Starting with rutile, containing more than 95% TiO2 and of the proper particle size, the commercial production of titanium tetrachloride via fluidized bed chlorination is relatively very simple and economical. As compared to shaft chlorination, it operates at a much higher capacity for given sizing of equipment, and appears more foolproof, requiring less attention.

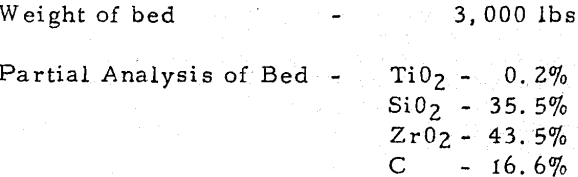

At the end of the campaign on February 15, a successful attempt was made to chlorinate the remaining TiO2 values in the bed. After stopping the rutile and coke feed, a sample of the bed was analyzed for TiO2. Chlorination was continued at decreasing rate over a period of six hours, until the calculated quantity of chlorine was fed. At this point, free chlorine began to appear in the off-gases. The bed was cooled, then emptied from the chlorinator.

A rutile utilization efficiency of 96% was reached along with 99% chlorine utilization efficiency in the fluidized bed unit.

The best efficiency obtained in the previous shaft chlorinator was:

89% rutile efficiency

90.8% chlorine efficiency

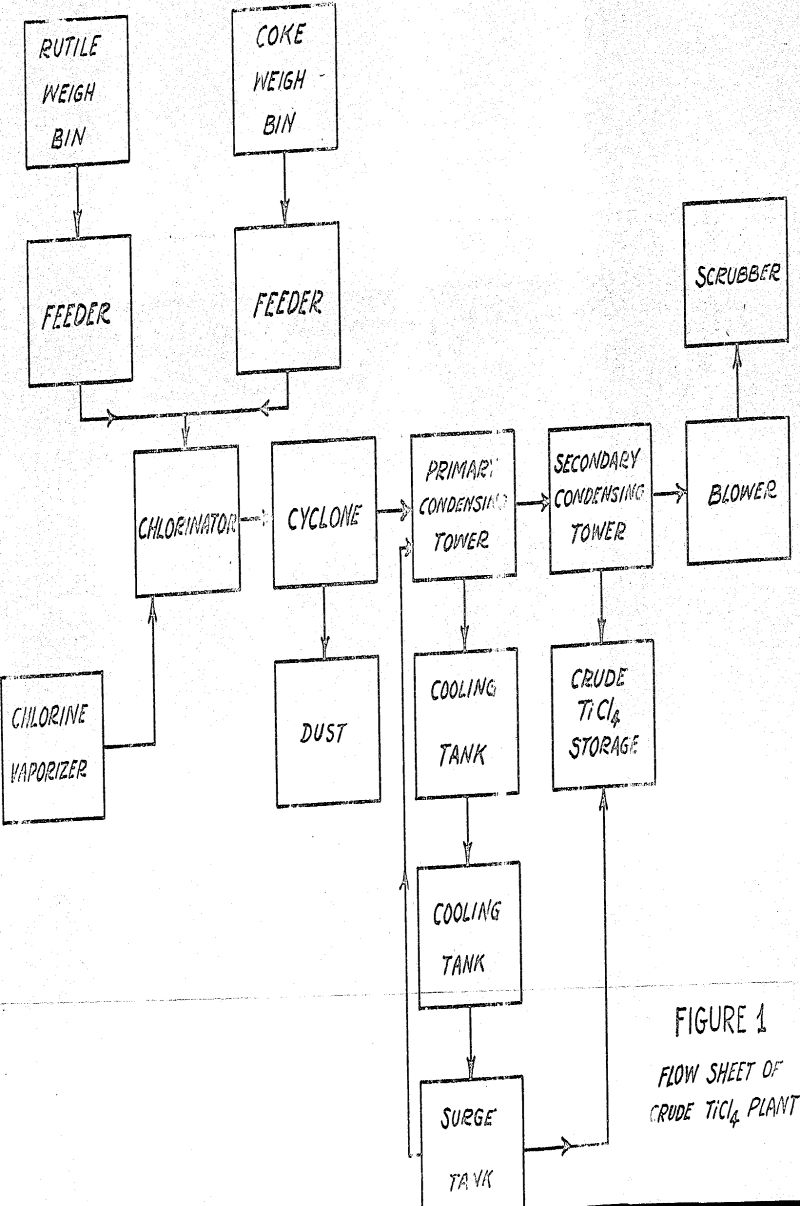

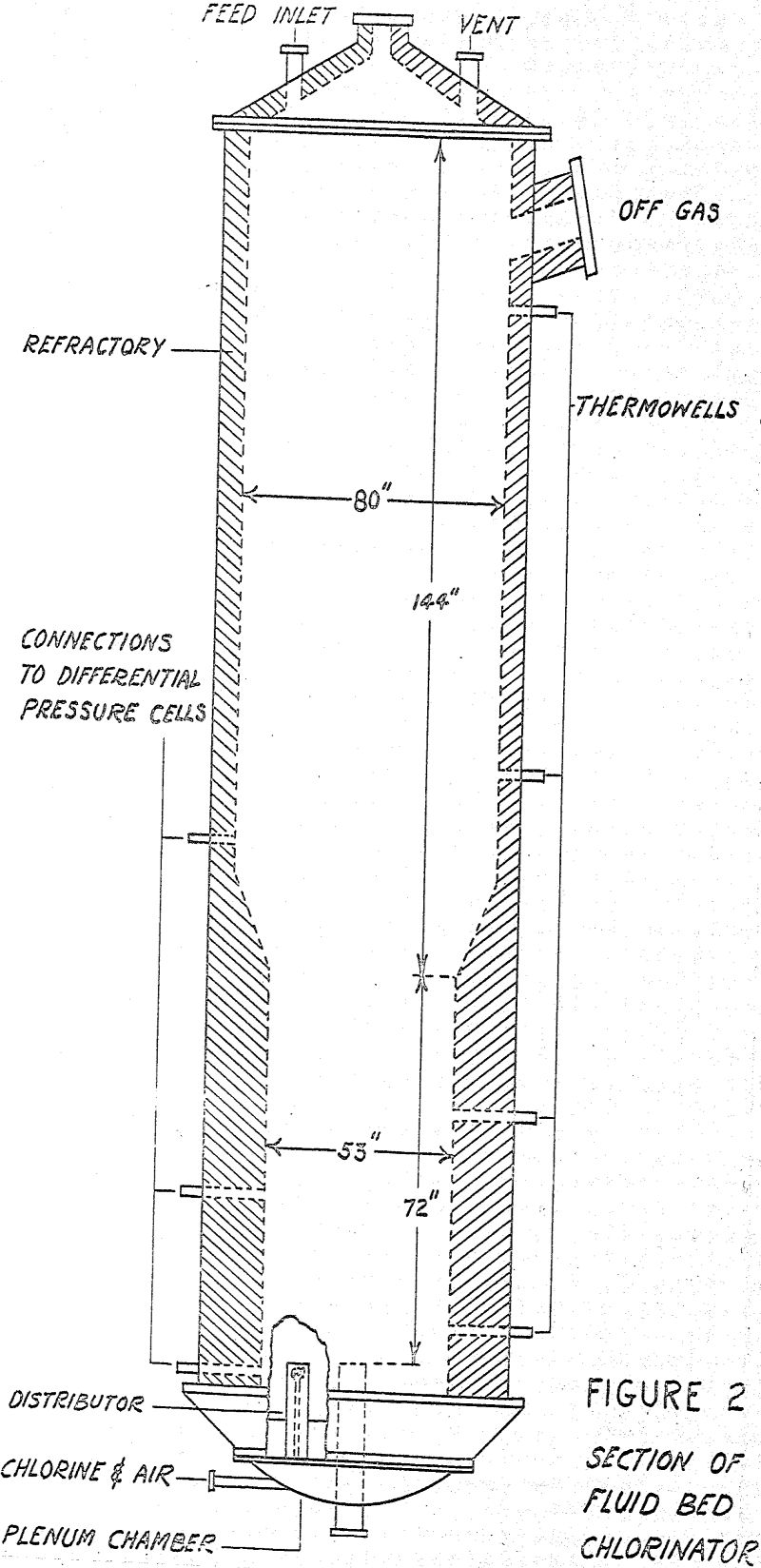

Rutile and petroleum coke were fed from weigh bins and entered the top of the reactor at room temperature. Chlorine and/or chlorine and air were fed directly from a chlorine vaporizer and the plant dry air system without pre-heat.

The desired temperature range of the fluidized bed during chlorination is 950 to 1000° C. Below 900°C free chlorine appears in the off-gases. The maximum temperature is limited to 1050°C in order to prolong the refractory life.

A higher heat loss results from operating with a deep bed. The tendency to slug is greater and the mass of material strikes the colder walls in the upper section of the reactor and is cooled. More heat is necessary to maintain a greater area at a higher temperature.

Finally, the production rate affects bed depth and a bed depth that is desirable in the following manner: first, a high production rate requires more chlorine, which, in turn, requires a reservoir of heat to raise its temperature to that level required for reaction.

During the heat up period, prior to chlorination, the off-gases are vented to the atmosphere. At the start of chlorination, the off-gas vent is closed and the gases pass through a hot cyclone dust collector then to the primary condensing tower. A draft of one inch of water (± ½ inch) is maintained in the chlorinator during chlorination.

Chlorine is fed to the reactor through the gas distributor system in sufficient quantity to give the desired titanium tetrachloride production rate. The rutile and carbon feed is adjusted accordingly. Bed samples are removed at four-hour intervals and analyzed for carbon.