This furnace is designed especially for the oxidation of sulphur or arsenic in pyritic ores, but may be used for all oxidizing or desulphurizing operations, and for calcining, roasting and chloridizing ores, or for drying ores in large quantities preparatory to treatment by magnetic separators or otherwise. It is of the tabular, revolving type, with automatic feed and delivery, and is a modification of the Cornish calcining furnace, designed by Brunton, from which it differs, however, not only in construction, but in two or more radical features, for which novelty is claimed and patents have been applied for. The principal of these novelties are:

- A series of concentric terraced floors, one above another.

- The introduction of superheated air upon the charge without contact with the fuel.

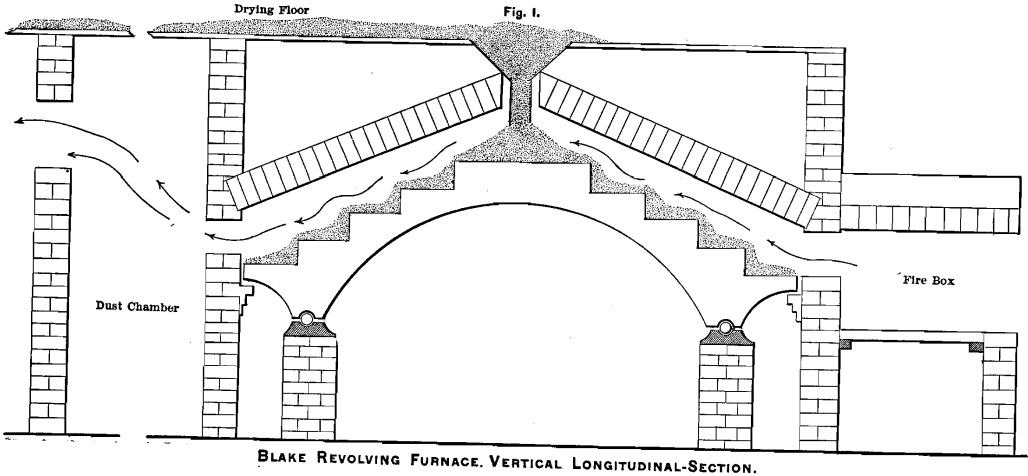

In the furnace which I have had in operation for more than a year the floor, or hearth, is a circular terraced table, sixteen feet in diameter, which is made to revolve slowly in a horizontal plane. It is covered with a layer of fire-brick, and the whole is supported upon cast-iron balls running in a grooved circular track twelve feet in diameter. The surface, as already indicated, is neither flat nor gently sloping from the center outwards, as in ordinary revolving hearths, but is built up in a series of annular terraces or concentric circular floors, making a series of steps rising from the outer edge of the hearth towards the center, as shown in the outline sketch (Fig. 1), which is a vertical section through the center of the hearth, including also the dome-shaped covering or roof of the roasting-chamber or oven, under and in which the hearth revolves, as also the drying-floor, dust-chamber, fire-place and outlet to the chimney or stack. The dust-chamber as shown is much contracted in order to bring it within the limits of the page.

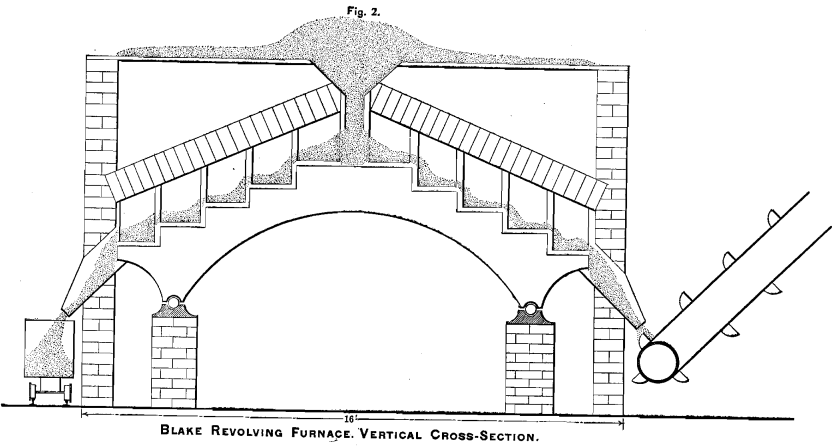

The terraces in a 16-foot furnace are 18 inches wide, except the upper one, which is 4 feet across or 2 feet in radius, and receives the ore as it descends from the hopper above. The height of the terraces or steps may be from 6 to 12 inches or more, according to the nature of the ore to be roasted. Ploughs or rabbles are fixed in the dome-shaped roof, two over each terrace, in a line at right angles to the plane of Sec. 1 (see Fig. 2). These ploughs being set at an angle of 45 degrees, turn the ore over in a succession of furrows as the table revolves, moving the ore constantly from the center outwards, taking it first to the edge of the central or highest terrace, from which it falls down to the next, within reach of the next plough. By this, after one revolution of the table, the ore is turned over into a furrow or ridge so as to lie within reach of the next plough, by which the ore is again thrown off upon the next lower floor or terrace, and so on successively until the ore is discharged over the lowest terrace into a spout, which delivers the hot roasted ore into a chain belt-conveyor or into an iron car. The ploughs are so placed that the ore turned over by one rests undisturbed until it has made a complete revolution with the table before it is turned by the next plough, or, if desired, it may be turned over at each half-revolution.

Fig. 2 shows the discharge of the ore at both sides, though in practice the discharge on one side only has been found preferable, the last plough on the opposite side being omitted. In the sketch only one plough is shown to each terrace, but two are preferred. The height of the ploughs is adjusted through the dome, but in the drawing these details are not shown, and for greater simplicity the brickwork of the dome is shown rather than the girder to which the ploughs are attached. The scale of Figs. 1 and 2 is approximately 4 feet to the inch.

The hearth is made to revolve slowly, generally not over ten revolutions in an hour, but its speed can be varied to meet the varying conditions of the heat of the furnace and the coarseness or fineness of the grains of the ore.

The fire-box for heating is placed at one end, opposite the outlet- flues of the chamber, and the flames, preferably of wood or of petroleum, are allowed to play freely across the table, while at the same time a large supply of pure superheated air is introduced into the chamber, giving an atmosphere of great oxidizing power and causing the rapid combustion of the sulphur vapor as formed and its removal as sulphurous acid. In most forms of roasting-furnaces little or no provision is made for access of pure air containing free oxygen, upon which oxidation depends. The gaseous products of the combustion of fuel contain but little free oxygen and are inert for oxidizing purposes. They dilute and impair an oxidizing atmosphere, and unless an excess of oxygen is present roasting cannot proceed. Ordinarily this does not appear to be taken into consideration, and roasting is effected more by the air which leaks in at the doors or open spaces than by the gases of combustion, which are presumably deprived of all free oxygen. The air so leaking in is cold and variable in quantity, and neither by its condition nor by its position with respect to the charge is it possible to obtain good results. Theoretically, the best conditions for free and rapid roasting are the requisite heat and an atmosphere equally heated but uncontaminated by the products of combustion. In practice, however, for economy of fuel for heating, these inert but hot gases of combustion may be allowed in the roasting-chamber, provided an excess of hot oxygen is supplied at the same time, which oxygen not only actively oxidizes the charge of ore, but also perfects and completes the combustion of any fuel-gases which have escaped combustion in the fire-box, and which otherwise would act as reducing agents on the ore, retarding oxidation rather than promoting it.

In roasting operations generally there is also too much dependence upon heat for the removal of the sulphur, with the result, of course, that the sulphur is not removed. If the operation proceeds too slowly, the heat is raised; and to effect this the furnace often has to be more tightly closed, thus excluding oxygen. With the proper atmosphere, roasting proceeds more rapidly at a lower temperature.

If we heat a charge of pyritic ore and then introduce a large volume of cold air, we supply the oxygen but chill the charge and check the oxidation; and in order to maintain the oxidation or combustion under such conditions of free access of cold air, the charge must be heated much hotter than will be required if we also heat the incoming air. In this furnace I have, therefore, not only made provision for the supply of large volumes of unvitiated air, but also for heating this air as hot as the charge upon which it is to act. The incoming air being thus heated, it is not necessary to over-heat the charge of ore, and the operation proceeds at a much lower temperature than is usually deemed essential in roasting operations.

By thus dividing the necessary amount of heat for rapid oxidation between the sulphur and the oxygen, the action is greatly facilitated and the result is far more satisfactory in every way; not alone in the more regular and perfect oxidation of the sulphur and the iron at a lower temperature for the mass of the charge, but with less danger of fusion or sintering, and with less wear and tear of the furnace. The advantages of roasting at a low temperature are especially manifested in the operation of roasting pyrite when mixed with blende and galenite, for which operation this furnace was primarily planned; for by it I am able to effect a complete oxidation of pyrite without injuring the blende and without fusion of the galenite. The desulphurization and oxidation by this combination does not, in fact, require more than a dull red heat, invisible by daylight; grains of galenite passing through the furnace are delivered with scarcely a tarnish upon the cleavage-faces; and the same is true of the blend, though it is possible to desulphurize blende in the same furnace by raising the heat and increasing the time.

For heating the pure air I make use of the Siemens accumulators, built in the usual form of brick checker-work, in two chambers. These accumulators not being in the plane of the section, are not shown in Fig. 1, but they are placed on both sides of the fire-box and are heated by a separate fire. The inlet-ports for the heated air are on the same level with the opening from the firebox, but are independent and are placed at intervals around half the circle.

The chambers are alternately heated and then opened for the ingress of air, which, after passing through the checker-work, arrives upon the charge in the chamber in a nearly red-hot state and not diluted by combustion-products, and instead of cooling the charge enters at once into combination with the sulphur or arsenic and increases the heat, but without fusion or matting. With such an atmosphere of superheated air, it is not necessary to use a high heat upon the hearth, and the oxidation proceeds rapidly and effectively, without any softening or fusion of the charge or any destructive action of the fire upon the hearth or dome. There is no agglomeration or sticking together of the grains of the ore. Such a furnace is very desirable and needs but few repairs. The fire-brick hearth and terraces, which have been in use for a year, are still uninjured and remain as clean and smooth as when put in. The function of the terraces is to expose more completely the grains of pyrite to the action of the heated air by causing them to fall through it, and thus exposing all sides at once to oxidation, and by aiding in the removal of the atmosphere of sulphur vapor which tends to surround each particle, especially when lying together upon the hearth of the furnace. The vapor of sulphur is heavy, and tends to lie upon and invest the fragments of the ore, but in good work in this furnace this condition does not exist. The vapor is not so easily removed by a current of air as by rapid oxidation. The hot oxidizing atmosphere disposes of it as fast as it is formed. In fact, there should not be any enveloping sulphur vapor; it should be oxidized into sulphurous acid within the pores or substance of the ore, and this is accomplished by the hot oxidizing atmosphere. The falling grains of ore give free access of air to all parts, and an outer envelope or crust of porous hematite is at once formed. This may account for the fact that the ore remains loose and granular throughout the operation, and is discharged without any traces of fusion. The useful effect of these terraces is well shown when the furnace is in operation; before any part of the charge begins to glow from combustion of the sulphur, the grains falling from one terrace to the next are seen to heat up to dull redness from the more rapid oxidation.

The furnace is self-feeding. After the dried ore is piled in the hopper it descends automatically by the action of the first rabble. The rate of feeding depends not only upon the speed of the table, but also upon the distance of the lower end of the feed-pipe from the top of the table. As the dried ore falls through the pipe it forms a conical heap, the breadth of which, at the base, is determined by the height of the pipe. The larger the pile of ore, the greater the quantity turned off by the first plough from the base of the conical heap, and more ore at once slides down to take the place of that so removed. One man easily attends to spreading the ore upon the drying-floor, and keeps the hopper full; the furnace-table does the rest.

With a 16-foot table and a free burning pyrite, like the marcasite of Wisconsin, from 10 to 20 tons can be put through in twenty- four hours, the quantity depending greatly upon the size of the fragments of ore, for the finer the grains the less the time required to remove the sulphur. In roasting the pyrite in blende-concentrates containing about equal parts of pyrite and blende, 20 tons is the usual product when running upon concentrates of the size of coarse sand or grains of wheat. For concentrates in which the fragments of pyrite are half an inch in diameter, a longer exposure is requisite, the speed of the table must be reduced, and 10 tons is a fair product. The most desirable size, when working upon zinc-ore concentrates, is about one-quarter of an inch in diameter.

A very important advantage in this form of furnace is the distribution of the charge over a constantly-widening area, from the center outwards, as the roasting proceeds. The charge is spread out thinner and thinner, instead of being thrown together upon itself, as in a revolving cylinder, where the area exposed to the action of the fire is not increased, but remains constant from one end of the cylinder to the other.

Very little power is required to turn the table of a 16-foot furnace ; it moves smoothly and noiselessly. The speed being under perfect control, the time of exposure of the charge can be varied according to necessity. If any of the grains of pyrite are delivered at the spout only partly roasted, the speed is slackened, by which, at the same time, the feeding is diminished.

Some of the advantages which this furnace is found to possess may be briefly recapitulated :

- Automatic feeding, rabbling, and delivery of the ore.

- Perfect control of the feed and rate of delivery.

- The spreading out of the charge over a constantly-widening area as the operation proceeds.

- Towards the close of the roasting the ore is brought nearer to the fire.

- Economy of fuel and labor.

- Few wearing parts, and durability.

- Rapid roasting at a low temperature.