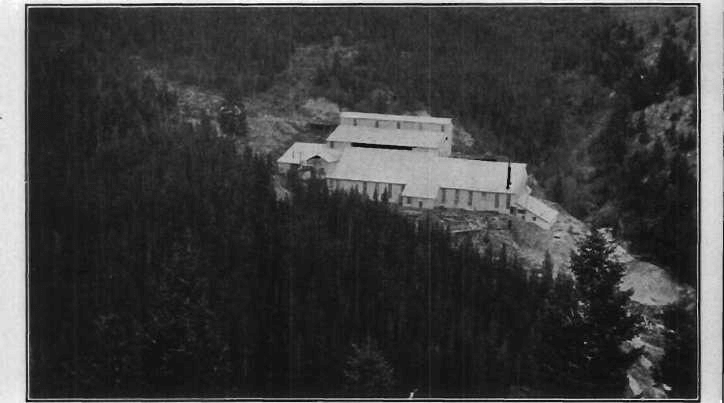

This plant, near Marysville, Montana, was planned to treat the ore from the Piegan and Gloster mines, the latter being one of the early and famous producers of the Marysville district. When the mill was closed, treatment consisted of stamp milling, followed by pans and settlers for pan amalgamation. The extraction was evidently poor, because, a few years later, thousands of tons of tailings were re-treated by the ranchers in the valley below the mill, by the then new cyanide process, and gave a handsome profit.

This plant, near Marysville, Montana, was planned to treat the ore from the Piegan and Gloster mines, the latter being one of the early and famous producers of the Marysville district. When the mill was closed, treatment consisted of stamp milling, followed by pans and settlers for pan amalgamation. The extraction was evidently poor, because, a few years later, thousands of tons of tailings were re-treated by the ranchers in the valley below the mill, by the then new cyanide process, and gave a handsome profit.

After laboratory tests and an experimental mill run, decided upon the following treatment: crushing to 40 mesh in cyanide solution, concentration, amalgamation, classification, and cyanidation of sands by leaching, and of slime by agitation and decantation in charges. The ore averaged about $7 per ton, gold and silver, the ratio of weight being 1 oz. gold to 7.56 oz. silver. The ratio of gold and silver in tailings was 1 oz. Au to 36.6 oz. Ag; the quartz was sharp and sandy, however finely ground, and rather difficult to slime.

The mechanical equipment was a No. 5 Symons gyratory crusher; three 10-ft. Lane slow-speed Chilean mills; one Wilfley roughing and one finishing table; one submerged-type Akins classifier; five 26 by 10-ft. fir leaching tanks; one 24 by 7-ft. Dorr thickener; four 14 by 16-ft. Dorr agitators; four 6-compartment double-row zinc-boxes having compartments 18 in. wide, 18 in. deep, and 34 in. long; Johnson zinc lathe; acid and vacuum filter tanks for treating precipitate; roasting furnace; and Case tilting No. 275 crucible furnace for melting precipitate.

The mill is driven by electric power supplied by the Montana Power Co. at the following rates, per kw.-hr.: 200 to 300 hp., 0.68 c.; 300 to 500 hp., 0.61 c.; 500 to 750 hp., 0.55 c.; plus $1 per month per installed motor horsepower.

The plant as above described was operated and when an additional Dorr thickener and a 12 by 12-ft. Portland revolving filter were added, increasing the nominal capacity of 100 tons per 24 hr., but not the percentage of extraction. The combined treatment, at a cost of $1.48 per ton, saved 90%, of the gold and 59%, of the silver, of which 78 per cent, was extracted by cyanide, 20%, by amalgamation and 2% by concentration.

The amalgamation was accomplished in copper launders, attached to the concentrate end of the Wilfley finishing table; concentrates, at a ratio of 1 ton to 510 tons ore, averaged 12 oz. gold and 59 oz. silver per ton, and were leached with cyanide solution for 14 days to an average value of 1.1 oz. gold and 26.75 oz. silver, before being shipped to a smeltery.

It will be noticed that the whole of the crushing was accomplished in two stages—gyratory crusher and Chilean mills—screen analyses of the products being given in Table 1.

Table 1.—Screen Analyses of Chilean Mill Product and Classifier Products

| Mesh | Chilean Mill Product | Sands | Slimes | |||

| Per Cent. | Cum. Per Cent. | Per Cent. | Cum. Per Cent. | Per Cent. | Cum. Per Cent. | |

| Over 48 | 10.9 | 10.9 | 24.2 | 24.2 | ||

| 48-65 | 11.6 | 22.5 | 20.9 | 45.1 | 2.1 | |

| 65-100 | 17.0 | 39.5 | 29.2 | 74.3 | 11.1 | 2.1 |

| 100-150 | 13.6 | 53.1 | 14.0 | 88.3 | 12.1 | 13.2 |

| 150-200 | 7.6 | 60.7 | 5.5 | 93.8 | 74.7 | 25.3 |

| Below 200 | 39.3 | 100.0 | 6.2 | 100.0 | 100.0 | 100.0 |

| 100 | 100.0 | |||||

The final products were admirably adapted for the treatment of that particular ore, if the cost of all-slime treatment was to be avoided.

During this period of operation of the plant, the development of the Shannon mine was going forward, with the expectation of beginning to mill Shannon ore. The Shannon ore is different in character from that of the Piegan and Gloster mines, the grade being nearly double, with 93%, of the total value in gold.

Since it was advisable to use the one mill for all the ores, an all-slime treatment was adopted, requiring the following changes and additions to existing milling equipment: A standard Dorr duplex classifier, in addition to the Akins classifier, following Chilean mills; two 5 by 16-ft. pebble tube-mills having Komata lining (each driven by 50-hp. motor, short.-belt drive) with two standard Dorr duplex classifiers in closed circuit; and two 12-in. bucket elevators in the crushing department. Three of the leaching tanks were converted into thickeners (one into a simple thickener and two into single-tray thickeners); the remaining two leaching tanks were converted into Dorr agitators, by increasing their depth to 20 ft; a new Dorr thickener, 29 by 7 ft., was added, and another

Portland revolving filter, 12 by 10 ft., also a set of twenty-eight 6 by 8-ft. clarifying leaves. Zinc-box capacity was doubled.

The remodeled plant, went into commission, with a nominal capacity of 150 tons per 24 hr., with 60-hr. treatment; for 10- day periods, over 200 tons per 24 hr. have been treated, with a slight decrease in extraction. Concentration and amalgamation were continued in the fine-grinding plant for a period of six weeks, and were then abandoned, with no loss in total percentage of extraction.

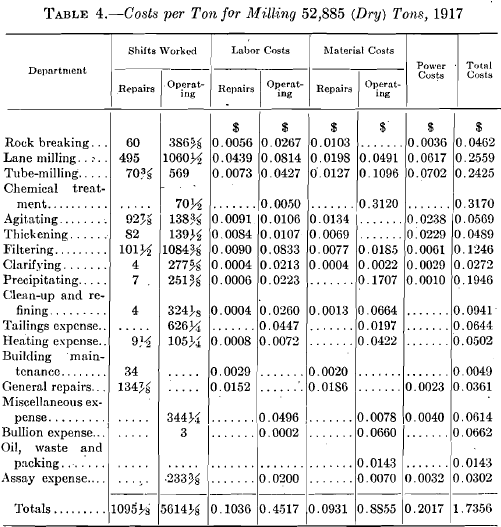

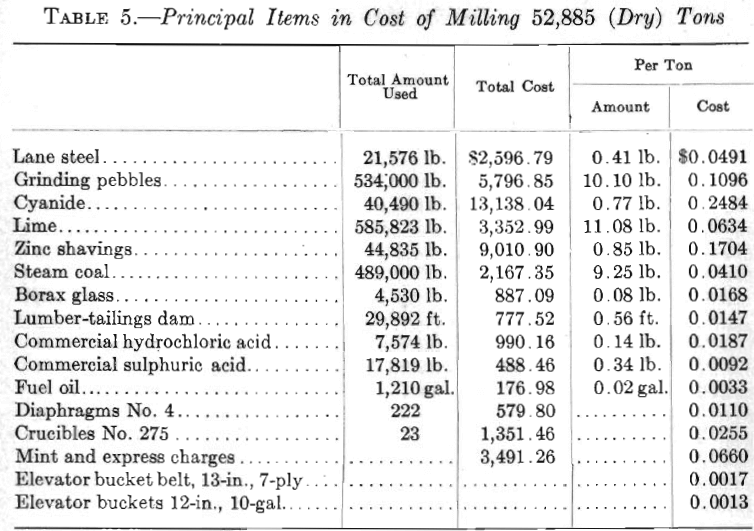

The unusual feature of the plant is the use of slow-speed Chilean mills for crushing the product of coarse breakers. These mills make a remarkable reduction, but leave some fine sand to be slimed in the tube-mills. Repairs are required rather frequently and access to make repairs is difficult, making the mills unpopular with the attendants. Crushing costs,

however, shown in Tables 4 and 5, compare favorably with other modes of coarse crushing, being, in fact, rather less than those shown by larger plants using ball-mills. An undesirable feature of these mills in a slime plant is that their product is too uniformly fine for regrinding in a pebble-mill without undue consumption of pebbles.

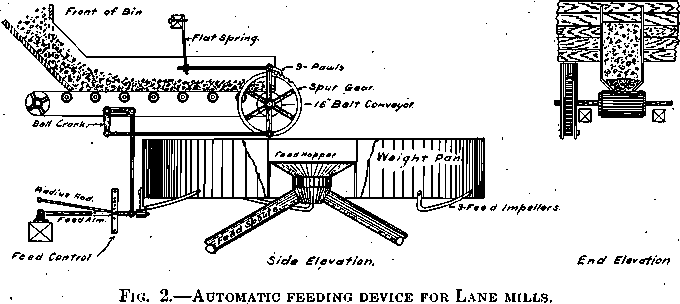

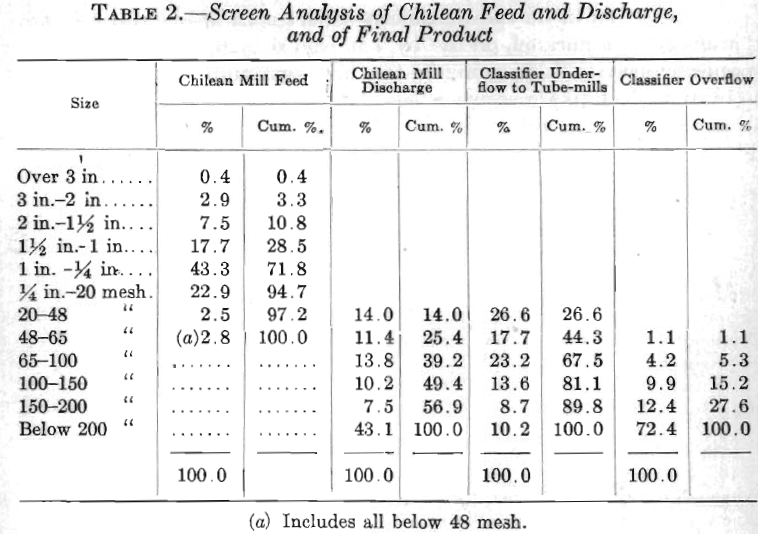

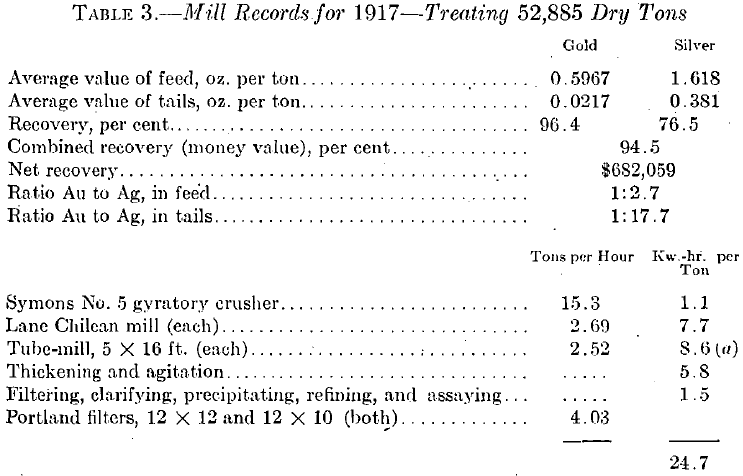

Treatment is now as follows (Fig. 1): crushed ore from the two mines, approximately 100 tons of Shannon and 50 tons of Gloster per day, carrying 6 and 8 per cent, moisture respectively, go into the same receiving bin, from which it is fed to the Chilean mills by belt-conveyor feeders, actuated by cams on the mills, which automatically keep a fairly uniform depth of ore between the tires and the dies (Fig. 2). To each ton of ore fed, 4.3 tons cyanide solution, 0.0375 per cent, strength, and 10 to 12 lb. of lime are added at the feed hoppers. The average rate of crushing in the Chilean mills is 2.69 tons per hour per mill, screen analysis of the feed and discharge being shown in Table 2.

The Chilean product is elevated to classifiers, from which the overflow goes to the slime-treatment department and sands to tube-mills; these are in closed circuit with classifiers, the overflow of which joins that

The Chilean product is elevated to classifiers, from which the overflow goes to the slime-treatment department and sands to tube-mills; these are in closed circuit with classifiers, the overflow of which joins that

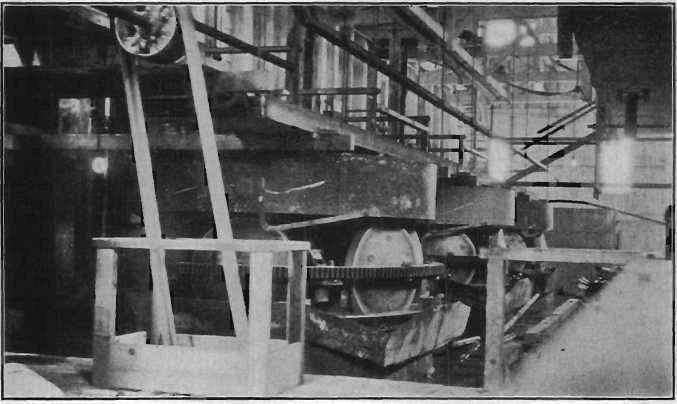

Fig.3- Installation of Lane Chillean Mills

from the Chilean-mill classifiers and goes to the slime-treatment department. Table 2 gives screen analysis of the slimes as treated.

The first unit in the treatment department is composed of two Dorr thickeners in parallel, one 24 by 7 ft. and one 26 by 10 ft., the underflow, specific gravity 1.35, going to the first agitation unit composed of four 14 by 16 ft. tanks in series, where enough cyanide to increase the solution strength to 0.05 per cent, is added, and sufficient mill solution to make dilution 2½ to 1; the overflow goes to clarifying leaves and precipitation.

(a) On basis of total mill feed; about 60 per cent of total feed goes through tube-mills.

The second thickener unit is a 26 by 10-ft. Dorr single-tray. The Underflow (specific gravity of tray product, 1.37—of tank compartment, 1.34) is raised 11 ft. net by a diaphragm pump, attached to each compartment, to the second agitation unit, which is a 26 by 20-ft. tank; here, sufficient overflow from No. 3 thickener unit is added by air lift to make the dilution 2 ½ to 1. The overflow from the second goes to mill-solution tank or to precipitation, as conditions allow.

The third thickener unit is a 26 by 13-ft. Dorr single-tray, where the underflow (specific gravity, tray product, 1.35—tank, 1.30) is raised 8 ½ ft. net by a diaphragm pump attached to each compartment, to agitation unit No. 4, where sufficient barren solution is added by air lift to make the dilution 2 1/2 to 1; overflow goes by gravity, counter-current, to No. 2 thickener unit.

The fourth thickener unit is composed of two tanks, 24 by 7 ft. and 29 by 7 ft., in parallel, where barren solution and filtrate from the Portland vacuum filters are mixed with pulp entering thickeners; underflow, specific gravity 1.39, is raised 5 ½ ft. net to the Portland filters, where pulp cake is given two washes of barren solution (one applied by a set of spray nozzles and a second by a perforated drip pipe), followed by a wash of water applied through perforated drip pipe. The filter cake, carrying 29.9%, water, is then discharged as tailings and 20 per cent more, water is added to move it to the pond. The filter tailings are sampled by teeter-box sampler, operated by barren solution; the latter is also sampled by the same teeter-box. Overflow from the fourth thickener unit is pumped (counter-current) to No. 3 thickener.

The Portland filters require new filtering medium of cotton drill and burlap, and wire winding, every six to seven months; the filter is out of commission 28 to 36 hr. for removing worn wire and cloth, cleaning, applying new burlap and drill, and rewinding.

Pregnant solution going to precipitation is metered and sampled by a teeter-box holding 0.483 ton of solution per cycle; 3.81 tons of solution

are precipitated per ton of ore treated . Average value of pregnant solution is 0.152 oz . Au, and 0.354 oz . Ag; average value of barren solution

Fig.4- Barnes-King Mill, Marysville, Mont.

is 0.0023 oz. Au per ton. A vacuum system was applied to pregnant solution, but no definite results can be given at this time beyond stating that precipitation is uniformly lower than before its adoption. Consumption of zinc shavings is 0.22 lb). per ton of solution precipitated.

| Table 6.- Wages Scale for 1917 | |

| Average Wages per shift | $ 4.70 |

| Precipitation men | $ 5.00 |

| Repair men | $ 5.00 |

| Chilean and tube-mill men | $ 4.50 |

| Solution men | $ 4.50 |

| Crusher men | $ 4.00 |

| Helpers | $ 4.00 |

Monthly clean-up is usually made, requiring four men one shift each, to clean up and repack boxes, and two men five shifts each to treat and smelt precipitate, a total of 14 shifts per clean-up. The precipitate, after acid treatment and vacuum filtering, carries 47 per cent, moisture, and after drying and a partial roast, carries 67 per cent, bullion—0.278 fine gold, and 0.639 fine silver.

Fine-grinding Cyanide Plant of Barnes-King Development Co.