Table of Contents

The variability in gold recovery (geometallurgy) is a very important problem to study during the first steps of the project and even during the operation. Probably, the explanation of that problem for some plants is not well known and the problem has to be solved with valid criterion that were not considered during the design phase. For this reason is important to analyze all possible variables during the metallurgical testing program so that all possible variations can be analyzed. Basically, the idea is to predict the plant performance throughout the mine block model for the process selected.

For many years gold mining companies have overlooked the importance of geometallurgical modeling on the plant performance. Probably, when difficult gold ores start to appear, the concern on project evaluation and gold metallurgy change its direction. Essentially, the modelling is employed to manage any risk during the early steps of the project. The main risks are associated to economical evaluation, plant design, and forecasting production. Then, the importance of geometallurgical studies is increases.

All this information must be used in the feasibility study, which follows a systematic evaluation of a specific gold project in order to determine the project for success. In this way, the feasibility study analyzes an idea based on the information provided by the analyst and measure the possible profitability of the project under economical, technical and financial aspects.

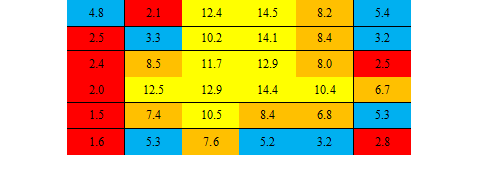

Gold grade (g/t) is variable in the deposit

Sampling

This point is the first step of any mining project. When sampling an ore body for the purposes of metallurgical tests and mineralogical studies, the samples must be selected on the basis of how they will affect the treatment process or any metallurgical operation to be included in the design. In this way, rock break properties and gold mineral liberation are key aspects of the comminution circuit and they should be correlated with gold grade. It is well know that deposits have different ore types and its variation in terms of hardness and metallic content can be huge. A proper mineralogical evaluation of the samples selected to characterize the ore body is useful so that the geologist and metallurgist can consider the different ores within the mineralized deposit. Some variations or changes in mineralogy are due to the presence of intrusives or any geological occurrence. Then, an evaluation of the material is an important part because each ore type and mineralized zone represents a significant part of the material that will be sent to the plant.

Examination of mineral can help to determine the identity, character, grain size and associations of the valuable minerals with non-valuable minerals. The information will indicate liberation size analyses for the comminution and process recovery selection. The analysis can be based on the microscopy of polished sections or stereoscopy for mineral sizes. If some minerals are difficult to be studied, specific and special equipment can be employed. Sometimes, minerals are in complex associations and this factor is important to consider due gold recovery can be affected.

Detailed information on the gold distribution in the deposits is important. Also, the distribution of other metals and non-metallic minerals are important aspects to be considered. Obviously, the person in charge of the recovery process considers this information a key point of the process. The person in charge of the comminution circuits may assess the first problems of the comminution circuit and the need for additional circuit design parameters. For example, the presence of clays or sulphate affects the comminution and recovery process, the fist produces slimes and the second one acidity.

With preliminary information will be assessed the limits and reserves of the deposits. Later, when more information is available, the initial assessment will be actualized. The mining engineer creates a mine model based on geological parameters such as ore types or lithology which have to be related to the gold distribution and minor metals present in the ore body. Process modeling, plant expansion or production is developed with this information. There is no doubt that metal values are variable and the sampling procedure is a key aspect.

The relatively cost of obtaining samples, performing the tests and the time employed are crucial factors in the selection of the process and forecast the gold production variability through life of mine. In the early stages of the project, samples are analyzed for gold and other elements. Some people are used to employ the rejected material in order to save money and time. However, this is a bad practice due to the sample was prepared for chemical assays and not for metallurgical test. Although, samples must be crushed, the procedure is different. Basically the production of fine material is different and this aspect has an effect on the metallurgical results. Next table shows cyanidation results obtained with the same sample, but prepared under different objectives. Cyanide consumption is affected by the presence of fine material and all samples from chemical assay preparation produced more material minus than 400 mesh. Also, the cost is affected. See next table.

| Sample | Au Grade

g/t |

Au Recovery

% |

NaCN

Kg/t |

K80

µm |

-400mesh

% |

| DDH-02 (assays) | 12.3 | 89.2 | 1.9 | 84 | 55 |

| DDH-02 (tests) | 12.8 | 90.4 | 1.1 | 86 | 39 |

| DDH-12 (assays) | 10.6 | 87.5 | 0.85 | 80 | 59 |

| DDH-12 (tests) | 10.1 | 84.2 | 0.76 | 89 | 41 |

| DDH-35 (assays) | 6.8 | 93.7 | 0.98 | 74 | 58 |

| DDH-35 (tests) | 6.9 | 90.3 | 0.85 | 86 | 45 |

Ore Grade and Final Product

As soon as the engineering team receives the scoping results, the ore feed and final product characterization must be specified so that the metallurgical testwork program can confirm the preliminary conclusions obtained at the beginning of the project. By preparing three or four master composites and testing some variability samples will be possible to estimate the low and high levels of ore feed and the effects on gold recovery. For example, it is important to estimate the size analysis of the plant ore feed or mine due the presence of fines material obliges to have special considerations in the crushing and comminution circuit, open pit mines can adjust the run of mime top size to the primary crusher requirements. Underground operations are used to provide a finer material according to the handling capabilities.

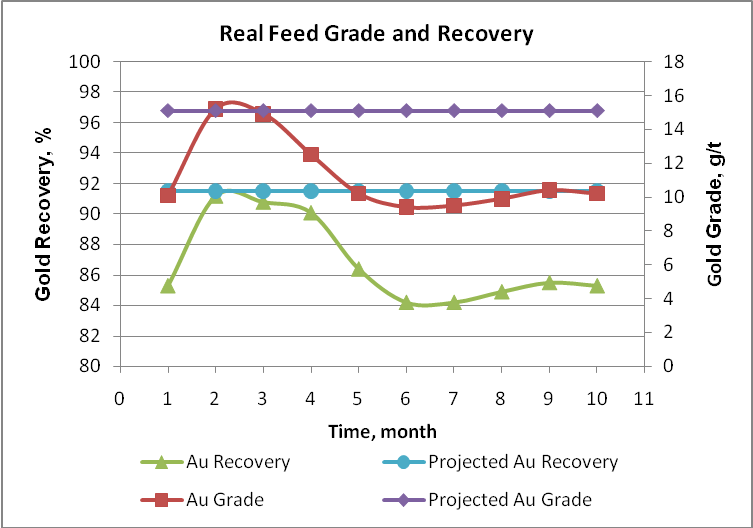

During the first ten months only two months reached the projected values

Geological properties are related to rock structure and rock mechanic, and these properties have an effect on the ore to be fed to the plant and the final product. Then, it is important to link geological parameters and rock properties with metallurgical performance; more even is gold is a metal very complex many times. Plant feed must be correlated to the lithological classification. Without any doubt, there is a variable ratio of gold values, grain size, and hardness that affect the comminution product or recovery process. Try to identify the critical zones of the ore body is the task that geologist, metallurgist and process engineers have to face and propose the solutions if any problem arise during this analysis.

The study must be focused on evaluating the effects of variables on feed plant and final product so the critical variables can be detected. In general, geometallurgical forms are dependent of the quality and effectiveness of the sampling program. This relationship plays an important role in any projection of the gold production or process efficiency.

Once all master composites of the entire deposits are specified, it will be necessary to perform a comminution testing in order to find out the different rock properties of the composites. Basically, the program must include point load tests (PLT), unconfined compressive strength tests (UCS), crushing work index, drop weight tests, SAG mill comminution tests (SMC), abrasion tests, and work index tests. By employing mathematical modeling will be possible to establish the estimated power required to design the crushing and comminution circuits and the variability of the material to be sent to the recovery process. Differential grinding causes each ore type to be ground to a different size distribution, some finer and some coarser than the average.

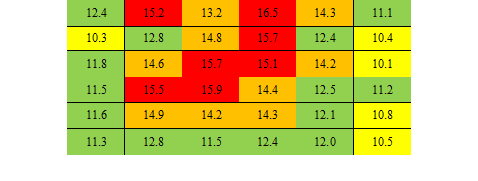

Work Index is variable in different mineralized zones

The same master composites must be evaluated through the same recovery processes (e.g. gravimetry, flotation, leaching) in order to know the respond of each composite. Probably, some ore types will give good recoveries, but others no. Then, the geologist, mining engineer and metallurgist must study the importance of the sample through the life of mine. It must be noted that some ore types will be processed short time and the impact on the economy of the project must be evaluated. For example, if the process includes cyanidation and the presence of oxidized copper minerals has been only detected in specific zones of the ore body, the analysis must be focused on its effect on gold recovery and the cash flow. If the impact is serious, one solution could be to reclassify the ore types or mix the problematic material with ores with high gold content and low content of oxidized copper. The idea is to get a solution to this problem. As can be seen, the interrelationship among Geology, Mine, and Metallurgy is fundamental in the testing program.

Metallurgical Process

With the preliminary information obtained in the scoping study is possible to design a tentative recovery process. Under this consideration, ore types and master composites must be tested in order to know the restrictions of reduction size circuit. Since gold content is different, the variability of the feed to the open circuit or close-circuit must be evaluated. Ideally, the plant must receive an ore without much variability, but this rhetorical affirmation is valid only in theory. For this reason, the circuit is sensitive to the ore type and no matter how simple or complex is the design.

Basically, the ore tell us how it must be ground. If the ore breaks along grain boundaries easily, gold particles can be liberated and recovered easily. However, many ores need special liberation in order to liberate all valuable minerals. It is important to mention that the comminution circuit is responsible for most of the power consumption in a mill. Then, the need for better blending for feed homogeneity is obvious as well as the need for closes monitoring since the mine until the processing plant. Gold operations with comminution circuits know that the operative cost of this circuit is approximately 65-70% of the total cost. For this reason gold low grade deposits (e.g. 0.8 – 1.0 g/t Au) try to employ a heap leaching process which does not require a comminution circuit with SAG mill and Ball mills.

The geometallurgical model is based on metallurgical tests performed on exploration samples so that the characterization of each ore type includes several aspects such as recovery, reagent consumption, losses, grade concentrate. Preliminary tests must be done on lithological samples provided by the project geologist. The model will be constructed on each zone after analyzed the metallurgical tests results. Basically, the model is based on gold recovery and final product quality.

| Ore Type | Au

g/t |

SPI

min |

Work Index

kw-h/t |

Au Recovery

% |

NaCN

Kg/t |

Cu (Ox)

% |

| A | 2.3 | 21 | 14.3 | 89.5 | 1.8 | 0.02 |

| B | 1.5 | 15 | 12.1 | 85.4 | 2.3 | 0.10 |

| C | 3.4 | 25 | 15.8 | 90.3 | 1.9 | 0.01 |

| D | 4.2 | 18 | 14.3 | 90.1 | 2.4 | 0.04 |

| E | 0.9 | 12 | 10.2 | 84.2 | 1.5 | 0.11 |

The metallurgist must be able to develop the metallurgical testing program based on global objectives, gold recovery, and common practices on similar ore deposits. It will be important to have an updated knowledge on metal prices in order to make a preliminary estimation of the profits. The impact of the process on environment must be studied in order to take appropriate solutions to the problem. For example, tails have free cyanide and the effluent has to be treated with any oxidation process, otherwise the project could be rejected by the authorities. Even, during the operation, the operation of the oxidation process must be monitored and improved.

If the metallurgical process was selected wrongly, the project could be approved, but the real operation could be a disaster. For this reason, the testing program must cover many possible combinations of recovery processes. In other words, the process must be selected under technical and economical considerations. Reserves and metallurgical process must be analyzed and probably the best way is to review and update the reserves so that the economy of the project can be optimized. Since mineralogy and gold content is variable, the plan must evaluate the order of treatment. Metallurgists want optimum recoveries and Project Managers want to improve the profitability of the project.

Next table shows the difference between two treatment options, gravimetric concentration + flotation+ concentrate cyanidation (Option 1) and direct cyanidation (Option 2). Both projects employ cyanidation, but Option 2 gives a better profitability.

| Item | Unit | Option 1 | Option 2 |

| Metal Price | |||

| Au | U.S. $/g | 24.1 | 24.1 |

| Ag | U.S. $/g | 0.322 | 0.322 |

| Grade | |||

| Au | g/t | 12.3 | 12.3 |

| Ag | g/t | 8.5 | 8.5 |

| Tails | |||

| Au | g/t | 1.61 | 0.91 |

| Ag | g/t | 0.90 | 1.77 |

| Recovery | |||

| Au | % | 86.9 | 92.6 |

| Ag | % | 89.4 | 79.2 |

| Value | U.S. $/t | 260.0 | 276.7 |

| Cost | % | 7.9 | 4.8 |

| Tonnage | t/year | 850,000 | 850,000 |

| Value | U.S.$ | 221,037,866 | 235,162,601 |

| Cost | U.S.$ | 17,461,991 | 11,287,805 |

| Net Income | U.S.$ | 203,575,874 | 223,874,797 |

Planning

Geometallurgical planning must be practiced during the evaluation of new gold projects and all the life of mine. When the prospect is evaluated, the planning and strategies are focused on the viability and profitability of the project. If the project was accepted, the forecast and considerations taken at the early stages of the project must be improved. Also, when the ore is being mined and treated, the planning is based on metallurgist results obtained on samples to be processed within three or six months. This period of time is variable and depends on the type and size of project. In this way the sample must be characterized for several metallurgical factors such as hardness, work index, recovery by gravimetric concentration, flotation recovery, leachability, liberation and reagent consumption. Obviously, the tests must be done according to the project selected.

To perform metallurgical tests on samples to be processed in the future is an advantage that metallurgists and plant operators need to study in order to confront the current results and the possible new results. If there are bad recoveries, the metallurgist will start to evaluate new alternatives oriented to solve the problem. In this way, the economy of the mine will not be affected. The economist or person responsible for marketing has to evaluate the results based on the new market trends, specifically the gold international price. For example, if the plant treats an ore by cyanidation and recoveries are close to 90%, and the new mine zone to be processed is partially leachable, the presence of a possible refractory ore is a warning voice that affects the process and profitability of the operation. If the plant was not designed for refractory ores, there are two possible options, redesign part of the plant or mix the problematic material with the non-problematic ore in order to get a balance on the operation. If the problem is very serious, the ore will not be processed and cash flow estimated during the early stages of the project is affected. This problem could have been detected during the scoping tests, but probably the lack of appropriate sampling procedures overlooked this problematic material.

The planning must be supported by mineralogical studies. When these studies are done in limited number and some problems appear during the operation, these studies are demanded in order to understand the problems of low gold recoveries. The process must be supported on mineralogical information no matter if gold recoveries were extremely high. It is important to cover all the mineralogical characteristics of the different ore types.

In general, geometallurgical planning needs the interaction of geologists, miners and metallurgist in order to coordinate and program the different ore types to be processed and any special requirement or treatment to be considered in the operation. Many times, the personnel responsible for the operation have to get a solution without having enough information.

The planning must define a production program based on mining and processing requirements during all the life of the mine so that the project can be supported economically. For many years, the valorization of gold deposits did not consider detailed information on the metallurgical characteristic of the resource. In this way, try to include many metallurgical parameters into the valorization modifies the definition or categorization of economical resource. An aspect very important in the evaluation is to optimize the Net Present Value (NPV), which is a projection of the profits in the time and consequently, the net cash flow must be optimized during each period.

It is well know that many gold operations valorize their resources considering the cut-off grade which has influence on the value of the ore block. However, there are other factors to be included such as gold recovery, processing arte or smelter costs. These factors are referred per tonne milled and not consider the value of the money in the time. The next table shows information on two ore zones.

| Block | Tonnage

kt |

Au

g/t |

Au Recovery

% |

Au

t |

| 1 | 1000 | 6 | 85 | 5.1 |

| 2 | 1000 | 7 | 88 | 6.2 |

If we consider gold grade and recovery, the main ore source is block 2. Now, the gold ore will be processed by cyanidation and the process includes comminution and leaching operations. An aspect very important of any comminution circuit is the power and each ore has different productivity due to rock breakage properties are different, especially hardness.

| Block | Tonnage

kt |

Treatment

tph |

Au

g/t |

Au Recovery

% |

Au

t/h |

| 1 | 1000 | 200 | 6 | 85 | 1.0 |

| 2 | 1000 | 180 | 7 | 88 | 0.98 |

Under this new analysis, block 1 is more important than block 2 and will generate more money for the company due to during the same period of time will produce 2% more of gold. Basically, the example tries to show the benefits of employing a cut-off grade, recovery and the processing rate together. A strategy based on the cut-off and production may have meaningful influence on the ore block to be mined and processed initially. For this reason is important to quantify the value to be generated when the processing rate is included in the economical evaluation of the project.

It is important to study the impact or influence of the blocks or mineralized zones on the economy of the project without modifying the mining plan. Don’t forget that the processing plant will have to handle any variation in the ore sent to the operation. Losses can be avoided if previous studies analyzed the different options of treatment. The inventory of resources must be used to prepare a detailed mining plan year by year, which may have restrictions such as the mineable ore, the treatment capacity or the ratio between waste material and total ore.

The objective is to define production plans according to the ore and objectives of the operation. The procedures or considerations used must include operative costs, gold price, capital investment and financial aspects. Ideally, planning must be developed thinking in the future, considering exploration programs, cut-off grades and the extraction program of mined and waste material. The main steps to follow are to study the development of the mine, design the phases of extraction, select the process and evaluate the profitability of the project.

The project and specifically the processing plant can be affected by the geographical location of the plant, climate, physical characteristics of the ore body and precipitations. Whereas the location of the ore body cannot be modified, the plant must be located in the right place. The location has an important impact on the operative cost. For example, if the mine is located in geographical places of low temperatures such minus 5°C, the design must consider special buildings, otherwise the efficiency of the process and some equipment may be affected. If the design did not consider a building and some problems appear in the first months of operations, the company will have to redesign the plant and expend more money than the initial consideration. Consequently, the plant is not able to operate with high efficiency and the economy of the project is affected. The metallurgist involved in the design must be able to analyze the effects of low temperatures on gold recovery.

The previous operations prior to send the ore to the plant could affect the nature of the ore. For example, a copper-gold ore must be treated by flotation and the final product is a copper concentrate with gold values. According to the feasibility study copper and gold are associated and recoveries must not be lower than 87%. It is well known that some copper minerals are affected by the weather. If the ore is exposed more time than necessary to the environment, copper minerals will suffer alterations due to the action of oxygen and the recovery is affected. Any geometallurgical planning or production projection is affected when the analysis is not complete.

Many considerations for large operations are not necessarily true for small operations or projects and the main restriction depends on economical aspects. In general, the geometallurgy of small projects has a serious impact on the economy and profitability of the project.

Production Plan

In order to prepare this projection is important to consider the gold recovery as variable parameter in order to favors the initial extraction of zones with higher processing rates. In this way, the cut-off per phase and period may be adapted in order to maintain an average gold feed value without much variation and also to maximize the net present value of the project. The inventory of mineable resources has to be designed so that the production rate can be used as key reference. Obviously, there are phases with more resources than others and this parameter must be studied on each ore type. The operational cut-off of each period is different and has an impact on the mineable resources. Next figure shows the variability and average cut-off grades for a fifteen year gold project.

Variability in Cut-Off Grade