Grinding and amalgamating are practical and satisfactory methods for treating gold-bearing concentrates or black sands or for cleaning up a mill. The gold is brightened and made more amalgamable. The tailings might be rich enough for cyaniding.

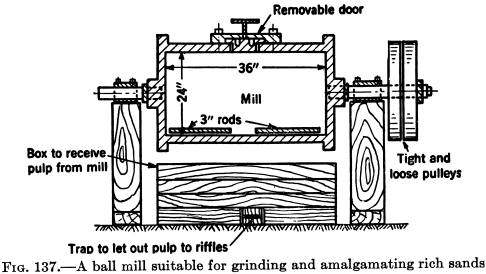

Figure 137 shows an amalgamation barrel. Laboratory ball- mills and the smaller of the ball-mills (amalgam gets behind liners in these) used in regular ore-grinding could be used; so could a small concrete mixer. Some firms make barrels for grinding and amalgamating. One can be made on the job from a pressed- steel oil-drum, but it should be scoured with hot water or by burning out the oil.

Amalgamation barrels may run on rollers, or a shafting attached to the ends sits in regular bearings. The barrels have a cover which is clamped on, with a rubber gasket to prevent leakage.

A barrel is charged partly full with concentrate, water, mercury, a little lime or lye, and several steel balls or short pieces of shafting. The lid is set, and the machine started. It is run for an hour or several hours, depending on what is being ground. The pulp is then let out; the mercury and amalgam are washed clean and finally retorted. To prevent flowing of the mercury, it may be added to the charge after the grinding is finished.

AMALGAMATING DRUM

Another suitable machine for treating small quantities of black sands or clean-up material is the amalgamating drum The 12-inch size has a capacity of 25 to 50 pounds per charge and sits on the same foundations as a ¾-horsepower gasoline engine or electric motor. The drum is belt-driven. Ordinarily, a single large ball grinds and amalgamates the pulp. A tilting device allows the slime to be drained out while the machine is rotating. The concentrate is removed through a drain outlet on the amalgam groove. This collects the mercury and holds the concentrate while the slime is being discharged.