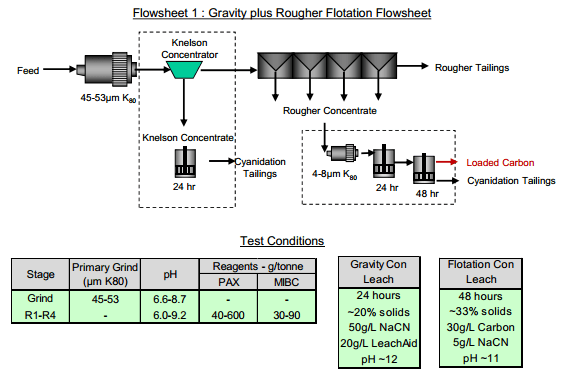

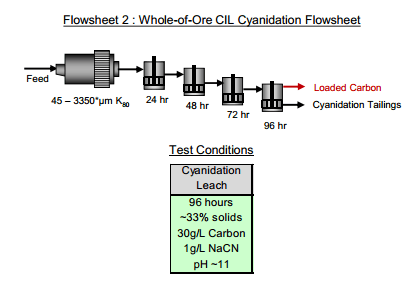

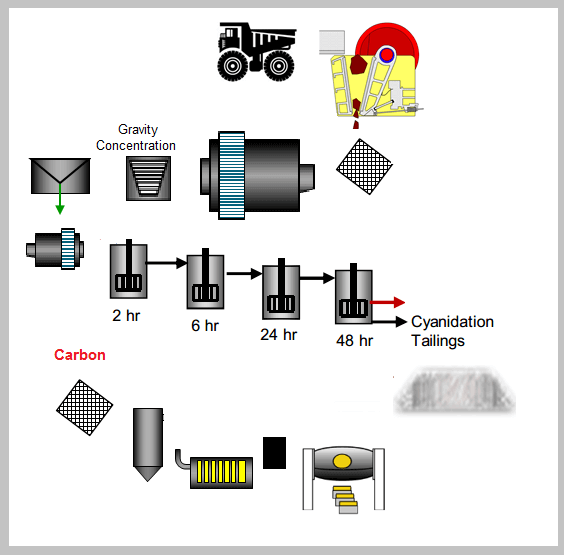

Of all the methods of extracting gold & processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery methods:

- Flotation and Leaching of the Float Conc

- Flotation and Leaching of the sulfide-free Float Tails

- Gravity Gold Concentration followed by Flotation and Leaching of the Float Conc

- Heap Leach amenability (cyanidation CIL) after coarse crush.

- Whole ore CIL

The metallurgical testing focused on assessment of metallurgical performance for two flowsheets, featuring flotation, cyanidation and gravity concentration unit operations.

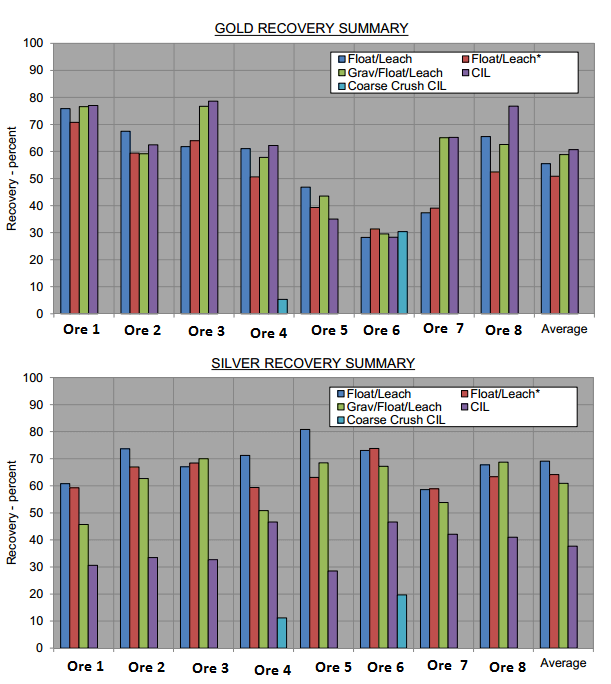

This was a geometallurgy exercise in which 8 lithologies from the same open-pit gold deposit were tested for Silver and Gold Extraction and evaluation of the response for 2 Processing Methods.

The feed gold and silver was amenable to gravity separation and flotation. However, the subsequent cyanidation of the concentrates did not provide any significant improvement, on average, over Whole-of-Ore CIL testing. The gravity/flotation flowsheet with cyanidation of the respective concentrates recovered between 30 and 77% of the gold in feed, with an average of about 59 percent across all eight lithology composites. Whole-of-ore CIL extracted between 28 and 79 percent of the gold in feed, with an average of about 61 percent. These results would indicate there is some degree of refractory gold, which would require alternative processing to recover.

Silver recoveries were higher using the flotation flowsheet with subsequent cyanidation of the flotation concentrates. Recoveries varied between 59 and 81 percent of the silver in the feed, with an average of about 69 percent. Whole-of-ore cyanidation extracted between 29 and 47 percent, for an average of about 38 percent.

Here, the gold extraction method selected was gravity/flotation as the flowsheet to pursue.