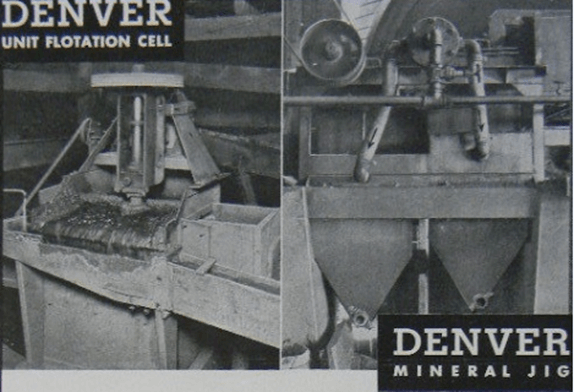

HIGHER RECOVERIES ALWAYS RESULT when freed mineral is removed from the fine grinding circuit. Here are the two profit making machines which have today made this step standard practice in milling plants the world over. The Denver unit Flotation cell has definite place in every flotation plant where lead, copper, zinc or other sulphides are concentrated. On gold ores the Denver Unit Flotation Cell immediately removes the free flaky mineral values and sulphides in a clean high grade concentration. This is the only flotation cell which successfully treats the grinding mill discharge. The exclusive gravity flow principle of the Denver “Sub-A” Flotation Machine makes possible the circulation of material as coarse as ¼ without choice-ups. Rubber cell liners molded rubber impeller and hood wearing plate give continuous “24 hour service per day”.

The Denver Mineral Jig gives additional profits in any gold milling plant whether cyanidation, flotation, or gravity concentration is the process used. Where tree values are present, they are recovered in a small bulk of high grade concentration, ideal for amalgamation treatment. In cyanide circuits the Denver Mineral Jig is often used to remove a bulk sulphide concentrate for retreatment or shipment to the smaller. This is not just another Jig. Sealed plungers together with rotating water valve entirely eliminate excess dilution found in other gravity devices and methods. Removable screen compartments with non-blinding screens plus rugged steel construction, insure continuous trouble-free operation. Write us today!