Table of Contents

Process Development

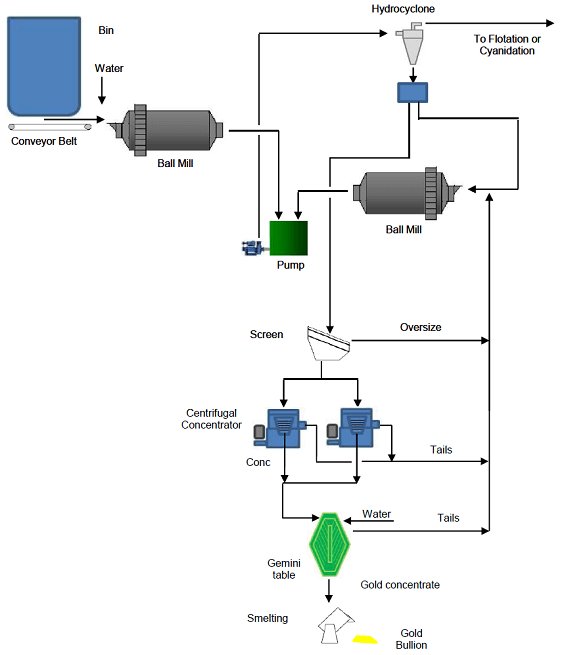

Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the unwanted material in order to increase the concentration of gold in an economically manner. This part treats the strategy of beneficiation as a combination of several processes. Joining together these units make possible to develop an appropriate flowsheet whose objective is to recover gold and the precious metals present in the ore.

Perhaps, one of the greatest challenges in the gold mining industry is to produce high grade concentrates consistently at maximum recovery from the mineralized deposit. To quantify recovery is a reasonable idea of the initial ore required to have an economical operation. In this part, a reliable sampling representing the ore is a key aspect. Separation, concentration and leaching processes involve several operations such as screening, classification, solid-liquid separations, gravimetry, flotation, and pregnant liquid solution treatment.

Sometime, the selection, design and operation of any process are complex and needs a special study. In this way, improvements in the understanding of the processes have developed better equipments, efficiency and productivity. Special operations have sophisticated instruments dedicated to control and give more realistic information about the process.

Sampling:

Gold operations are not a trivial exercise and the investment is influenced by the quality of material sampled for assays and metallurgical tests. The success of this is sometimes complex due to many decisions can create an impact in the economy of the project. It is important that this small fraction can be representative as possible of the ore body. The importance of selecting a representative sample for gold projects can not be overemphasized.

The alluvial gold mining industry has enormous sampling problems. For example, large boulders, sometimes over one meter in their largest dimension are sometimes found along with tiny particles of free gold. Big trommels are employed to remove the washed oversize, but this stream can transport some gold particles creating losses.

Testing with an average sample and designing for average conditions will result in a operation that in absence of continuous ore blending will have moments of inadequacies in ore treatment rate and final product quality.

The main sources of error at the moment of sampling a placer are the low gold content, difference between gold specific gravity and gangue, and gold distribution. In general, sampling for a reliable process study must include representative samples, including easy and difficult materials. In this way, the testing program can be prepared considering single samples and mixtures at different proportions.

Drill Hole Sample

The same considerations are important at the beginning of any project or at the moment of considering a plant expansion. In this way the process to be selected is a critical route and can be oriented towards two aspects, improve project economics, expected recoveries and environmental considerations.

Sampling is a very close item to the process selection. All this aspect is an iterative process that usually starts as soon as exploration has established the presence of gold in sufficient grade and reserves for the ore body. The work devoted to sampling and process selection is related to the degree of certainly of the grade and reserve estimations and their absolute values, such as attractiveness of the deposit.

Selecting a Process

The process to be employed must be selected considering several factors such as geology, mineralogy, metallurgy, contamination, location and profitability.

- Geology

At the beginning of any gold project, there are some questions that typically appear, one is related to the compositing schemes and is related to the ore body type, and second, the level of variability in the deposit. Both factors are influenced by geological considerations such as rock type, lithology and ore type. They are involved to the character of the rock described I terms of structure, mineral composition, particle size and arrangements.

The single most difficult task in any project is the acquisition of an understanding of the mineralized deposit. In some cases, representative samples can be obtained by diamond drilling in a relatively tight pattern encompassing the mineralized zone. Drill core intervals are subdivided by lithological horizon and ore types composites are prepared. It is considered that a good ore sample from a given lithological type within a deposit will produce constant results. However, in some deposits, well defined zones formed by remobilization may overprint the lithological horizons resulting in important differences in gold particle size and its distribution.

In the construction of a composite much importance is considered in order to be approximated to the average gold content of the deposit. In order to get this condition, samples are compared and related according to geological considerations. Sometimes, the gold content is variable and will be important to study its distribution. When there are sulphide deposits, gold grade intercepts and sulphide grains can influence the composite construction.

Differentiation between lithologies by core logging can be an issue due to many times similar material is classified in two classes. This must be avoided. The only solution to offset the effects of this problem is to exercise increased diligence in classify and identify the lithologies within the deposit. The composites to be tested, intercepts from any given lithology from various parts of the deposit should be subjected to detailed mineralogical study. The resultant information provides precise information on gold characteristics within the deposit.

The ore body formation affects the mining method and the sequence of extracting different zones so that the beneficiation process can be effective. Changes in ore properties, such as ore gold distribution and hardness have influence in gold liberation and consequently will be affected the recovery process. For example, orebodies containing clays have problems due to the excessive amount of fine material liberated during the comminution process due to rheological and physiochemical properties are modified.

- Mineralogy

Mineralogy is related to the identification and occurrence of economical minerals to be recovered by concentration and leaching processes. The practice of gold minerals beneficiation is optimized by using the information obtained from applied mineralogy. In this way, at the moment of development and select a process for treatment a gold ore, try to identify the gold minerals is the first step. Obviously, the detection of non-valuable minerals is important. In simple ores, the amenability of the composite to the recovery influenced by the gold minerals distribution, gold particle size, degree of oxidation and occurrence. Sometimes, gold deposits are not exploited due to the mineral was not well understood and the process was not able to give high recoveries, or at least, expected recoveries.

The concept explained in the previous paragraph is valid at the moment of considering any plant expansion because the mineralogy can be different and the process employed could not be able to give good results. Then, there is a close relationship between mineralogy and metallurgical results. Mineralogy information is obtained by employing optical, chemical and instrumental devices. For example, we can know the existence of fine particles of free gold or in solid solution in pyrite or arsenopyrite. Even the presence of polymetallic deposits with important amounts of gold. Other information very important is related to gold composition variability in the host rock.

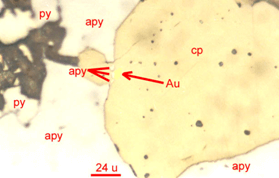

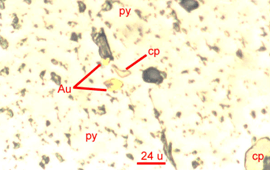

Gold in contact with pyrite and chalcopyrite Free gold hosted by pyrite

Also, gold mineral textures and associations with other minerals can be done by modal analysis. In this case, we can know the existence of rims coatings, fine intergrowths, extremely tiny inclusions of gold and identification of potential deleterious elements and minerals in to the final product. According to be process to be followed, impurities create problems.

All the information obtained must be treated closely with the metallurgical results from the first steps of the project or plant under operation. Quantitative mineralogy can be done from optical microscopy or automatic methods such as Quantitative Evaluation of Materials by Scanning Electron Microscopy (QEMSCAN) or Mineral Liberation Analyzer (MLA). The idea is to observe and record statistically significant number of minerals grains in ground or ground mineralized samples. In this way, can be identified the relative proportion of liberated and locked particles for each mineral in the sample. It is possible to obtain mineral head grades and liberation values. The information is used explain the behavior of the several ore types.

- Metallurgy

Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized copper minerals and organic matter. The optimizing ore treatment process needs that the unit operating cost established as a base for a main element of the deposit. The key economic components have to be identified and correlated with the metallurgical testwork program.

The metallurgical information must be based on measurements of mass and gold content. It has to be based on a full revision using the best practices to produce accurate information for the process. In general, the information generated must be consistent and transparent and the source of all input data to the system must be understood by the management and metallurgy area. An aspect very important to be included is the risk assessment of some assumptions due to some restrictions found in the testwork program.

Results must be obtained timeously to meet project schedule needs, including the information for any contingency so that all the procedure can facilitate corrective actions. Target accuracies for sampling and analysis must be identified for each input used for process selection. In this way, metallurgical data must be generated to prepare balances, economical studies and mine plan development.

- Contamination

All gold recovery processes generate waste material and must be disposed in the environment. This material is different according to the process selected and must be studied carefully in order to avoid legal problems. The latter item is important at the moment of get a work authorization, during the operation and at the end of the life of the project. This area is a key aspect of the project. For example, if the waste material has pyrite, there is a potential problem, acid drainage. Then, the designer has to consider several options to avoid surprised problems in the future. Other interesting situation is a cyanidation process due to have to consider a special item related to cyanide destruction.

The idea is to select an economical and optimum metallurgical process without overlooking environment aspects. Sometimes, this situation is complex and all the efforts have to be focused on this subject. The flowsheet and mass balances must shows information with clarity so that the critical points can be identified.

- Location

There are two considerations on this point. One is referred to the mine and the other is the treatment plant. Ideally the first one must be close to the plant, but sometimes the area and accessibility are serious issues. Probably, the most critical aspect is the plant location due to the idea is to have a good foundation for the buildings to be constructed and use the geography of the area. The latter is important because the gravity force must be utilized at maximum because the energy is an operative cost that will influence the economy of the project.

If the plant will be located near cold zones where the temperature can reach low values, the building must consider special protection due to exists the possibility of having frozen problems with the slurry. This situation is painful if the problem is not considered before. There is a solution when the problem is real, but solution generated an extra cost. Engineering companies are important needs some inputs to develop their work efficiently.

- Profitability

The economy and profitability of the project is influenced by the mining costs, operative costs, shipping costs, impurity levels, concentrate treatment charges and smelter/refinery returns. These factors have to be projected from the laboratory tests or scaled metallurgical tests. Basically, a gold concentrate has to be related to the mineralized block, gold distribution, diluents such as pyrite, graphite, clays, organic matter. All these factor must be studied together in order to optimize the revenue of the project according to the mineralized zone.

The metallurgist must indicate the sensitivity of the basic assumptions in the cost projections to the uncertainty in the world economic market. One of the key aspects is the price projections for the mine products. Other considerations are addressed to the overall financial analyses for ore quality, product returns, and all direct and indirect costs for the operation. Some of the uncertainties are the gold price, price forecast for consumables and energy, variations in mine reserve blocks, confidence in ore grade and quality, and others according to the process. The average process cost per tonne or per unit of metal produced for the future operation will be obtained from this information.

Crushing and Comminution

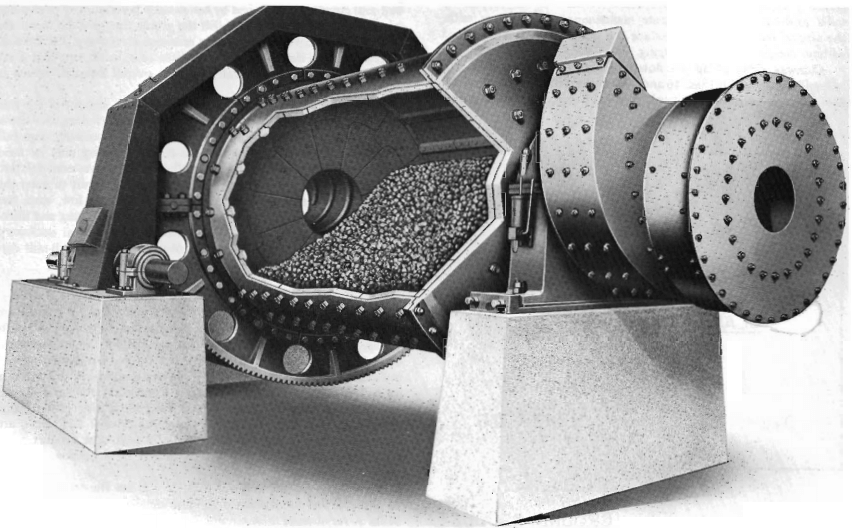

The selection of an appropriate crushing and comminution circuit for a specific ore type is one of the most important key aspects in a new gold project. The importance is related to the fact that the capital and operating costs for generated for these operations represent the major part of the plant operative costs (65-70% of the total cost). The number of factors to be considered depends on the type project. If the project is an entirely new mine operation, the process is critical. If the project is a plant expansion, the existing operation has an impact on the design factors.

The number of factors is big considering the fact that gold ores are different due to the occurrence of gold and gangue is variable according to the geographical location. In general, the most important step in the development is the analysis and understanding of the ore characteristics such as the hardness, abrasiveness, moisture content, gold grade, gold mineralization, gangue type and other more. With the information generated, we will able to know the plant assize, specifically the throughput.

The metallurgical flowsheet has to indicate the fineness of primary grind required and probably, the necessity of including multi stage grinding with intermediate concentration steps. Based on this information, the metallurgist must perform hardness tests. This is a critical step and s easy the evaluation process when there are alternative processes. All this studies will help to get the appropriate gold liberation for the concentration or leaching process to be used.

Circuits can be designed based on standard configurations developed by manufacturers or considering old operations. It will be important to know how much to be ground per line and whether the circuit will be closed or open. Other aspect very important is the feed variation to the circuit. The ore tells how it must be ground. If the ore breaks along boundaries easily, the valuable minerals can be liberated at a coarser grind. With certain ores, slimes production is a serious problem. Generally, comminution circuits need time to be understood, and time is variable. The cost benefit of time and relative production losses or gains has to be worked out.

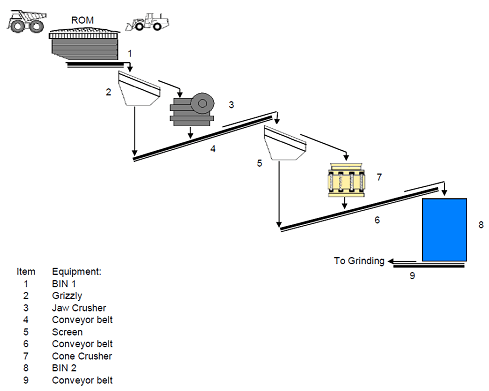

Crushing circuit without circulating load

The processing of gold ores has traditionally made use of conventional crushing and grinding circuits. In each case where gold is formed either as coarse native particles or in coarse grained sulphides, it is recovered by gravimetry concentration in the in the comminution circuit in addition to recovery of finer values by leaching. Jigs are the most common types of gravimetric equipment placed to intercept the ball mill discharge prior to classification. Lime and sodium cyanide are used in the dissolution of gold and there is considerable advantage in including them to the grinding circuit due to high dissolution rates usually result from agitation and oxygenation of the slurry during the grinding operation.

- Comminution effects

Perhaps one of the most interesting subjects on gold metallurgy is its high malleability and natural hydrophobicity. This has been a well-known phenomenon for many years and both properties have advantages and disadvantages on gold recovery. The first one makes possible to obtain particles no very thick and the second one can creates some problems during the operation of some gravimetric equipments due to there is a tendency of native gold to float on the surface of a slurry in a sluice box and be lost in the tailings. This situation is sometimes called skin flotation.

Native gold and electrum are variable in composition and different parts of a particle have different compositions. This mean that some gold particles can be naturally floatable due to its composition and the presence of silver or other metallic minerals can modify partial or totally this property. In general, gold particles can be floatable by chemical or physical surface changes caused by geological processes over time. Some experiments showed that gold particles polished with regular polishing powder can get a finite contact angle and flotation even when washed with pure water and pure alcohol before use. Then, it is possible that geological processes of an unknown nature can made a similar effect. This physical condition could be obtained by work-hardened during any previous step.

Free gold particles are normally flakey and show deformation and flattening caused during their liberation from the host rock and transport to the place from where they are recovered. This was caused by work hardening that contributes to natural floatability. In the same way, gold particles obtained in comminution processes are easily deformed and flattened. It is therefore work hardened and its surface may well be contaminated. During comminution there is a generation of abraded iron surfaces from grinding media and the broken particles can be deposited on gold surface changing gold particles characteristics and its behavior during recovery processes such as flotation and leaching. In this way, gold particles are smeared and its natural properties are affected.

Other sources of contamination are organic substances. It is well known that many organic compounds produced by plants and timbers affect the gold properties. Since they are soluble in water and the slurry is treated in flotation or leaching processes, the recovery efficiency is reduced.

- Particles Classification

Particles must be separated according to its size due to comminution equipment will not produce an appropriate product to feed the concentration process. In this way crushers and grinding equipments are conducted in closed systems with classification performed in screens and hydrocyclones. The reason of including these equipments is to control overgrinding as well as to achieve the gold liberation size. When the operation is running, the information available about gold liberation must be real; otherwise we can create losses in the comminution circuit or during the same recovery processes.

Perhaps, small gold operations don’t have all the information available and must employ operator’s experience and knowledge at the moment of performing any change during the operation. Even during the testwork program, it will be important to determine the right grinding product. Concepts and ideas like must be kept in mind due to this will definitely improve gold recovery by gravity concentration.

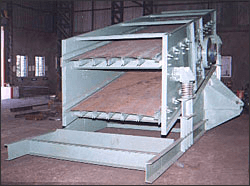

Grizzly Vibratory Screen

As the material is being fed to the screen is dropped onto the screen surface, it tends to develop a fluid state. The larger particles remain on the top and the smaller particles sift through the voids and find their way to the bottom of the bed of material. This characteristic particle orientation is known as stratification. The latter concept is an obvious necessity without which separation could not take place. In order to take the maximum advantage of this situation, the depth of bed material at the feed and discharge ends have to be reasonable for the size separation to be made. In this way, for a given rate of feed, the width of screen is selected to control this depth of bed and achieve optimum stratification.

In general stratification is influenced by ore feed rate, stroke screen, moisture and critical size particles. The last two factors reduce the efficiency of the process.

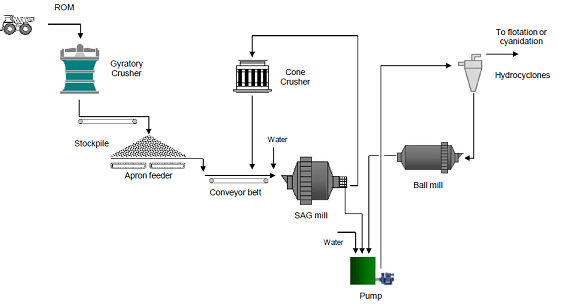

Grinding circuits consist of one or more pieces of equipment to grind ores. Generally, these circuits include one or more grinding mills, classification equipment and the required materials handling equipment such as pumps and conveyor belts. SAG mills, rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants. There is an increasing trend to employ SAG mills (semiautogenous mills) in place of secondary and tertiary crushing and primary grinding. The most common type of rod mill is the overflow mill. There are two typed of ball mills used. Overflow discharge and grate discharge. Hydrocyclones are the predominant size classification equipment employed in wet grinding circuits. Screw classifiers still have their place, especially for coarse size classification. Screens are gaining favor for specific applications. They are frequently employed for coarse sizing in SAG circuits, and basically in circuits where a close top particle size separation is advantageous.

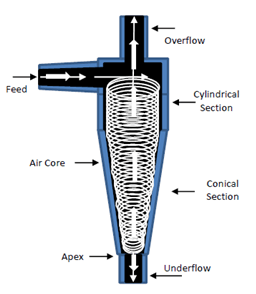

Hydrocyclone Underflow Hydrocyclone cutaway

For many years hydrocyclones have been employed in mining operations in order to classify particles according to its size. The practical range of classification for hydrocyclones is 30 to 350 µm, with some special applications finer or coarser than the range mentioned. During the operation the slurry enters under pressure through the cylindrical chamber. As the feed moves into the chamber, the particles go downward in a spiral movement towards the conical section. In this step, the particles are separated in two streams, one with finer particles and other with coarse particles. The first one goes to the top of the hydrocyclones and is called overflow and the second one, leaves the hydrocyclone through the conical part. The second stream is called underflow and usually transports gold coarse particles. For this reason is important to operate the grinding-classification circuit with all the information related to gold liberation. Normally, gravimetric equipments are fed with this stream.

In this way, size classification has been used in grinding circuits to prevent the entry of undersize material into the ball mills and gold recovery can be performed in the first moment. Fine gold particles can be recovered in other concentration devices such as flotation and/or leaching.

SAG mill circuit

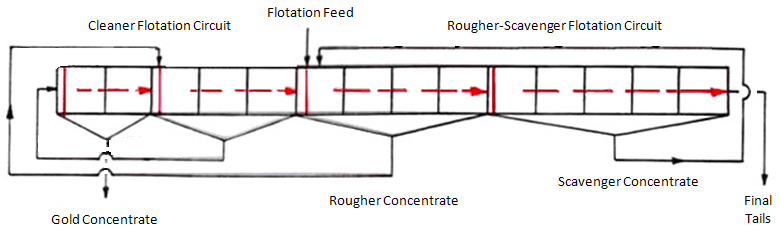

Gold Recovery

Gold recovery comprises similar stages to the processing of most ores. First, the valuable minerals are separated from the gangue through concentration. The final concentrate is obtained by repeated processing and is smelted or leached in order to get a Dore bar. In generals, the concentration of gold includes three stages: roughing, cleaning and scavenging. The reason of concentration is to separate the raw material into two products, concentrate and tails. Ideally, in free gold recovery, all the gold will be in the concentrate and the other part will be in the tails. Separations are not perfect and in practice some waste material is reported into the concentrate and some gold particles remains in the tails. Intermediate products are called middlings and can be defined as particles that belong in either the concentrate or tails. Sometime, this product is a serious problem.

Roughing can be considered as the upgrading of the ore to produce either a low grade, preliminary concentrate or to reject tails that contain gangue at an early stage. The equipment used in this part can produce a large amount of concentrate and permit the recovery of a very high percentage of gold, produce clean tails or a combination of both. The most common equipments are cones Reichert, jigs, sluices and dry washers.

The rougher concentrate is sent to the cleaning stage in order to eliminate impurities; the process can be as simple as washing black sands by using a vanning dish. Mineral concentrates can pass through several stages of cleaning before a final concentrate is obtained. The equipment employed in this stage is the same equipment used in the rougher stage. Other equipment such as a shaking table is employed in the cleaning stage and let to obtain clean gold concentrates.

The last stage is called scavenger and consist in to process tails from rougher and cleaning stages before discarding. The material is treated through equipment that concentrates the last particles of gold. This stage is included according to the design adopted in the operation and can be simple or complex depending on the ore type. In operations where there is amalgamation, this stage is employed to recover quicksilver that otherwise will be reported in the environment. In general the equipment employed in the other stages can be used in this stage.

There are some considerations related to the concentration process. Recovery is the percentage of gold in the raw ore collected in the concentrate. For example a recovery of 85% means that 85% of the gold is reported in the concentrate and the remaining part is in the tails. A concentrate grade is the gold content in the concentrate and usually is expressed in grams per tonne (g/t) or ounces per tonne (oz/t). the ratio of concentration is the proportion of the weight of the feed to the weight of the concentrate. For example, if 500 tonnes ore feed are processed and 100 kilos of concentrate is obtained, the ratio of concentration is 5,000. If we compare this value with a mine operation whose ratio of concentration is 2,000 and the concentrate grade is similar, the second operation is economically better due to don’t need excessive raw ore in order to get a good gold concentrate.

Exist an inverse relationship between recovery and concentrate grade. This means, the higher the concentrate grade, the lower the total recovery. In general, some valuable mineral is lost in producing a high grade concentrate. Under this consideration, the higher concentrate grade is easier to refine reducing refinery costs. For each operation, a special combination of grade and recovery must be achieved to get optimum incomes.

- Gravimetric concentration

Concentration by gravimetry was the first method employed to concentrate minerals and has been the bastion of concentration for many years. Froth flotation has been a competitor due to gravity concentration is not able to give the sharpness of separation possible with flotation. Gravity concentrator has two main characteristics, coarse gold particles can be recovered and the operative cost is low.

The difference between the specific gravity of gold (19.0) and the low specific gravity of the gangue (2.7) makes gravity concentration the primary means of recovery free gold particles. In general, gravity separation has some advantages over flotation and leaching, it needs significant lower capital investment, less power and low handling costs. Also waste material disposed in the environment is less harmful.

As was mentioned, the high specific gravity of gold is an advantage, but there are negative characteristics of free gold that trend to affect its recovery. Basically, flattened particles, cavities and irregularities reduce the effective specific gravity of gold and could cause it to float rather than sink. The flat shape of tiny particles can create hydroplaning.

It has been noted that the size and shape of a particle has a very significant effect on its settling velocity due to the gravity is related to the mass of the particle. Under this idea, coarse gravel must be removed by screening from the feed before trying gold recovery. Usually, a grizzly followed by a trommel is appropriate to perform this operation. Then, it will important to consider elaborate feed sizing if the gold particles have big variable distribution.

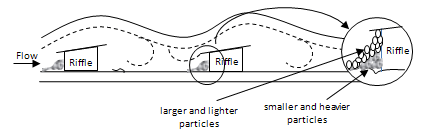

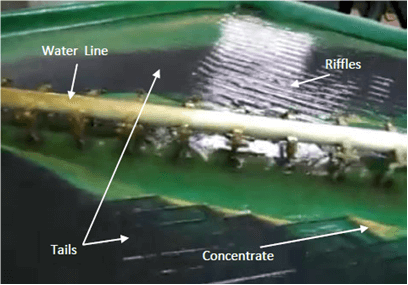

- Sluice

A sluice is defined as a channel through which controlled amounts of diluted slurry. Sluice box and riffles are one of the oldest forms of gravity separation equipment. The size of this equipment is variable and range from small and portable metallic models to large units. Small models are employed for prospecting purposes. In general, sluices can be made of wood, aluminum, steel or plastic. A typical sluice section is 12 feet long and one feet wide. As a rule, a long narrow sluice is more efficient than a short wide one. The sluice must slope 4 to 12 inches per 12 feet depending on the water available, the coarse particle to be processed and the possible gold particle size.

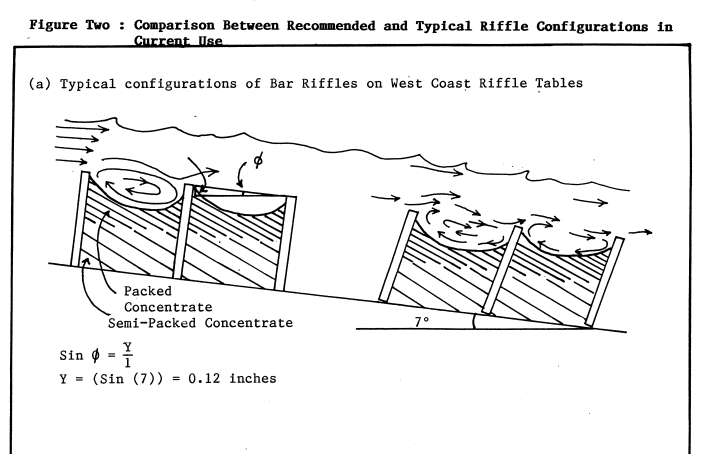

The riffles in a sluice retard material flowing in the water that forms the sand bed that traps heavy particles and created turbulence. This turbulence causes heavy particles to tumble and repeatedly exposes them to the trapping medium. An overhanging lip known as Hungarian riffle increases the turbulence behind the riffle that agitates the sand bed improving gold recovery. Riffles are fabricated of wood, rocks, rubber, steel and they are 1-1/2 inches high, placed from one half inch to several inches apart. The riffles are commonly fastened to a rack that is wedged into the sluice so that they can be easily removed. Many years ago, quicksilver was added to riffles to facilitate fine gold recovery, but its release into the environment make this practice dangerous.

Riffles

Riffles and other material are used to line sluices for enhanced recovery. In the past, carpet, corduroy, burlap and denim were all employed to line sluices to aid in the recovery of gold. Long-strnad Astro Turf carpet, screens and rubber mats are employed today for the same purpose. In Russia, some dredges use sluices with continuously moving rubber matting for fine gold recovery. Extensive use of sisal clothes as sluice boxes liners to concentrate gold was employed in mining operations in Africa. The main problem is to use very opened sisal clothes than can work properly for coarse gold, but it is unlikely efficient for medium and fine gold particles. This material costs around US$ 4/m2. It is matter of trying different types in order to get the most appropriate according to the gold ore to be processes.

Typical operative parameters are listed below:

- Slurry, steady and pre-screened at 5 mm

- Percent solids, 15%. Clayed material needs special conditions

- Flow velocity, depend on box width and slope

- Stream depth, 20-30 mm

- Slope, 10-25 degrees

- Length, 2-5 m

- Width, depend on flow speed

- Water, 30-70 m3/h/m

To perform efficiently, a sluice needs large amounts of water. Enough water must be added to the feed to build up a sand bed in the bottom of the sluice. For maximum recovery, the flow should be turbulent, yet not forceful enough to wash away the sand bed. Russian studies have shown that recovery increases with the frequency of cleaning. For clean up, clear water is run through the sluice until the riffles are clear of gravel. A pan or barrel is placed at the discharge end to prevent loss of concentrate. Starting from the head of the sluice, riffles are carefully washed into the sluice. According to the model, any bottom covering is removed and washed into a separate container. Clean up continues until all riffles are washed. Large particles of gold should be removed by hand, and then the concentrate is washed out of the sluice or dumped into an appropriate container. The concentrate can be smelted or cleaned more by panning. After clean up, the sluice is reassembled and more ore is processed.

Riffles separate heavy and light particles

Gold recovery with sluices can vary depending on several factors. Fine gold losses can be minimized by cleaning up more frequently, reducing the speed of the slurry flow to around 0.50 to 0.80 m/s., and decreasing the feed size by performing a previous screening. Some experienced operators have increased recovery by adding a liner to the sluice to trap fine gold and other have lengthened sluices to increase the residence time and the trapping area.

Sluices are used due to their low cost and availability. They need little supervision and maintenance, they can tolerate large fluctuations in feed volume; they are portable and can be achieved acceptable gold recoveries. Unfortunately, there some disadvantages such as very fine particles are not recovered, needs frequently clean up, and is important to have a big source of water. Some manufacturers offer sluice boxes fabricated for specific conditions.

- Jigs

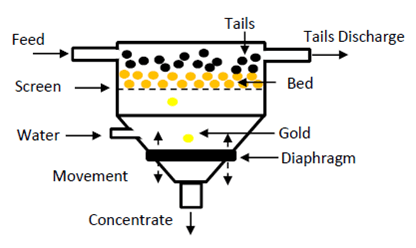

Jigging is one of the oldest methods of gravity concentration. The elementary equipment is a hindered settling device consisting of shallow, flat trays with perforated bottoms that contains layers of high density material such as particles of steel balls through which water pulsates up and down. The direction of flow through the bed is reversed several times. In this way, the bed is dilated by the forward stroke of a plunger and compacted by the plunger’s backward stroke.

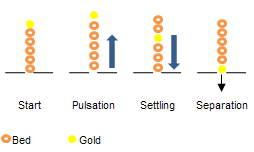

In general, this equipment uses the differential acceleration of particles of different specific gravity to separate gold minerals and gangue. The slurry containing the minerals to be concentrated is fed onto a permeable screen. The jig operates by the periodic movement of water pulse through the screen. Stratification in a bed of particles results from the repeated pulsation of a current of fluid up through the bed. The particles in the bed are expanded so that when pulsation finish, the particles are allowable to consolidate under the influence of gravity. The expansion and contraction is repeated in a cycle operation until the heavy and light particles are stratified according to their densities (specific gravity).

The jigs operate by the periodic movement of water through the screen. The upward velocity of the water brings all the particles into a suspension with particles surrounded by liquid. The water maintained in this movement and then allowed to drain back through the grid. The bed of particles collapses back onto the screen and differential acceleration of particles occurs during this stage of the process. The next figure shows the expansion and contraction of bed particles.

Typically jigs are able to treat coarse material and for this reason they are located in the grinding circuit. They can receive slurry from the ball mill discharge or hydrocyclone underflow. The idea is to recover gold minerals soon in order to avoid overgrinding. The concentrate is collected at the bottom of the jig and the tails are moving out of the jig at the top of the bed. Although most gold is collected at the bottom, coarse gold particles like nuggets can stay at the top due to the screening opening size is smaller than the nugget.

Diagram of a jig

The conventional jig is a high capacity concentrator that can separate material from one inch down to about 150 µm, although significant recovery of gold finer than 80 µm has been reported. Jigs can process 7-25 t/h depending on their size with recoveries around 70%. A common configuration is a double line of four cells in series, and each two cells driven by an eccentric box provided with a geared motor. The design of conventional jigs differs mainly in the placement of the plunger and the jig bed and in where the makeup water enters the jig. In this way, a design can include a plunger with a short compression stroke and a long, slow suction stroke. This configuration modifies the jigging process.

Jigs can receive coarse particles such as a ball mill discharge. The jig concentrate is sent to the concentrate thickener or leaching depending on the gold ore type. Jig tails are classified and reground. Next figure shows a comminution circuit including a jig.

| Parameter | Stream | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Pulp density | 2.57 | 1.93 | 1.90 | 1.58 | 1.28 | 1.92 | 1.08 | 1.10 |

| S.G. | 2.70 | 2.71 | 2.72 | 2.70 | 2.70 | 2.72 | 3.75 | 2.70 |

| Solids, % | 97.0 | 76.3 | 74.9 | 58.6 | 34.7 | 75.7 | 10.1 | 14.4 |

| Solids, tph | 20.8 | 60.0 | 26.1 | 86.3 | 21.1 | 65.2 | 0.30 | 0.59 |

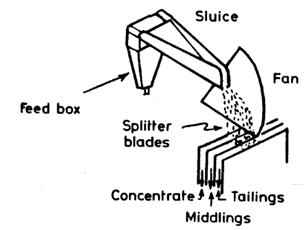

- Modified Sluice

Pinched sluice is a modified sluice that has been used for many years ago. In its elementary form, the equipment is inclined trough 2 feet long, narrowing from about nine inches in width at the feed end to one inch at discharge. Basically, feed consists of slurry at 55-60% solids that enters gently and stratifies as the particles flow through the sluice and crowd into the narrow discharge area. Heavy minerals migrate to the bottom and lighter minerals are forced to the top. Separation is influenced by the walls of the sluice due to drag force. In this way the resulting mineral bands are separated by splitters at the discharge.

This equipment work on the concept that as a fine material is exposed to an opening, the arc formed by the heaviest particles dropping will be much narrow than the arc formed by the lighter minerals. A divider placed perpendicular to and below the pinched outfall lets heavy materials to collect on one side and lighter particles can be collected separately. Pinched sluices are very simple inexpensive equipment and don’t need much space. Operative problems are related to the feed percent solids variations and gold content variability. Other issued to be considered is the circulating load that is problematic and special care must be taken in order to get a stable operation.

Pinched Sluice Diagram

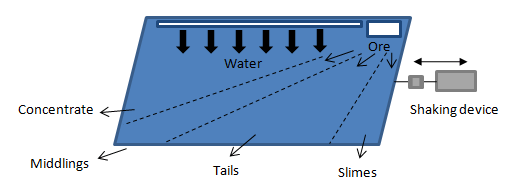

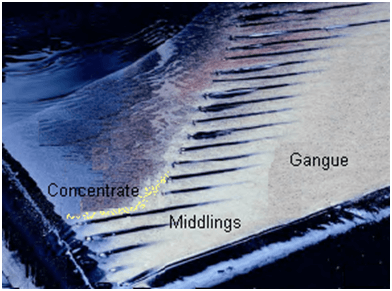

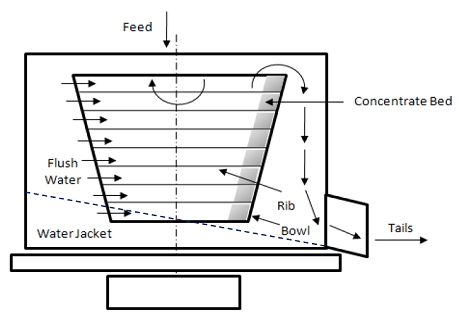

- Shaking Table

This is one of the best equipments employed to obtain clean gold concentrates. They consist of a ruffled deck on some type of support. A motor placed on one side drives a small arm that shakes the table along its length. The table has riffles that are not more than one inch high and cover almost half table. Varied riffle designs are available in the market and each manufacturer has a special according to its use. The table oscillates horizontally and concentrates the heavy particles due to inertia differences created by the brisk, reciprocating motion of the inclined deck of the table. Coarse particles feed need long strokes at lower speeds and fine particles need shorter strokes at faster speed.

Deck sizes range from 18 by 40 inches for laboratory tests to by 15 feet for industrial applications. Tables can treat 175 t/d. The equipment is fabricated with two basic deck types, rectangular and diagonal. The first one is roughly rectangle shaped with riffles parallel to the long dimension. The second group is irregular rectangles with riffles at an angle. In both types the shaking motion is parallel to the riffle pattern. The diagonal decks are usually constructed of wood and metal, and are lined with rubber or plastic. These materials have a high coefficient of friction that aids gold recovery.

Shaking table products

When the equipment is working abed of particles experiences a horizontal movement oriented to create segregation according to the specific gravity and size. Under this concept, particles with high specific gravity will sink and the lighter particles will rise to the top of the riffles. In order to get an appropriate shaking, the movement must be enough to expand the bed. This movement must let a particle to particle contact. If small particles of light minerals and large particles of heavy minerals segregate to the same position, the separation will be difficult. A practical way to judge the process is to observe the stream color formed on the deck.

Shaking table concentrate with free gold particles

- Washing plants

This kind of plant is oriented to reject non-valuable material and reduce the problems produced by fine material, specifically when the clay content is high. In general, washing plants are able to perform classification, concentration and Recovery of gold minerals from Placer/Alluvial Fields and hard rock. They can be combined with other concentration plants.

Washing plants have an important advantage, they are easily moved and some of them were designed with water tanks for use in places where the water source can be a problem. Small designs can treat 150 to 180 cubic meters per hour at 20% solids.

A point very important is the screening due to is the first separation operation and the screen surface must be designed considering the apertures for the passage of fine material. The screening area must be enough to support the weight of material being screened, also have to be flexible to promote vibrating forces and light to avoid obstructions so that the throughput can not be affected. Typically, a grizzly is included at the beginning of the washing plant. The oversize material can be rejected is the gold is present in fine particles and can fed the crushing circuit when there are interesting amounts of free gold (nuggets). A gravimetric device such as a jig can be included in the design of the equipment. The flowsheet must consider several options so that the operations can be able to treat different gold ores.

Some design includes a scrubbing trommel. In this case during the treatment, the ore enters through the screen where it is washed. Minus one quarter material passes through the screen in to the sluice. The last one vibrates during the processing in order to promote the recovery of fine gold particles and preventing the formation of agglomerates. Heavy minerals are collected in the riffles and the gangue is discharged.

Washing Plant with trommel and sluices

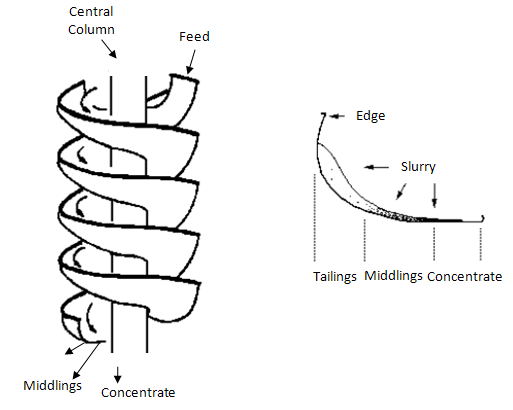

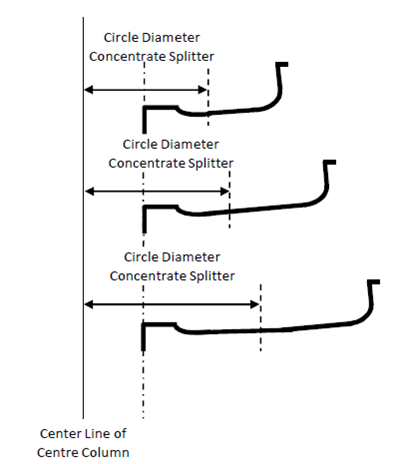

- Spiral Concentrators

These equipments have changed with the years. They were used in the first years of the last century with the name of Humpreys Spirals and were made of cast iron. Nowadays they are fabricated with plastic material and the water addition is not a very special requirement. In general spiral can be considered single or double helical wrapped around a central column with a series of concentrate take-off ports placed at specific intervals along the spiral. Also, there are splitters located at the bottom of the unit so that the concentrate quality can be regulated. In order to increase capacity, two or more units are assembled around one central column.

Schematic section of the spiral

There are several manufacturers of spirals and the equipment has been accepted in many operations in Australia and South Africa. An interesting change in the design has been the modified cross section and only one concentrate take off port that is located at the bottom of the spiral. The next figure shows several profiles of spiral concentrators. The main difference of these spirals is the possibility of obtaining better concentrates grades due to the separation zone is different and the selectivity between light and heavy particles can be improved.

Different spiral concentrator profiles

Spiral usually operates at 40-50% solids and the design can consider employing a hydrocyclone as the first separation stage. In this way the underflow can be directed to the spiral. Once the slurry is in the spiral, light and heavy mineral are classified according to their densities. In general, heavy particles have a high rate settling and form a slow moving fluid film. The flow stream in divided vertically in two parts, one with heavy particles and the other with light particles and most of water. With the splitters is possible to selected the quality of these products and can be included a stream composed by heavy a light particles called middlings. The slow moving fluid film reduces its velocity due to friction forces. In general, separation is performed by the differences in centrifugal forces. Spirals can be employed as rougher and cleaner equipment. One of the key operative factors is the wash water addition and the difference between the different minerals.

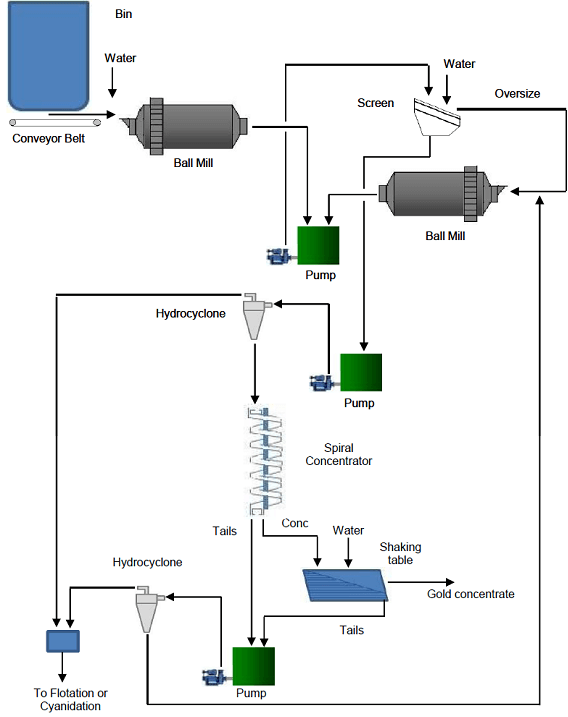

Gravimetric circuit with Spiral and Shaking Table

- Cone Concentrator

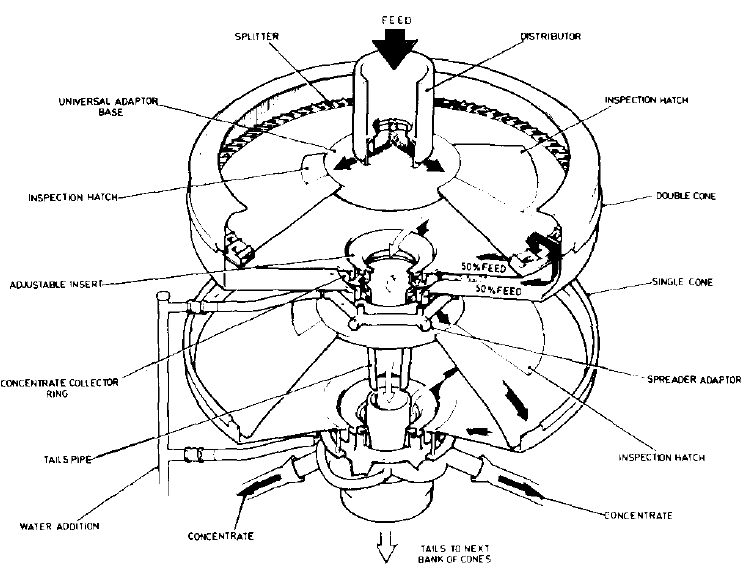

This equipment is a flowing film type of concentrator consisting of a series of inverted conical concentration decks surmounted by conical distribution decks arranged in a vertical array and employing various combinations of double and single deck elements. A double cone, single cone concentrator is shown in next figure. The arrangements form the basis of virtually all the configurations for cone concentrators. In general, the configuration consists of two stages surmounting other stage.

Double cone-Single cone configuration

All cones are fitted with adjustable inserts in which by means of a handle, the inner section of the insert can be moved vertically in relation to the outer section. This arrangement enables the concentrate take to be varied while the cone is on stream. This provision can be automated if necessary so that the circuit can have flexibility which is needed to cater for variations in grade and throughput. All cones have facilities for the addition of dilution water to control independently the percent solids of the feed on individual single cones.

Cones are made of fiberglass and covered with rubber and mounted in circular self supporting frames over 19-21 feet. The slurry can feed the equipment at 50-60% solids. In general the unit is very efficient at recovering fine particles sizes such as 53 µm. During the operation the slurry is distributed around the periphery of the cone. The size of the particles can be controlled by coarse screening to remove tramp material and particles coarser than 2.5 mm. If the material has a high content of clays or fine material, a preliminary separation with hydrocyclones can be performed in order to avoid problems during the operation. The following feed material acts as a dense medium that hinders the settling of lighter particles. Heavy particles settle to the bottom of the flow. Separation efficiency is not very high and the concentration process must be repeated several times in the same unit.

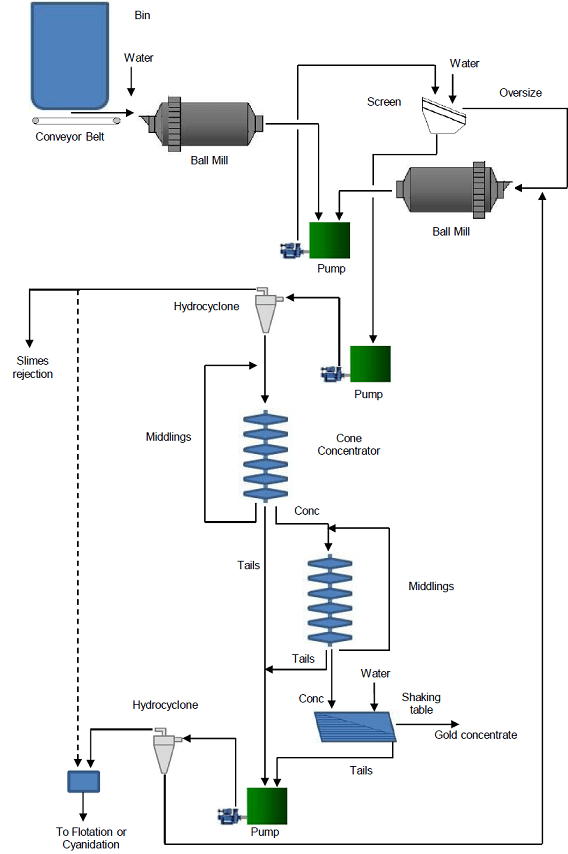

Gravimetric circuit with Spiral and Shaking Table

The design of any gravimetric circuit with cones must consider the following aspects:

Thin steel flakes from broken grinding media, wires and other sources of steel are used to found their way through the slotted scalping screen ahead of the cone and form part of the cone feed. They could become cemented onto the surface of the cone by pyrite that had oxidized and probably any soft mineral like carbonates. These surface obstructions are used to act as traps for the liberated gold. For example five or more kilos could be trapped and lost.

The inspection hatches must be designed in the right size, otherwise they could be very small for the deck surfaces to be inspected or cleaned in the right way. Larger hatches could be cut and the feed distribution could be distorted leading to uneven feeding of the concentrating cones.

It is important to include water addition points in order to get the right pulp density; otherwise the density will not be adjusted at the optimum point. During the operation is very important to take density readings near of the feed pumps. The operator must be able to take samples and add the appropriate flow of water because is very easy to modify the stability of the circuit.

The election of single or double cones must be studied carefully due to the slots feeding the cones could be blocked with pieces of rubber, coarse particles, wood or steel, which prevent the operation of one section of the double cone. Under this consideration, the design should consider one or more singles cones with the appropriate pulp distributor.

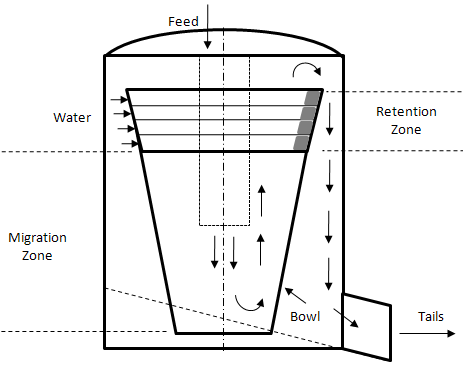

- Knelson Concentrator

This centrifugal concentrator can recover fine particles of free gold. The pulp is screened in order to avoid coarse particles such as 4 mm or more. The material in slurry form is fed centrally to the bottom of a ribbed inner cone rotating at a high speed. Centrifugal force causes the first feed to fill the bottom rib with solids and the next higher slightly larger diameter rib with solids and the next higher slightly larger diameter rib and subsequent ones are sequentially filled in few seconds. After that all the feed moves upward as thin film over the conical surface of the sand filled ribs and out. Compaction of solids trapped in the ribs of the cone is prevented by adding water through a series of holes in the cone wall. In this way, the trapped solids are fluidized.

The Knelson concentrator employs the principles of hindered settling and centrifugal force. A central perforated cone containing horizontal ribs is rotated in order to get a centrifugal force of 60g (g is gravity acceleration). The cone is surrounded by a pressurized water jacket that forces water through holes to keep the bed of heavy particles fluidized. In this way, the force of the water acts against the centrifugal force of the rotating cone.

Cut away schematic of a Knelson Centrifugal Concentrator

If there are free gold particles or particles transporting gold in the film of slurry that is passing over the fluidized solids trapped in the ribs of the cone, they will penetrate the fluidized bed under enhanced gravity situation and displace lighter particles of similar volume trapped in the rib. This process is repeated several times until saturate the ribs with heavy particles. In other words, this is a trading process that exchange light particles for heavy particles.

The pressure and flow of fluidization water controls the concentrate bed and porosity and hence the capacity to select what minerals will or will not into the concentrate. Many operator think that lower pressures are employed for lo specific gravity gangue material and vice versa. Also higher pressure will be used for coarse particles due to more water will be needed to clean the concentrate bed.

The flowsheet can include a Knelson concentrator in the primary grinding circuit in order to recover the gold present in the underflow due to this stream contains heavy particles and the problem of fine particles of gangue is minimized. The Knelson can be used to as rougher and cleaner units and the last cleaning stage is performed in shaking tables, typically a Gemini table has proved to be very efficient.

By using a Knelson Concentrator can be recovered fine free gold/electrum particles from the grinding circuit. The ratio of concentration for gold in a hydrocyclone is a good way to estimate if gravity concentration is possible. Normally if the gold is concentrating to the underflow, then it must be as a free gold bearing alloy. When a pilot scale testing is possible, we can confirm many design parameters and flowsheet options. A big plant will determine the effect of a gravity circuit on the plant gold distribution. In this way, the gravity circuit must improve the plant payment for gold. The method of handling gravity concentrate is plant dependent. Plants with gold treatment or with significant gravity gold production may include a smelting stage in order to get a gold ingot.

- Falcon Concentrator

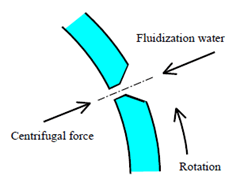

This equipment is a fluidized bed spinning bowl gravity concentrator. It is has been designed primarily for gold recovery from grinding circuit hydrocyclone underflows or alluvial operations. The concentrator is capable of fine and coarser feed applications. Enhanced gravity concentrators accelerate feed slurries in a rotating cone shaped bowl to take advantage of the difference in density of valuable minerals and gangue in order to perform a separation.

The material is stratified according to specific gravity and then passed over a concentrate bed fluidized from behind by pressure water. The fluidized bed is required to retain coarse particles. Free gold or gold bearing minerals are retaining in the concentrate bed in preference to light minerals. Initially the design considered non-continuous operation, but with the years the design was improved and this centrifugal concentrator can work in continuous or not. There are several types of equipments to each need. The equipment functions and rising cycle are automated with variable frequency drive device.

Generally, the higher the field or the stronger separation gravity forces between different particles of different density, the more fast and efficient is the separation. Within limits, an enhanced gravity concentrator can treat more material and recover finer particles if it is spun faster. Falcon concentrators are able of centrifugal fields of 300g. The equipment can change this value due to the unit is equipped with a variable speed motor. Concentrating surface area is the single most important determinant for enhanced gravity concentrator. Similarly to jigs or shaking tables, the larger the surface area, the higher the overall capacity since performance is a function of residence time. T

The bowl has a high depth to diameter ratio when compared to other designs which means that for a given bowl diameter, Falcon has a higher unit capacity. It is not necessary to spin the concentrating surface to apply the enhanced gravity fields, it is also necessary to accelerate the slurry. If the valuable particles must travel through a thicker flowing film, they will need more time to reach the zone where they will be concentrated in the fluidized bed. The smaller the flow of fluidizing water required, the less likely this water will transport fine particles away from the retention zone. If fluidization water is injected low in the rotor before the feed material is accelerated or stratified, it is actually counter productive to recovery because additional water is a barrier to gold particles travelling to the concentration zone and may actually wash fine gold particles out of the bowl.

Cut away schematic of a Falcon Centrifugal Concentrator

The holes through which the fluidization water is injected in the Falcon concentrator are perpendicular to the axis of rotation. This consideration significantly reduces the tendency for holes plugged with solids from the slurry being processed. The retention zone is deep enough to allow the fluidization water holes to be larger and more widely spaced.

Fluidization Water Injection

The gravimetric concentrate is usually cleaned in a special shaking table called Gemini, which has a different geometry in relation to the Wilfley or Deister table. The concentrate is collected in the middle of the table and tails are discharged on both sides of the table.

Gemini Shaking Table

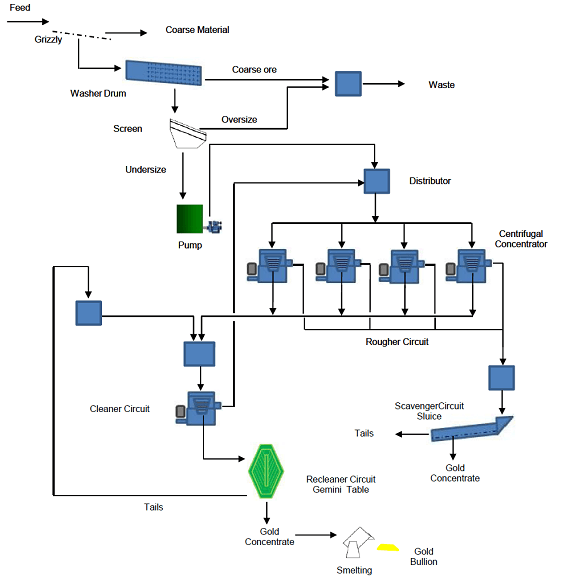

Flowsheet for alluvial ores

Grinding circuit with centrifugal concentrators

Amalgamation

Amalgamation is one of the oldest methods of extracting gold from its ores. The amalgamation of gold possibly dates from Roman times. The extraction of silver by amalgamation is generally attributed to the Spanish in Latin America in the late sixteenth century even though Biringuccio describes the fundamental principles of the “patio process” about a half a century earlier.

The amalgamation of gold ores as described by Agricola in De Re Metallica is essentially the same as modern practice. The only changes are in the equipment employed and the sources of power to grind, mix, and separate. Probably, the chemical and physical processes are more clearly understood.

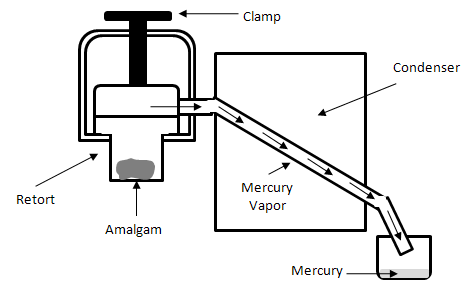

Mercury is a heavy metal with specific gravity of 13.5, is liquid and boils at 357 oC. Its vapor pressure is low and can be in vapor state easily. Amalgam is an alloy between gold and mercury. There are three types of amalgams to be formed, AuHg2, Au2hg and Au3Hg. The content of mercury in the amalgams depends on two factors, gold feed grade and squeezing efficiency. In this way, a regular amalgam contains 60-65% of gold, but an amalgam treated by filtration can contain 80-85% of gold.

Basically, the amalgamation process comprises the following stages, crushing and grinding the ore until get a K80 of approximately 35 mesh. Finer values work and the final particle size is dependent on the mineralogy. The next stage is to pass the ore in the form of a thin pulp over a mercury covered copper or silver coated plate. The third stage is to remove the gold-mercury amalgam at regular intervals and re-dressing the plates with new mercury. Finally, it will necessary to eliminate the mercury by distilling the gold amalgam (retorting), thereby producing nearly pure gold and recovering the mercury for reuse on the plates. Many years ago, particle size reduction was done by gravity stamps and years later, was common to employ crushers such as jaw or cone crushers, and ball mills to reduce to whatever mesh is desired.

Ores can be treated successfully by amalgamation are called free milling ores. It is practically never possible to obtain high extraction of gold by amalgamation alone. This is due two reasons, fine gold that fails to settle upon and make contact with the plates, and a type of gold occurrence in which gold particles are brown lusterless. This may be due to coatings of oxide of iron, manganese or tellurium. Free milling ores seldom produce more than 70% recovery. This is the explanation of the existence of tailings piles about some countries assaying interesting gold contents. Many of them have been retreated by cyanidation and/or flotation.

Amalgamation is used to recover relatively coarse gold and for this reason has been very important in gold recovery systems. Cyanide acts too slowly on coarse gold, but readily dissolves fine gold. Flotation concentration is not effective on coarse gold. The small miners who wish to treat a small tonnage of high grade ore and want a quick return rather than for recoveries near to 100%, probably still find the amalgamation process the best available recovery method. The final product grade depends on the gold ore treated. This means that high head grades will allow getting a final product with high gold content. As example, in places where there are important contents of silver, the final product can content 75 to 85% of gold.

Amalgamation is a very efficient process for recovering coarse free gold, but there is problem related to the hazards of working with mercury. Like most things in our environment it is safe enough if it is treated with due respect and reasonable precautions are observed. However, the effects of mercuric poisoning are cumulative and it can do considerable damage. Mercury can be absorbed through the skin or inhaled in vapor form. Waterproof work Gloves should be worn whenever it is handled. Be sure that you are in a well ventilated area if there is any possibility of vapors forming. Avoid breathing any of the vapor at all costs.

Schematic view of a retort

South America is place where the amalgamation process has been practiced for a long time. Basically the Jungle has been traditionally the favorite. Small miners employ this process due to alluvial deposits contain free gold, the process is fast and efficient, the final product has a high gold grade and recoveries are between 80 to 95%, commercialization is fast and simple without brokers, the process is simple and is not necessary a big investment or very special technical knowledge, the mercury can be reused and its losses are minimized, the final product weight is small and can be transported easily from the process plant to the commercialization place, the incomes can be distributed easily without much trouble, and the key reagent is mercury and can be obtained in many places without special authorizations.

There are some disadvantages with this process. Mercury and the final product are toxic and contaminant, the process produces environment problems due to earth and water receive the tailings, when is performed the gold-mercury separation by retorting the air and the operator receives gases containing mercury. With the time the retorting process evolved, but they are not totally efficient and the contamination problem is only solved partially. Other disadvantage is the lack of mechanical equipment and consequently the operator has to employ his hands. In the jungle is common to find other values valuable minerals (e.g. rutile, zirconium) that are not recovered by amalgamation.

If the amalgamation feed can be a gravimetric concentrate, the process will be more efficient and the material to be handled will be reduced and consequently gold losses. In order words the process must work as a secondary process. The main parameters that affect the amalgamation process are lack of liberation, gold surface contamination, and mercury degraded.

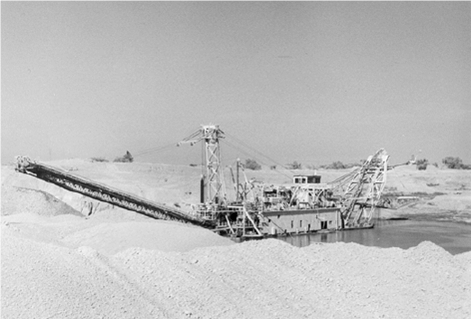

Dredging:

Dredging is an underwater excavation performed to recover gold from placer deposits. Initially, the excavation need to make a channel, the continuous dredging will let you know the potentiality of the deposit. Obviously, dredging is not exclusive for mining purposes; this operation can be employed to clean lakes and different aquatic environments that must stay safety for navigation purposes.

Essentially, a dredge is a machine that removes material from aquatic environments. In this way, the process involves a digging operation of underwater placer deposits by using two types of equipments, cutter head and cutting bucket line. During the operation, digs, scrapes removes material and send it onto the platform that is located in the dredge. Normally, the ore is treated on the dredge by washing, screening and concentration operations. The non-valuable material is returned to the water. The final place is selected considering environmental aspects.

People have been dredging placer deposits for a long time. At the beginning of the last century, dredges were effective to extract gold. Keeping the dredge in the right place, the extraction was very encouraging and the process has become a mixture of technology and operator skills.

Dredging Operation

Sometimes, people ask about the reason of dredging operation. The reason is based on the concept that as river moves with turbulence and variable velocity, heavy materials such as free gold, will settle at the bottom. It is important to mention that streams have periods of high turbulence during some periods and the formation of gravel bars is common. This material is light and contains silt and clay particles do not settle out until the stream lost its velocity. The material deposited at the bottom is sediment and contains gold particles. Then, the idea is to mine this material.

The dredging equipment can be categorized in three groups based on the digging or raising system. The first group is formed by cutterheads and suction pumps; the second one comprises bucket wheel elevators, and the last one by mechanical shovels. Cutterhead pipeline dredges work best in large areas with deep shoals, where the cutterhead is buried in the bottom. Water pumped with the dredged material must be contained in the disposal site until the solids settle out. It is then discharged, usually back into the waterway. This method of dredging is not suitable in areas where sediments are contaminated with chemicals that would dissolve in the dredging water and be spread in the environment during discharge. The second type employ buckets to removes the material and its work is very competitive with the first group. The last type employs a clamshell to extract the material. Although, this dredge is not very used in gold operations, it is important to mention that this dredge lowers the opened bucket from the end of a crane into the sediment. After penetrating the material, the bucket jaws are closed and the material is picked up until the surface and is usually dumped into a barge or the place to be processed the material.

Cutterheads and suction pumps are employed to remove material by using a pumping system. Once the suction device is at the bottom, water is added to fluidize the sand so that it can be pumped to the surface for further treatment. This dredge is simple, but there is a disadvantage, heavy material can be lost during the fluidization and also sometimes, heavy material is difficult to be removed due to its geological formation. Perhaps, one way of reducing this problem is to employ special cutterheads whose duty is to facilitate the movement of material out of the bottom. The cutterheads design has been improved with the years. One design considers cutters with curved blades and the driving mechanism is assembled on a ladder with the suction pipe. The ladder is lowered to the alluvial zone and the digging, fluidization, and pumping actions are performed. Normally, the concentration plant is placed out of the dredge.

Bucket wheel elevators consist of a series of steel buckets supported by a dredging ladder. The dredging ladder transports buckets with material whose treatment is performed by gravimetric devices. Once processed the material, the non-valuable material is discharged. This type of dredges needs a special study due to the investment cost is high. The study must include enough reserves; otherwise the project will produce losses.

The selection of a dredging equipment is influenced by the type of material to be dredged, the amount of clays and inorganic material, the rock type, the material formed by glaciations, size deposit, plant treatment location, throughput required to achieve expected incomes, and the type of environment.

Flotation

Flotation is one of the most important gold recovery processes and its main restriction is to recover coarse gold particles ranging from 400 to 250 µm. This process recovers fine particles of free gold, gold associated in any form with sulphides, and native gold present in polymetallic deposits with certain degree of oxidation. For many years, a combination of amalgamation, cyanidation and flotation made possible to get high gold recoveries. With the time the technology and design consideration changed and flotation and/or cyanidation processes are the favorite combination. When gold is recovered by flotation, a high grade concentrate contains gold and can give an extra value to copper and lead concentrates. The concentrate can be ground, roasted, treated by cyanidation and the final product is gold bullion.

Considering the fact that native gold and electrum have variable composition and different parts of the same particle could present different composition, the recoveries of these particles by flotation is possible due to they are naturally floatable. Also, there is a theory about the effect of silver content on gold flotation rate. By this theory, if there are two silver-gold particles, the particle with higher silver content has a high flotation rate. This effect is probably influenced by the galvanic interactions between silver, gold and grinding media.

Native gold is floatable by chemical or physical actions on its surface. In this way, free gold particles affected by word-hard can have better floatability than a clean surface. Alluvial gold particles are normally flakey and have received deformation and flattening during their formation from the host rock and transport to the final location. This action created work hardening. During comminution, gold surface is contaminated by minerals and steel from grinding media. This process promotes flotation.

Flotation Circuit with Mechanical Cells

An aspect very important is gold particle shape. This factor affects gold recovery due to flattened gold particles have a better surface area and can react more efficiently with the collector and the settling action is very slow compared with small nuggets or rounded particles. Then the grinding operation has two important actions, to liberate gold particles and create an appropriate surface for collector.

Chemical composition of gold particles and associations with other minerals affect gold recovery by flotation. In general, gold-pyrite or gold-copper minerals associations have no problems and gold can be recovered without major problem. The lack of good liberation is a problem and the comminution circuit is the key element. The treatment of auriferous pyrite or silver sulphosalts with gold, have an excellent recovery by flotation.

Sometimes the gold is very difficult to recover because the gold is associated with sulphide mineral in a way that can be considered difficult to the usual recovery techniques. The factors that can affect free gold floatability are particle size, flakiness, composition, surface contaminants, collector type and loading, and cell type. Gold hydrophobicity is enhanced by the addition of flotation collectors such as xanthates. The mechanism invoked in enhancing hydrophobicity of gold with the collectors is similar to that of pyrite, whereby collector anions are oxidized at the gold surface to form dimers. The conducting surface of gold facilities the transfer of electrons. This catalytic action is influenced by the galvanic reactions that occur during grinding. Thus, the problem in gold flotation is in direct relation with the oxygen present in the common and current air because favors oxidation of sulphides since the grinding step and follow during flotation. One way to improve gold recovery by flotation is to consider the use of nitrogen as flotation gas. There is a process developed by Newmont Technologies and it is called N2Tec®. The use of nitrogen inhibits the oxidation of auriferous sulfide mineral fines and measuring pulp potential would appear to be a useful method of monitoring the process.

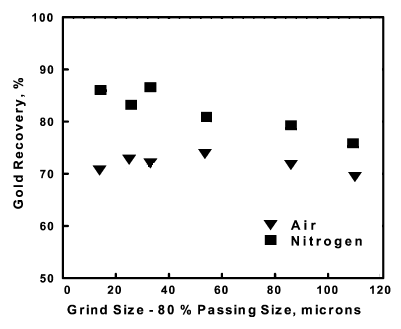

Effect of Nitrogen on gold recovery

A very important option to be considered in the design of any gold flotation circuit is to recover gold as soon as it can be done. One alternative is to include a flash flotation cell which is able to recover coarse gold. The functioning is similar to other flotation cells and the only difference is the capacity of receiving coarse particles from the ball mill discharge or cyclone underflow. The concentrate is mixed with the concentrate obtained from the cleaner flotation circuit. Without any doubt the most important flotation cell in the market is manufactured by Outotec and is called Skim Air.

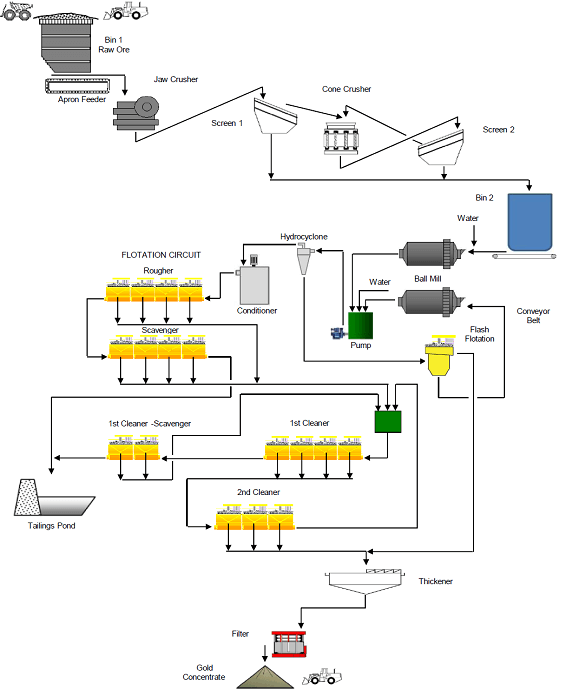

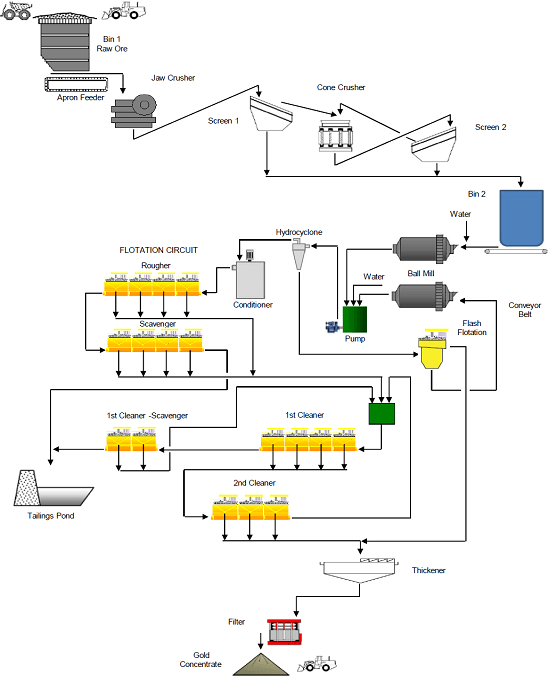

A typical flotation circuit with flash flotation is shown in next figure.

Flotation Circuit with two cleaning stages and flash flotation

A variable in the flotation circuit design is to include column cells in the cleaner circuit in order to improve the gold concentrate quality and to reject insoluble material. Column cells are particularly important when the ore present high content of silicates, carbonates and clays, which affect thickening, filtration and concentrate grade. The first one is affected due to the settling rate is retarded and the overflow is characterized by its high turbidity. The filtration rate and efficiency is affected because tiny particles blocked the pores of the filtration media, and consequently the moisture content is extremely affected. The right operation of cleaner circuit with columns improves the metallurgical efficiency of the operation. The variables of any column cell operation are froth level, air flow and wash water flow. They govern the successful performance of any column. See next figure.

Flotation Circuit with column cells

Leaching

Cyanidation

When we have to mention hydrometallurgical treatments, the cyanidation process must be mentioned initially due to has been employed in the gold mining industry for a long time. The cyanidation process was invented in 1887 when the gold recovery started to have some problems due to the lack of good technology. Basically the process is supported by two facts, gold is soluble in dilute solutions of cyanide, and second, the pregnant solution can be processed successfully by using zinc powder or activated carbon and electrowinning. In other words, the process involves several steps from crushing until obtaining a Dore bar.

The basic principle of the cyanidation process is that alkaline cyanide solutions have a preferential dissolving action on the precious metals contained in an ore. The reaction generally accepted is shown below:

4Au + 8NaCN + O2 + 2H2O = 4Na[fusion_builder_container hundred_percent=”yes” overflow=”visible”]

[Au(CN)2] + 4NaOH

The reaction of silver sulphides, commonly associated with gold ores, is not quite so straight-forward,

Ag2 + 4NaCN = 2NaAg(CN)2 + Na2S

The gold dissolution rate is dependent on the concentration of NaCN and the alkalinity of the solution, the optimum pH is around 10.5. For efficient leaching, the gold should occur as free, fine-size, clean particles in an ore. The presence the certain minerals such oxidized copper minerals is a poison for the process due to copper will be dissolved in first instance and the free cyanide will not be used for gold dissolution. Also, it is important to mention that an adequate supply of dissolved oxygen must be present in the cyanide process.

Cyanidation by agitation

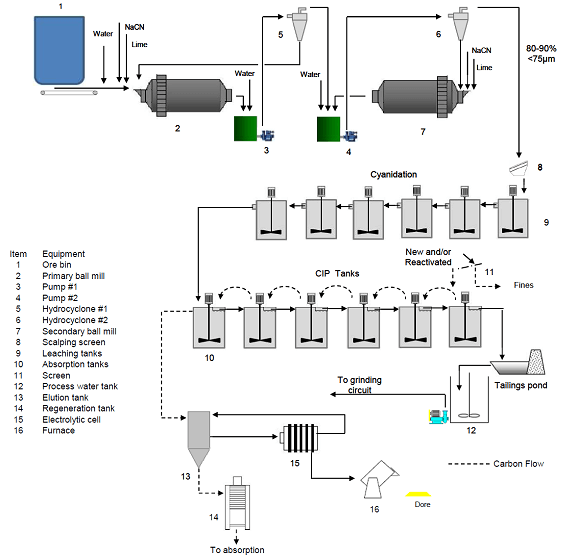

Cyanidation by agitation and heap leaching are the most employed processes for treating gold ores. The first one comprises several steps: crushing and grinding operations oriented to liberate gold particles so that they can be leached. The comminution product must be 80-90% passing 75 µm. Normally, the processes is employed when the gold content is ranging from 5 to 15 g/t. The grinding circuit is the first cyanidation circuit and the ball mill works as leaching drums. Once liberation is complete, the next step is to agitate the slurry to perform a complete dissolution of gold. The solution and the non-valuable ore must be separated directly is the gold content is high, otherwise must be enriched by using activated carbon. The pregnant solution from the activated carbon is eluted and feeds the electrolytic cell where gold will be recovered in form of cathodes. If the solution is rich enough can be treated by zinc powder and the precipitated obtained (cement) obtained will be sent to retorting and smelting. For gold extraction the strength of cyanide solution ranges from 0.01 to 0.05%. Lime is added to the process in order to have a pH near to 10-11.

The different minerals foreign substances can affect the cyanidation process in a number of different ways. Silver is usually present with gold either in small or high amounts. The silver content in gold ores may range from 1 g/t to 300g/t. Oxidized copper minerals may be dissolved by the cyanide leach solution and thus consume large quantities of NaCN and oxygen. Arsenic minerals may also interfere with cyanidation. Realgar and orpiment react rapidly with the cyanide solution and inhibit the dissolution of gold. Arsenopyrite, generally oxidizes very slowly in an aerated cyanide solution and has very little adverse effect on the leaching of gold. Stibnite affects negatively the cyanidation process. The presence of base metal ions such as Fe2+, Ni2+, Cu2+, Zn2+, and Mn2+ makes slow the cyanidation of gold. Other negative compounds are carbonaceous materials because they act as adsorbents for the gold dissolved by cyanide solutions. Organic substances such as wood, oil, and grease, slow down cyanidation of gold by consuming the dissolved oxygen in the pregnant solution.

Pachuca Tank

CIP tanks are connected by launders with screens

CIP circuit

Heap leaching can be considered as a percolation process on ore piles. The process is characterized for its economic cost against the agitated leaching process when the ore deposit has a low gold content. Typically the process can process ores whose gold content is 0.8-1.1 g/t. The leaching solution is spread at the top of the pile and the pregnant solution will have to percolate through the pile. The design considers special drainage pads for pregnant liquid collection. The design is influenced by the manner of occurrence of the gold or gold host minerals, geological characteristics of the ore, and the volume of the deposit. Operations are conducted on ore stacked on impermeable pads. Special pad and piping systems are required to collect and transport de pregnant solution so that the losses of gold to the ground can be eliminated. Commonly, the materials used for constructing the pads are rock mixed with bentonite, asphalt mixed with gravel, reinforced concrete pads, and rubber covers on an excavated area.

There are two popular heap leaching designs, one is called short-term leaching of crushed ore, and the other is a long term leaching of run of mine ore. The first one comprises one or two crushing stages previous to form the ore pile. Cyanide solution percolates through the heap leaching the gold and silver and is collected on the pregnant solution pad. The ore is crushed to a size that will give good liberation of gold minerals. In most operations with this crushing stage, the ore is crushed until two-three inch. A finer size can be considered if the ore needs fine liberation. The leach cycle is normally from 20 to 30 days. When the leaching cycle is complete, a new crushed ore is piled.

The second option is the most economical option and the ore is taken directly from the blasting. A typical ore size is six inch. A heap constructed under this design can treat high tons of material. Most heaps look like truncated pyramid 25 to 40 feet high. The height is in based on ore permeability, residual alkalinity, cyanide strength and dissolved oxygen.

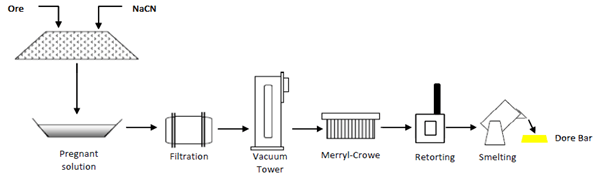

Pad Construction

The leaching solution is introduced onto the heaps by spraying from perforated plastic tubes, and by sprinkling using plastic sprinkler heads. The pregnant solution can be treated by activated carbon or zinc powder (Merryl Crowe process). The second is applied in many operations, but the final decision is based on the silver/gold ratio and economical considerations. Activated carbon does not recover much of the silver, but the gold recovery is high. In other words, the efficiency of the recovery process is influenced by the silver content.

Heap leaching process

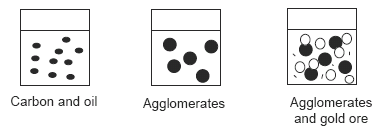

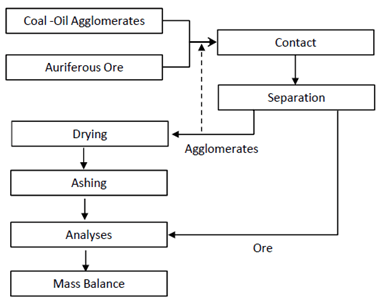

Agglomeration: