Let’s begin with fine ore storage bin or stockpile, get it out of the way and then proceed to grinding. You would think that there isn’t that much to learn about when talking of fine ore storage, after all, all that this area is really for is to provide surge capacity for each of the circuits. True, but there are a couple of things that operators should know about. To begin with, I would like to explain to you what surge capacity is.

SURGE CAPACITY is an area that holds a minimum amount of ore to allow independent operating or an unbalanced volume of production for which ever circuits are involved. In this case it is crushing and milling. There are times when it is desirable to have either one or the other of these departments shut-down while the other department is operating.

This may he when there is mechanical maintenance being done or heaven forbid an operating error, surge capacity allows one circuit or the other to be shut down for a limited period of time without affecting the rest of the plants operation.

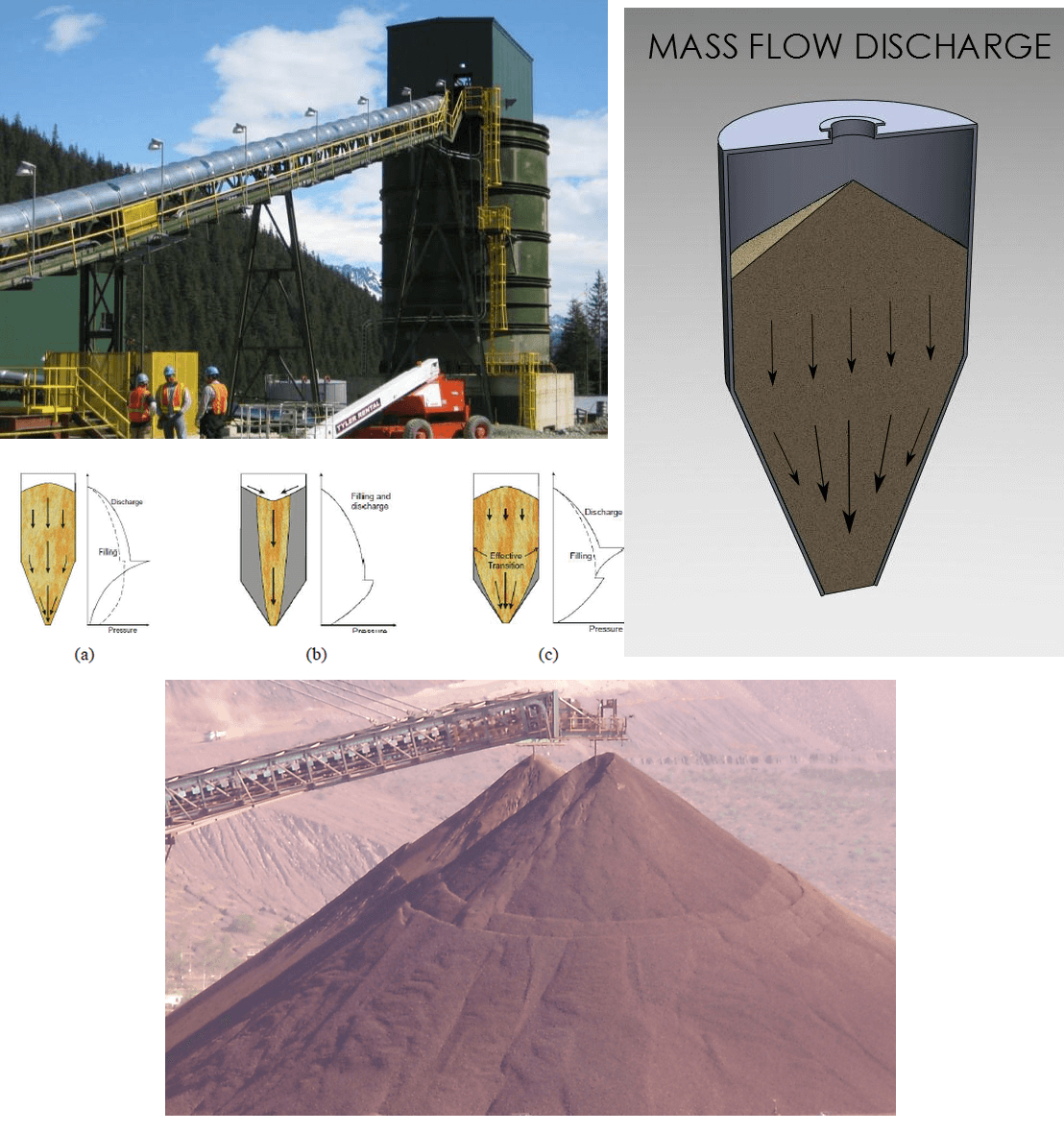

The design of a bin or pile is very basic, the ore is put onto the storage area from the top usually by a conveyor. The removal of the ore is from the bottom by more conveyors. There are a few factors that go into the design and selection of the type and size of a storage area however, the first is weather conditions.

Will the ore have to be protected from the elements such as rain and snow? What is the size of the milling department?

The holding area has to be large enough to allow the mill ample operating time. This usually is between sixteen to forty-eight hours depending on the difference in tonnage between the through put of the crushing department and the through put of the milling department. In many mines especially the smaller ones the crushers are big enough to crush enough ore for the grinding circuit to run through a weekend without having to have an operating crew in to run the crushers.

Now that we know what the bin or pile is for, some of the problems that are associated with them are, TRAMP GARBAGE, FROZEN ORE, (these two are explained in detail in other segments) CLASSIFICATION, and of course the ever present SAFETY HAZARDS.

Any time that you have an ore movement the ore automatically classifies. It begins on the conveyor belt as it is taken to the fine ore bin. The shaking and vibration of the belt makes the finer particles of ore settle in to the spaces between the larger ore until the majority of the smaller rock is on the bottom of the load, near the surface of the conveyor belt. The trajectory of the ore as it leaves the conveyor belt will determine where in the bin or pile each size of the crushed ore will land.

Once in the bin, another stage of classification takes place. The smaller ore due to its lesser size and weight, tends to filter downwards faster than the coarse material does. This results in two different ore flows happening. The larger slow material and the smaller faster ore. To complicate this process, the ore is being pulled from the DRAW POINTS, these are the feeders that control the rate of flow of the ore as it leaves the storage area. What this does is guide the ore to these points. Much like the current you would find in a pond where there is a discharge creek. The maximum amount of movement is directly in front of the exit point. The effect of the current is lessened as you go to the side or get farther away from this point, the current is much the same within the fine ore storage area. The difference here is the faster settling fine material is being pulled toward the exit first. This means that as the bin is emptied there will be less and less fine material in the feed. This causes problems in the next stage of processing due to the larger rock interfering with the effectiveness of the process.

On the positive side, the fact that the feed does become coarse, is an early warning indication that the fine ore storage is almost empty and that closer monitoring of the feed will be required until the normal ore flow has resumed.

I mentioned earlier that tramp garbage was a problem, if steel, wire or wood is accidentally put into the storage area the problems that may develop are belts being ripped and chutes or screens plugged. This doesn’t mean that all metal, wood, mine trash will cause damage, just the pieces that are too big to fit through feeders or are shaped in such a way that it is possible to cause a restriction in ore flow. In either case it may be expensive for the operation in both equipment and lost production. This is one of the main things that an operator will be on the lookout for when they are doing their circuit checks. That and of course any safety hazards that may be present.