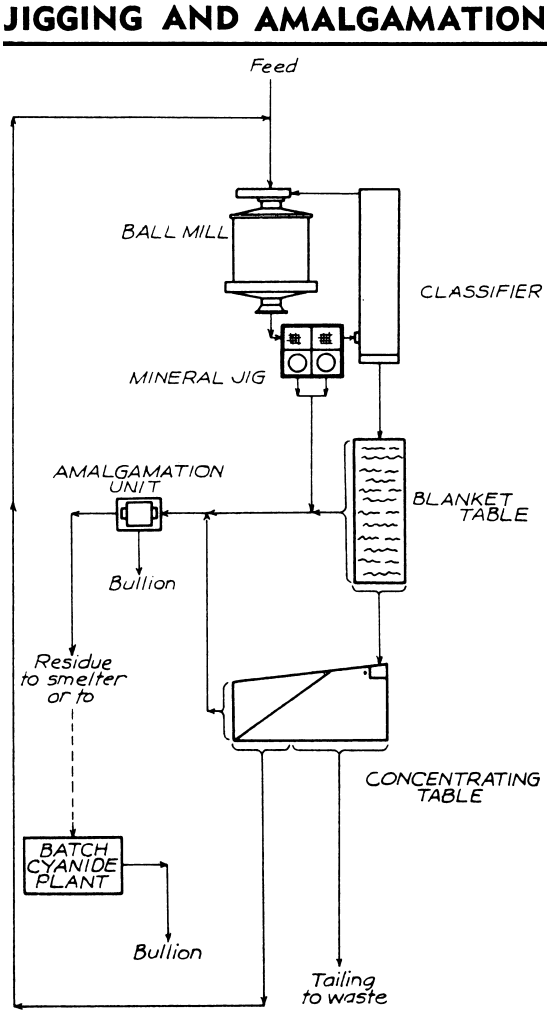

CIRCUIT PROCESS FLOWSHEET DESCRIPTION: Modern, inexpensive amalgamation circuit with the Mineral Jig as the major recovery unit.

ORE TREATED: Practically any gold ore containing native or free gold.

ADVANTAGES From sixty to ninety-five percent recovery can be made with this simple flowsheet on many ores, and the gold produced in bullion form. The Mineral Jig is used between the grinding mill and classifier and recovers not only the free gold but auriferous sulphides and high gravity oxides and carbonates. The gold is recovered in highly concentrated form for subsequent batch treatment by forced amalgamation.

Amalgamation can now be applied to practically any gold ore whereas formerly this process was limited to the few rare ores where the gold was coarse, free and bright. By segregating the gold values into a small bulk of high grade concentrates, the gold can be amalgamated after finer grinding, polishing, and through the use of common reagents to overcome the effect of any deleterious minerals or compounds present.

PROCESSING COMMENTS: The Amalgamation Unit is a vital part of this flowsheet and has so simplified this step that the services of an experienced amalgamation operator are not necessary. This flowsheet is being widely used for bulk sampling and for treating development ore. In many cases, the recovery from these plants is carrying the expenses of the development work.