Fly ash is extremely variable and heterogeneous in all respects except its fine size. Because of its production in huge quantities, it becomes significant as a potential raw material.

Fly ash is a finely-divided, widely variable, heterogeneous material most of which is formed by the solidification of molten droplets of inorganic substances in the cooler portions of a furnace fired with pulverized coal. It originates from the mineral matter of the coal. Some inorganic particles exist in fly ash, which have been freed of combustibles, but apparently have not encountered temperatures in excess of their softening points. Small quantities of coke-like entities, result from coal particles which have been combusted or carbonized to various degrees.

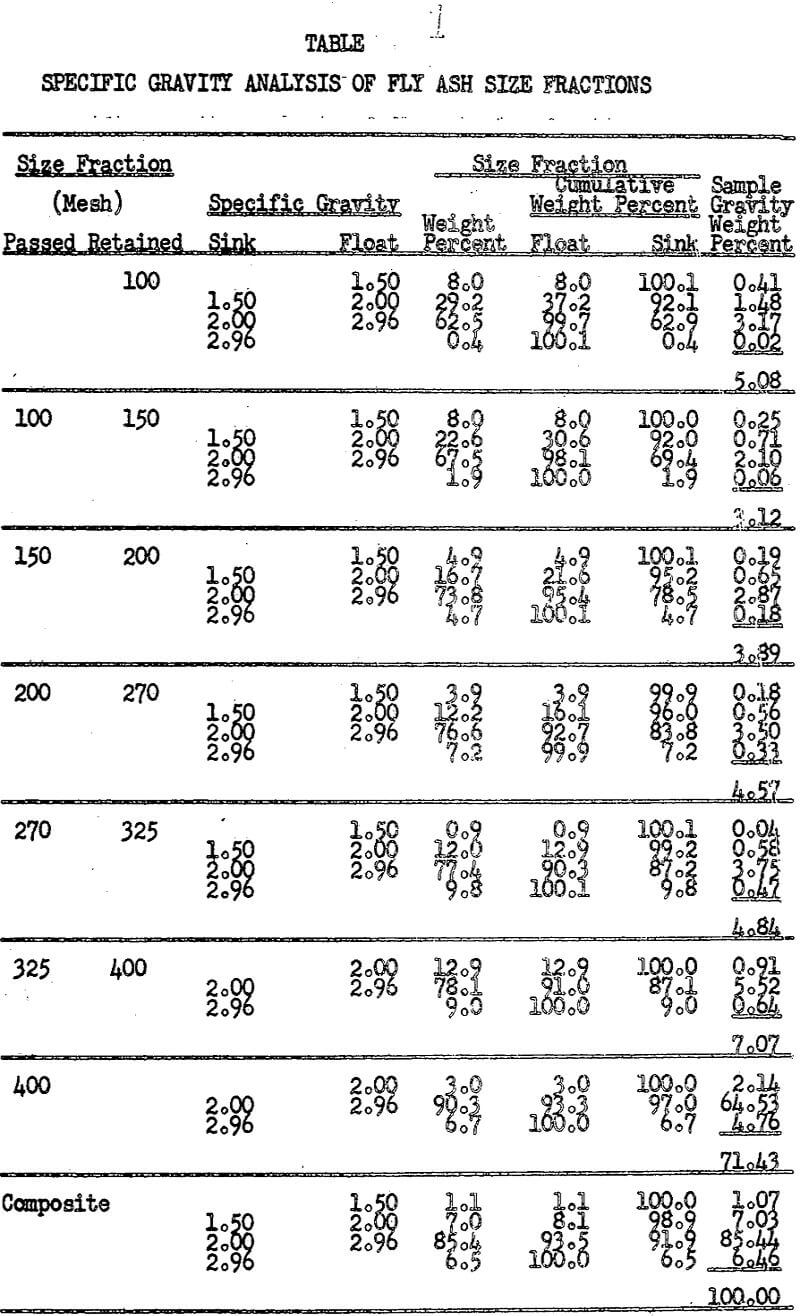

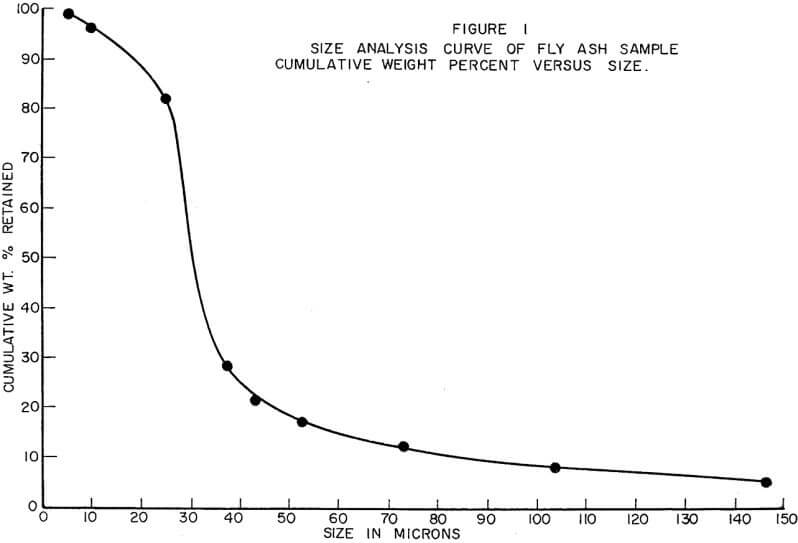

Particles larger than 400 mesh were separated by dry screening while smaller-sized grains were evaluated by optical microscopic study. Few measurements have previously been available on the subsieve sizes. Most significantly, the particles in this minus 400 mesh region, which comprise the bulk of most fly ashes, do not follow the usual distribution tendencies established by the larger sized grains but show a major fraction (75.2 percent of the minus 400 mesh) in the 25 by 37 micron grouping.

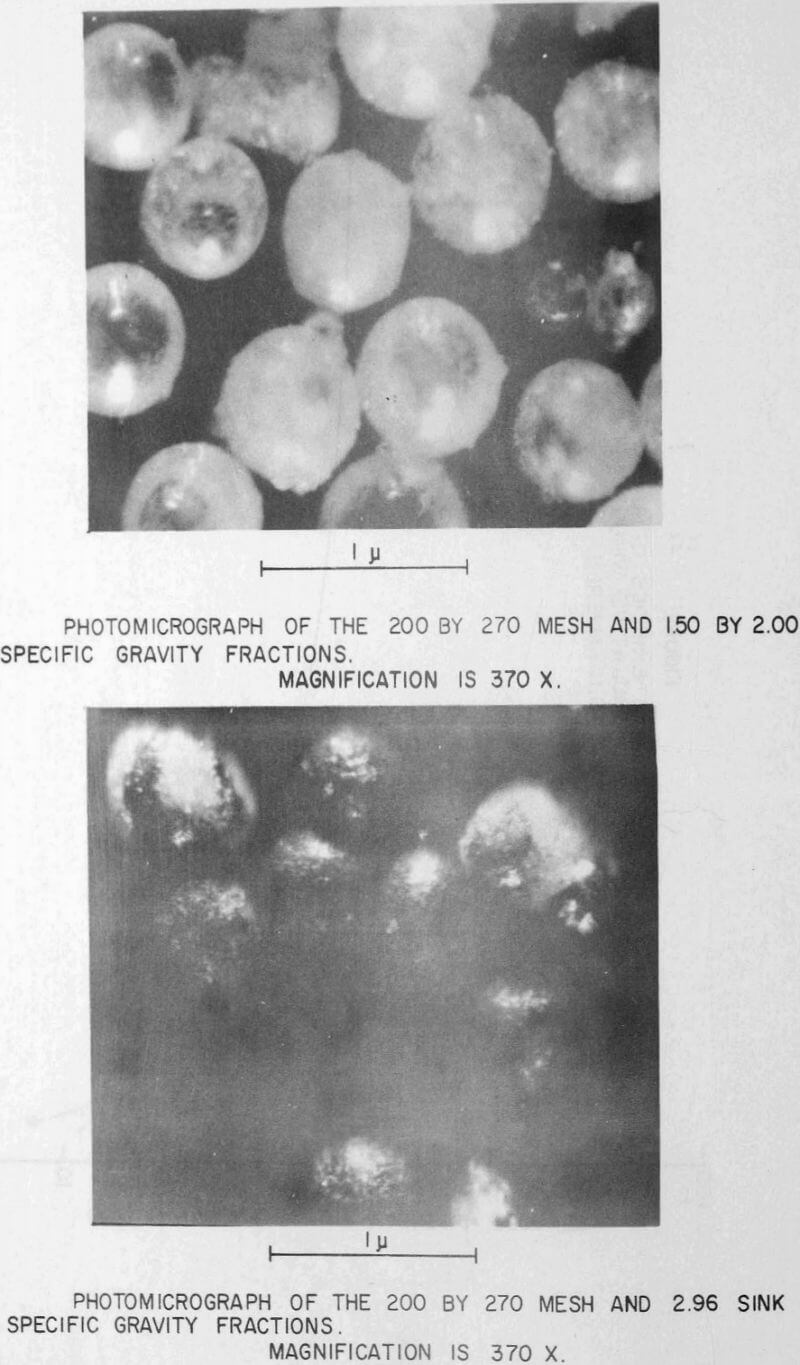

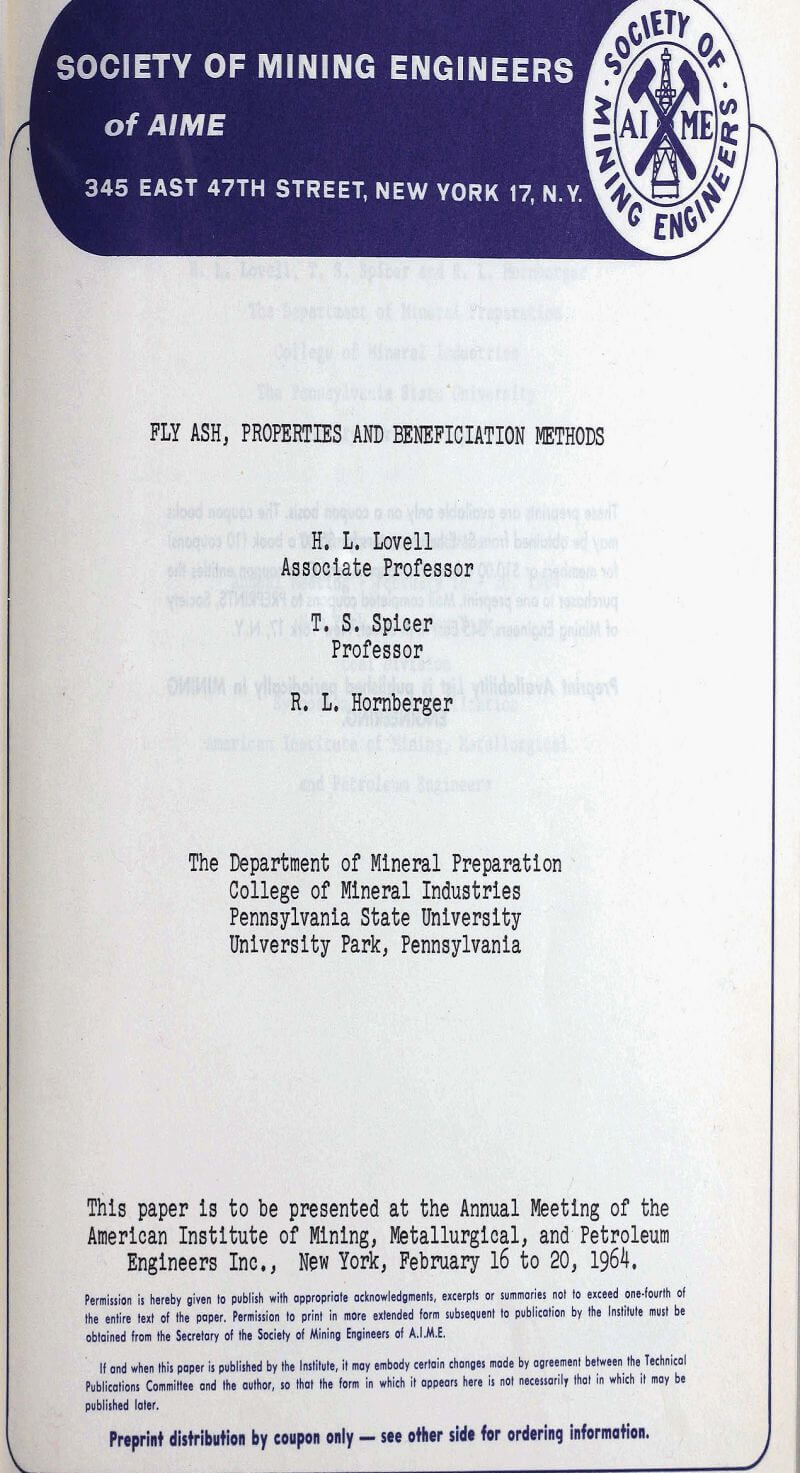

Most of the particles are perfect spheres, both solid and hollow, with smooth surfaces. Some have rougher, more irregular and apparently porous surfaces. Small number of particles exist as: (1) thin-walled polyhedrons sometimes called “cenospheres”, (2) irregularly fractured portions of original coal minerals, or (3) partially combusted or carbonized coal particles.

With the possibility of controlling certain fly ash characteristics directly by comminution or of comminution prior to further processing, a size stability study of the minus 400 mesh fraction was made. Samples were subject to extensive degradation for various times in a laboratory Wig-L-Bug and average particle sizes were measured with the Fisher Sub-Sieve Sizer.

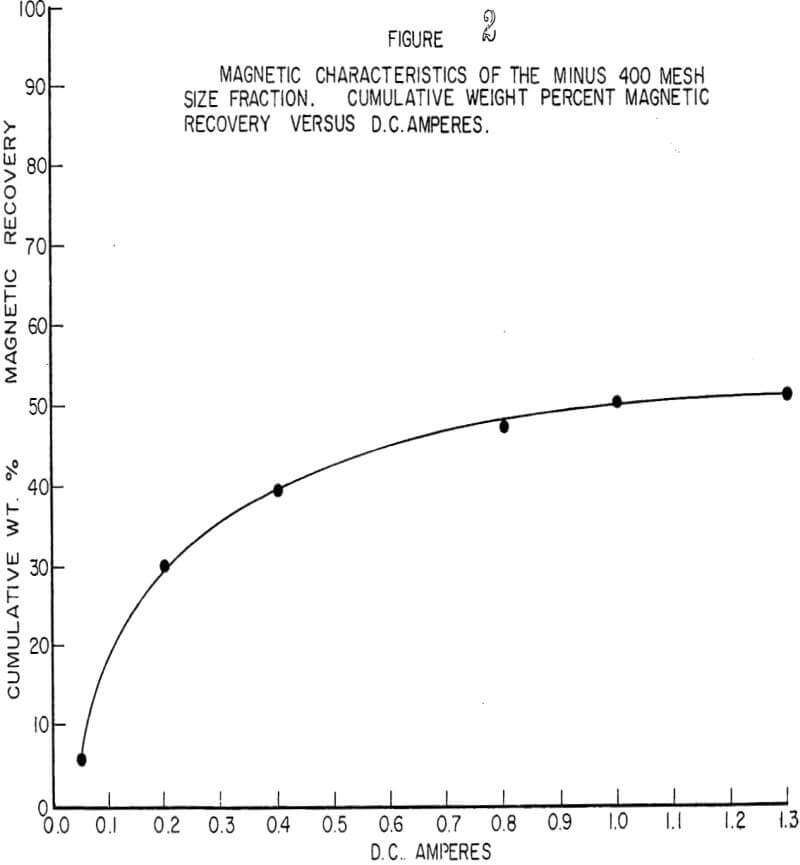

Although mechanical screening at extremely small sizes on a modest industrial scale is practiced, including fly ash sizing, it does not appear to be entirely satisfactory on a very large scale. Accordingly, air classification at 200 mesh has been considered using a laboratory device designed by R. L. Hornberger as a modified, dual, Buell-type unit. Strict sizing of the sample being considered at 200 mesh would yield an 87.9 percent fines product. It would contain 90.9 percent of the 2.00 sink material, 84.0 percent of the strongly magnetic fraction; and,an estimated 70 – 80 percent of the carbonaceous material.

Other fly ash properties, basic to potential benefication and use considerations are under study. Among these are: surface area, flow characteristics, hygroscopicity, solubility, absorptivity, wetting characteristics and characteristic chemical reactions.