The Humboldt and its Grate-Kiln System Operation on crude ore is a mixture of cherty specular hematite and magnetite, with minor amounts of martite and sericite. Mineralization varies from coarse to extremely fine grained. The overburden varies from zero to 50 ft. The ore body is approximately 1300 ft. long and varies in thickness from 250-400′.

Crushing is accomplished in three stages of open pit circuit crushing to a rod mill feed size of ½”. One 48″ Primary, one 7′ st’d Cone Crusher as a Secondary, and two 5-84 Tertiary Crushers are used to obtain this nominal ½” crushed product.

The crude ore is reduced to 8 mesh in a 450 HP rod mill in open circuit. A ball mill (450 HP) in closed circuit with an hydroscillator does the final grinding for liberation. The hydroscillator overflows at about 65% passing 200 mesh. This will vary somewhat, dependent upon ore hardness and mill feed rates.

The cyclone underflow discharges into conditioners at about 68% solids. Reagents are added to this series of conditioners to prepare the slurry for flotation. About 1.5 of Tall Oil is added per ton of feed. Other reagents are Aerosal OT 75 and a frother.

Two, 1000 tons per day units, are installed in the pelletizing section. Plant design is pointed towards the production of 646,000 LT per year on a 323 operating day level. The plant actually runs 365 days per year with one of the units down for repairs about once a month. There are no scheduled-down shifts on a weekly basis.

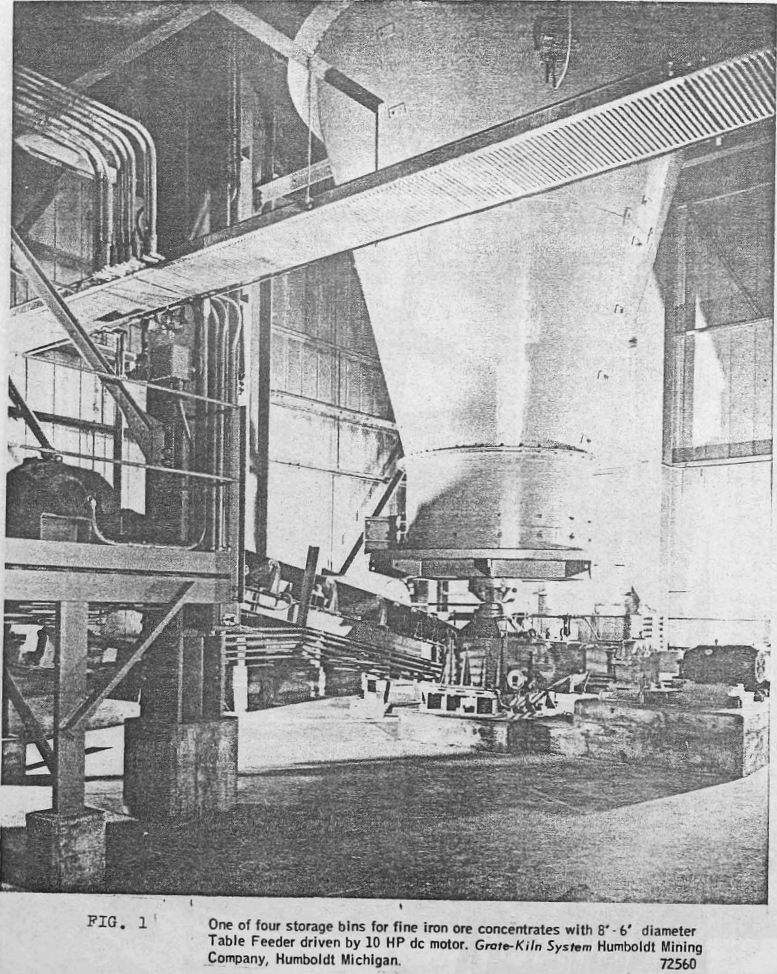

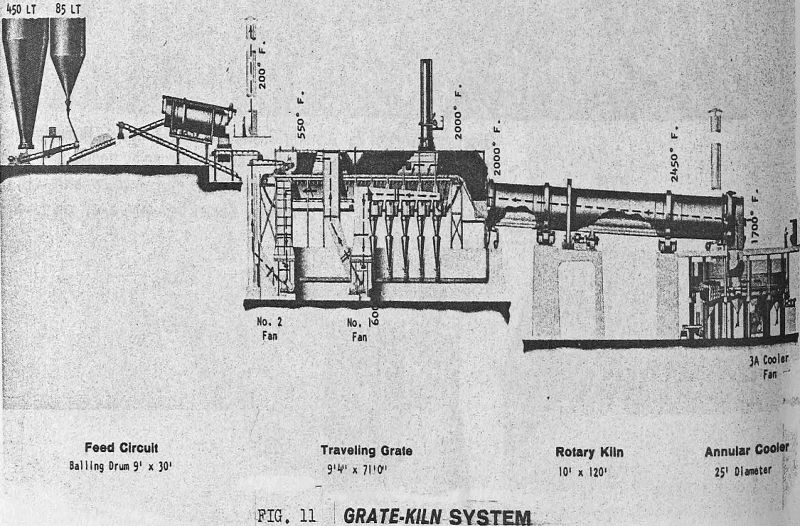

Reground concentrate is fed from 450 LT storage bins into each of the balling circuits by 8’6″ table feeders. These feeders are driven by D.C. motors controlled by belt scales to give a uniform tonnage per unit time. One half of one percent bentonite is added to the raw concentrate prior to its being mixed and “fluffed” in reel type mixers.

The refractory kiln blocks are 9″ deep in this photo while in the feed end of the Kiln they are 6″ deep. The Kiln burner has a capacity of 500. gph of No. 6 oil, heated to 230° at a pressure of 350 psig. Each kiln is driven by a 100 HP D.C. motor which results in a variable speed of up to 120 revolutions/hour.

Primary cooling air enters below the pallets in the annular cooler and passes updraft through the hot bed of pellets. During passage through the 30″ deep bed, the air temperature rises to about 1700° F. This hot air is directed into the Kiln, through the firing hood for use as secondary combustion air within the Kiln.

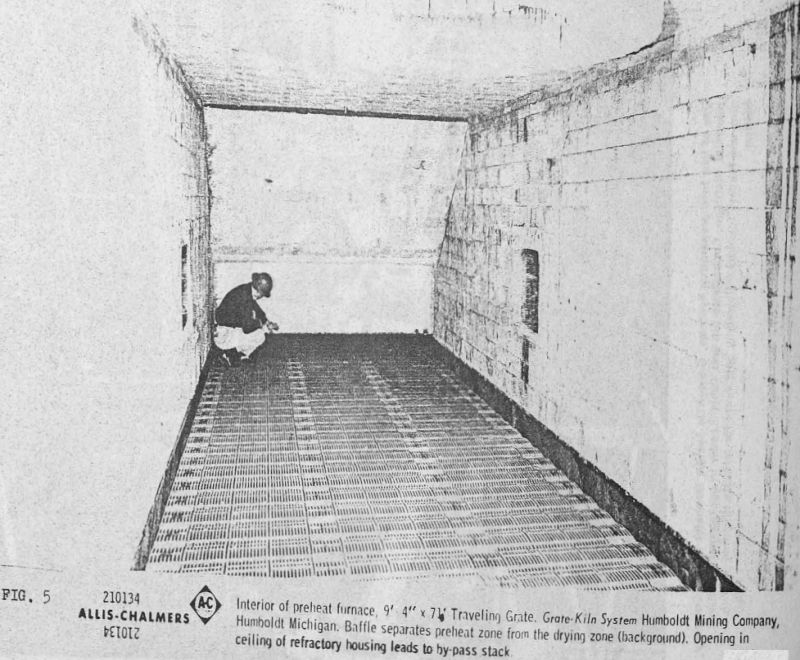

The kiln exit gas is directed up into the preheat furnace where it is, pulled downdraft through the 7″ bed of pellets by the No. 1 Fan. The temperature of the gases over the bed varies from 1700-1900° F. After passage through the bed, the gas temperature drops to an average of 600° F.

Control of the system is basically located in two control panels, (1) the Kiln Control Panel, and (2) the Balling Drum Panel.

The Kiln operator has direct control over the gas flows, system temperatures and tonnage. He has a variety of sensing, indicating, and recording instruments to aid him in evaluating the performance of the system at any given instant. The balling drum operator, while under the Kiln operator’s directives, can control and gauge tonnage thru any one drum, the ratio of bentonite, and the amount of water, if any, added to the incoming concentrate.

A tumble test on the pellets reports an average of 4.7% passing 28 mesh after 200 revolutions in an ASTM coke tumbling drum. The crushing strength of a nominal ½” pellet is in the range of 750-850 lbs.