Previous work has shown that significant, free milling gold values exist in the Ryan Lode ore. This project used pilot scale equipment to estimate the percentage of gold recoverable by gravity methods from the circulating load of a conventional, closed-circuit, grinding mill. The pilot scale flowsheet employed three stages of gravity concentration, hydraulic classification and batch grinding to simulate a full scale milling circuit. 172 kg (379 lbs) of Ryan Lode ore were processed, having a head grade of 4.8 g/metric ton (0.14 oz/ton).

Results showed that simple gravity methods are capable of recovering 45-50% of the gold values in a concentrate grading in excess of 3430 g/metric ton (100 oz/ton). Of the remaining gold values reporting to the classifier overflow solids (80% passing 70 microns, 3.1 g/metric ton (0.09 oz/ton)) 89% were recovered from 48 hour bottle roll tests.

Introduction

Ryan Lode Mines, Inc. (previously Citigold Alaska, Inc.), a wholly-owned subsidiary of La Teko Resources, Ltd., has been exploring the Ryan Lode hard rock gold deposit, located near Fairbanks, Alaska for the last four years to bring the property to production status. The 1993 exploration program, comprised of 19,500 meters of reverse circulation drilling and 1,600 meters of core drilling, brought total drilling in the system to 59,070 meters of reverse circulation and 7,800 meters of core drilling. Analysis of the data received from the program has identified 25,575 minable kg (822,200 minable ounces) of gold contained in 13,221,000 metric tons of ore. The ore has a cut-off grade of 0.51 g/metric ton (0.015 oz/ton), an average grade of 1.92 g/metric ton, (0.056 oz/ton) and the stripping ratio is 3.8 to 1 (Hughes, 1994).

From 1987-1990, under previous management, Citigold Alaska, Inc. attempted heap leaching 295,000 metric tons of the Ryan Lode ore with moderate success, at an estimated gold recovery of 60-65%. Previous work (Walsh, 1989, 1991, 1992) has shown that significant, free milling gold values exist in the Ryan Lode ore. Pilot scale gravity concentration tests have shown that free gold as coarse as 0.84 mm (20 mesh) occurs in the ore, closely associated with sulfide mineralization. Microscopic analysis of gravity concentrates has shown abundant hexagonal arsenopyrite grains and numerous blades of stibnite with lesser amounts of antimony oxides and scheelite. Microprobe analyses have confirmed the above mineral species as well as native antimony. Gold of relatively high fineness (910-930) is very abundant in grains ranging from 5 to 50 µm, mainly as inclusions in arsenopyrite and the arsenic oxide, scorodite, and to a minor extent between blades of stibnite. The probe found aurostibnite (AuSb2) in one arsenopyrite grain (Walsh, 1989).

In addition to the above, the lead-bismuth sulfides, hammarite and galenobismuthite, were found in arsenopyrite. A very rare sulfosalt, ustarasite ((Pb Sb Bi)S), occurs as inclusions in arsenopyrite and as inclusions in gold. The scheelite contains less than 1.0% (by weight) M0O3, indicating that this mineral represents the tungsten end member of the partial solid solution series scheelite-powellite (Walsh, 1989).

As part of Ryan Lode Mines (RLM) ongoing metallurgical test program, in the summer of 1993, the Mineral Industry Research Laboratory, University of Alaska Fairbanks, conducted another pilot scale study to investigate and simulate gravity concentration of gold values from the circulating load of a grinding circuit, which would process Ryan Lode ore. The flowsheet employed three stages of gravity concentration, hydraulic classification and batch grinding to simulate a full scale milling circuit. Additionally, the test program was intended to help define: (1) the grade of the gold concentrate recovered by gravity methods and; (2) the grade of material advancing to the cyanidation circuit. RLM personnel delivered approximately 181 kg (400 lbs) of sample to the Mineral Industry Research Laboratory. The ore sample consisted of approximately 67% crushed (-10 mm) and uncrushed North Pit ore and 33% crushed (-10 mm) Hilltop-South Pit ore. RLM geologists selected the sample from these ore zones with the object of acquiring a sample, which equaled or exceeded 3.43 g/metric ton (0.1 oz/ton) gold grade. Random grab samples were collected from the bulk sample for a moisture determination, which showed the bulk sample to be 4.3% moisture. The net, dry sample mass processed was 172.0 kg (379.2 lbs).

Test Procedures and Unit Processes Descriptions

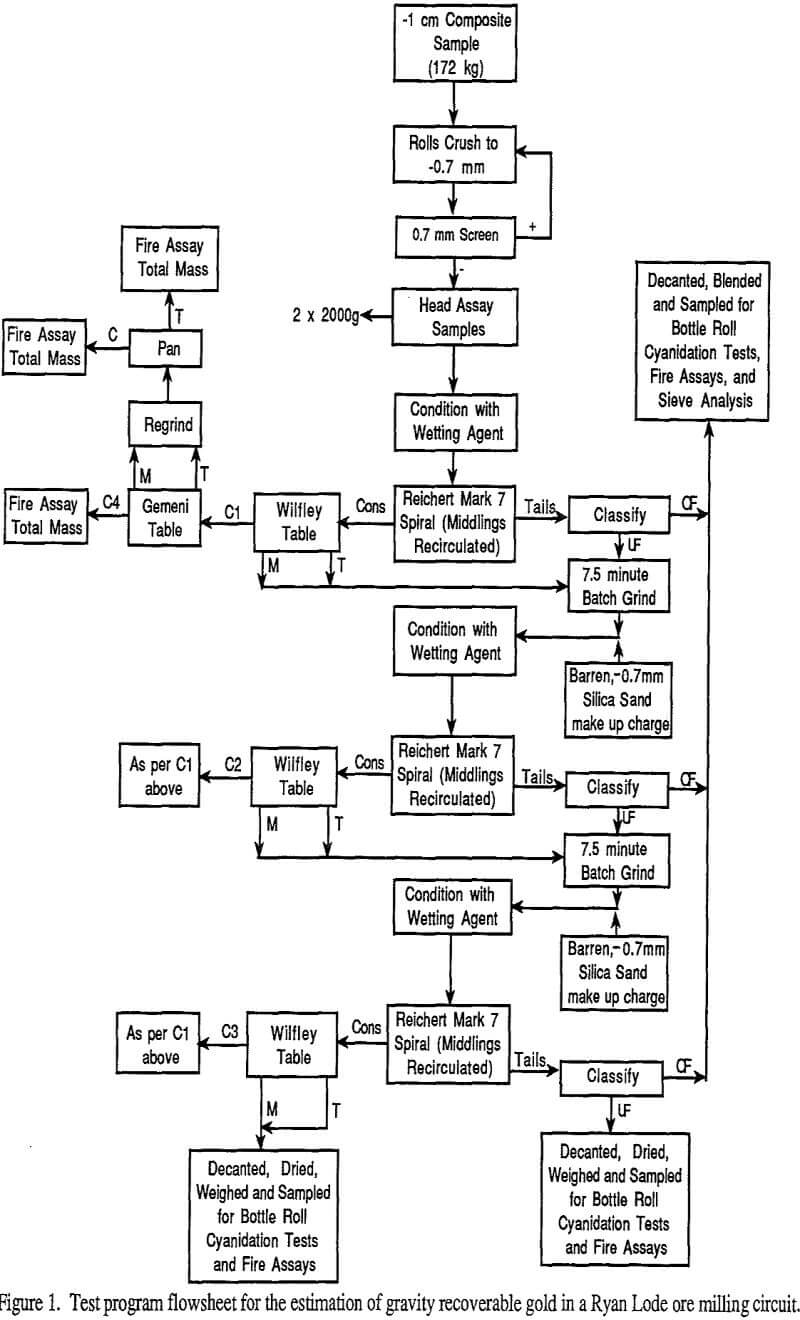

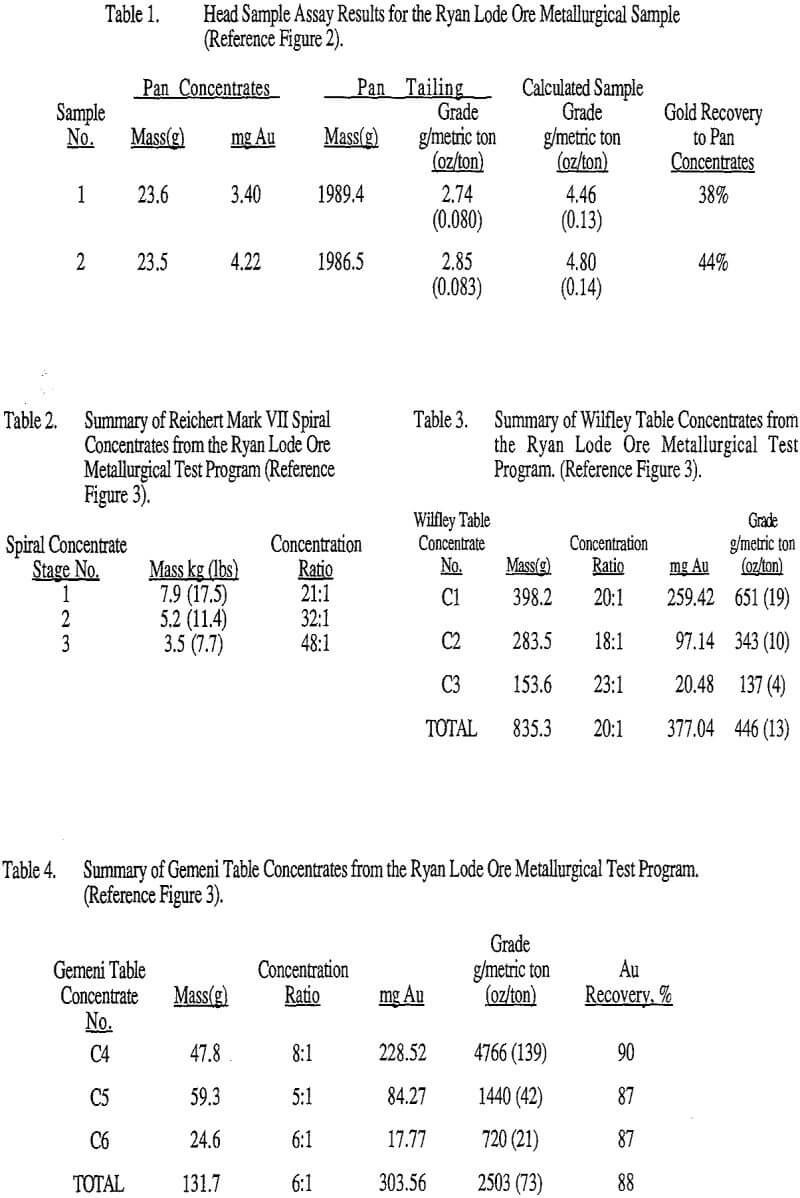

The protocol for the test procedures is summarized in Figure 1. The “as received” sample was rolls crushed to minus 0.7 mm (25 mesh) in closed circuit with a screen. The crushed ore was blended and two, 2000 gram, grab samples were taken. These head samples were taken to estimate the grade of the material and to insure that the gold grade of the ore was at least 2.74 g/metric ton (0.08 oz/ton) before proceeding with additional test work. These head samples were processed as shown in Figure 2 and the results are summarized in Table 1. The head samples showed grades of 4.46 and 4.80 g/metric ton (0.13 and 0.14 oz/ton).

Basically, the test procedure required sequential steps of comminution, gravity concentration and classification to simulate the gravity recoverable gold from the circulating load of a mill processing Ryan Lode ore. -0.7 mm (25 mesh), barren silica sand was added at stages 2 and 3 to reduce overgrinding and to provide the primary gravity concentrator with roughly the same feed size distribution at each stage. Individual unit processes are described below.

Comminution

The first stage of comminution was rolls crushing to 0.7 mm (-25 mesh). Subsequent grinding steps 2 and 3 were conducted by batch grinding 11.3 kg (25 lb) charges of ore in a 0.3 m (12 inch) diameter by 0.6 m (24 inch) long ball mill. Batch grinds were 7.5 minutes in length at 60% solids, with the aim of producing an 80% passing 0.15 mm (100 mesh) classifier overflow product. These grinding times were chosen from previous test work, which showed that a 15 minute grind produced a 95% passing 0.21 mm (70 mesh) product from -2.4 mm (8 mesh) feed. Batch ground material was collected in 0.1 m³ (30 gallon), Nalgene tanks, allowed to settle, decanted and transferred to 0.02 m³ (5 gallon) buckets. Ground ore was fed to a 0.08 m³ (20 gallon) conditioner, from these buckets, ahead of gravity concentration.

Gravity Concentration

Three stages of gravity concentration were used. The primary concentrator was a Reichert Mark VII spiral. The spiral was fed 4.77 m³/hr (21 gpm) of slurry at approximately 30-40% (w/w) solids from a conditioner. The spiral middlings split was recirculated to lend stability to the system. A wetting agent, Aerosol OT-75, was added at the conditioner to yield a 10 ppm level in solution. The use of a wetting agent was suggested from previous spiral concentration work by Walsh and Kelly, 1992. Spiral concentration data is summarized in Table 2. Spiral tailings were collected in a 1.14 m³ (300 gallon), steel sump, where they were allowed to settle for 16 hours. After settling the water was decanted and the solids were collected in buckets for classification.

Spiral concentrates were upgraded on a laboratory Wilfley table, again in the presence of a wetting agent. Table concentrates were collected and table middlings were recirculated until the table reached equilibrium, after which the middlings were collected separately. Table 3 summarizes Wilfley table concentrate data. Table middlings and tailings were dried, weighed and returned with the classified spiral tailings for batch grinding after stages 1 and 2. Stage 3 table middlings and tailings were analyzed separately.

Wilfley table concentrates were upgraded at the third stage a gravity concentration, a Gemeni table, in the presence of a wetting agent. Table 4 summarizes Gemeni table concentrate data. Gemeni table concentrates were fire assayed in total. The middlings and tailings products were each batch ground for 5 minutes in a laboratory ball mill, then panned to check for the presence of gravity recoverable gold values liberated by additional grinding.

Classification

Spiral tailings were classified ahead of batch grinding. An upflow hydraulic classifier was employed with a surface overflow rate of 2 cm/sec in order to overflow -0.15 mm (100 mesh) material. The overflow stream was collected in several 0.19 m³ (50 gallon), Nalgene drums, allowed to settle, decanted and the solids collected in 0.02 m³ (5 gallon) buckets. The underflow solids collected in a container beneath the classifier and were decanted, dried and weighed ahead of grinding or analysis. After all three stages of classification were completed, the overflow solids were blended and sampled. A size distribution of the overflow solids is presented in Figure 3. It can be seen that the size is finer than the targeted 80% passing 0.15 mm (100 mesh). This was not due to overgrinding or poor classifier operation, but rather to the large quantity of fines in the feed material, which dominate the size distribution. In order to achieve an 80% passing 0.15 mm (100 mesh) product, the classifier would have had to have been set at such a high surface overflow rate as to reject coarse particles, which legitimately should be sent to regrind.

Analyses

Gold values and product grades were determined by fire assay techniques. High grade gravity products from the Gemeni table were assayed in total to yield contained gold masses, in milligrams. These gold values were used to back-calculate Wilfley table concentrate grades.

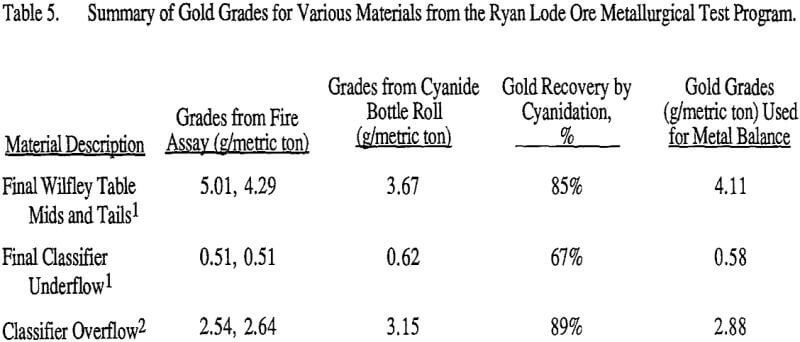

Lower grade materials, that had been stripped of particulated gold values by gravity concentration, were split, pulverized and subsampled for multiple fire assays. Additionally, cyanide bottle roll tests were conducted on large samples of the combined classifier overflow solids, the final classifier underflow solids, and the final Wilfley table tailings and middlings product. Solution assays for these bottle roll tests were by lead boat fire assay. Leach residues were filtered, dried, weighed, sampled and pulverized for fire assay.

Results and Discussion

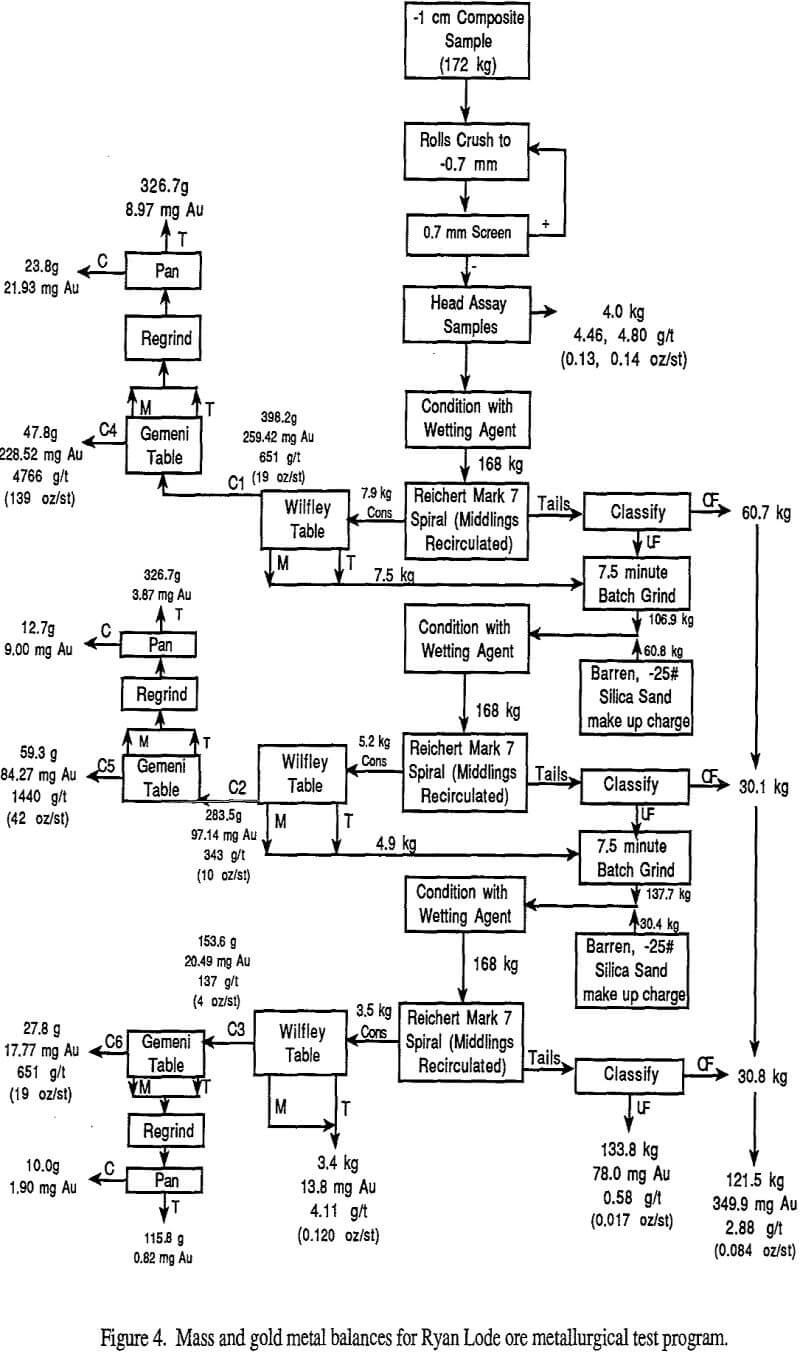

Figure 4 shows the mass and gold metal balances for the test program’s pilot plant. Gold mass values for all table concentrate products and pan products were determined directly by fire assay procedures. A metal balance over the process, shows the 168.0 kg (370.4 lbs) of Ryan Lode ore feed, processed by the gravity flowsheet, contained 819 mg of gold for a calculated head grade of 4.8 g/metric ton (0.14 oz/ton), which compares very well to the head assay split grades of 4.46 and 4.80 g/metric ton.

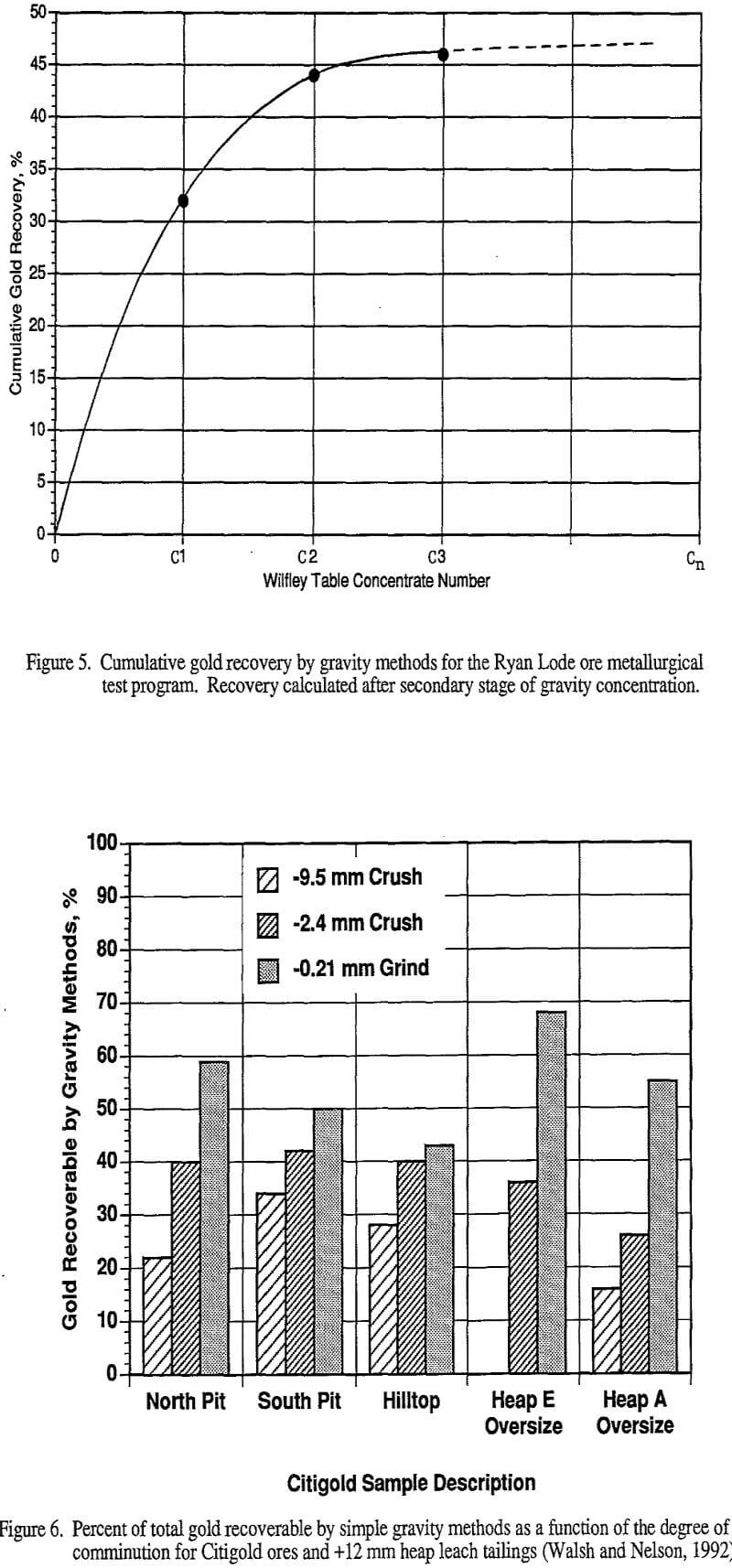

Table 3 shows that through the secondary stage of gravity concentration, the Wilfley table captured 377 mg of the total gold, or 46%. Figure 5 plots cumulative gold recovery by stage for the Wilfley table and indicates a gravity recoverable gold range of 45-50% at a grade of 343-514 g/metric ton (10-15 oz/ton). Wilfley table concentrates can be further upgraded on the Gemeni table with little gold loss, Table 4. Given that a regrind circuit is employed at the tertiary stage of gravity concentration, gold grades in excess of 3429 g/metric ton (100 oz/ton) should be achievable, with overall gravity recoveries holding in the 45-50% range. This work agrees well with previous work by Walsh and Nelson (1992), shown in Figure 6, for a variety of Ryan Lode ores and heap leach tailings. Gravity concentrates will contain high levels of arsenic and antimony.

Each Gemeni table concentrate was observed under a binocular microscope prior to assaying. The Gemeni table concentrate from stage 1, showed gold of a crystalline nature both free and locked with quartz and sulfide minerals. Gold as coarse as 0.7 mm (25 mesh) was observed. Little flattening of the gold was noticeable and some wire gold was present. The Gemeni table concentrates from stages 2 and 3 were of a much finer size distribution; gold as fine as 20 microns was observed. Larger gold was also present, but this lacked the crystalline nature of the stage 1 concentrate gold, and had been flattened and enlarged by ball milling. Gold locking with guange and sulfides was not so readily apparent as in the stage 1 concentrate.

The combined classifier overflow solids leached well at a reasonable cyanide level and lime consumption, yielding an 89% gold recovery in the 48 hour bottle roll tests; Table 5. Combining this gold yield with that after the secondary stage of gravity concentration (45%) indicates an overall gold recovery of 94% for a milling circuit employing gravity concentration and agitated tank leaching. Soluable gold loss was not considered in this study. Taking into account the barren silica sand dilution of the classifier overflow solids, the grade of the Ryan Lode material advancing to the classifier overflow stream was approximately 3.1 g/metric ton (0.09 oz/ton).

Notes:

1 Cyanidation bottle rolls conducted at ph 10-11,4 lb/ton cyanide, for 48 hours.

2 Cyanidation bottle rolls conducted at ph 10-11,1.7 lb/ton cyanide, for 48 hours. Consumed 3.75 lb/ton lime.