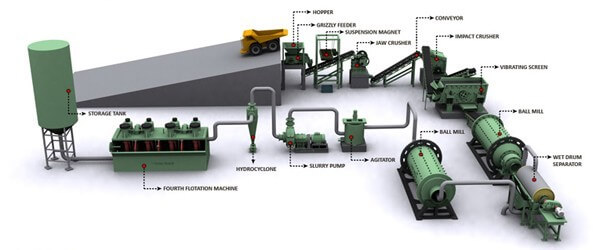

In our Gold Process Description EXAMPLE, the ore will be received by the crushing plant initially by rail haulage from the ABC Zone and later by truck from the DEF Zones. The 350 tonne live capacity coarse ore bin is sufficient for train or truck load surges and provides approximately five hours storage of ore, permitting 1 shift of haulage.

Minus 16″ run-of-mine ore is crushed to minus 3″ in a 24″ x 36″ primary jaw crusher. The jaw crusher product is screened on a 6′ x 10′ vibrating double-deck screen and the screen oversize is crushed from minus 3″ to minus 1/2″ in a secondary 4′ standard cone crusher. The secondary crusher product is combined with the primary crusher product and recycled back to the vibrating screen. The minus 5/8″ screen undersize

material is conveyed to the 500 tonne live capacity fine ore bin.

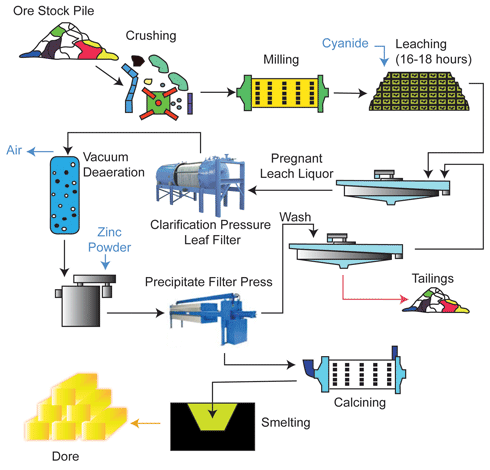

Crushed ore is reclaimed from the fine ore bin and is fed into the 10′-6″ diameter x 13′-0″ long single stage overflow ball mill. Leaching is designed to begin in the grinding circuit by the addition of recycled barren solution for repulping. The grinding circuit is a very efficient leaching unit with violent agitation and good aeration. Ball mill discharge is pumped through one of two 15″ diameter cyclones where the cyclone underflow discharges into the ball mill feed chute and the cyclone overflow, at 70% minus 200 mesh, flows by gravity to the thickener, where much of the dissolved gold and silver are removed in the thickener overflow. Some leaching does continue, although at a very reduced rate due to the reduction of oxygen, in the thickener.

The thickener underflow is removed at a density of 60% solids to minimize the transfer of high gold and silver content solutions to the leach circuit. The underflow is then diluted with barren solution to the leach feed density of 45% solids. With this flow configuration a large portion, approximately 70%, of the gold and silver dissolved in the grinding circuit will flow via the thickener overflow directly to the precipitation circuit.

The four 8.0 meter diameter x 8.5 meter high leach tanks are sized for a total retention time of 48 hours at 45% solids. Air is sparged into each tank and oxygen is dissolved into solution by 20 HP hydrofoil type agitators. Fresh cyanide and lime are also added to the leach circuit to facilitate gold and silver dissolution.

https://www.911metallurgist.com/small-crushing-plant-operating-guide

The leached slurry is fed to the two stage drum filtration circuit. Flocculant is added to the feed slurry of both filtration stages to obtain the necessary filtration from the four 12′-0″ diameter x 18′-0″ long drum filters. Maintaining a good wash ratio of approximately 1.6:1.0 on all drum filters and repulping the slurry between filtration stages will reduce soluble losses of both gold and silver. The wash cycle on the drum filters rinses the filter cake and allows dissolved gold and silver (pregnant solution), entrained in the filter cake, to be drawn out of the filter cake. Repulping the filter cake from the primary filters dilutes the filter cake and allows any remaining pregnant solution to be recovered in the secondary filtration stage. Barren solution is used as wash and repulp water on the primary filtration stage whereas a barren bleed solution and/or reclaim water is used as wash water on the secondary filtration stage. Reclaim water is used for repulping the final secondary filter cake.

Filtrate or pregnant solution from the drum filters is fed to the pregnant solution tanks, or to the thickener. The residue from the second stage filters is repulped to 35% solids and is pumped to the flotation conditioning circuit.

Filtrate or pregnant solution from the drum filters is fed to the pregnant solution tanks, or to the thickener. The residue from the second stage filters is repulped to 35% solids and is pumped to the flotation conditioning circuit.

The flotation conditioning circuit consists of two 4.0 meter diameter x 4.0 meter tanks, each equipped with a 50 HP agitator. The first conditioning tank is used primarily for cyanide destruction; the cyanide concentration in the flotation pulp must be less than 5 ppm for effective flotation recovery. The second conditioning tank is primarily used for conditioning the flotation pulp with flotation reagents. Conditioned pulp is pumped to the Argentite (silver mineral) flotation circuit.

The three stage flotation circuit will recover floatable silver minerals remaining in the primary leach residue. Two banks of 4-100 cu. ft. rougher flotation cells must recover as much of the silver mineral as possible within the 30 minutes allotted contact time. The rougher concentrate is cleaned in two stages. First stage cleaning consists of 3-30 cu.ft. cleaner flotation cells. The first cleaner concentrate is further cleaned in a single 30 cu. ft. second stage cleaner cell. The second cleaner tails are fed to the first cleaner cells and the first cleaner tails are fed to the rougher cells. Rougher flotation tailings are the primary tailings from the mill. The second cleaner flotation concentrate is the feed to the Argentite leach circuit.

The cleaned silver (and gold) bearing mineral concentrates are leached in a high cyanide strength solution for 96 hours at 20% solids. The leached slurry is filtered to recover the dissolved silver (and gold) in the filtrate. The filtrate or pregnant solution from the small Argentite drum filter is combined with the pregnant solution from the primary and secondary filters and is fed to either the pregnant solution tanks or the thickener. Residue from the Argentite drum filters is repulped and pumped to the tailings box.

Pregnant solution is clarified prior to deaeration in a 53 sq. meter vacuum precoat clarifier. The pregnant solution must be clarified prior to precipitation as solids in the pregnant solution will impede precipitation. Two parallel clarifier units are installed, one of which is on standby while the other is operating. The leaves of the clarifier are precoated with diatomaceous earth filter media before each clarification cycle. When the clarification cycle is complete, as noted by a pressure increase, the solution flow is diverted to the standby clarifier.

The clarified solution is deaerated in a 5′-0″ diameter x 10′-0″ high tower containing horizontal baffles which distribute the solution and assist deaeration. The clarified pregnant solution must be deaerated prior to the Merrill Crowe precipitation process as the oxygen in solution will prevent the gold and silver from being precipitated. Vacuum for this tower is supplied by the primary and secondary filter vacuum pumps.

After discharging from the deaeration tower, a slurry of zinc dust and lead nitrate is introduced into the suction pipe of the filter feed pump to facilitate gold and silver precipitation. The gold and silver cement onto the zinc particles, precipitating the precious metals out of solution. The cement precipitate is then filtered to remove the gold and silver from the slurry. The barren solution filtrate from the precipitate filters is discharged to the barren solution tank where it is recycled throughout the process. A small portion of the barren solution is continuously bled to the tailings line to prevent the accumulation of impurities that may impede leaching or precipitation.

The two pressure filters, one operating and one standby, are alternately operated. The operating press will fill with precipitate approximately every two days. The loaded press is then shut down and the standby press put into operation. The wet precipitate from the filter press is dumped down a chute onto a screw conveyor which feeds the rotary electric dryer. Once dry, the necessary refining fluxes are added to the dryer to mix with the precipitate. The mixture is then discharged from the dryer into a 500 kg, 150 KW induction furnace for refining.

During the refining process, the slag is poured out of the furnace at regular intervals and additional flux and precipitate are added to the furnace crucible. When the dryer is empty and all of the slag has been poured out of the furnace, the molten precious metal is poured into cascading 1000 Troy ounce dore bullion moulds. The cooled dore bars are secured in the refinery safe and the slag is fed manually into the ball mill for reprocessing.

The production rate of the EXAMPLE Gold Mines processing plant is expected to be approximately 4000 troy ounces of combined gold and silver (dore) per day. Each refining day will produce 8-1000 troy ounce dore bars.

https://www.911metallurgist.com/good-concentrator-safety-guidelines-practices