In view of the tendency of fine gold recover by floating and the dominance of heavy minerals, the prospects for flotation were worthy of re-investigation, particularly with the new tools of the air sparged hydrocyclone (ASH) and the flotation column. Although gold readily and naturally forms a hydrophobic film, dithiophosphates have been advanced as more selective for gold than xanthates and float gold up to 200 micron in size despite its density.

Our initial investigations in the mechanical flotation cell were with a wide variety of samples, including beach sands and alluvium. The more definitive work with the ASH and the flotation column has been on three samples. Some of the beach sands are cemented and can require vigorous attritioning to achieve liberation of the gold. All three samples had been scrubbed or attritioned, and were a product of either spiral or Knelson bowl concentration. There was no plus 0.5 mm material; 90% was between 50 and 200 microns and the gold was distributed fairly evenly through the size range.

Mechanical Fine Gold Flotation Cell

Initially our interest arose from a need, in the laboratory, to pre-concentrate a sample prior to analysis, either to enhance the confidence in the analysis or to facilitate morphological characterisation. A Wemeco Fagergren machine with a 2 litre cell was used. Recoveries were somewhat inconsistent but it seemed more suitable for well- sorted (or de-slimed) feeds such as beach sands.

Subsequent client-funded work confirmed this, with consistently high recoveries (over 80%) and low mass yields (less than 5%). Rougher, scavenger and cleaner circuits appeared necessary to achieve the very high recoveries required for gold and sufficiently high concentration ratios to facilitate the final recovery step. It was becoming evident, however, that a conventional mechanical cell was inappropriate for such a coarse (minus 0.5 mm) and dense feed. The impeller had to turn at its maximum speed of 2600 rpm to maintain suspension. This was confirmed by our unsuccessful attempts to modify a two cell No. 5 Denver “Sub-A” mechanical flotation machine. The fixed speed impellors (1400 rpm) did not provide sufficient agitation. Modifications could only increase the speed to 2000 rpm, which was again not sufficient to maintain suspension. Higher speeds caused the onset of unacceptable stress. Whereas a mechanical cell could be designed for such a feed and the impellor speed could be minimised, the abrasive nature of the slurry could present tremendous wear problems.

Air Sparged Hydrocyclone

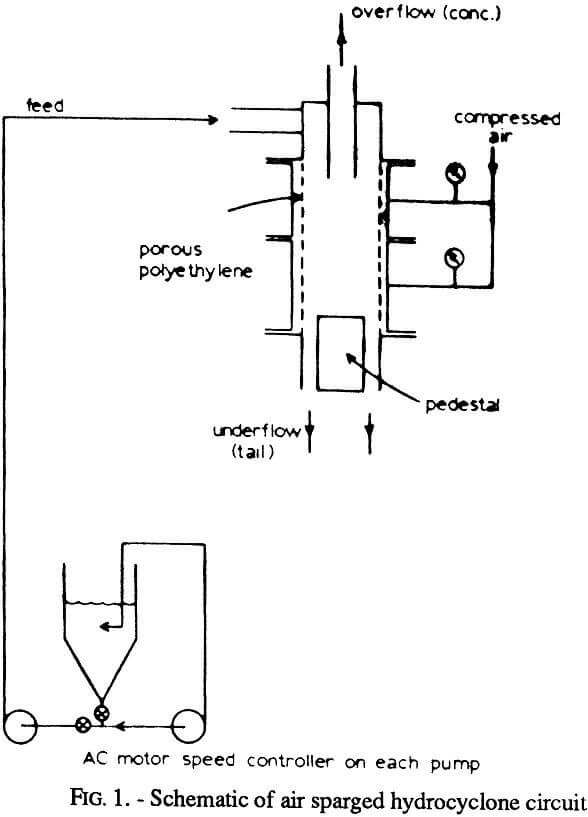

The ASH embraces the cyclone principle but uses a long parallel porous body through which air is forced to carry hydrophobic minerals in a conditioned feed to the vortex and thus to overflow (Figure 1). Details of its design and fundamentals was developed for the flotation of fine particles.

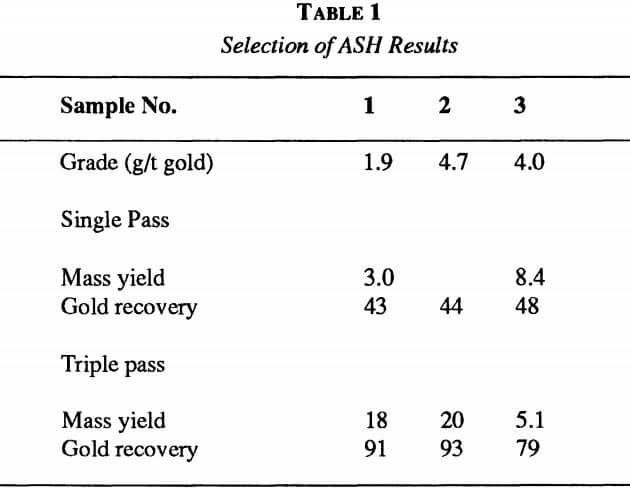

However its ability to recover gold certainly warranted its investigation. The gold recovery and mass yield were 81% and 0.5% respectively. Both the sand and the gold were fine and the sand less dense than the three beach sands. An ASH2 (i.e. 2″ diameter) was installed in open circuit (Figure 1). A 250 litre reservoir of feed pulp was conditioned and maintained in suspension with a pump and closed loop, and which enabled a 5 minute run at 50 l/min (-0.3tph at 10% solids). Details on the ASH configuration, operating conditions, precedures and results are described and a selection of results in Table 1.

The conditions used to float the gold were used as a starting point, but were not the most appropriate. A lower pulp density and feed rate of 10% and 50 l/min respectively were necessary. Feed inlet pressure was by far the most sensitive parameter, at least in terms of mass yield. Low yields could only be obtained at pressures approaching the collapse of the vortex. Whereas the flotation reagents used were reasonably effective (xanthates and kerosene), those used in the work described above using the mechanical cell (dithiophosphate and MIBC) were quite ineffective.

The parameters examined were conditioning time (3 to 20 mins), pulp density (4 to 10%), inlet pressure (4 to 8 psi), pedestal diameter (3 sizes) and to a small extent reagent levels. Rarely did the gold recovery exceed 50% even with high mass yields. The gold remaining in the tailing was slightly coarser than that in the concentrate but could be recovered by re-passing. Cumulative gold recoveries of 80 to 90% could be obtained from three passes, but the cumulative mass yield was as high as 20%. Clearly therefore we have not been able to obtain the same success as for river sand. The coarser and denser nature of these sands is the likely cause.

The residence period is of the order of one second. Its higher capacity and therefore lower cost, relative to mechanical cells, highlight its potential. However long conditioning times (20 minutes in the case of the river sand), if indeed they are necessary, detract from the advantage.

Gold Flotation Column

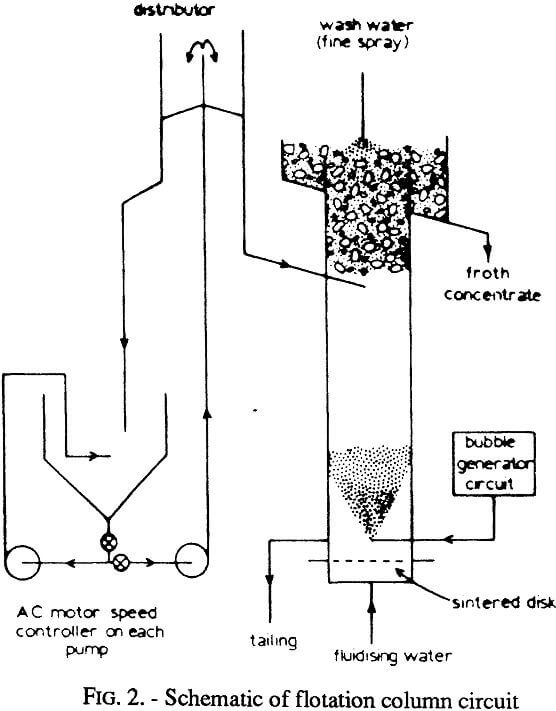

The flotation column was developed for the improved recovery of fine particles too, and is finding commercial application. It embodies principles which are, with modification, appropriate for the flotation of gold from coarse dense sands. A small laboratory column, 1 m high by 50 mm in diameter (Figure 2), was constructed. It differed from other columns by having a stainless

steel sintered disc base through which fluidising water was passed to facilitate discharge by maintaining the sands in suspension. The external bubble generator was based on a design of the US Bureau of Mines (Anon 1987).

The feed rate to the column was as low as 2 l/min, which is a very low flow for reliable delivery where the feed is a slurry of coarse dense sand. It was achieved, in the system shown in Figure 2, by ensuring that the rising line velocity was well above the maximum terminal velocity and by using a distributor to split the pulp. Feed rates of up to 12 l/min were possible. The column was fed in open circuit from the 250 litre reservoir maintained in suspension by a pump and closed loop. In theory, runs of 2 hours duration were possible, but because of declining pulp density (max of 15% solids) they usually lasted about an hour. For this reason and because gold tended to concentrate in the reservoir, balances were based on what passed through the column.

Since there was close control of all inflows and outflows, the column could be readily balanced for the duration of the run, maintaining the froth/slurry interface (somewhat diffuse anyway) just above the feed port.

The reagent regime was similar to that used in the ASH, viz a xanthate collector (80 g/t), kerosene (50 g/t) and a propyleneglycol/methyl ether frother (100 g/t). The dithiophosphate was again not very effective.

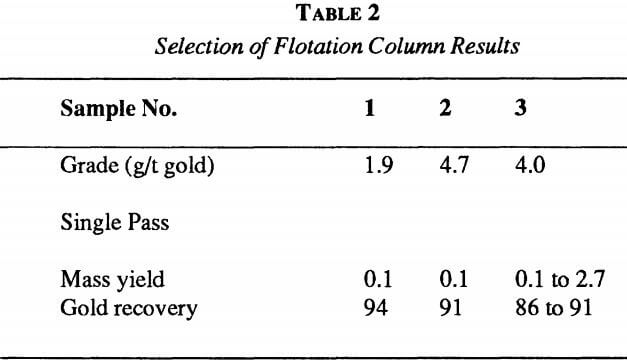

The experimental programme was not exhaustive, since the material was being used to commission and evaluate the column. Many important parameters were not investigated, such as bubble size, air flow and feed rate. Nevertheless the results are very encouraging, with gold recoveries over 90% and mass yields less than 1% for a single pass. A selection of results is shown in Table 2.

There was evidence that even better results would be obtained under more quiescent conditions, i.e. at lower airflows. The specific slurry rates and specific solids rates per unit volume were considerably greater than those reported elsewhere but on different materials. In this sense, therefore, optimum performance can be expected to be even better.

The flotation column offers a lot of promise and can be designed to discharge a coarse dense sand by using a fluidised base. Recoveries of over 90% and mass yields of less than 1% should be possible.