Table of Contents

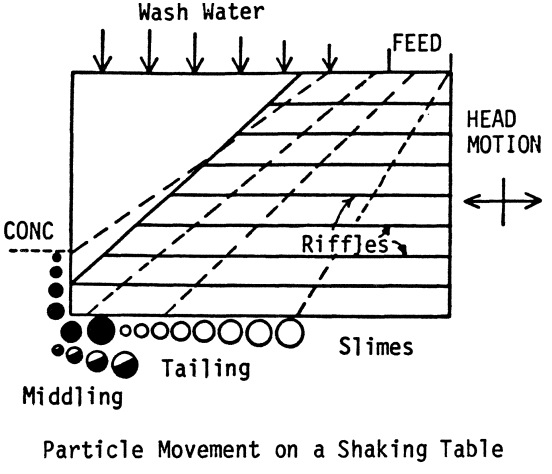

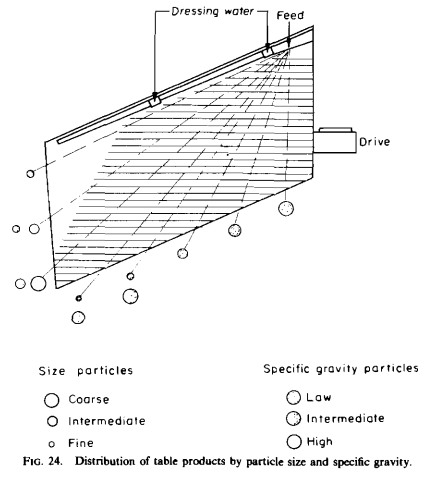

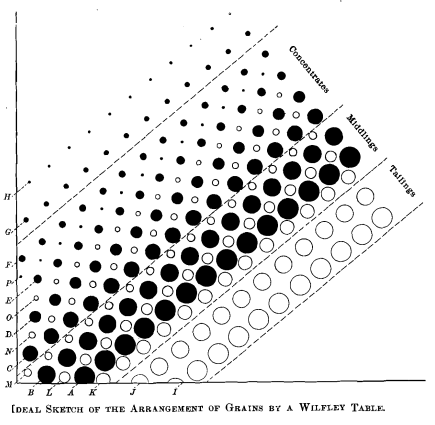

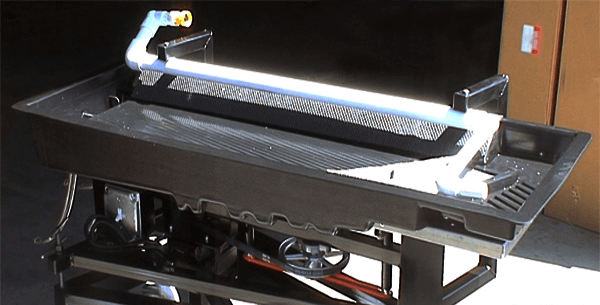

A Gold Shaking Table are basically low-capacity machines used as last step in the gold upgrading process. The shaking table is a thin film, shear flow process equipment, that separates particle grains of its feed material based on the differences in their specific gravity, density, size and shape. Mineral rich particles, from light to heavy and fine to coarse will be sorted by net effective weight.

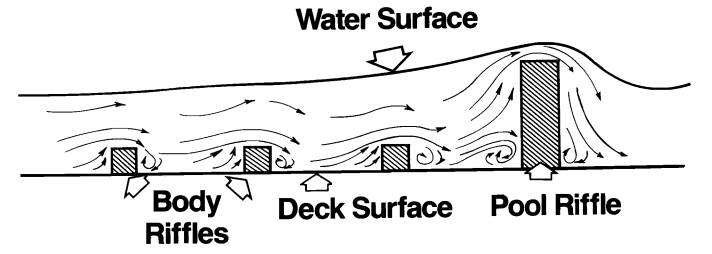

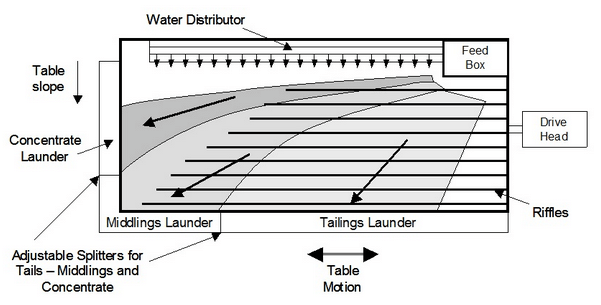

Finely crushed or ground ore material goes as feed mixed with water to form a pulp (mud) and fed as slurry of an average about 20–25% of solids by weight onto the highest point of the table deck. The gold table’s deck has a reciprocal movement along its main axis that is given using a vibrator or an eccentric head motion. The table surface is manufactured and fitted with several tapered strips called riffles or grooves, often made with of yellow pine (way back in time that is), low-density polythene or aluminum surfacing. Shaking tables and other thin film separating plant recover finely divided gold under conditions of subcritical laminar and supercritical laminar regimes of flow, which may occur only where there is a very thin depth of fluid.

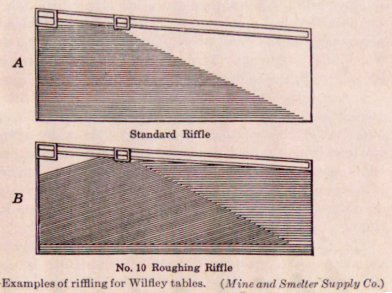

A gold shaking table’s riffles taper downwards in elevation in the direction the gold (and all heavies), precious metals concentrate discharge end of the table. This facilitates the ease with which mineral particles can move transversal to the table‘s axis or shaker-line, therefore helping separation over the complete table length. Riffle heights and pattern designs are selected based on the desired and required duty/function expected.

List of operating variables of shaker table:

- solids characteristics

- table speed

- stroke length

- deck inclination

- wash water volume

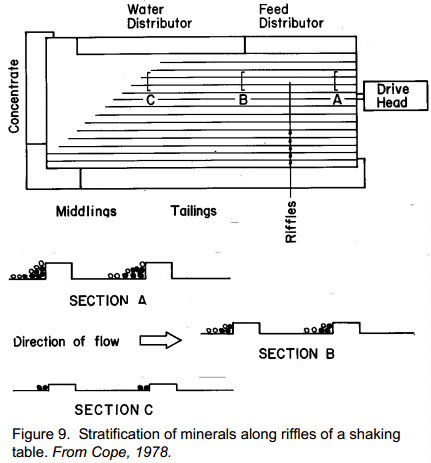

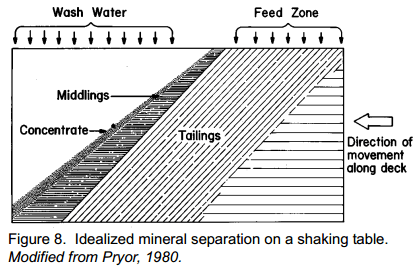

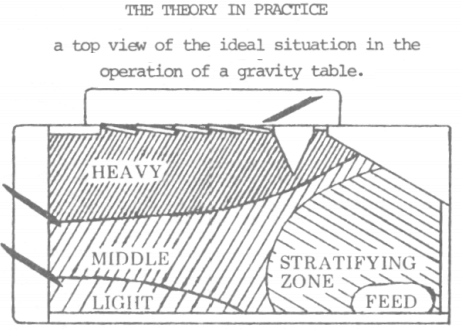

Preparing several size fractions for tabling is usually achieved in a hydrosizer. If gold is present in both coarse and finely divided sizings at least three, or perhaps four separate size fractions must be treated, each under a different set of operating conditions. Tables operate most efficiently with a closely sized feed. The slurry fans out across a smooth section of the surface until it reaches the riffles. The lighter and very fine particles are washed over the riffles and moved along the riffles by the reciprocating motion imparted to the deck while the heavier particles are held back.

The concentrates of heavy mineral and gold are discharged over the end of the deck. Tailings are washed over the lower edge and a middlings fraction is taken off between the lower edge of the concentrate strip and the higher edge of the tailing strip.

Wash water usage is dependent upon the particle diameter and varies from as low as 0.7 m³/t/h of solids for slime decks, up to 5–6 m³/t/h for coarse solids separation. Coarse fractions are usually treated at feed rates of up to 1 t/h using approximately 15 to 20 mm stroke lengths at around 280 rpm (Wilfley table data). The stroke lengths of finer fractions are reduced to 9–15 mm with increased speeds of up to 325 rpm but, because of the corresponding lower film, thickness capacities may fall to around 0.25 t/h. The inclination of the deck is adjusted during operation using a hand-operated tilting device. It is important following each adjustment to allow the table operation to settle down before making a fresh adjustment. The correct inclination is reached when the ribbon of concentrates is clearly defined and remains steady.

Wash water usage is dependent upon the particle diameter and varies from as low as 0.7 m³/t/h of solids for slime decks, up to 5–6 m³/t/h for coarse solids separation. Coarse fractions are usually treated at feed rates of up to 1 t/h using approximately 15 to 20 mm stroke lengths at around 280 rpm (Wilfley table data). The stroke lengths of finer fractions are reduced to 9–15 mm with increased speeds of up to 325 rpm but, because of the corresponding lower film, thickness capacities may fall to around 0.25 t/h. The inclination of the deck is adjusted during operation using a hand-operated tilting device. It is important following each adjustment to allow the table operation to settle down before making a fresh adjustment. The correct inclination is reached when the ribbon of concentrates is clearly defined and remains steady.

The extreme sensitivity of water depths and corresponding current depths to obtain F = 1, and the use of stationary tables as primary concentrating units, was probably the main reason for the consistently low (R.E. 60–65%) gold recoveries of early dredgers. For such table types, the fluid forces are applied to the stream-beds as a whole and ripples form, which keep the sand in orbital motion and provide for the denser particles to sink to the bed. Deposition is most favoured by anti-dune conditions produced by free-surface flow at or near the supercritical state. Such bed forms are in phase with the water surface and are produced in the rapid flow conditions of Froude Number F = 1. In this state of flow, the bed forms of the upper flow regime are stable. Below F = 1 the flow is tranquil and shear forces are reduced. In reviewing recovery distributions of certain dredgers it was noted that some coarse gold reported with the tailing after passing through two stages of tabling and that fine gold did not concentrate noticeably down the line.

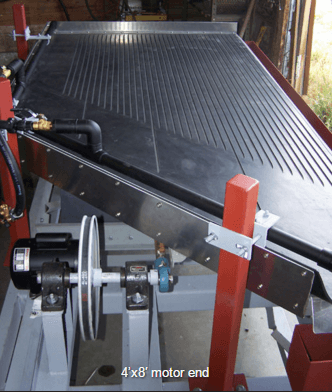

RP4 Shaker Table for Sale

It is hard to find the perfect image to express gravity concentration and operating principle of tables. I am sure that’s enough and you get the idea!

|

|

|

|

|

I consider the gold shaker table to be a “shaking sluice box” OR “self cleaning sluice” as they both essentially are classifiers used as heavy gold concentrating devices. Apart from nuggets; generally the valuable minerals like heavy precious metals like platinum and palladium that can be recovered by tables and sluices, are found in one size range (generally the finest) and the waste minerals in another. On a gold sluice, large particles (gravel) travel by sliding and rolling over the riffles, with finer particles travelling by saltation. Sand travels by a combination of modes described earlier with some saltation over the riffles. Very fine particles are maintained in suspension by turbulent and inter-particle collision.

Riffles function properly only if in the space between them and the slurry is sufficiently live (turbulent) to reject the lighter particles, but not so lively that the gold cannot settle. On a gold shaker table, those particles are allowed to settle as they will get transported to the other end by the vibrating/shaking back-and-forth motion. Lower grade, light pieces, will be able to escape the table a the riffles becomes shorter along the table’s length.Once the particle has started to move, the coefficient of friction changes to a dynamic coefficient of friction. In fact, because the fluid push on the particles is larger at the top of the particle than at the bottom, the particle rolls, largely according to the shape of the particle and according to the speed. At low speeds, the effective friction is the relatively large coefficient of dynamic sliding friction, and at high speeds it is the lower coefficient of rolling friction. The change probably takes place partly continuously and partly discontinuously. As a first approximation, the dynamic coefficient of friction may, however, be regarded as constant.

Riffles function properly only if in the space between them and the slurry is sufficiently live (turbulent) to reject the lighter particles, but not so lively that the gold cannot settle. On a gold shaker table, those particles are allowed to settle as they will get transported to the other end by the vibrating/shaking back-and-forth motion. Lower grade, light pieces, will be able to escape the table a the riffles becomes shorter along the table’s length.Once the particle has started to move, the coefficient of friction changes to a dynamic coefficient of friction. In fact, because the fluid push on the particles is larger at the top of the particle than at the bottom, the particle rolls, largely according to the shape of the particle and according to the speed. At low speeds, the effective friction is the relatively large coefficient of dynamic sliding friction, and at high speeds it is the lower coefficient of rolling friction. The change probably takes place partly continuously and partly discontinuously. As a first approximation, the dynamic coefficient of friction may, however, be regarded as constant.

Sluicebox VS Table

In a sluice box, the settling of heavy minerals between the riffles requires frequent stirring to prevent the riffle spaces from blinding. This also disturbs the gold, which then moves progressively down-sluice. Frequent clean-ups are needed to avoid excessive loss. Boxes may be used in parallel to avoid loss of production time. One box is kept in operation while cleaning up in the other.

You see here the parallel with a gold concentrating table?

The shaker table is a self-cleaning sluice.

Effect of Deck Roughness: The foregoing analysis is based on the postulate that the deck is perfectly smooth. If the deck is rough, i.e., if it has at its surface some recesses capable of partly shielding fine particles from the rub of the fluid, the slope required to move the particles by either rolling or sliding will be increased. At the same time such an effect, while present also for large particles, may be so much smaller for them as to be imperceptible. The relationship of critical angle to size obtained above will therefore not hold for rough surfaces. The problem is analytically complex and it is nevertheless a problem that might well be explored further if a full insight is desired into the mechanism of flowing-film concentration.

Operation of Shaking Tables

Operation of Shaking Tables

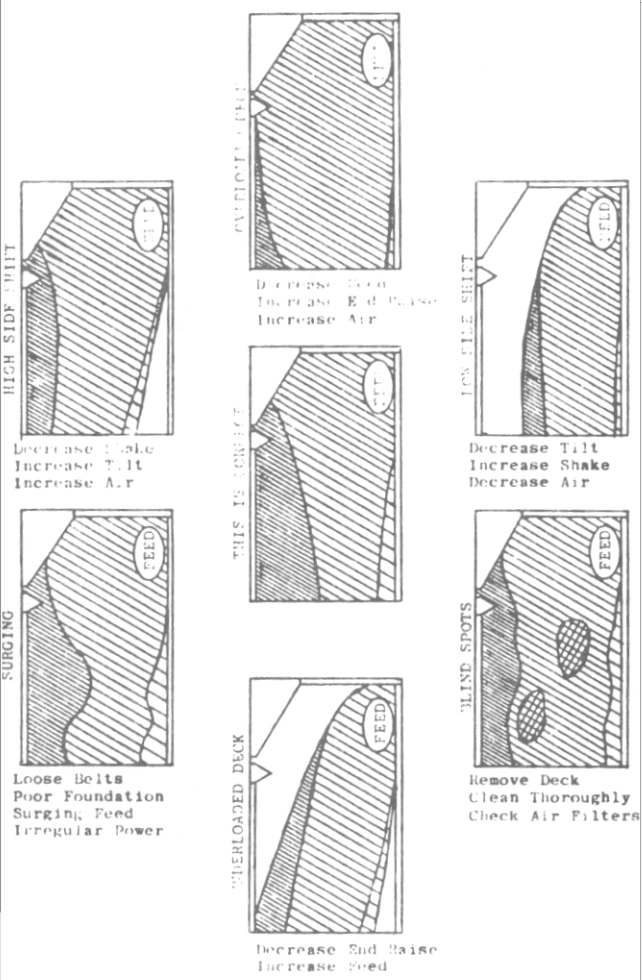

Adjustments are provided in all tables for the amount of wash water, the cross tilt, the speed, and the length of the stroke. The speed of the table ranges usually from 180 to 270 strokes per minute, and the strokes are from 1/2″ to 1 1/2″ long.

Generally speaking, a gold shaker table will see the adjustments as follows:

For a roughing operation:

- more water

- more feed

- more tilt

- and longer stroke

For a cleaning operation:

- less water

- less ore/feed

- lens tilt

- a shorter stroke

For fine feed:

- less water

- less feed

- faster reciprocation

- shorter stroke.

For coarse feed:

- more water

- more feed

- slower reciprocation

- longer stroke

Variations in character of feed require variations in operation. The operator’s duty is to take care of them by adjusting the tilt, the wash water, and the position of the splitters that control discharge of table into concentrate, middling, and tailing launders. One man may look after 10 to 100 tables, depending upon the regularity of the feed and the difficulty of the task assigned to the table.

Table tonnage treated depends upon:

- Size of feed.

- Whether the operation is roughing or cleaning.

- The difference in specific gravity between the minerals that are to be separated.

- The relative abundance of locked particle.

- The average specific gravity of the material treated.

A coarse feed can be treated in larger amounts than a fine feed. It would seem that the treatable tonnage increases at least as the square of the average size (theory indicates that it increases as the cube of the particle size).

A coarse feed can be treated in larger amounts than a fine feed. It would seem that the treatable tonnage increases at least as the square of the average size (theory indicates that it increases as the cube of the particle size).

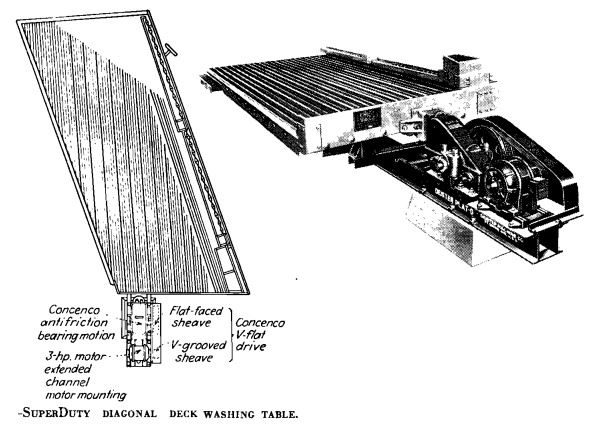

A roughing operation is preferably conducted on a fully riffled deck. These decks have a greater capacity because the particles are treated throughout the deck in the form of a teetering suspension many particles deep instead of as a restive layer one particle deep. Such decks do not provide flowing-film concentration but some sort of jigging. On the other hand, a cleaning operation is preferably performed on a partly riffled deck.

It is clear that minerals of different specific gravity must be present the greater the spread in specific gravity between minerals, the greater the capacity since that sort of condition permits crowding without considerable penalty.

The effect of locked particles on capacity of tables should also be recognized. These particles behave in a fashion intermediate between that of pure particles of their constituent minerals. It is as if a three-product separation were sought in which one of the products would guide-in specific gravity between the two other.

|

|

|

Capacity of a Shaking Tables

Table capacity may be as high as 200 tons per 24 hr. on a fully riffled deck 4 by 12 ft. treating minus 3-mm. sulphide ore having a specific gravity of about 3.0 (roughing duty), or 500 tons per 24 hr. But table capacity may be as low as 5 tons per 24 hr., or even less, for fine ore (minus 0.3 mm.) if there is only a small specific-gravity differential between minerals.

Operating a shaking table is cheap as power requirement per table are typically low. Most of the energy is expended to move the deck, which must therefore be as light as is consistent with rigidity. Laboratory gold shaking table testing report.

Repairs consist of renewals of riffle cleats and of deck. Those must be made at regular intervals. Lost time is not considerable.

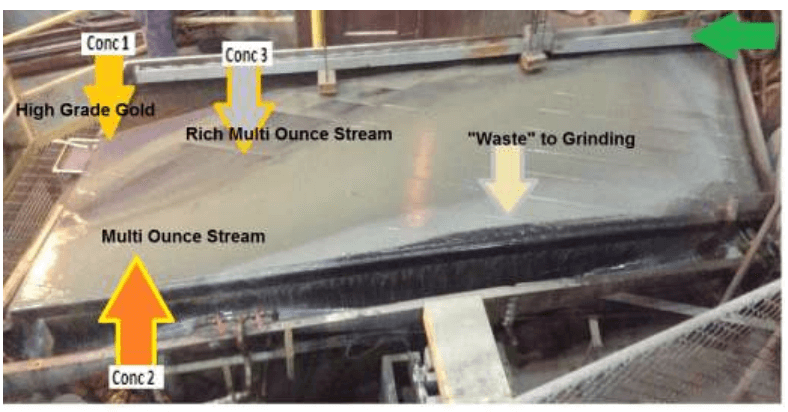

Here is a table running a high content of native copper and arsenopyrite. The concentrate runs crazy 20% Cu, 17000 g/t Au and 2500 Ag g/t.

Gold Shaker Table

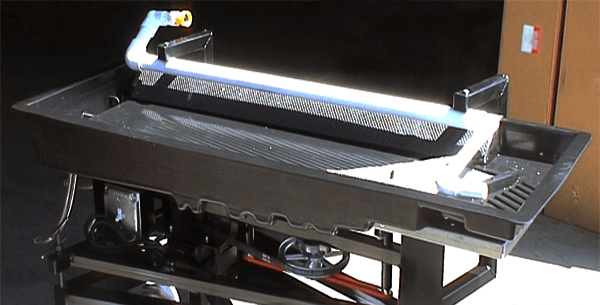

There are a few steps that need to be taken in order to get your gold shaker table to work efficiently. The first step that aspiring gold miners must take would be to make sure that all four corners of the table are level from forward to back. It is very important to anchor the bolts so that the shaking of the gold goes to the table and not through the frame. After you begin running your table, you may need to adjust your table from side to side to maintain an even flow of materials on both sides of the table.

There are a few steps that need to be taken in order to get your gold shaker table to work efficiently. The first step that aspiring gold miners must take would be to make sure that all four corners of the table are level from forward to back. It is very important to anchor the bolts so that the shaking of the gold goes to the table and not through the frame. After you begin running your table, you may need to adjust your table from side to side to maintain an even flow of materials on both sides of the table.

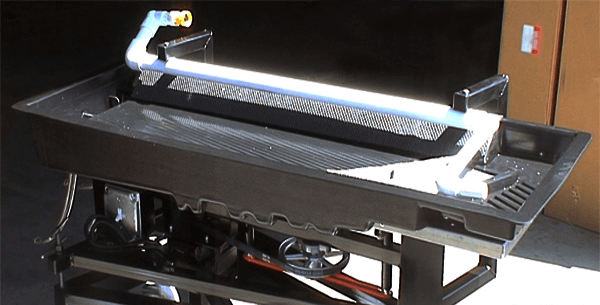

A gold shaker table contains a water access point where you can fill it with clean water, which can be seen right under the control area. Alternatively you can directly fill the tank of the shaker table with clean water. The water access point allows you to connect a clean water system through a garden hose. The valve that is right behind the tank is then turned off and the pump system is not running during the process of running fresh water. When clean washing water is distributed at the top of the table at right angles, particles are moved diagonally across the deck and separate from each other according to their size and density.

During the fast shaking process, you will gradually begin to see the separation of materials. For example, when you have dirt and rocks that contain materials like lead, sulfides and gold, because of the varying weights of these different materials, you will see these materials venture off in different directions on the shaker table. The lead and the sulfides will be carried over to the right side of the table while the pure gold will be carried over to the far left side of the table.

The tint/color of each area on the table depicts its quality or gold/mineral content.

There is one term to remember when professional gold miners describe the actions of a gold shaker table. When professional gold miners say that small particles of gold are being carried through the grooves, they are referring to the ripples that you can plainly see on the shaker table. When they say that there is an overflow of materials like Black Pyrrhotite, White Quartz, silver and gold on the grooves, then this is a good thing.

When materials are washed by the clean water they are supposed to drop into 3 hoppers/launders underneath the table. There is a centre launder that will gather the purest portions of gold while the two outside launders will gather some gold, though not as much.

When materials are washed by the clean water they are supposed to drop into 3 hoppers/launders underneath the table. There is a centre launder that will gather the purest portions of gold while the two outside launders will gather some gold, though not as much.

It is crucial to remember to plug the cable of your shaker table into a GFCI (Ground Fault Circuit Interrupter) outlet. Most shaker tables will not work if they are plugged into any other kind of outlet.

Percussion Gold Shaker Table

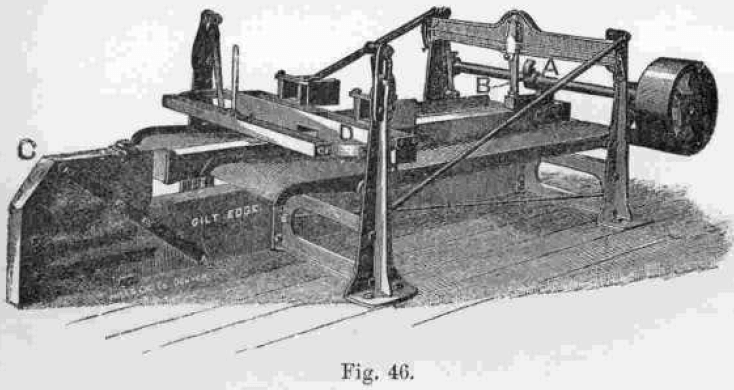

In a Percussion Gold Shaker Table, the work of keeping the pulp in a state of agitation, done by the rakes or brushes in the German and Cornish buddies described above, is affected by sudden blows or bumps imparted sideways or endways to the table. The table is made of wood or sheet metal, the surface being either smooth or riffled.

End-bump tables are hung by chains or in some similar manner, so as to be capable of limited movement, and receive a number of blows delivered on the upper end. These blows are given by cams acting through rods, or else the table is pushed forward against the action of strong springs by cams on a revolving shaft, and then being suddenly released is thrown back violently by the springs against a fixed horizontal beam. The movement of the pulp depends on the inertia of the particles, which are thrown backward up the inclined table by the blow given to the table, the amount of movement varying with their mass, and depending, therefore, both on their size and density. The vibrations produced by the percussion also perform the work of the rakes in destroying the cohesion between the particles, and a stream of water washes them down. The result is that the larger and heavier particles may be made to travel up the table in the direction in which they are thrown by the blow, by regulating the quantity of water, while the smaller and lighter particles are carried down. These machines yield only two classes of material, headings and tailings. One such machine, the Gilpin County “ Gilt Edge Concentrator” was devised in Colorado, and has displaced the blanket sluices at almost all the mills at Blackhawk. It consists (Fig. 46) essentially of a cast-iron or copper table, 7 feet long and 3 feet wide, divided into two equal sections by a 4-inch square bumping-beam. The table has raised edges, and its inclination is about 4 inches in 5½ feet at its lower end, the remaining 1½ feet at the head having a somewhat steeper grade. The table is hung by iron rods to an iron frame, the length of the rods being altered by screw threads, so as to regulate the inclination to the required amount. A shaft with double cams, A, making 65 revolutions per minute, enables 130 blows per minute to be given to the table in the following manner; on being released by the cam, the table is forced forward by the strong spring, B, so that its head strikes against the solid beam, C, which is firmly united to the rest of the frame.

The pulp coming from the copper plates is fed on to the table near its upper end by a distributing box, D, and is spread out and kept in agitation by the rapid blows. The sulphides settle to the bottom of the pulp, and are thrown forward by the shock, and eventually discharged over the head of the table at the left hand of the figure, while the gangue is carried down by the water and discharged at the other end. One machine is enough to concentrate the pulp from five stamps. If the table consists of amalgamated copper plates, it is of some use for catching free gold also, treating about 8 cwts. of ore per hour. This machine is not so effective in saving slimed pyrites as the Wilfley table or the vanners.

Gold shaker tables are environmentally friendly (chemical free) for recovering pure gold as they can play an important part in reducing the use of mercury by gold miners. With gold shaker tables miners don’t need to resort to mercury amalgamation or cyanide to recover gold. The filter will constantly need to be removed and cleaned as it will get dirty even after using the table a few times.

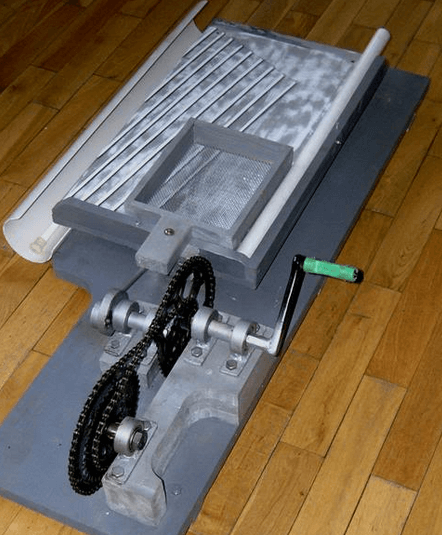

Miners can design and construct a basic shaking table out of cheap materials that are affordable in local stores, including a drive mechanism that contains bicycle gears, chains and rubber bands that are made from car tire inner tubes. The drive mechanism for a gold shaker table can be a hand crank or it can contain parts of a motorcycle frame and engine. If one prefers to use a motor for his or her table, either an electric motor or a motor that runs on diesel fuel would be the ideal options.

|

|

It is important to keep in mind that there is no one specific way to create your own gold shaker table system. Many professional gold mining organizations will create tables of different shapes and sizes to cater to the needs of their customers. Some shaker table systems will feature machines that can crush hard rocks, which are referred to as jaw crushers. The speeds of shaker table systems will vary as they can shake from hundreds to thousands of pounds of materials per hour.

See table motion https://www.holmanwilfley.co.uk/wilfley-7000-shaking-table.swf

I will explain later how I view a shaker table as an evolution of the sluice box and we should think of the shaking table as a self-cleaning sluice.

Someday soon, I will explain in greater details the Magic of the Gemini Shaking Table.

Someday soon, I will explain in greater details the Magic of the Gemini Shaking Table.

- Gaudin AM. Principles of Mineral Dressing. New York: McGraw-Hill; 1939.

- Fisher N. The origin and composition of alluvial gold with special reference to the Morobe Goldfield, New Guinea. Trans AIMM. 1935

- PRINCIPLES OF GRAVITY SEPARATION Jim Thomas

- Practical aspects of tabling. Mr. John W. Amos and John A. Christopherson from the Diester Company.

Industrial practice of fine coal processing. Chapter 10 - The Wilfley Table, I. BY ROBERT H. RICHARDS, BOSTON, MASS. (Toronto Meeting, July, 1907.)