Table of Contents

The Bureau of Mines investigated the concentration and distribution of precious metals in the various fractions produced from mechanical processing of obsolete military electronic scrap. Whole avionic units, printed circuit cards, and electrical connectors were processed and analyzed. Materials recovered included baghouse lights, wire bundles, magnetics , and metal concentrates from eddy-current and high-tension separation. Higher value fractions were processed by a commercial toll refiner for recovery of gold and silver. Lower value fractions were analyzed by the Bureau. Three fractions, the lights, wire bundles, and metallics from high-tension separation, contained most of the precious metals. Depending on the type of scrap feed, these fractions represented 34 to 60 pct of the original sample weight. Collectively, they represented 68 to 97 pct and 75 to 98 pct of the contained gold and silver, respectively.

Scrap from a variety of sources represents an important component of the domestic supply of gold and silver, as well as other metals. U.S. refinery production of gold and silver in 1982 was estimated at 3.4 and 74 million troy ounces, respectively of which 79 and 38 pct, respectively, were reclaimed from scrap. Net import reliance for gold and silver in 1982 was 43 and 59 pct, respectively, of apparent consumption. Obsolete electronic equipment is one variety of scrap that contains significant amounts of gold and silver. The use of gold and silver in electronic products represents a substantial portion of consumption (29 pct in 1982); however, recovery of these metals from electronic scrap is difficult and expensive because of the complexity and heterogeneity of such scrap.

The Defense Property Disposal Service (DPDS), an agency in the U.S. Department of Defense, is responsible for the disposal of millions of pounds of obsolete military electronic scrap annually. For example, 12 million pounds a year from aircraft avionics alone is typical. Some of the equipment is sold to scrap dealers who specialize in the recovery of base and precious metals, and some is sold to dealers in surplus electronic materials who resell functional equipment and component parts to electronic experimenters. With the increased complexity and expense of military electronic equipment, getting a fair value for this material has become a pressing problem for DPDS. Precious metals can be found throughout electronic equipment in components such as pin connectors, contact points, silver-coated wire, terminals, capacitors, plugs, and relays. The precious-metals content of the equipment ranges from relatively high concentrations to insignificant values.

Each generation of electronic units contains varying amounts of precious metals-bearing modules, but in outer appearance each unit is basically a black box, regardless of precious-metals content. Therefore, no generalization can be made as to the metal value of an electronic unit since the manufacturers have no coding system to indicate which metals or materials were used in its construction. Most units look alike, except for size, shape, weight, and dial face, until the outer casing is removed. Even after removal of the outer casing, an approximate assessment of a unit’s scrap value can be made only by personnel trained to recognize the metal value contained in the different electronic components. Although mechanical processing technology is currently available, there is no known integral system at a single site for dry separating the conglomerate metals of an electronic unit into salable fractions.

As part of the Bureau of Mines mission to conserve U.S. mineral resources through secondary recovery, researchers at the Bureau’s Avondale (Md.) Research Center investigated mechanical processing techniques for recovering base and precious metals from electronic scrap. The purpose was to recover the metal values from obsolete military electronic scrap that are not currently recovered in terms of adequate monetary return to the Federal Government. For example, during precious-metals recovery operations from electronic scrap, aluminum metal may be lost completely, and portions of nickel bearing items may report with precious metals items that are subsequently processed at a copper refinery. The nickel is a contaminant in this case, and its presence results in a costly penalty. Upgrading of the electronic scrap to recover aluminum, nickel, and other base metals would result in a greater return to the Government in two ways. First, the aluminum and nickel recovered could be sold for their intrinsic scrap recycle value; second, the quantity of material processed for precious-metals recovery would be reduced. This would result in lower toll charges for the same amount of precious metals recovered and would reduce penalties for the contained nickel.

In an effort to get an estimate of the distribution of precious metals in obsolete electronic equipment, dismantling studies were conducted and a minerals processing concept was first demonstrated on a laboratory scale. Based on the laboratory model, a small pilot plant referred to as a process research unit (PRU) was assembled for upgrading scrap into valuable metal concentrates at feed rates of up to 500 lb/hr. Details of the dismantling studies and the PRU have been described elsewhere. Briefly, the unit operations consist of shredding, air classification, wire picking, magnetic separation, and sizing, all operated in a continuous sequence. These are followed by magnetic precleaning and eddy-current and high-tension separations, which are batch operations. Products obtained by this process include an iron-base fraction, an aluminum fraction, a mixed metal fraction, a wire fraction, air classifier lights, and nonmagnetic metal fractions from high-tension separation. The last three fractions contain most of the precious metals.

This report describes the results of mechanically processing more than 11,000 lb of obsolete military electronic scrap. Types of scrap processed included whole avionic units, printed circuit cards, and electrical connectors. Details are presented on materials distributions and analyses for the three categories of scrap.

General Avionic Scrap

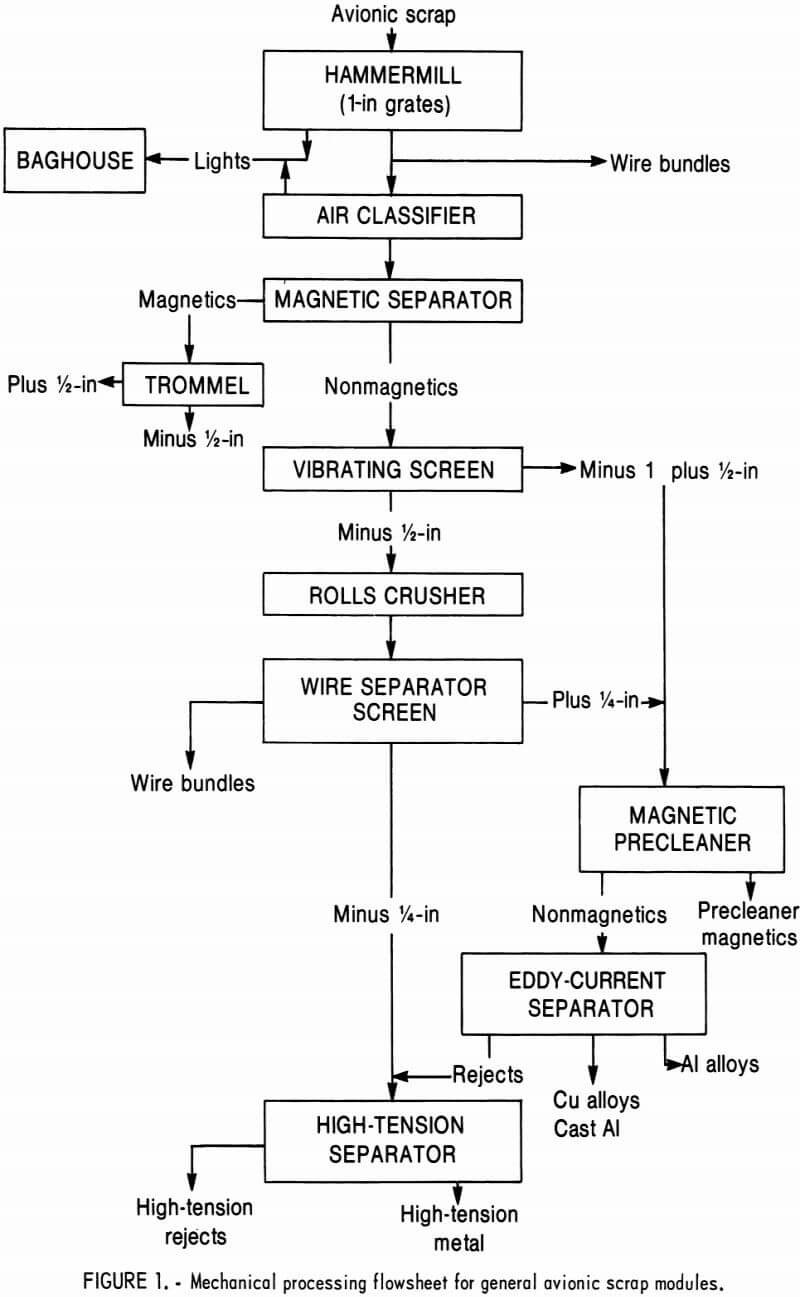

The material processed through the PRU consisted of more than 5 tons of general avionic scrap received from the Department of Defense. It included (1) complete units, (2) units with parts missing, and (3) units that had been stripped of pullout printed circuit cards and electrical connectors, which were removed by shearing the wires . The only precious-metals-bearing parts remaining in the stripped units (item 3) were components that had been connected to the modular frames with rivets or screw fasteners. The total test lot was processed by shredding in a 25-hp hammermill, followed by several unit operations to produce upgraded fractions. The shredder, equipped with 8-lb hammers and 1-in grates, was capable of accepting units or portions of units up to approximately a 10-in maximum. The unit operations after shredding included air classification, magnetic separation, screening, wire picking, magnetic precleaning, eddy-current separation, and high-tension separation. A flowsheet is shown in figure 1 and views of the PRU are shown in figures 2 and 3.

The material distribution obtained from processing the 5 tons of general avionic scrap as described above is shown in table 1. Analyses and recoverable precious metals from each of these fractions are shown in table 2. Each fraction is discussed separately as to its value on a short ton basis. Only gold and silver values are reported since other precious metals were undetected or were present in very low concentrations. Earlier dismantling studies showed that, except for palladium in some electrical contact alloys, military electronic scrap did not contain significant amounts of precious metals other than gold and silver. All contact points do not contain palladium and those that do would require careful presegregation to avoid dissipative dilution during mechanical processing. In the current tests, the toll refiner reported that, where detected, palladium was less than the equivalent of 1 tr oz/ton, too low to be credited.

Baghouse Lights

The light materials were collected in two baghouses. One baghouse was a small portable unit located at the hammermill discharge, and the other, a large industrial type measuring approximately 6 ft square by 15 ft high, was connected to the air classifier. The material collected in these two units was combined into one sample prior to toll refining. Because of abrading action in the hammermill, some of the precious-metal plating is removed from the base metal. These thin flakes of precious metal are entrained by the lights and report to the baghouse. In this test, the baghouse lights represented approximately 9 pct of the feed and contained the equivalent of 6.1 and 96.2 tr oz/ton of gold and silver, respectively.

Wire Bundles

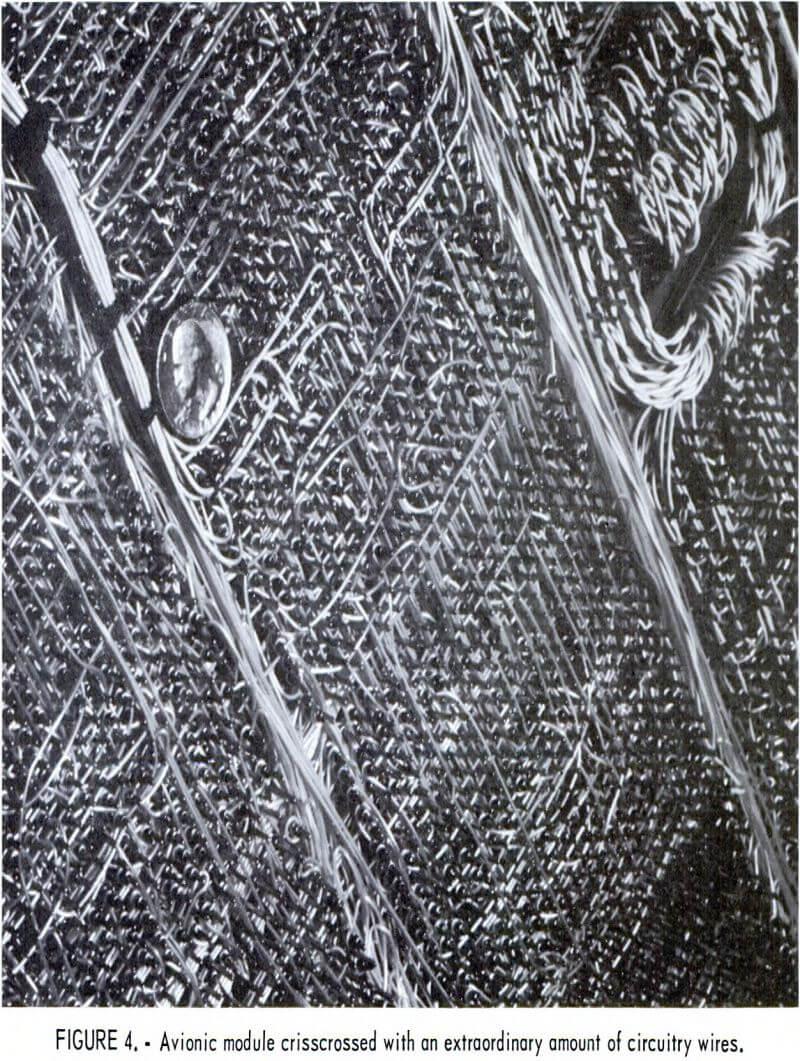

Some avionic modules contain a criss-cross pattern of small wires (fig. 4), while others contain relatively few wires. When hundreds of feet of wire are involved, as shown in figure 4, hammer-milling produces wire bundles or tangles that tend to block exit chutes in certain mechanical processing operations. Thus, massive wire bundles were handpicked off the conveyor between the hammermill and the air classifier. Remaining wire continued to the modified vibrating screen

where most of it agglomerated for easy hand removal at this point. The wire bundles were combined into one sample representing approximately 8 pct of the feed. The gold and silver content of the wire bundle was equivalent to 6.1 and 224.5 tr oz/ton, respectively.

Magnetics

The air classifier heavies are conveyed to a magnetic drum separator from which the magnetics are conveyed to a trommel screen and separated into minus ½-in and plus ½-in fractions.

The minus ½-in magnetics contained pieces of modular framework, fasteners, transformer iron laminae, and gold-and silver-plated nickel alloy pins and transistors. This magnetic fraction was too lean in precious metals and too high in iron and nickel to be processed economically by a toll refiner. The Bureau’s Salt Lake City (Utah) Research Center used a portion of the Avondale minus ½-in magnetic scrap, obtained from earlier laboratory tests, in their copper cementation studies. In those studies, 85 to 90 pct of the magnetic scrap was utilized as a copper precipitant. The washed cement copper contained a portion of the recoverable gold and silver. Nickel was concentrated to about 45 pct in the cementation residue along with the remainder of the available gold and silver. The minus ½-in magnetics represented approximately 11.5 pct of the feed and, on a per ton basis, contained 4.4 and 20.4 tr oz of gold and silver, respectively.

The plus ½-in magnetics represented the largest fraction of the feed. Visual observation indicated that very little precious-metal value reported to this fraction, aside from a few large power transistors that were easily identified for hand removal. This fraction was mostly transformer iron laminae and would also be suitable for copper cementation, thus assuring recovery of precious metal that might be present.

Eddy-Current Precleaner Magnetics

Avionic modules contain some nonmagnetic austenitic (300 series) stainless steel items either as fasteners or structural framework. Hammer milling nonmagnetic stainless steel causes localized transformation of austenite to martensite, which is weakly magnetic. This transformed steel is too weakly magnetic to be removed by the drum magnet but is sufficiently magnetic to be attracted to the strong strontium ferrite magnets on the inclined eddy-current separator. Therefore, an eddy-current precleaner device was constructed to remove the work-hardened and slightly magnetic stainless steel prior to feeding the remaining stream of material to the eddy-current separator. The eddy-current precleaner magnetics collected in this test represented 4 pct of the initial PRU feed. Gold and silver content was equivalent to 18.6 and 119.5 tr oz/ton, respectively.

Eddy-Current Aluminum

The inclined eddy-current separator works on the principle that when metallic particles move through a magnetic field, electric eddy currents are induced in them that give rise to a force acting perpendicular to the direction of particle movement. This force and a combination of other variables , such as inclination angle of the board, coefficient of sliding friction of the cover surface on the board, force of gravity, particle density and shape, and electrical conductivity, will determine the amount a moving particle will deflect from its normal path down the inclined plane. Strips of magnets of alternating polarity are placed at 45° to the normal path on the inclined plane. The magnets are covered with a smooth material, generally a very thin sheet of nonmagnetic stainless steel. Detailed explanations of the principles and operation of permanent magnet types of eddy-current separators have been published.

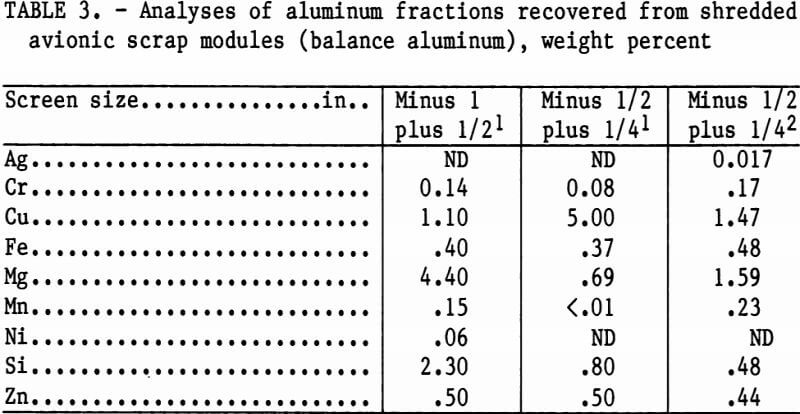

Wrought aluminum and pure copper particles that are reasonably flat and approximately equal in size and shape exhibit the largest degree of deflection of all the metals tested. There is very little copper sheet stock in avionic scrap modules, however; thus, copper contamination of the aluminum product is minor. The aluminum fraction recovered in the large-scale test represented approximately 11 pct of the feed. Two 100-lb samples were laboratory melted by Reynolds Metal Co., and a 10-lb sample was melted at the Bureau’s Avondale Research Center. The analytical results of these melts are listed int table 3. Reynolds Metal Co. judged the quality of this fraction acceptable for making aluminum diecasting alloy 380, a major commercial casting alloy. The differences in analyses shown for the two minus ½- plus ¼-in fractions reflect inherent heterogenity of the sample. The copper concentration is not a major concern, and although the percentage of magnesium is high compared with that specified for alloy 380, magnesium is routinely refined from the melt during commercial remelting.

Eddy-Current Middles

The eddy-current middles represented about 9 pct of the test feed and contained brasses, bronzes, monels , and cast aluminum alloys. Some of the brasses were silver plated. These aluminum and copper alloys have lower electrical conductivity than wrought aluminum and copper and deflect much less than the purer wrought aluminum and copper metals. On the basis of a 6-lb sample of eddy-current middles leached with 20 pct NaOH, aluminum was estimated at 30 pct. A 5-lb test melt of eddy-current middles was determined to contain 0.87 and 186.6 tr oz/ton of gold and silver, respectively.

Eddy-Current Rejects

Eddy-current rejects included items that showed little or no deflection during their movement down the inclined plane. This fraction contained nonmetals such as plastics and ceramics, combinations of metal and nonmetals such as circuit card chips, die-cast zinc, pieces of lead, pieces of copper wire, nonmagnetic stainless steel, and pieces of nonferrous metals that, because of their size and shape, are not affected by the magnetic field. The minus 1- plus ½-in and minus ½- plus ¼-in eddy-current reject fractions are fed directly to the high-tension separator to separate them into metallics and nonmetallics.

High-Tension Metal

High-tension separation involves the passing of a dry mixture of materials, metallics (conductors), and nonmetallics (dielectrics) onto a grounded rotor in the presence of an electric field. The conductors and dielectrics receive surface charges that have opposite polarity

to that of the rotor. The conductive particles (metallics) lose these surface charges in a very short interval and follow a trajectory past a splitter arrangement. Nonconductive particles (dielectrics) do not readily lose their surface charges , and are attracted to the rotor until they are drawn behind the splitter. In processing a particular sample through the high-tension separator, particle shape, density, range of particle size, ballistics, and splitter placement are some of the determining factors in the efficiency of separating metallics from nonmetallics.

High-tension metal is the fraction richest in precious metals. It represented about 17 pct by weight of the initial feed and contained approximately 51 and 56 pct of the gold and silver, respectively. The high-tension separator operates with greater efficiency when the particle feed is kept within narrow size limits. In this test, three size fractions of nonmagnetic materials were fed to the high-tension separator: minus ¼ in, minus ½ plus ¼ in, and minus 1 plus ½ in. As listed in table 2, the coarser fractions contained progressively less precious metals than the finer fractions. The combined high-tension metal fractions from this test contained the equivalent of 18.4 and 465.1 tr oz/ton of gold and silver, respectively.

High-Tension Rejects

The high-tension rejects, a combination of middles and tails, contained a high percentage of nonmetallic material along with circuit card chips that still had metal attached. A trial sample (75 lb) of this material, processed and assayed by the toll refiner, contained the equivalent of 5.0 and 87.5 tr oz/ton gold and silver, respectively. This amount of gold and silver is high compared with the amount in some ores from commercial mines; e.g., 0.09-0.50 and 15-16 tr oz/ton of gold and silver, respectively. However, the refiner considered it too lean at that time for commercial toll refining.

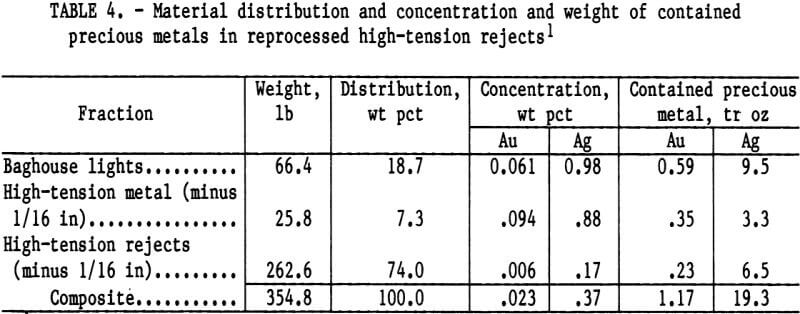

The minus 1- plus ½-in high-tension tails consisted mostly of printed circuit card chips. This material was added to minus ½-in high-tension rejects obtained from a separate test on printed circuit cards and reshredded in a knife granulator with a 1/16-in screen. The products from this shredding consisted of a fluffy, powdered glass-rich product, which was collected in a small baghouse, and a minus 1/16-in heavy fraction. To further liberate metallics from the epoxy-bound fiberglass board, 1/16-in material was then the high-tension separator, the minus processed Table 4 shows the results of this additional processing of high-tension rejects. About 7 pct of the reprocessed printed circuit card chips reported as metallics and 74 pct as rejects. The fine glass powder collected in the baghouse accounted for the remaining 19 pct.

A large sample (210 lb) of the minus 1/16-in high-tension rejects was sent

to the toll refiner. The assay of this fraction was equivalent to 1.7 and 49.6 tr oz/ton of gold and silver, respectively. This was the only sample sent to the toll refiner for which the shipping, toll refining, and assay charges exceeded the value of the recovered gold and silver. The sample still contained more gold and silver than naturally occurring ores but, from a practical standpoint, was too lean to justify additional mechanical processing.

Knockout Box Contents

The hammermill knockout box is a protective device incorporated in the design of the mill. Objects that did not shatter or shear into pieces small enough to pass through the grates reported here. These included large egg-shaped pieces of wrought aluminum and battered sheets of stainless steel.

Printed Circuit Cards

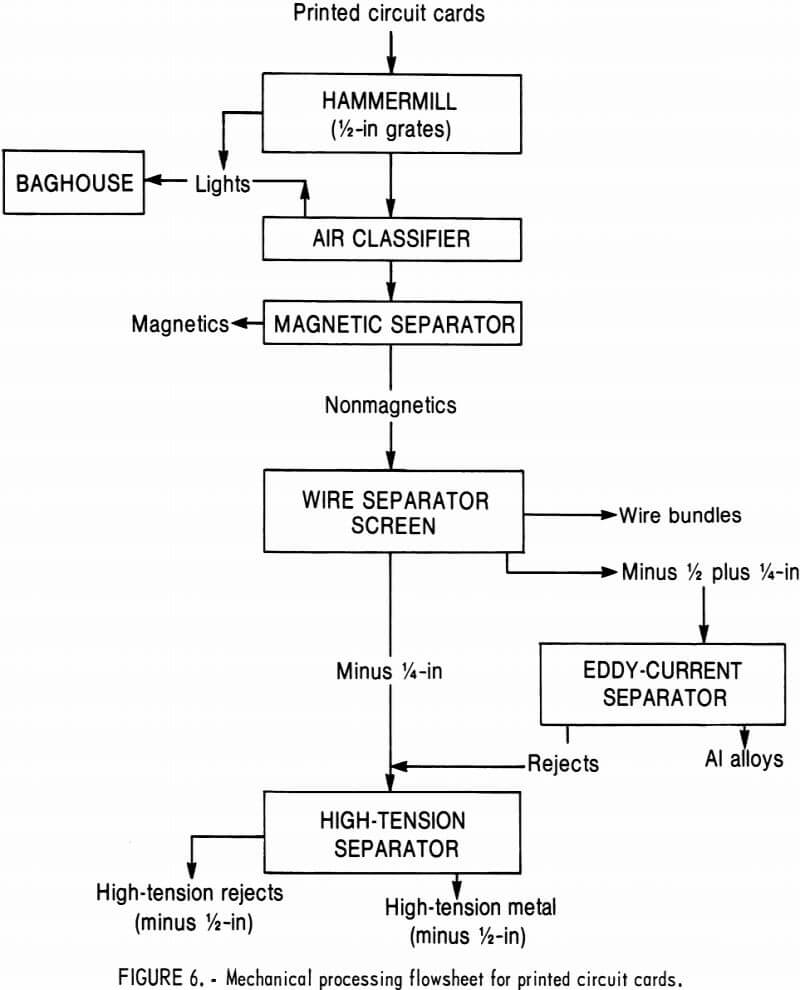

A separate mechanical processing test was run on printed circuit cards that were hand separated by the DPDS from avionic scrap modules. A modified procedure was used to eliminate unnecessary unit operations.

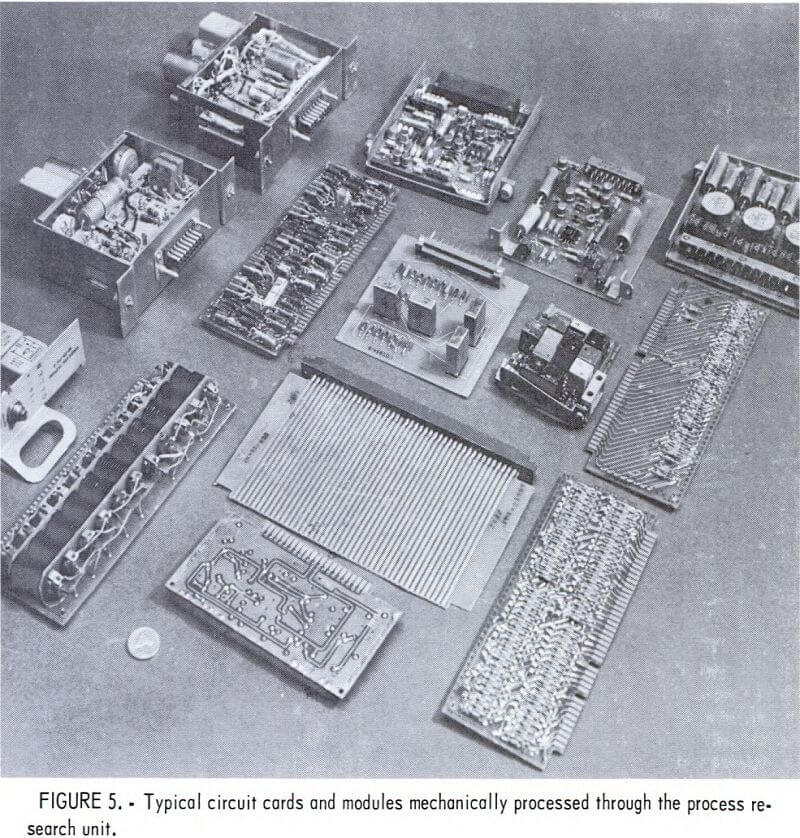

More than 900 lb of printed circuit cards of the types shown in figure 5 were processed through the unit operations

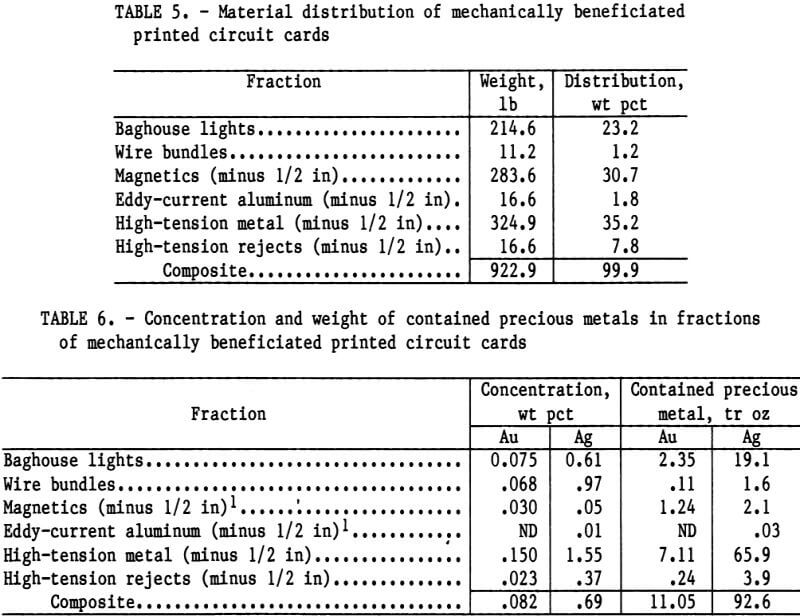

shown in figure 6. Material distribution for the various unit operations and analyses of the fractions recovered are shown in tables 5 and 6. The high-tension metal in table 5 represented 35 pct of the material feed and, as in previous tests with general avionic scrap modules, contained more than 50 pct, of the available gold and silver. Three product fractions — baghouse lights, wire bundles, and high-tension metal — represented about 60 pct of the printed circuit card feed. These three fractions contained approximately 87 and 93 pct of the total gold and silver, respectively.

Conventional processing of printed circuit cards by toll refiners currently includes burning, rod-milling or ball-milling, screening, and dissolving the screen oversize in a molten heel of copper for assaying and subsequent electrorefining. The screen undersize is blended for assay. This conventional procedure may be more practical than mechanical processing since the products recovered from the latter would require the burning and subsequent steps to assay and recover the precious metals. Since the circuit cards are easily segregated, the value of mechanical processing seems doubtful.

The sample of printed circuit cards processed in this test (approximately 923 lb) contained the equivalent of 23.9 and 201.2 tr oz/ton of gold and silver, respectively. For comparison, a sample of mixed printed circuit cards removed from an obsolete computer and mechanically processed through the PRU contained 24 and 57 tr oz/ton gold and silver.

Electrical Plugs and Connectors

Approximately 600 lb of electrical plugs and connectors of various sizes and shapes were also hand separated from avionic scrap modules and mechanically processed in a modified series of PRU unit operations. Electrical plugs and connectors are cast or deep drawn metal bands surrounding an insulator made of ceramic, thermosetting plastic, or rubber. Gold- and silver-plated pins or receptacles, crimped or soldered to wires, are embedded in the insulating material in various patterns. The modified procedure for processing the connectors is the same as that shown in figure 6, except the air classifier and stationary baghouse were not used. The only air classifiable light materials generated during the hammer-milling of electrical plugs and connectors were powdered ceramic, thermo-setting plastic, or wire insulation. This light material was collected in the portable baghouse at

the hammermill discharge chute. The air classifier and stationary baghouse were not required for the rest of the material leaving the hammermill, which was fed directly to the magnetic separator.

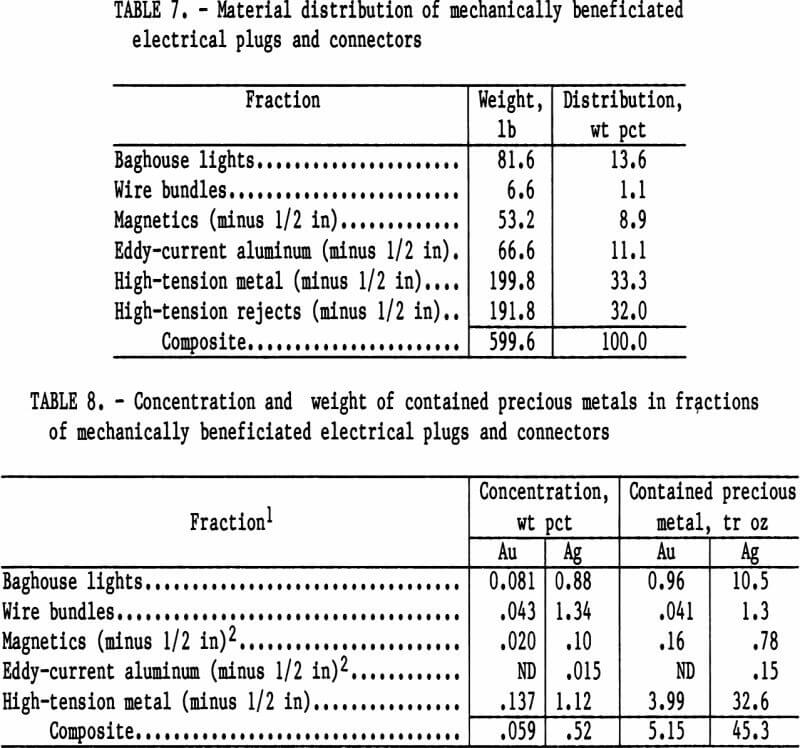

Distribution and analyses of products recovered from mechanical processing of electrical plugs and connectors are shown in tables 7 and 8. The high-tension metal, representing 33 pct of the feed, contained more than 50 pct of the total gold and silver. The combination of baghouse lights, wire, and high-tension metal represented 48 pct of the feed and contained 97 and 98 pct of the available gold and silver, respectively. As described earlier, the magnetic fraction is suitable for the copper cementation process, permitting the recovery of the precious metals. Mechanical processing of electrical plugs and connectors involves fewer processing steps than are required for the printed circuit cards and achieves considerable upgrading in products representing approximately one-half the weight of the original feed. The significance of this upgrading is discussed in the following section.

Economics

An economic evaluation for mechanical upgrading using the operations shown in figure 1 was reported earlier. The results, reflecting first-quarter 1980 equipment costs, showed operating costs of $219/ton for a 6-ton/d and $44/ton for a 60-ton/d scrap feed throughput, respectively.

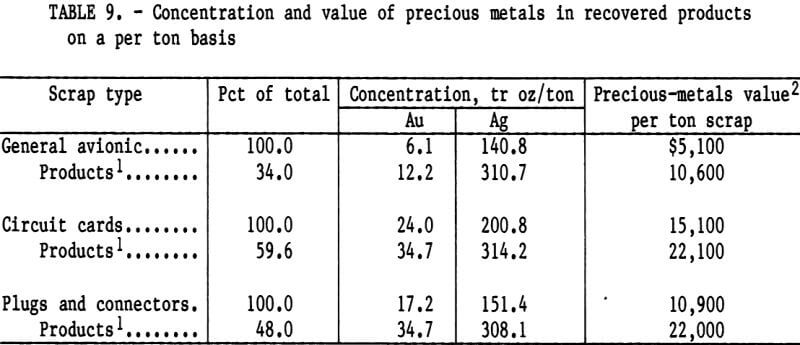

Table 9 is a summary of scrap and recovered product value based on the gold and silver contents shown in tables 2, 6, and 8, and the 1983 high prices for gold and silver quoted in American Metal Market, Feb. 2, 1983 ($508.50 and $14. 26/tr oz , respectively). The data for general avionic scrap show that the value of contained gold and silver in the original heterogeneous scrap was approximately $5,000/ton. Mechanical processing yielded products aggregating only 34 pct of the total feed but valued at almost $11,000/ton. The magnetics and eddy-current aluminum and copper-base metals can also be marketed for additional revenue to help offset processing costs.

Data for the electrical plugs and connectors also indicate attractive potential for utilizing mechanical processing. The precious-metals value of the scrap sample as received was approximately $11,000/ton. After mechanical upgrading, more than 97 pct of the gold and silver was concentrated in products representing only 48 pct of the feed but valued at over $22,000/ton. Some potential value may also be realized for the recovered aluminum and magnetics.

Mechanical processing of printed circuit cards is less attractive. The cards as received reflected a precious-metals value of almost $15,000/ton. After processing, products representing about 60 pct of the feed contained a precious metals value of more than $22,000/ton. Although some concentration is achieved, economic justification for mechanical processing seems doubtful since incineration and further processing for assay and final recovery of precious metals is still required. Use of the conventional processing may be more practical if applied to the circuit cards as received, without the additional cost of mechanical processing.

Recommendations

Observations made during this study indicate that a shear-type shredder (high torque, low speed) may be more suitable than a hammermill for processing large electronic scrap modules that have or have not been partially stripped of items containing precious metals. Hammer-milling tends to bundle up the steel and roll the wrought aluminum into egg shapes before they are ejected through the grates. A shear-type shredder has no grates , and the shredded material size depends on the configuration of the moving and stationary cutting surfaces of the mill.

One immediate expected benefit of using a shear-type shredder is that aluminum and aluminum alloys should be in larger and flatter pieces, thus increasing the efficiency of the inclined eddy-current board, without the need for a rolls crusher or other flattening machine. Also, the nonmagnetic stainless steel would not be impacted as severely as in hammermilling and would thus exhibit little or no magnetic behavior, which will also increase the efficiency of the inclined eddy-current board.

Addition of a granulator is also recommended as a means to further upgrade certain fine fractions prior to toll refining. It would provide capability also for processing manufacturer’s rejects of individual components and for processing miniature circuits to achieve better liberation of metals and nonmetals.

Conclusions

- Dry mechanical processing of general electronic scrap, printed circuit cards, and electrical plugs and connectors concentrates precious metals into three main fractions: high-tension metal, wire bundles, and baghouse lights. Some value can also be realized from the base metals upgraded and segregated during mechanical processing.

- The process appears attractive for upgrading general avionic modules that have been stripped of easily removed items but still contain precious metals-bearing components riveted to the modular frame or otherwise not readily accessible. Concentrates from the general avionic scrap represented only 34 pct of the total weight, yet contained 68 and 75 pct of the total gold and silver, respectively. Contained precious-metals value for the concentrates is almost $11,000/ ton compared with $5,100/ton of as-received scrap.

- Electrical plugs and connectors also exhibited marked upgrading via mechanical processing. Concentrates representing 48 pct of the total weight contained 97 pct of the total gold and silver. The precious-metals value of the concentrates is approximately $22,000/ton compared with about $11,000/ton for the as-received plugs and connectors.

- Mechanical processing of printed circuit cards seems to be less attractive, although excellent concentrates are produced. Concentrates amounting to 60 pct of the total weight contained 87 and 94 pct of the total gold and silver, respectively. Precious-metals value of the concentrates is about $22,000/ton compared with $15,000/ton for the as-received circuit cards. This degree of upgrading does not seem to justify the added costs of mechanical processing. Circuit cards are a well-segregated form of scrap, and conventional processing, such as incineration, grinding, assay, and refining, without the added cost of prior mechanical processing, may be more practical. Actual economic feasibility of mechanical processing of this type of scrap as well as the above types can be assessed accurately only by refiners and others having detailed knowledge of the costs of precious-metals assaying and refining.

- The magnetic fraction containing gold, silver, and nickel can be used for copper cementation. A gold, silver, and nickel residue would be a valuable by product from the copper cementation process.