Table of Contents

The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores, and it is generally more efficient as regards the recovery of the minerals than any other process applicable to the treatment of similar types of ores. The metallic contents of the minerals are recovered from the concentrates in a subsequent series of metallurgical operations—e.g., smelting, refining, etc. —the final product of ingot metal constituting the manufacturer’s raw material. There are very few cases where a flotation concentrate is marketed direct without further treatment. As a rule, a flotation plant comprises one stage in the series of operations for extracting the metallic constituents of an ore with the final production of one or more marketable metals. It receives the crude ore from the mining department, and delivers one or more concentrates of sufficiently high grade and in a suitable form to the next department where the extraction of the metals is commenced, generally, but not necessarily, by smelting or leaching.

What is Ore

Ore may be defined as rock containing enough mineral of economic value to make its extraction from the remainder commercially profitable. There may be more than one type of mineral in the ore and not all of them may be of economic value ; those of economic value are often termed VALUABLE MINERALS, the remainder of the ore being classed as GANGUE.

In the process of extraction it is frequently desirable to collect the valuable minerals in the form of a CONCENTRATE which should contain the bulk of the minerals with the least possible amount of gangue. More than one concentrate may be made if the ore contains two or more types of valuable mineral and it is possible to extract each of them separately. That part of the ore which does not enter a concentrate is finally rejected as a TAILING.

What Ore is Suitable for Flotation

The largest class of ores treated by the flotation process consists of those containing the sulphide minerals of copper ; these sometimes contain native copper and also gold and silver, all of which can generally be floated with the sulphide minerals in one concentrate. Any pyrite or other iron sulphide present can usually be prevented from floating and made to pass out of the plant in the tailing. The oxidized minerals of copper, chiefly the carbonate, can be extracted from ores containing them by methods which differ somewhat from those required for the flotation of the sulphide minerals ; the flotation of ores in which sulphide and oxidized minerals occur together has not been very successful up to the present.

The second largest class of ores amenable to flotation are those containing the mixed sulphides of lead and zinc with or without pyrite.

By modern methods it is generally possible to remove separate concentrates in successive stages of flotation, each concentrate containing one of the minerals more or less uncontaminated by the others. The treatment of an ore in which a lead or a zinc sulphide occurs alone is normally a simple matter, but most of these ores are concentrated by other methods. The oxidized minerals of lead can generally be concentrated by flotation but require a special method of treatment; their occurrence is comparatively rare. The use of flotation to supplement or replace the cyanidation of gold and silver ores is slowly increasing.

Standard Flotation Procedure

Although the method of treatment of every individual ore may present problems which demand special consideration, the general procedure for the flotation of each of the above classes of ore has become to a large degree standardized. In this volume only those methods of milling and flotation are described which can be reduced to a more or less standard basis ; the few special methods included are developments of standard procedure and indicate the trend of progress. Many minerals in addition to those already mentioned can be concentrated by flotation, such as molybdenite, graphite, sulphur, and even coal, but their treatment calls for specialized methods.

Flotation Plant

The actual process of concentrating the minerals by flotation is but one of a sequence of operations, a complete flotation plant comprising five of these:

- crushing

- grinding,

- flotation,

- concentrate filtration, and

- tailing disposal sections.

In the crushing section of the plant the ore from the mine is broken down to about 3/8-in. size in two or three stages without the use of water except as a spray to remove dust, this being the economical limit of dry crushing machinery in modern practice.

The crushed product is then delivered to the grinding section where it is mixed with water and ground in one or two stages to the required size. As a rule, a pulp containing particles larger than 48 mesh (0.295 mm.) is not suitable for flotation, nor is it common for the ore to be ground to a product finer than that at which 95% will pass through a 200-mesh screen (0.074 mm.). The size of the finished material usually lies between these two limits.

The reduction of the ore by dry crushing followed by wet grinding is essential to successful flotation. The size is correct if it is fine enough to release the bulk of the mineral from the gangue without the production of an undue amount of slime. The last stage of reduction must take place in water in order that every fresh surface exposed during the grinding, whether of metallic or rock-forming mineral, shall be immediately wetted. Wet grinding of the ore is therefore a necessity quite apart from the fact that it is also the most economical method.

During or immediately after grinding, and before the actual operation of flotation which follows, certain oils and chemicals are mixed with the ore pulp. These reagents have distinct functions and are added for three purposes : (1) To affect the faces of the minerals to be floated in such a way that they will adhere to the air bubbles introduced into the pulp in the flotation machines, (2) to stabilize these bubbles in order to render possible the formation of a sufficiently coherent froth, and (3) to render unwanted metallic and rock-forming minerals unfloatable. The bubbles of air, sucked or blown into the pulp in the flotation machines, become coated with mineral and rise to the surface where they collect in the form of a mineralized froth. This primary concentrate, in which the bulk of the mineral is collected, continuously flows or is scraped over the lip of the machine into a collecting launder. If a product clean enough to be passed on to the next department cannot be produced in a single stage of flotation, the primary concentrate is re-treated in a similar but smaller machine to remove impurities as far as possible.

The final concentrate is filtered to remove most of the water. The dried product then leaves the flotation plant and passes to the smelting, leaching, or other metallurgical reduction section.

The disposal of the tailing, usually by thickening and settlement with recovery of the water, comprises the last stage in the treatment of the ore.

It is an almost universal custom to run the crushing section for one or two eight-hour shifts only per day so as to have time available for inspection of the machinery and any necessary repairs. The fact that crushing machines can be started and stopped without much loss of time makes this arrangement possible, since within a few minutes of being started they will be working at full capacity. This is one of the main points of difference between the crushing section and those that follow it. It takes hours instead of minutes to work the grinding and concentrating sections up to full capacity and efficiency, and it is therefore essential to keep them running continuously with as few stops as possible. For this reason the whole of the flotation plant with the exception of the crushing section is kept running for 24 hours per day.

PNEUMATIC FLOTATION

Early in 1909, I did a great deal of work with the Macquisten flotation process and in the installation of the tube-plant of the Morning mill at Mullan, Idaho. This work was followed by a large amount of experimenting on the different kinds of existing flotation processes, the outcome of which was the development of the pneumatic method.

The first application of pneumatic flotation for the treatment of ore was made by me at the mill of the National Copper Co. at Mullan. This plant was designed and built by me and was a success in every way from the very start.

Since that date, the method has been adopted by nearly all the other mills in the Coeur d’Alene treating lead and lead-zinc ores, notably the Gold Hunter, Morning, Hercules, Bunker Hill & Sullivan, Caledonia, Last Chance, Hecla, Standard, etc., a total of about 50 cells in all, treating from 1500 to 2000 tons of slime and fine sand per day. The same method also has since been adopted by the Inspiration, Arizona. Anaconda, Magma, and other copper companies, and by the Silver King, Daly-Judge, Duquesne, and El Rayo mining companies, on lead, zinc, and other ores, making a total of some 680 cells in operation or in the course of erection, having a combined capacity of 25,000 to 28,000 tons per day.

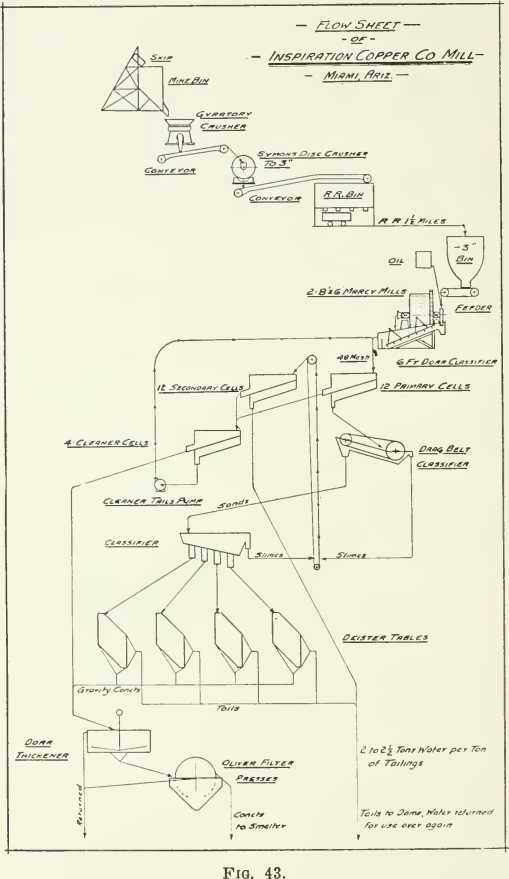

The flow-sheets of the Inspiration and the Arizona Copper plants are given in Fig. 43 and 44. The Daly-Judge flow-sheet, in Fig. 45, is an interesting example of the recoveries possible on zinc-lead, fine sand, and slime. The accompanying diagram, Fig. 46, illustrates the various elements composing the Callow method.

A is a mixer operated by compressed air for the purpose of mixing and emulsifying the oil, the air, and the water, the same type of apparatus being in common use in cyanide work. In cases where the oil or frothing agent can be fed into the crushing machine or tube- mill, this mixer, or Pachuca tank, can be eliminated, so that the oil is fed direct into the mill and thence into the separatory cell.

It has been proved conclusively that agitation is not necessary to successful flotation by the pneumatic method. In one of the plants a Pachuca mixer for each four roughing-cells was installed. This received the thickened feed from a Dorr tank, which feed was elevated by a belt-and-bucket elevator. The oil was fed into the boot of the elevator and the mixing there served all purposes, since the results without the Pachucas were found to be just as good as with them. Therefore the use of them in this plant has been abandoned.

B is the initial or roughing separatory cell. It consists of a tank about 9 ft. long over all and 24 in. wide, with a bottom inclined at from 3 to 4 inches of fall per foot; it is 20 in. at the shallow end and 45 in. deep at the deepest end. It may be built of either steel or wood, preferably wood.

Fig. 47 and 48 show the cell in detail. The bottom of the tank consists of a porous medium made of four thicknesses of loosely woven canvas twill, properly supported by a backing of perforated metal to prevent bulging when under air-pressure. Through this porous medium compressed air is forced by the blower E. Porous brick or any other ceramic material may be used to ensure the necessary fine subdivision of the air. Some of these have been tried, but for practical and mechanical reasons the loosely woven canvas-twill seems to serve all purposes better than anything else, and has been adopted as the standard porous-bottom construction.

The space underneath this porous medium or bottom is subdivided into eight compartments, each connected by an individual pipe and valve with the main air-pipe F. By this means the air-pressure to each compartment can be regulated (by throttling the valve) to correspond with the varying hydraulic head within the tank, so as to discharge a uniform amount of air throughout the length of the bottom and maintain a uniform aeration of the contents. A pressure of from 4 to 5 lb. is generally used and each square foot of porous medium requires from 8 to 10 cubic feet of free air per minute.

The space underneath this porous medium or bottom is subdivided into eight compartments, each connected by an individual pipe and valve with the main air-pipe F. By this means the air-pressure to each compartment can be regulated (by throttling the valve) to correspond with the varying hydraulic head within the tank, so as to discharge a uniform amount of air throughout the length of the bottom and maintain a uniform aeration of the contents. A pressure of from 4 to 5 lb. is generally used and each square foot of porous medium requires from 8 to 10 cubic feet of free air per minute.

Each longitudinal edge of the tank is provided with a lip and an overflow gutter for the reception of the froth to be discharged. The lower end of the tank is furnished with a spigot-discharge fitted with a plug-valve, operated by a float, for the purpose of maintaining a uniform water-level within the tank, thus in turn securing a uniform and constant discharge of froth under all the varying conditions of feed incident to practical milling operations. The water-level may, of course, be varied; but it is usually maintained at about 10 to 12 inches below the level of the overflow-lips. The tailing is discharged through the spigot and the frothy concentrate is conveyed by means of the side-gutters to the pump D-1, thence to the cleaner-separatory cells marked C. This cleaner-cell is a machine of the same construction as the rougher; in operation, however, it is usually run with a lower air-pressure; the tailing from the cleaner is pumped by D-2 back to the original feed, and thus a closed circuit is maintained on this portion of the feed. The concentrate from the cleaner is the shipping or finished product. Dump D-1 can well be eliminated by setting the cleaner at a lower elevation and conveying the rougher-froth to it by gravity. Usually one cleaner serves four roughers.

PARALLEL OR SERIES

The machine may be run either in parallel or in series without any sacrifice in capacity for a given number of cells. Recent experience goes to show that, on some ores at least, the series treatment gives a slightly better tailing; on others it does not. It is unnecessary to extend this arrangement of cells beyond two cells in series. In a heavily mineralized ore this arrangement is decidedly advantageous and in such a case the rougher-concentrate might be of high enough grade to omit the re-cleaning operation. The froth from the second cell in the series might be returned into the original feed in the same way that the tailing is returned from the cleaner when practising a roughing and cleaning operation. A number of such combinations is possible. At the Inspiration, the original feed goes to 12 primary roughers, the tailings from which are classified into sand and slime, the sand going to tables and the slime being returned to 12 secondary roughers. The concentrates from both the primary and secondary roughers go to four cleaners, and the cleaner-tailing back into circuit.

FROTH FORMATION

The froth is generated as the result of injecting the finely divided air into the bottom of the already emulsified pulp; it continues to form and to overflow so long as it is furnished with pulp of the proper consistence, properly mixed with the right quantity and kind of oil or frothing agent. Measured from the water-level within the tank, the froth produced may be from 14 to 16 inches in depth or thickness, and according to the character of ore, kind and quantity of oil introduced, will be more or less voluminous, coarse or fine grained, dry or watery—all of these conditions being adjusted by the regulation of the kind or quantity of oil and the quantity of air injected.

In the case of some ores, rich in sulphides, when a comparatively low-grade concentrate will suffice, the ‘cleaner’ may not be necessary, but on low-grade ores having a high ratio of concentration and demanding a concentrate of maximum purity, a cleaner is desirable.

PULP-DENSITY

The pulp to be treated may be of varying density, from 2½ : 1 water and ore, up to 5 or 6:1; for a mixture of sand and slime the former ratio is preferable, but for a pure slime mixture (—200-mesh) the larger proportion of water is allowable. The particular density is not a matter of so much importance as that the supply of pulp be uniform in density, since each variation in the density of the pulp requires a re-adjustment of the oil-supply, the quantity of oil increasing in proportion to the increased volume of pulp independent of its solid content.

FLOTATION CAPACITIES

A normal capacity per standard roughing-cell is 50 tons per 24 hours. This, of course, will vary with the nature of the ore. In one plant that employs gravitation previous to flotation the fine sand and slime only are treated at the rate of 50 tons per rougher. The Inspiration Copper Co. uses flotation as the prime process, and its 800 tons per section is treated by 24 roughing-cells and 4 cleaners. In this case the cells are run in series, the primary cells treating the original feed and the secondary cells re-treating only the slime from the primary tailing after the sand has been removed. This gives an average of 33.3 tons per roughing-cell. The Arizona Copper Co.’s plant will treat the slime and re-crushed sand from previous gravity-treatment; out of an original tonnage of 4000 there will be about 3600 tons of flotation feed. This will be handled on 63 roughers run in parallel, and 18 cleaners, or an average of approximately 57 tons per roughing-cell, or 45 tons per cell for roughing and cleaning.

Some tests have shown little difference in recovery, whether running 45 tons to the cell or 65; but the recoveries commence to decline as soon as the feed exceeds 75 tons. In the Coeur d’Alene, on zinc-lead ore, 35 tons per cell is an average capacity.

OILS. The oils used may be broadly divided into ‘frothers’ and ‘collectors.’ The pine-oils are good frothers; coal-tar and its various subdivisions are good collectors. On some ores crude pine-tar will in itself combine both the properties of frothing and collecting. On others, this may have to be enriched by the addition of some one of its more volatile constituents, such as refined pine-oil, turpentine, or wood-creosote.

Generally speaking, the coal-tar products are poor frothers; to get a sufficient volume of froth to insure a high recovery, it is often necessary to add refined or crude pine-oil, creosote, etc. At the Inspiration, for instance, the mixture is 80% crude coal-tar, 20% coal-tar creosote; at another plant on similar ore 45% El Paso coal-tar, 40% coal-tar creosote, 10% cresol, and 5% pine-oil. At the Daly-Judge we used 40% crude coal-tar, 40% creosote, 20% pine-oil. In the Coeur d’Alene on zinc ore we used straight wood- creosote; on the National Copper ore plain turpentine will work,

but pine-oil is better. At the Inspiration we used from 1½ to 2 pounds of the mixture per ton of ore; at the Daly-Judge, 1 to 1½ lb.; and at the National 0.3 lb. oil is sufficient. In the experimental work at another plant the consumption of oil was approximately one pound of mixture per ton, but since the entire plant has been in operation and the circuit-water is reclaimed and used over again, the oil consumption has dropped from 1 t0 0.35 lb. The proper kind or kinds of oil and the quantity requisite can only be determined at present by tentative experiment; so far no scientific short-cut is known.

CHARACTER OF FROTH

The nature of the froth made by the pneumatic method has the distinctive characteristic of being unstable or ephemeral, that is, it quickly dies when removed from the action of the injected air. The bubbles composing the froth, being generated under a hydraulic pressure varying from 15 to 40 inches, on rising above the water and to the froth-level, burst by reason of the lower surrounding atmospheric pressure. On bursting, they release the mineral attached to them, but this in turn is caught up by those bubbles immediately following behind. The instability or stability of the bubbles will depend, to some extent, upon the oil used and the nature of the gangue. Pine-oil makes a very brittle froth, which dies immediately on arriving at the surface. Creosote and light oil make a more elastic envelope, which at times will expand into bubbles 3 to 4 inches in diameter before bursting. The pine-oil bubbles will rarely be over ¼ or ½ inch diameter. Castor-oil, olive-oil, candle- makers’ oil (oleic acid), palm-oil, sperm-oil, and other oils of a lubricating nature, have in general been replaced by oils more or less soluble or miscible in water—such as turpentine, pine-oil, and all the coal and wood-tar distillations. The very volatile oils, such as naphtha, gasoline, ether, alcohol, seem to serve very little purpose except as a means for making the pitchy ingredients of the tars more soluble or miscible.

A large, coarse, and elastic bubble seems necessary to the recovery of coarse-grained mineral, but for the very fine or colloidal mineral, a small and comparatively brittle bubble is necessary.

FLOTATION COST

The oil-mixtures generally in use will cost from 1.25c. up to 3c. per lb. depending on the proportion of cresol and other high- priced oils used, but 1½c. per lb. will be a safe average on most oils. A consumption of 1 to 1½ lb. per ton or from 1.25c. to 4.5c. per ton of feed, say 2½c., would be a safe average. The labor, of course, will vary with the size of the plant. At one plant consisting of 60 cells, two men per shift operate the entire plant, equivalent to a cost of 1¼c. per ton. One man per shift on a 250-ton plant will mean a cost of 5.4c. per ton in maintenance. Assuming a life of three months per blanket and 50 tons per cell and an allowance for repairs to blowers, motors, pumps, etc., we have ½c. per ton as a liberal estimate.

Power at 1c. per kw. hour ($60 per hp.-year) and 2½ kw.-hours per ton equals 2.5c. per ton of feed.

Summarized, my estimate on a 2000-ton plant will stand approximately as follows, in cents per ton of feed:

On a plant of 250 tons the extra labor would bring it up to approximately 10c. per ton. Actual figures from a large plant of over 2000 tons gave 6.1c. per ton. The flotation feed in this case represents 60% of the crude-ore tonnage or 3.5c. per ton of crude ore treated.

FLOTATION THEORIES

So far no satisfactory explanation of flotation phenomena has been advanced. At my instigation and under my direction, a large amount of research work has been done in an earnest endeavor to formulate some logical explanation, and perhaps to find some scientific way of conducting experiments in lieu of the empirical methods now in vogue. While this purpose has not yet been fully attained, the experiments have resulted in the formulation of a theory that appears to be well grounded and that may prove of value to others engaged in this branch of metallurgy.

Much work has been done at the Mellen Institute at Pittsburg under the direction of Raymond C. Bacon, and lately by James A. Block at the local station of the U. S. Bureau of Mines. The results of some of this work are summarized in the following statements:

In considering the connection between flotation phenomena and the physical properties of the minerals concerned, there are two parallelisms to be noticed:

First: It has been noticed for some time that the minerals which floated were not easily wetted by water, while those which were easily wetted did not tend to come up with the froth. This is the basis of about the only theory that has been widely circulated up to this time. It is well stated by Hoover in his book, ‘Concentrating Ores by Flotation,’ the first authoritative publication on the subject.

Second: There is a parallelism between certain electro-static characteristics and the flotation properties of ores, as will be explained.

In the theory first mentioned, it may be demonstrated by a consideration of surface tensions and contact angles that certain floatable minerals, such as galena, will float on the surface of still water, while gangue particles, on the other hand, possess a greater adhesive attraction for the water than the water’s cohesive attraction for itself, and are therefore drawn through the surface film into the interior, where they sink because of their greater specific gravity. These properties of floatable minerals and gangues are increased by the presence of oil and acid. Oil sticks to galena with greater tenacity than it sticks to silica, and an oil surface is far less easily wetted than a galena surface. The acid in the water causes a still greater difference in the various surface tensions. This, it seems, is without question the explanation of such flotation as is obtained by the Macquisten process, in which the ore particles are lifted to the surface and those remaining are removed by skimming the surface layer of the liquid.

As regards the second parallelism mentioned, it has been noticed that extremely small amounts of certain colloidal impurities, such as saponine or tannine, were detrimental to flotation, while others, such as Congo red and methyline blue, did not interfere, and were, if anything, beneficial. In classifying these, the injurious ones generally came under the head of what physical chemists call electronegative colloids, while electro-positive colloids were not harmful. This classification is derived from the fact that suspended particles will generally migrate when placed in an electric field, and the classification comes naturally from the direction of their migration. This migration is called electro-phoresis, or electrical endosmose, and is the result of the fact that the liquid containing the particles forms contact-layers around them, similar to the surface-films formed when liquids come in contact with air. These contact-films almost invariably have a difference of potential between their inner and outer surfaces. The film of an air-water contact has, for instance, a difference of 0.055 volts, and other contact-films have similar charges. This causes the particles to act like charged solids, and to be attracted by electric charges of opposite sign.

The charges on solids and non-miscible liquids can be conveniently studied on the stage of a microscope.

This work led naturally to the study of the charges exhibited by various ores and minerals, and in that work an interesting parallelism was observed; namely, that floatable minerals seemed to have positive charges and non-floatable gangues negative charges. Some gangues were found with positive charges, but they were characteristically hard to handle, having a tendency to come up with the froth. These charges sometimes vary with the acidity or alkalinity of the liquid, and this variation is not inconsistent with the effects of acidity or alkalinity on the flotation of ores.

It has been noticed that these electro-static properties depend on the condition of the surface of the particles and not upon the composition of the mass. For instance, lead oxide, which is ordinarily negative or neutral, when covered with a sulphide coating takes upon itself a positive charge.

Although these charges are small, recent work on the coagulation and deflocculation of slime, on the coagulation and dispersion of colloids, and along similar lines, shows that the contact-film charges have an important bearing on the dispersion or coherence of particles suspended in liquid mediums. In fine suspensions and in colloidal solutions, these charges may often be neutralized by the introduction of oppositely-charged ions, and precipitation will generally take place whenever these charges fall below certain limits. Oppositively- charged contact-films generally have a tendency to absorb each other, and to coalesce, while similarly-charged films, if their charges are great enough to overcome natural cohesiveness, do not seem to coalesce, but to repel each other, and if the weight of the particles is small enough in relation to their size and surface, permanent dispersion will take place, the particles distributing themselves through a liquid in much the same manner that a gas will fill a container.

In view of the above observations, it seems possible that flotation is due to differences in polarity in the charges on the various particles of ore, and on the bubbles. Since oil contact-films and air contact- films have both been proved to have negative charges, the positively- charged minerals might adhere to either. The bubble-mantles in a flotation machine are undoubtedly composed of oil, or of oil in emulsion, since pure water alone will not froth. The same forces, then, that cause oppositively-charged colloids to agglomerate and precipitate, cause the minerals to adhere to the oil-covered bubbles; and the same forces that keep the particles of an oil emulsion dispersed, keep the gangue-particles repelled from the bubbles.

Expressed briefly, the theory is as follows: That oil flotation is an electrostatic process. It is a scientific fact that when a solid particle is suspended in water, the water will form around the particle a contact-film that generally possesses an electric charge, the amount and polarity of which will depend upon the nature of the surface of the particle and the electrolyte in which it is suspended. The presence of these charges can be demonstrated by the fact that the particles possessing them will migrate when placed in an electric field. It has been demonstrated that floatable particles have charges of one polarity (positive), and that non-floatable particles have charges of the opposite polarity (negative), and that the froth is charged negatively and so attracts the positively-charged or floatable minerals, and repels the negatively-charged or non- floatable ones. It is this, it is believed, that causes the floatable minerals, such as galena or sphalerite, to adhere to the froth and rise, while the gangue-minerals, such as silica and limestone, remain in the liquid where they can be discharged as tailing.