Hazardous Chemical |

There are 3 hazardous chemical

1.Acid danger

2.Poison gas danger

3.Heating danger

THIS IS FOR AN UNVERIFIED APPROXIMATE DEPICTION OF A RECYCLING PROCESS.

I HAVE NOT TESTED THIS MYSELF.

DO NOT PERFORM AT HOME.

| Chemical is very dangerous. You should protect in every step. You have to wear gloves, mask or protective clothing when you work. When extracting gold finish, you must clean thoroughly with water immediately and learn all kinds of chemicals that you used and how thoroughly protected. |

| Gold refining it’s an easy method that you can do it alone. Silt gold refining is suitable for gold alloy, scrap gold, Lode gold, gold jewelry and so on. |

The sample gold material

|

|

Gold alloy, scrap gold, old gold, Lode gold, gold jewelry. Qualified low percentage of gold used need more purity 75%

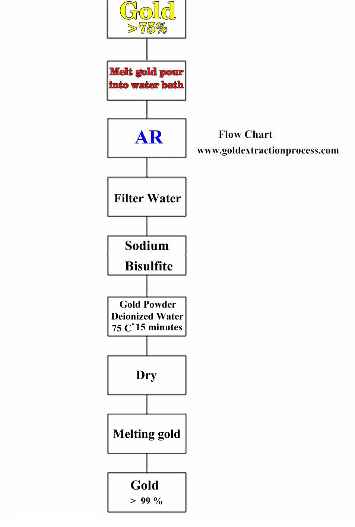

Gold refining

Refining the extraction of gold for more than 99% purity. Gold alloy, scrap gold, old gold, Lode gold, gold jewelry. Qualified low percentage of gold used need more purity 75%

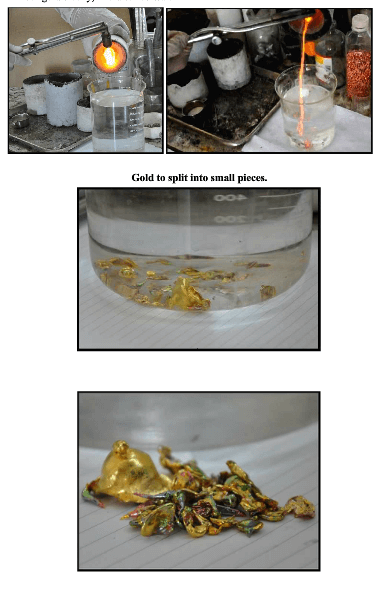

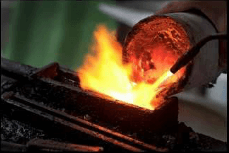

Melting scrap gold to melt

Pour gold slowly, into distilled water

AR Dissolving the gold with acid. Increase the Percentage of gold >99 %

Ratio chemical 1 : 3.5 ( Acid AR 100 ml Dissolving the gold 20 g)

- Nitric acid HNO3 68% 20ml

- Hydrochloric acid HCL 35% 70ml

Gold extraction in this process, gold used to make AR need purity 75% because if less than 75% purity, the precipitation of sodium sulpite is not incomplete. Gold is gone and the water is not pure. AR is increasing the percentage of gold or made of pure gold> 99%

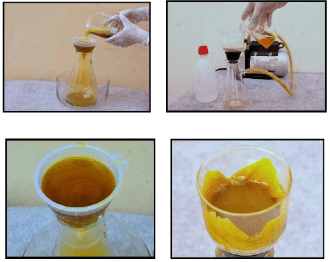

Fill nitric acid into hydrochloric acid

Wait for about 3 minutes, chemical mixed together. This step, you must be careful because the acid is capable of high crosion

Fill AR acid into Gold. (Gold 18g = acid AR 90 ml)

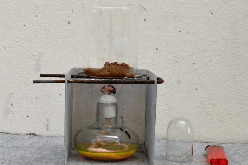

Boil with 70-90 Degree Celsius gold until melted

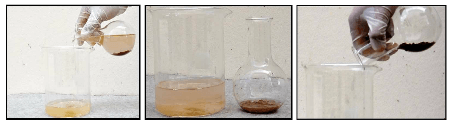

Filter gold water as clean as possible. Gold is a high percentage if it is much clean

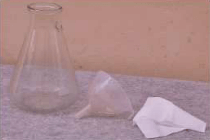

Gold water filtrations are 2 types.

Water gold flows down. It is natural force of gravity. It is easy. It is fine for simple devices but it takes a very long time

Equipment

- Cotton wool or filter paper

- Filtering flask

- Funnel

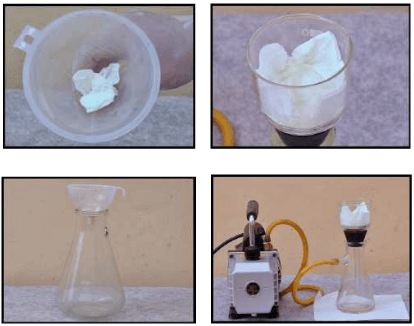

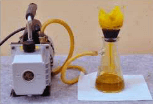

Use vacuum air is faster. Disadvantages are expensive and rare. If you do not plug well, polluted sediment will flow out

Equipment

– Tissue or filter paper – Filtering flask

– Air sucker vaccum pump – Rubber tube

– Washer cone filter – Filter funnel

Compare

Air sucker vacuum pumps will filter more sensitive than conventional filter. It depends on the convenience and budget

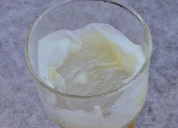

Wash gold water that attached to the filter paper by using a spray bottle. If gold color changes to white, show that out. (Do not fill much water 3 times of gold water)

Following image; filter paper that no gold water was cleaned by distilled water completely. Gold water was filter

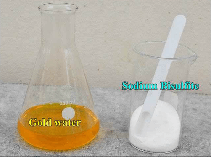

Gold Precipitated with sodium sulfite

One of technique for higher gold percentage is the cleanness. The vessel must be glass. Water must be distilled water. Gold will be higher than 99%.

Ratio chemical

- Sodium bisulfite HaNSO3

- Chemical spoon

- Strong percolated gold water

Fill Sodium Bisulfite slowly in gold water. By gradually add in small increments. Do not pour one out because it can be severe reactions. There will be lot of bubbles overflowing.

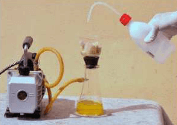

When you fill Sodium Bisulfite in gold water, it will change from gold water into brown gold dregs

Warning: Adding much Sodium Bisulfite in gold water, it makes Sodium Bisulfite cannot completely dissolved. It precipitated mixed with gold.

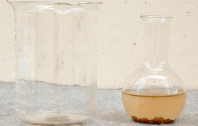

Following images; gold dregs are brown lump and they became clearer

Observing that, gold precipitated out or not? Look at the bubbles. If we fill Sodium Bisulfite and it has no air bubbles, put Sodium Bisulfite until no air bubbles.

When gold water stopped on the chemical reaction. Leave at least 15 minutes to precipitated the gold

Slowly pour the water out. Be careful gold dregs flow with water

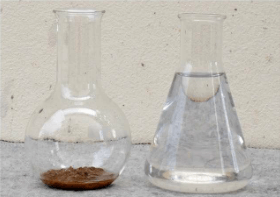

We will gold dregs that mixed with Sodium Bisulfite. If the precipitated step, we put too much Sodium Bisulfite, it will see a small white cube beads are mixed. You have to boil distilled water 10-30 minute of the amount of gold powder residue

Fill distilled water beaker that has gold dregs

Boil distilled water with 60-75 Degree Celsius about 15-30 minutes. Do not exceed 80 degree Celsius

Observe from water, It will become white. Wait for 15 minutes for gold dregs

Slowly pour some water. Be careful precipitated gold will flow with water. And observe that, there is Sodium sulfite; you have to pour the water out. Fill distilled water and boil again. Go to the next page.

Boil with alcohol stove or hot plate to dry. Be careful gold dregs splash if you use high temperatures. <90 Celsius

Water will dry slowly

This is dry gold dregs

Slowly pour the gold powder into a crucible

The crucible should be a cone to protect some gold lump spill while melt a lump

Give some heat to gold powder but use low heater

Fill little Borax for beautiful and shine. Then scoop gold out

Scoop gold out from crucible when it coagulated. Suddenly fill in distilled water. Because of if gold lost heat, gold will adhere with the crucible

If you use electric crucible or ceramic crucible, when gold was melt pour into the block

You can use printing block

A high percentage of gold is round and glossy. This pure of gold is 99.8%. If you want gold cleaner, you can boil with nitric acid about 10-20 minutes

Water used in step 15 and water used in step 12, leave it 50 hours. Gold remaining sediment will settle down. Pour the water out. Make it dry out gold and bring it into cubes melt

Distilled water is used for gold extraction or the cleanest water that you can find.

The best acid-resistant equipment for gold extraction is glass.

THIS IS FOR AN UNVERIFIED APPROXIMATE DEPICTION OF A RECYCLING PROCESS.

I HAVE NOT TESTED THIS MYSELF.

DO NOT PERFORM AT HOME.