Table of Contents

- Description of Samples

- Preparation of Samples

- Factors Affecting Flotation of Pyrite

- Kind and Physical Condition of Mineral

- Size of Mineral Grains

- Method of Pulverizing

- Kind and Physical Condition of Gangue

- Amounts of Oils and Reagents Used

- Pulp Dilution

- Method of Testing

- Tests on Mountain Copper Pyrite

- Effect of Addition Agents

- Effect of Tarnish or Surface Oxidation

- Tests on Chestatee Pyrite

- Tests on Sulphur Mining and Railroad Pyrite

- Effect of Size of Mineral Grain on the Flotation of Pyrite

This paper is a record of the first of a series of tests on sulfide minerals to be made by the metallurgical department of the University of California. The purpose of the tests here recorded is to determine the action of standard oils, oil mixtures, and addition agents on the flotation of pyrites. The question of the commercial value of pyrite was not considered.

Summary of Results

Of the twenty-two standard oils and oil mixtures, only four, Pentarco Nos. 350 and 400, acid sludge, and mixture A gave recoveries above 90 per cent., when tested on Mountain copper under the conditions given.

Considering both concentration and recovery, mixture A gave the best results. G. N. S. No. 17 gave the highest recovery of pyrite. Four of the flotative agents used, G. N. S. No. 20, G. N. S. No. 28, kerosene, and crude oil, had no action under the conditions of the tests.

The recovery of zinc, as sphalerite, is generally higher than that of either pyrite or chalcopyrite, using the standard oils and oil-mixtures tried.

The recovery of copper, as chalcopyrite, is variable; the highest recovery (93.2 per cent.) was obtained by the use of X cake and xylidine in alkaline solution. This reagent at the same time gave much lower recoveries for both pyrite (47.9 per cent.) and zinc (71.0 per cent.), thus indicating possibilities of differential or selective flotation.

Sulfuric acid was by far the most efficient of the modifying agents used. The increase in the concentration of pyrite is particularly noticeable. Sodium silicate was somewhat effective in causing a differential or selective flotation of copper, as chalcopyrite from pyrite by keeping pyrite from floating. Sodium hydroxide and sodium sulfide gave, in most cases, a distinct separation of sphalerite from chalcopyrite; i.e., a high copper and low zinc by suppressing the flotation of sphalerite.

Tarnish on the Mountain copper pyrite tended to prevent flotation.

Sulfuric acid was the most effective addition agent in removing the tarnish, and giving good recoveries of the pyrite, copper, and zinc.

The action of Pentarco Nos. 350 and 400, mixture A, acid sludge, and sulfuric acid on Chestatee pyrite, and Sulphur Mining and Railroad pyrite was similar to their action on Mountain copper pyrite.

The finer the material, the greater is the percentage of recovery; the pyrite should pass at least a 170-mesh screen in order to get efficient flotation under the conditions of the tests.

Of the many factors affecting flotation, only two—the oil and the other agent used—were made variable. The flotation agents used are given in the accompanying table.

X Cake and Xylidine, supplied by General Engineering Co.

Kerosene acid sludge (Standard Oil No. 1) as supplied by Standard Oil Co. Kerosene (ordinary) as purchased in market.

Fuel oil (topped residuum), sp. gr. 0.95, as supplied by Associated Oil Co. Stove oil (ordinary), sp. gr. 0.825, as supplied by Standard Oil Co.

The writer wishes to thank James M. Hyde, of Stanford University, for the suggestion concerning this line of investigation, and Dean Probert, of the College of Mining, of the University of California, for his constant assistance and encouragement. Mr. G. T. O’Brien, a senior student in metallurgy, assisted in some of this work. The samples of pyrite were donated by the Mountain Copper Co., Martinez, Calif., the Chestatee Pyrites and Chemical Corpn., Atlanta, Ga., and the Sulphur Mining and Railroad Co., Mineral, Va. A quantity of silica sand was donated by the Henry Cowell Lime and Cement Co., San Francisco, Calif. Samples of flotation oils were supplied by the Pensacola Tar and Turpentine Co., the General Naval Stores Co., and the General Engineering Co.

Description of Samples

Sample No. 1 was a portion of a lot of pyrite received from the Mountain Copper Co.; its analysis was as follows: Iron, 41.80 per cent.; sulfur, 48.50 per cent.; copper, 0.65 per cent.; zinc, 1.30 per cent.; insoluble, 7.25 per cent. The original sample, which contained 88.33 per cent, pyrite, was in large pieces, clean, and free from oxidized material. Associated with the pyrite was a small amount of chalcopyrite and sphalerite. For test purposes, this material was mixed with clean siliceous sand in the proportion of one to three. This test sample material is called sample mixture No. 1.

A portion of sample mixture No. 1 crushed to pass a 100-mesh Tyler standard screen was exposed to atmospheric oxidation for six months; it was then called sample mixture No. 1a.

Another portion of sample No. 1 was crushed through rolls to pass a 48-mesh Tyler standard screen instead of a 100-mesh screen; this material, called sample mixture No. 4, was used in the tests made to determine the effect of size of mineral grains on the flotation of pyrite.

Sample No. 2 was taken from the pyrite donated by the Chestatee Pyrites and Chemical Corpn. It was in lump form and clean and its analysis was as follows: Iron, 41.60 per cent.; sulfur, 48.00 per cent.; copper, 1.40 per cent.; zinc, 1.50 per cent.; insoluble 7.20 per cent.

It contained 86.49 per cent, pyrite and small amounts of chalcopyrite and sphalerite. A portion of the sample was mixed with clean siliceous sand; and in this form is called sample mixture No. 2.

Sample No. 3 was selected from the material donated by the Sulphur Mining and Railroad Co: In addition to a large amount of pyrite, it contained a noticeable amount of magnetite, biotite, muscovite, quartz, and small amounts of chalcopyrite and sphalerite; its analysis was as follows: Iron, 46.20 per cent.; sulfur, 39.50 per cent.; copper, 0.70 per cent.; zinc, 1.10 per cent.; insoluble, 9.00 per cent. It contained 71.76 per cent, pyrite and for these tests it was mixed with clean, siliceous sand.

Preparation of Samples

After each sample was mixed with clean siliceous sand in the proportion of about one to three, it was pulverized by rolls to pass an ordinary 100-mesh laboratory screen, except sample mixture No. 4, which was crushed to pass a 48-mesh Tyler standard screen. Each pulverized sample was then thoroughly mixed by rolling and subdivided into 500-gm. test portions, which were placed in large paper envelopes and held for laboratory tests.

To make certain that the material in each case was uniformly mixed and to determine the pyrite, copper, and zinc in each sample, a number of assay samples were taken during the subdivision into the 500-gm. portions, and analyzed. Analyses were run in triplicate and close uni¬formity of results in each set of samples were obtained.

Sample mixtures Nos. 1, 1a, 2, and 4 were practically free from iron compounds other than the pyrite and chalcopyrite, for which reason, and because of the rapidity and accuracy of the method, the pyritic content of the head and concentrate samples was calculated from the iron content by means of the factor 2.143, which represents the ratio of pyrite to iron in FeS2. Due allowance was made for the iron in chalcopyrite, which was calculated from the copper content.

The pyritic content of sample No. 3, head and concentrate, could not be obtained by this method because of the presence of iron compounds other than pyrite and chalcopyrite. Here the sulfur content was obtained, by the usual method, and multiplied by the factor 1.875, the ratio of pyrite to sulfur in FeS2. Due allowance was made for the sulfur in chalcopyrite and sphalerite, which was calculated from the copper and zinc contents.

The copper in all cases was determined by the electrolytic precipitation (battery) method, and the zinc by the ferro-cyanide method.

Factors Affecting Flotation of Pyrite

Among the factors affecting the flotation of pyrite, or any metallic sulfide mineral, are the following: Kind and physical condition of mineral; size of mineral grains; method of pulverizing the mineral; kind and physical condition of gangue associated with the mineral; kind of oil, oils or other reagents used as flotation agent; amount of oil, oils, or other reagents used; ratio of ore to water in pulp; percentage of

sulfide mineral in material treated; kind of water used, whether free from impurities or not; temperature of pulp; style of machine used.

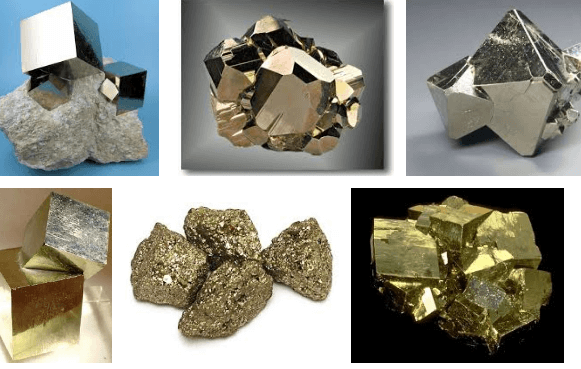

Kind and Physical Condition of Mineral

As is well known, practically all metallic sulfide minerals are readily floated. Any particular sample of a given metallic sulfide treated by flotation may give different results from another sample of the same sulfide because of differences in structure, surface oxidation, etc. In these tests, sample mixtures Nos. 1, 2, and 3 contained clean untarnished pyrite, and any differences in the results obtained are due to causes other than variations in surface oxidation. Sample mixture No. 1a was in all respects similar to No. 1, except that exposure to the air for six months caused the pyrite to become tarnished.

Size of Mineral Grains

The size of mineral grain best suited to flotation is the coarsest that will give the highest grade of concentrate with the greatest recovery, as, generally speaking, the finer the material the more readily and efficiently it can be floated, a balance must be obtained between recovery and cost of grinding. In these tests, preliminary work indicated that grinding coarser than 100 mesh would not give efficient results under any condition, while grinding to pass a 100-mesh screen resulted in efficient flotation under certain conditions.

In order to determine the effect of size of mineral grains on the flotation of pyrite, sample mixture No. 4 was thoroughly mixed and a number of 500-gm. portions weighed out. Tests were then made using the four oils or mixtures that gave the best results on the more finely ground sample. Sizing tests showing the distribution of the pyrite both before and after flotation are given in Tables 7 and 8. Sizing tests showing the distribution of pyrite in sample mixtures Nos. 1, 1a, 2, and 3 are given in Table 1. These results show that, in the material treated, a close degree of uniformity—as to size and distribution—was maintained in these mixtures; and although the material was ground to just pass a 100-mesh screen, the fineness secured approximates that usually obtained on a large scale when tube mills and wet grinding are the rule.

Method of Pulverizing

The method of pulverizing the material may affect the results. Dry crushing in machinery other than rolls is likely to produce surface oxidation, particularly in the case of pyrite and chalcopyrite, which may interfere with efficient flotation. In these tests all material wag crushed by rolls. It was recognized that wet crushing in a ball or similar mill would be more in accordance with practice but difficulties in the preparation of small samples prevented this method of pulverizing.

Kind and Physical Condition of Gangue

This factor might easily cause the success or failure of a flotation mill. In these tests, the material that most often occurs as gangue (silica) was used. Therefore, clean siliceous sand was used in the preparation of the sample mixture and this factor was kept constant throughout all the tests.

Oil and Reagents Used

The kind of flotation agent used is, perhaps, the most important factor in flotation work. In these tests no attempt was made to investigate the constitution of flotation agents. Rather the oils and other agents were selected because of their extended commercial use and the possible results to be obtained.

The effect of a large number of flotation agents was studied in connection with sample mixture No. 1. Those agents showing the highest, grade of concentrate and recovery were used in tests on sample mixtures Nos. 2, 3, and 4. The effect of modifying agents, as distinguished from flotation agents, was studied in connection with sample mixtures 1 and 3.

Amounts of Oils and Reagents Used

Generally speaking this factor was a constant in these tests. The amount of oil required to produce a maximum recovery did not in any case exceed 0.15 per cent, of the amount of ore taken. This amount of oil was used in all the tests recorded. As stated above, certain accessory or modifying agents were used in connection with the oils; the amounts used are indicated in the tables.

Pulp Dilution

The ratio of pulp to water in flotation work is generally given as 1 to 3 or 5. With the type of machine used, it was found that a ratio of 1 to 7 (500 gm. of pulp to 3500 c.c. of water) gave better results in a shorter time than when a ratio of 1 to 3 or 5 was used. This factor was kept constant at 1 to 7 in these tests.

Percentage of Sulfide Present

The percentage of pyrite or other sulfide mineral in an ore would, to a certain degree, affect the other factors. Hence in these tests the amount of pyrite in the material treated was kept within 15 to 25 per cent.

Purity of Water Used

The purity of water used in flotation work may have a very important effect on the results to be obtained; in these experiments ordinary city water was used.

Temperature of Pulp

The temperature of the pulp during flotation may affect the action of certain reagents; in these tests the pulp was at room temperature (20 to 25° C.)

Style of Machine Used

Several styles of flotation machines suitable for laboratory testing are on the market. Most of these machines give thoroughly satisfactory results, but are of complicated construction and difficult to clean and keep in order. The machine used in these tests was built to specifications furnished by J. M. Hyde. It is a mechanically agitated froth machine, simple in construction and convenient. Rapid and thorough cleaning is possible; and aside from the lubrication of one bearing it requires no attention to keep in order. In these tests a speed of 1565 r.p.m. for the impeller was maintained. The action of the machine is largely dependent on the height of the impeller, a variation of ½. in. will, change entirely the results obtained. A clearance of 3½ in. between impeller and cell bottom gave the best results under the conditions governing the tests.

Method of Testing

In these tests an endeavor was made to have all conditions identical, except those pertaining to the material tested and the flotation agent used. Before starting any test, the machine is thoroughly cleaned, 3½ liters of ordinary city water at room temperature is then poured into the agitation cell and, after the motor was started, 500 gm. of the material to be tested, care being taken to avoid loss by spattering. Any chemical modifying reagent to be used is now introduced into the cell and agitation continued for 1 min. Next 2 c.c. of flotation oil is introduced into the cell by means of a pipette and agitation continued for 5 min. Any froth collecting in the spitzkasten is skimmed off, 0.2 c.c. more of oil is added and the agitation continued for another 5 min., when the froth, if any, is removed as before. This addition of oil and removal of froth is repeated until 1 c.c. of oil has been added, the total running time with oil being 25 min. The water, etc., are then run into a second pan and finally discarded. When the machine is again scrubbed and cleaned, it is ready for another test.

The froth concentrate is filtered through a Buechner funnel using two sheets of filter paper, which with the concentrate is carefully dried in a steam bath and the weight of concentrate determined. The concentrate is then thoroughly mixed, placed in a paper bag, and later analyzed.

A certain amount of water is removed with the froth, thus lowering the water level in the machine. Therefore, water is added from time to time during the test, to maintain the proper level. The appearance of the froth in the spitzkasten is of special significance in flotation testing.

The size and persistency of the bubble, the thickness of the froth, and the amount and nature of the load are indicative of the action of the flotation agent.

Tests on Mountain Copper Pyrite

Twenty-two standard flotative agents, including four standard mixtures, were used in the tests recorded in Table 2. The test material

(sample mixtures Nos. 1 and 1a) gave the following analysis: Iron, 10.59 per cent.; sulfur, 11.95 per cent.; copper, 0.16 per cent.; zinc, 0.32 per cent.; insoluble, 73.60 per cent. The pyrite content may be calculated from the ratio FeS2 : Fe = 120 : 56 = 2.143 : 1, after allowing for the iron in the chalcopyrite. Thus in the above sample mixture, the Cu-Fe S2 containing 0.16 per cent, copper contains 0.14 per cent, iron, which deducted from 10.59 leaves 10.45. This .multiplied by 2.143 gives 22.40 as the per cent, of pyrite in the mixture.

Some flotative agents, particularly those containing viscous ingredients like coal tar, while giving excellent results in practice when the oils etc. are thoroughly mixed with the pulp by being introduced into the tube-mill or other grinding device, practically failed in this investigation when used direct in a laboratory testing machine. An excellent flotation reagent would give (from the standpoint of concentration) 100.00 per cent, recovery and a clean concentrate of pure sulfide, but that ideal condition would presuppose the freeing of all sulfides from the adhering gangue.

Considering the tests made, the reagents used in Tests 2, 6, 15, and 19 would seem to be the best under the conditions of operating.

Effect of Addition Agents

Tests Nos. 2, 6, 15, and 19 were repeated, and the effect of adding different addition agents noted. These results are recorded in Table 3. On the samples tested, sulfuric acid tends to produce a cleaner concentrate and a higher recovery, and to decrease the amount of oil necessary. However, its effect varies according to the material and the kind of flotation agent used. The results for copper varied, but on the whole were better than those obtained without the use of acid. The results for zinc are decidedly lower than those obtained without acid. The froth in the four tests was characterized by its clean, metallic appearance. No attempt was made to determine the effect of sulfuric acid on the oil consumption.

Sodium hydroxide has been used in flotation practice as a modifying agent with beneficial results; with the material used in these tests, no unusual effect was expected. Lime is not desirable as an addition agent with the material tested; although voluminous froth was produced, the load was comparatively light. Bleaching-powder, as an addition agent, acts like sodium hydroxide and sodium sulfide; it is essentially a gangue lifter. When copper sulfate is used with acid sludge, there is a material increase in the amount of gangue floated. Of all the addition agents used (except sulfuric acid), sodium silicate would seem to have some value in differential flotation.

Effect of Tarnish or Surface Oxidation

An examination of the sample mixture exposed to the action of atmospheric agencies for six months, under the microscope, showed the sulfide particles to be highly tarnished. Tests run, using those agents that on the fresh material gave good results, gave such poor results that it was thought advisable to try the effect of the different addition agents used in the first series of tests. The results are given in Table 4.

Flotation agents, Pentarco Nos. 350 and 400, acid sludge and mixture A, that gave excellent results on the fresh sample, gave poor results on the tarnished sample, except for the recovery of copper by means of acid sludge, which was in test No. 53. In test No. 63, using Pentarco No. 400 and sodium silicate, there is a decided differential flotation effect, giving high copper and zinc recoveries with low recovery of pyrite.

Tests on Chestatee Pyrite

The test material (sample mixture No. 2) on which the following tests were made, was prepared by mixing one part of Chestatee pyrite and three parts of clean siliceous sand. Its analysis is: Iron 11.34 per cent.; sulfur, 12.07 per cent.; copper, 0.37 per cent.; zinc, 0.40 per cent.; insoluble, 70.65 per cent. Since no iron compounds, other than pyrite and chalcopyrite, were present, the pyrite was calculated from the ratio FeS2 : Fe = 2.143 : 1, after deducting the iron held by the chalcopyrite, as in sample mixture No. 1; the pyritic content in sample mixture No. 2 was found to be 23.60 per cent. The tests were run precisely as in the case of the Mountain Copper sample.

Acid sludge gives a much different result from that obtained with Mountain Copper pyrite. Not so much gangue is floated in this test, but the concentration for pyrite is higher. The recoveries, except of copper, are decidedly lower. This test was repeated a number of times with no different result. Possibly there was some variation in the manner of adding the reagent, resulting in a difference in contact between oil and material in the mixing cell.

Only one modifying agent, sulfuric acid, was used. It seemed to have a disturbing effect on the action of mixture A. A great deal of gangue was lifted, resulting in a low concentration of pyrite, although the recovery is excellent. The recovery of copper is higher, and that of zinc slightly lower than before.

The results, on the whole, while similar to those obtained when testing Mountain Copper pyrite, are not so good.

Tests on Sulphur Mining and Railroad Pyrite

Sulphur Mining and Railroad pyrite was mixed with clean, siliceous sand, in a manner similar to the sample mixtures prepared with Mountain Copper and Chestatee pyrite. The sample mixture (No. 3) then gave the following analysis: Iron, 8.84 per cent.; sulfur, 7.79 per cent.; copper, 0.13 per cent.; zinc, 0.21 per cent.; insoluble, 81.44 per cent. As this material contained iron minerals other than pyrite, it was necessary to calculate the pyrite from the ratio FeS2 : S2 = 1.875 : 1, after deducting the sulfur held by the chalcopyrite and sphalerite. According to the above calculation the pyrite content of sample mixture No. 3 is 14.20 per cent. Tests similar to those recorded in Table 5 were made on this material. The results obtained with this pyrite, shown in Table 6, compare favorably with the results obtained under similar conditions with both Mountain copper pyrite and Chestatee pyrite. In every case but one, the recovery of pyrite is over 90.0 per cent. The recovery of copper is uniformly good. The addition of sulfuric acid was of no advantage.

Effect of Size of Mineral Grain on the Flotation of Pyrite

Sample mixture No. 4, used in these tests, was prepared in a manner similar to sample mixtures Nos. 1, 2 and 3, except that it was crushed to pass a 48-mesh Tyler standard screen. A partial analysis of the mixed and crushed sample showed 10.70 per cent, iron and 0.18 per cent, copper. From this, the pyrite content was calculated to be 22.59 per cent, or 112.95 gm. in 500 gm. of the sample mixture.

In Fig. 1, the curves show the relation between the total pyrite recovered for each screen size (except the through 200) and the screen opening. For any particular screen size the per cent, of pyrite remaining on this screen plus the per cent, remaining on all the preceding (coarser) screens is given.