCESSING COMMENTS: This circuit has been used to increase extraction without costly additions to the plant and in other cases has made worthwhile sayings in new plant construction and in plant additions where more tonnage has ‘been required. The installation of a Jig and concentrate grinding circuit has allowed as high as fifty percent increased capacity without sacrifice in recovery.

https://www.911metallurgist.com/ccd-continuous-counter-current-decantation-cyanidation

https://www.911metallurgist.com/gold-recovery-by-cyanide-leaching-plant