Table of Contents

Centrifugal separation of gold experienced a regain in activity with the advent of the Knudsen Bowl. This device appears extremely efficient in recovering fine gold, although very little published data are available.

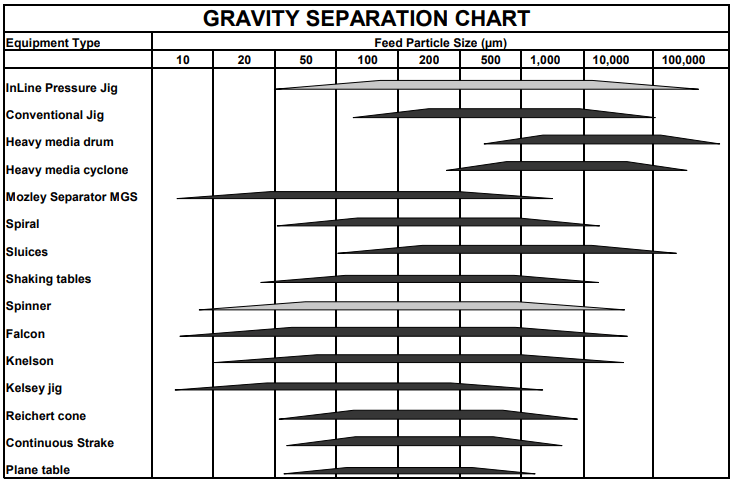

Installing a gravity plant increased overall gold recovery by about 3-4% in some plants. Gravity concentration was achieved with pinched sluices and 76cm Knelson bowls, with a significant increase in fine gold recovery.

Again, the first material fills the rings completely. At this point, any similarity in the two centrifugal type concentrators begins to separate as the unit greatly enhances and improves the centrifugal factors.

- A 30-inch Knelson Concentrator spins at approximately 400 RPM

- creates 60 forces of gravity,

- does not allow compaction,

- will process up to 40 tph of minus ¼ inch material,

- in typical alluvial operations will operate up to 24 hours without clean up with no increased loss of gold.

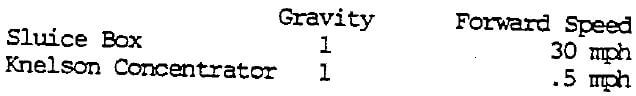

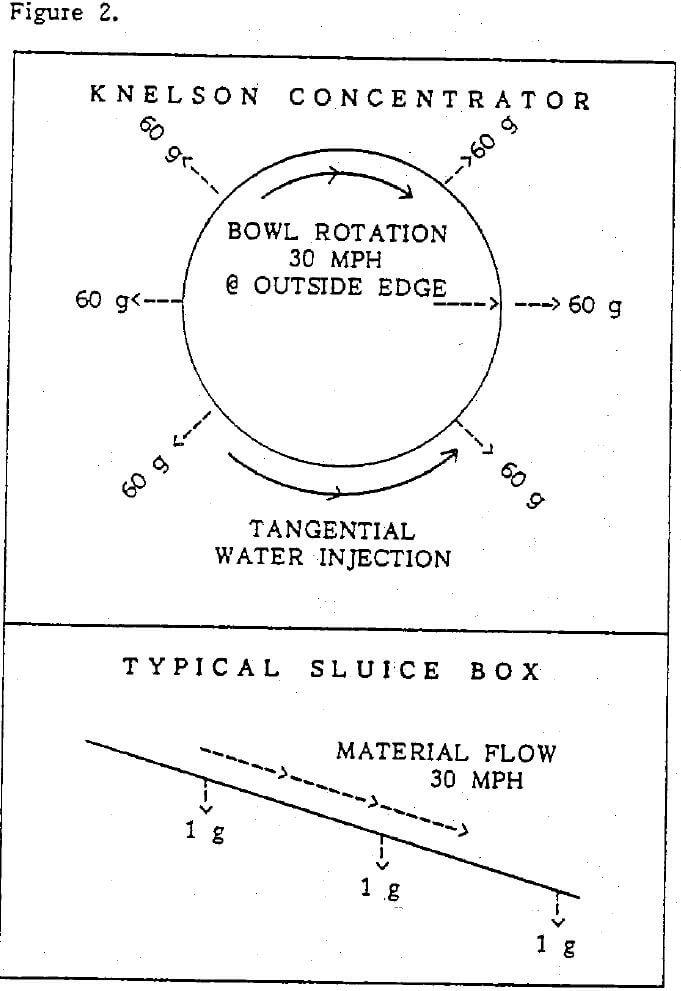

In order to understand what happens with a particle, we must return to the sluice box for a moment. We realize that as the material heads down a sluice box it picks up speed. In fact, in a rough box, it will get up to nearly 30 mph. The closer it gets to full speed the further it is away from the speed of the container which is zero.

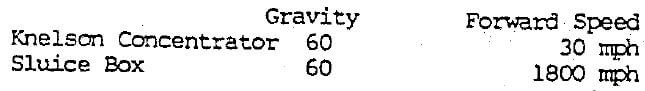

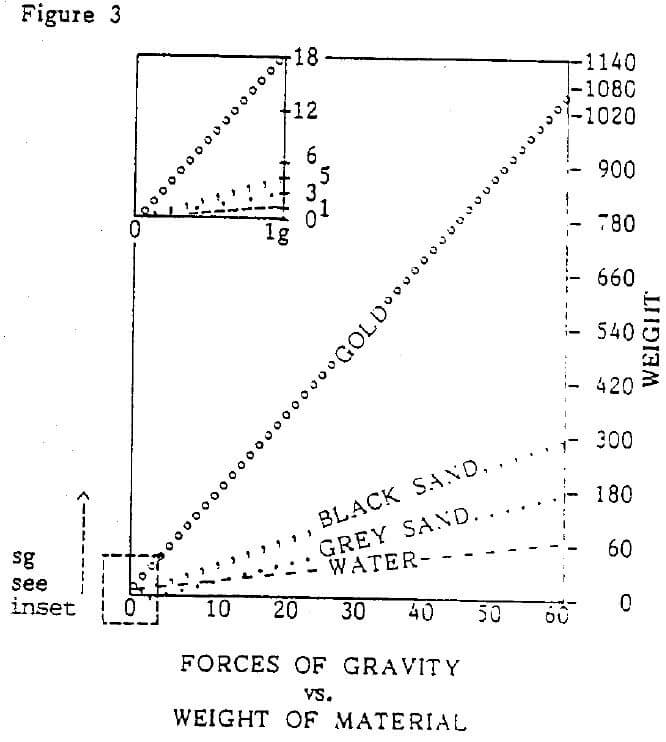

When a particle in a Knelson Concentrator hits the bottom of the cone, it starts to gain momentum and converse to a sluice box, as it gains in speed it gets closer to the rim speed of the cone which happens to be approximately 30 mph. thus if we take the top speed of both as a factor, in the sluice box we have a 30 mph of forward speed with 1 force of gravity. In the Knelson Concentrator, we have a forward speed of 30 mph. with 60 forces of gravity.

If both units are reduced to 1 g, then the comparison would look like this:

Conversely, if you raised the sluice box to match the Knelson, the comparison would be as follows:

The foregoing shows an immense settling force in relation to the forward speed in the Knelson Concentrator.

As in all gravity devices, the larger gold particles will go to concentration in the bottom rings or first area available: as the gold particles decrease in size, they will become harder to concentrate and so will be contained further up the rings.

No compaction will take place because of water being injected from behind the material trapped in the rings. This results in even the finest particles being able to inject in and displace a less dense particle of the same general dimensions or volume. Even extremely fine and flat particles with very large aspect ratios will inject in and be concentrated. At some point, the following situation will take place. The thin edge of the particle will be presented to the moving water thus offering little resistance to the water and a 90° thin edge of this same particle will be facing outward toward the area of concentration. When this happens at 60 forces of gravity, that particle will go into concentration like a bullet.

Clay balls can be of several types but for our purpose here we can cover it by discussing the most common two.

First: clay particles that have not been reduced to their smallest particle size by whatever wash and scrub system is used. Most gravity systems will not break this up in the concentrating mechanism and any gold trapped inside will continue on to tails.

Second: (the most annoying) is the plasticene type clay that does, in fact, form into a true ball and in a sluice box actually gather material including gold as it rolls down the box. They are commonly called box robbers. Neither of these types of balls survives in a Knelson Concentrator for the following reasons:

- Material entering the Knelson Concentrator is traveling vertically but on the horizontal, it is dead still. It must both change directions and by friction be forced to attempt to attain the 30 mph speed of the container. At the edge it changes directions again going up the inclined wall of the concentrator and as it passes each ring it has a new speed to attain. All of this creates the most abrasive material-on-material rub of any concentrating device in existence; and, like a centrifugal pump, only more so, it will destroy both types of clay balls.

- The second reason concerns only the plasticene type of clay. At 60 g forces, this type of clay cannot maintain its round shape on impact with any solid particles. The result is that these balls impact the wall where they are flattened by the immense g force and are then abraded away by subsequent material flow. Clay does not affect concentration here as the injected backpressure water constantly dilutes the gangue at each ring, so the liquids to solids ratio is being increased as the gangue moves through the concentrator and no blinding takes place.

An interesting point is that I am frequently asked how a 10 µm particle of gold can possibly dislodge a 6 mm particle of rock when the 6 mm particle obviously has much more total weight than the 10 µm particle of gold. The answer is: it doesn’t. What happens is that any particle of gold only needs to dislodge a particle of like size but lesser density and since gold has a sg of 19.3 and most rock is around 3, it happens fairly easily. Something you should understand is that water is not only injected from behind the material trapped in the rings but it is also injected tangentially in the opposite direction to rotation (see figure 2.). This assists in keeping the concentrate shifting within the container and as long as fluidization and shifting of material take place, so will the concentration of dense particles (gold, platinum, etc.).

Water injected tangentially was a major breakthrough as it helps to keep the material moving within the unit. Most people have done the same panning and will agree that if you just gently roll a pan and tip it far enough to wash some of the material over the edge, you will in effect create the same performance as a stream on alluvial gravels. You will create a surface enrichment but you will not move the heavies to the bottom of the pan. If you are to move the heavies to the bottom of the pan, you are going to have to move that pan violently enough to make all of the material moves within or in relation to the pan. By doing so, you cause material shifting and as it shifts, the heavier particles will go to the bottom. This is the same effect we strive for in the concentrator. We don’t want the material to ever attain the same speed as the cone because if it does, it will be stagnant, so by injecting the water in the reverse direction to rotation, we help to keep the material in a constant fluid motion thereby allowing any particle that is heavier than what is in the rings to inject in and displace something that is lighter.

In creating tangential injection, we got a fringe benefit we never even thought about. Whom you shut the machine down to drop out the concentrate, you simply turn on the backpressure water and it immediately blows everything off the rings and you only need to hose out the bottom ring. This cuts cleanup time from thirty minutes to five minutes.

With regard to black sand, one must understand that this unit does not recover by seeking a given specific gravity. What it does is magnify by a figure of 60 the difference in specific gravity between all particle densities in the gangue. It is this magnification of the differentiating factors which explain the machine’s ability to effectively recover free gold particles far beyond the parameter of the aforementioned 1 g devices. Consequently, the Knelson Concentrator can handle virtually any content of black sand or other material with high specific gravity and still recover a very high percentage of the free gold contained in a given product. Because gold and platinum are two of the materials at the high range of the SG chart, they will concentrate ahead of mercury, lead, scheelite, black sand, etc. in the Knelson Concentrator.

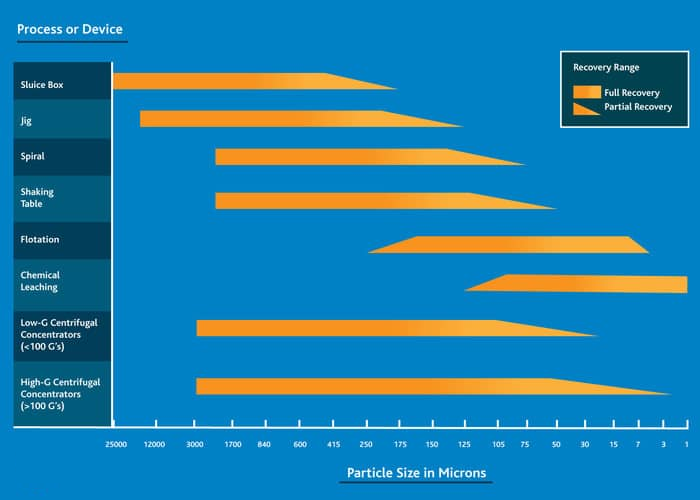

Compare Gold Recovery Equipment

Gold Size by Size Recovery