Table of Contents

GORE-TEX membrane filter cloths for liquid filtration consist of expanded polytetrafluoroethylene (PTFE) membranes bonded to a variety of felts and other fabrics (including fabric woven of PTFE fiber). The PTFE membrane/PTFE fabric filter cloth is inert to practically all chemicals and can be used at temperatures up to 500°F (260°C) . These materials combine the filtration efficiencies of membranes with the durability of high strength felts and woven cloths.

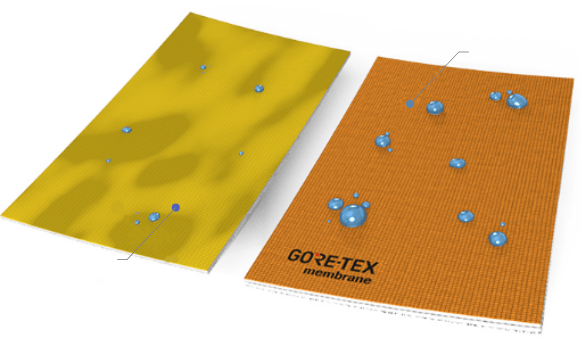

Porosity and particle retention of the membrane can be controlled to fit specific filtration requirements. Typically, membranes used in liquid filtration retain 90% of 3 µm down to submicrometer latex beads with corresponding air permeabilities of 8-10 cfm (4-5 l/s) to 1 cfm (0.5 l/s). One of the more open GORE-TEX membranes is compared with conventional filter media in Figure 1. This membrane (Figure 1a) has a nominal particle retention of 90% of 3 µm latex beads without- cake formation. Woven polypropylene cloth and a heavily glazed polypropylene felt are shown in Figures 1b and 1c respectively. Note the very small proportion of open area and the large sizes of the openings in these media.

The result of this combination of the GORE-TEX membrane with strong support materials is filter media with:

- high permeability

- sub-micron openings

- high strength

resulting in benefits of:

- high flow rates

- high solids retention (filtrate clarity)

- long media life

- excellent cake release

- chemical inertness (for the PTFE

- membrane/PTFE fabric filter media).

GORE Back-Pulse Filtration

The term “GORE Back-Pulse Filtration” refers to the method of filtration discussed in this paper and the use of the GORE-TEX membrane filter cloth.

Using GORE-TEX membrane filter cloths, it is possible to operate tubular filters as “liquid baghouses” (Figure II). In this type of filtration, pressure differential is limited to 10-15 psi (70-100 kPa), and cake removal is by momentary flow reversal (pulsing, Figure III), which takes only 1-3 seconds. Filtration starts immediately after pulsing and is, for all practical purposes, continuous. The filter vessel is not drained of liquid during or after pulsing. Suspended solids, which have been consolidated into a cake, settle rapidly to the bottom of the filter vessel where they are discharged as a paste-like slurry. The filter can be operated under vacuum (shown here) or pressure.

The objective of this mode of filtration is to operate at low filter pressures, and short cake removal times. Because cake removal time may be only a few seconds, filtration times may be as short as 2-3 minutes and filter cakes as thin as 0.1 mm.

GORE-TEX membrane filter cloths for liquid filtration make this type of filtration possible because they give immediate filtrate clarity, high flow rates, and complete cake release.

For this filtration method to operate, it must be possible to form a filter cake on the surface of the membrane which will then release during the back-pulse. Throughput must be sufficient to allow for a back-pulse filtrate usage of approximately 0.05-0.1 gal/sq. ft. of filter area.

Precoat Replacement in Filtration of Merrill Crowe Precipitates

In the use of zinc dust for the precipitation of gold and siver, filtration is accomplished in tubular filters using a precoat filter aid. The use of precoat presents many problems as outlined by Smith and Rinschler. To overcome these problems a 750 ft² (70 m²) Stella-Meta filter at FMC Gold’s Paradise Peak mine was converted from precoat to GORE Back-Pulse Filtration. The changes in operating conditions were very similar to those described above comparing back-pulse with conventional tubular filter operation.

The conversion was made the week of October 4, 1988 and the filter started up filtering precipitated gold and silver. All objectives of the conversion from precoat to back-pulse filtration were met, i.e., flow rate, solids removal, filter cycle time, down time for cleaning and going back on stream, obtaining adequate solids removal and elimination of precoat and water addition for cake removal.

The operation is summarized in the table below. The only change from those outlined in the paper is the draining of the filter after the pulse. This was done to minimize cake build-up between candles which had been slightly bent (due to the operating problems described in the paper) and were therefore very close together.