In our EXAMPLE precipitate from the – Zinc Precipitation Circuit will be considerably wet and therefore it must be dried prior to entering the induction furnace. Excess moisture in the precipitate essentially wastes energy; as energy is required to evaporate the water before the precious metals and fluxes are melted. In addition, water not only wastes energy but it may cause small explosions in the furnace, preventing efficient separation of the precious metal from the slag. The precipitate is therefore delivered to a rotary dryer via a screw feeder, where it is first dried, then mixed with fluxes, discharged into another screw feeder, and fed to the induction furnace for refining. This section is intended to be read in conjunction with Flowsheets and Piping and Instrument Diagram.

The Gold and Silver Refining Circuit is designed to operate on a batch basis according to the following criteria:

The Gold and Silver Refining Circuit is designed to operate on a batch basis according to the following criteria:

Moisture Content of Precipitate ————50 %

Gold content ——————————— 7200 gn/filter cycle

Silver Content ——————————–260,000 gm/filter cycle

Flux Addition ———————————2.1 x precipitate impurities b.w.

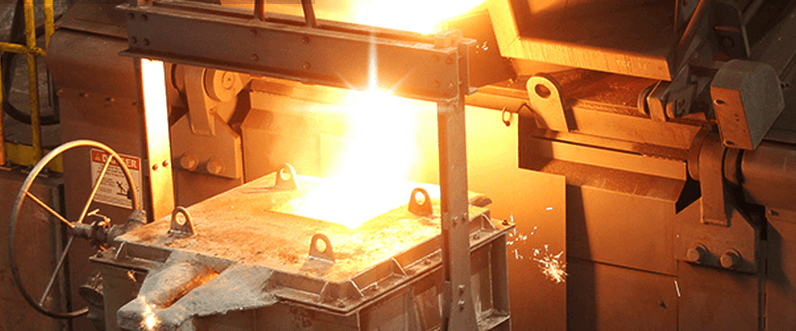

Precipitate from the precipitate filter presses is discharged down a chute onto a variable speed screw feeder, which feeds the wet precipitate into the rotary precipitate dryer. The wet precipitate is first dried and then refining fluxes are added to the dryer via the bag loading hopper and dryer screw feeder. Once the precipitate has been dried and thoroughly mixed with the desired fluxes, the dryer is reversed and the precipitate/flux mixture is discharged onto the variable speed furnace screw feeder, which discharges the mixture into the preheated 500kg induction furnace. When the furnace crucible is charged to the correct level, the furnace continues to run (at 2200 degrees Fahrenheit) until the charge is molten and the slag is fluid. When the kiln charge is fluid, the slag is poured into the slag cart by tilting the whole furnace, leaving the molten precious metal in the kiln. The kiln crucible is then again charged with the dried precipitate/flux mixture and the process repeated until the entire contents of the drier have been refined.

When the entire contents of the drier have been refined, and the slag is poured out of the furnace, the precious metal are poured into the dore bullion moulds.

The slag is allowed to cool and solidify and is then manually fed into the ball mill for recovery of any precious metal that may be entrained in the slag. The dore bullion bars are cooled and stored in the refinery room safe.

During the drying and melting process, the drier and furnace vacuum baghouse dust collectors, respectively, must be running. The contents of the dust collectors are discharged into a small portable container and can be added to the furnace during the refining process.

Operation of this EXAMPLE Gold and Silver Refining Circuit

Within the refinery room there are two major operations that are run independently:

- Precipitate drying and flux mixing.

- Precious metal smelting.

Refining Circuit Preparation for Start Up

The following items must be checked before the equipment in the Refining Circuit is started.

- Ensure that the precipitate dryer, dryer screw feeder and drier dust collector are available to operate.

- Check that the dryer is rotating in the drying/mixing direction.

- Ensure that the induction furnace FR-557, the furnace screw feeder CV-579 and the furnace dust collector DC- 571 are available to operate.

- Start the furnace and allow the furnace to heat up to 2000 degrees Fahrenheit. Check that the furnace cooling system has an adequate supply of fresh cooling water.

- Ensure that the precipitate is dry and that the proper fluxes have been mixed with the precipitate before charging the furnace.

Start Up Sequence and Normal Operation of a Silver and Gold Refining Circuit

For greatest safety and equipment performance, the precipitate dryer and the induction furnace must be operated according to the equipment manufacturer’s detailed operating instructions. The following is a brief equipment start up sequence for all equipment in the Refining Circuit.

- Start the precipitate dryer rotating.

- Start the dryer dust collection system.

- Adjust the temperature of the dryer with the appropriate temperature controller.

- Start the variable speed dryer screw feeder CV-578 and slowly feed wet precipitate into the dryer.

- When all the wet precipitate is fed into the dryer, shut down the screw feeder and allow the dryer to dry the precipitate.

- Start the screw feeder and feed the appropriate fluxes, through the flux bag loading hopper, into the dryer. Allow the dry precipitate and the fluxes to thoroughly mix in the dryer.

- Ensure that the furnace is ready to be charged. If it is, stop the dryer and immediately push the dryer “unload” button; the dryer will begin to rotate in the opposite direction, and the dryer discharge discharge conveyor will start.

- When the furnace is up to temperature (2000 degrees Fahrenheit) it can be charged with the dry precipitate/flux mixture.

- Start the furnace dust collection system.

- Swing the dryer discharge screw conveyor over the furnace and place the screw conveyor discharge nozzle into the furnace crucible.

- Discharge material from the dryer onto the furnace feed conveyor and into the furnace crucible until the crucible is filled to the desired level.

- Melt and precipitate and flux in the furnace, and when the slag is fluid, hydraulically rotate the furnace and pour the slag out of the furnace into the slag cart. Add more precipitate and flux into the furnace and again remove the slag when it is fluid. Continue this procedure until the precipitate dryer is empty of its contents.

- Pour the molten precious metal into the dore bullion molds and allow the metal to cool into dore bullion bars.

Normal Shutdown Sequence/Procedure of the Refining Circuit

For personal safety and equipment protection, the precipitate dryer and induction furnace must be shut down according to the equipment manufacturer’s detailed operating instructions. The following is a brief equipment shutdown sequence for all equipment in the refining circuit.

- Shutdown the precipitate dryer. Ensure that the dryer shell is empty and cooled down before shutting down the dryer.

- Shutdown the dryer dust collection system.

- Shutdown the furnace. Ensure that the crucible is empty of all slag and precious metal before shutting down the furnace.

- Shutdown the furnace dust collection system.

Refining Circuit Emergency Shutdown

In the event of an emergency, the dryer and associated screw feeders, and the furnace are shut down at their locally mounted control panels. The dust collection systems are shut down by locally mounted START/STOP switches.

Care must be taken to ensure that the dryer or furnace is cooled down before any work on the units is performed.

https://www.911metallurgist.com/merrill-crowe-zinc-precipitation-startup-and-shutdown-procedure

https://www.911metallurgist.com/effect-operating-variables-metallurgical-process-parameters