This section is about the feeders that control the fine ore. This is the ore that has already been through the crushing stage of concentration. Of these feeders there are three basic types, chute/gate, pipe, and slot feeders.

The circuits that carry out the remainder of the steps required to concentrate the fine ore must be fed in a continuous steady manner for accurate tonnage control.

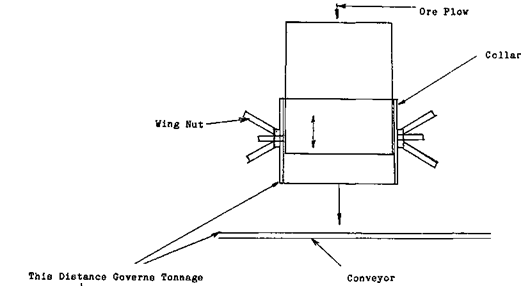

Tonnage may be controlled by manipulating either the volume of the ore going through the feeders or the speed that it is moving. All three of these feeder types may have a variable speed conveyor taking away the ore. If this is the case the tonnage is controlled by increasing or decreasing the speed of the conveyor.

If the conveyor is a constant speed model however the three different feeders control the tonnage in their own ways.

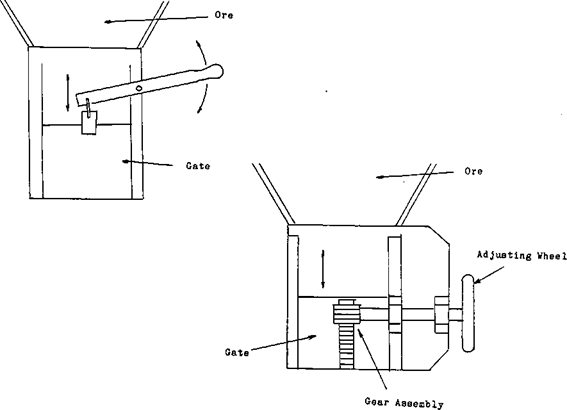

The chute/gate feeder will simply have a sliding gate similar to the one that was described in the previous portion on coarse ore feeders.

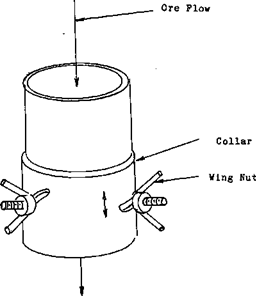

The pipe feeder, which is a large diameter pipe with a larger adjustable collar over the bottom half of it, controls the tonnage by lifting the collar up and down increasing the space between the feeder and the conveyor belt. This will allow a larger volume of ore to be deposited onto the conveyor to be taken away.

- Feeders control the flow of ore.

- Tonnage is controlled in two ways

- Increase or decrease the volume of ore going through a feeder.

- And/or decrease or increase the speed of the ore.

- Operators on their circuit checks will watch for.

- Restrictions of ore through put in the form of hang ups, blockages, or build-up of fines.

- Wear on the equipment both mechanical and abrasion wear.

- Mechanical and equipment operating adjustments

- Safety hazards to both men and machines.