Fine Coal Recovery and Mine Backfill Preparation: The coal mines in the Sunnyside, Utah, area have been mined continuously since 1896 and prospered as Bee Hive oven coke producers until 1924. The introduction of natural gas for firing reverberatory copper furnaces curtailed the market for Bee Hive oven coke and the mine production fell drastically. Some of the mines were abandoned and the others were ready to close when Kaiser Steel Corporation leased one of the abandoned mines in 1942. Kaiser eventually acquired the entire Sunnyside property and rebuilt the coal washing plant after proving that coal at the lower elevations could be economically mined and cleaned by washing and flotation to meet specifications for Kaiser’s Fontana Steel Plant furnaces.

Location

Sunnyside Coal Mines of Kaiser Steel Corporation are about 150 miles southeast of Salt Lake City, Utah, at the end of ten miles of paved Utah State Highway No. 123, which turns northeast from U. S. Highways No. 6 and No. 50, fourteen miles east of Price, Utah. Mines are at the base of the rugged Book Cliff Mountains. Kaiser Steel Corporation controls over one hundred million tons of mineable coal in this area.

General

There are two main coal seams on the Sunnyside properties which includes 12,000 acres of coal land. Seams range from 4′ to 16′ in thickness and outcrop for a distance of about six miles near the base of a rugged mountain range. Seams pitch downhill from the outcrop from 6% to 26% dip, averaging 10%. Overburden varies with the topography from a few hundred to a maximum of 2500 feet. Weak roof rock, heavy cover, and numerous faults make roof support a major problem. The use of mine waste for backfilling commenced in 1959 and alleviated many of the ground support problems.

Coal fines of 6-6.5% ash are recovered by “Sub-A” Flotation at Kaiser’s Sunnyside Preparation Plant.

Mining

The mine haulage and coal preparation plant capacity is between 9,000 and 10,000 tons of coal per day (two shift basis) containing approximately 70% clean coal and 30% washery reject comprising rock, bone, and high ash coal. Haulage is done by electric trolley locomotive on the level and slope hoists on the mine slopes. Five-ton steel cars with swivel couplings, to allow tipple dumping of cars without uncoupling, are used. The property is now divided into three individual mines, each having its own independent haulage, ventilation, power, and water systems. The maximum length of haul is about 4½ miles.

Both conventional and continuous mining is practiced. One Dowty Longwell setup is being used to advantage. About 60% of the present production is with continuous miners which cut the coal from the face without the necessity of drilling and blasting. Conventional mining uses rubber-tired undercutting machines, hydraulic drills, and blasting with permissible explosives. Whether mined by continuous or conventional methods, the coal is loaded by crawler-mounted machines and delivered to rubber-tired shuttle cars which in turn haul the coal to the nearest track where it is discharged into mine cars.

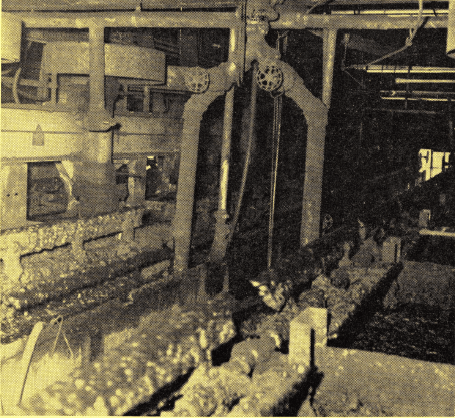

Two 10-Cell No. 30 “Sub-A” Flotation Machines recover coal fines from the cyclone classifier overflow.

Water and Power

The principal source of water is from the mines and is reclaimed for re-use wherever possible.

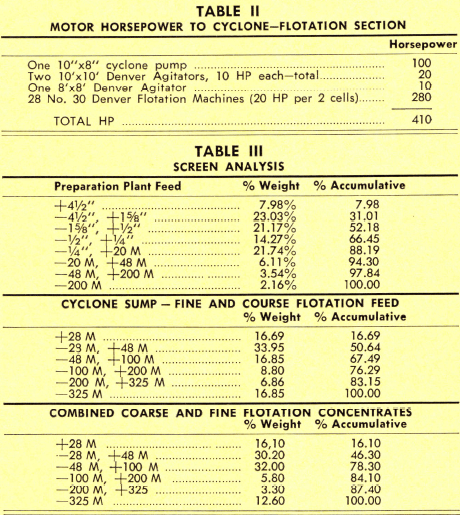

Power is used as 3 phase, 60 cycle, 440/4160 volt. Haulage motors are direct current at 550 volts. Total connected horsepower in the coal preparation plant is 3,000 HP.

Coarse coal fines (cyclone underflow) are recovered by two 4-cell No. 30 “Sub-A” Flotation Machines equipped with chain drive froth rakes.

Coal Preparation Plant

The mines produce on two 8-hour shifts each working day. The preparation plant operates two 7¼-hour shifts per day, and the mine backfill plant operates three 8-hour shifts per day. Coal preparation plant average daily production is 6500 tons of clean coal having an ash content of 6% to 6.5%. Approximately 1500 to 1800 tons of refuse is sent to the backfill plant daily and the remaining refuse is trucked to the waste dump.

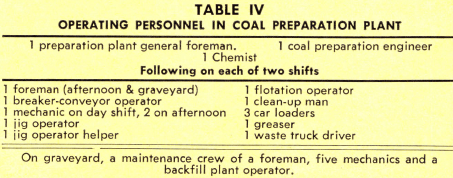

The coal from the three mines is dumped by two rotary dumps into a 100-ton hopper from which it is fed by a 6’x14′ reciprocating feeder onto a 60″ belt conveyor which delivers the coal to a 12’x27′ revolving cylinder type coal breaker. The breaker removes large rock, tramp wood, and trash. The breaker has 5½” round holes in the shell and is provided with an internal scoop for removing waste timber, coarse rock and other material that do not get through the holes. The minus 5½” mine run coal from the breaker is transported by belt conveyor and belt tripper car to 16 concrete blending bins where storage capacity is approximately 4000 tons. The mine run is discharged from the blending bins by eight 20″x72″ vibrating pan feeders (two bins discharging to each feeder) onto a 48″ blending belt conveyor and transported to a 60″ flat rotary splitter feeding two 84″ six-compartment Baum Type Primary Coal Jigs.

Even though 5½” round holes are used in the breaker the mine run is called 6″x 0″.

Each cleaning jig produces primary and secondary refuse and clean coal. The primary refuse from, size 6″x0″, is sent by conveyor belt to the backfill plant. The secondary refuse is sent to a ring crusher where the size is reduced from 6″x 0″ to 1½”x 0″. By belt conveyor it goes to a re-wash jig. This jig is an 84″ five-compartment Baum Type Jig. Both primary and secondary refuse from this jig is transported by belt conveyor to the backfill plant. Refuse is 1½”x 0″. While this is the usual practice, the arrangements of conveyors and chutes are such that all refuse from both primary and secondary jigs can be sent to the backfill plant or to the refuse bins as required.

Jigged coal from both primary and re-wash jigs flows by gravity to a double 8’x 45′ reciprocating coarse coal screen with 1 5/8″ round hole screen on the upper deck and ½” slotted screen on the lower deck. The coarse coal from both screen decks, and all finished products of the plant, are fed to a 48″ blending drag conveyor and discharged directly to the railroad cars or alternately transported by belt conveyor to a 20,000 ton open storage area when cars are not available. Open storage is then belt conveyed to cars on double tracks when the cars are available.

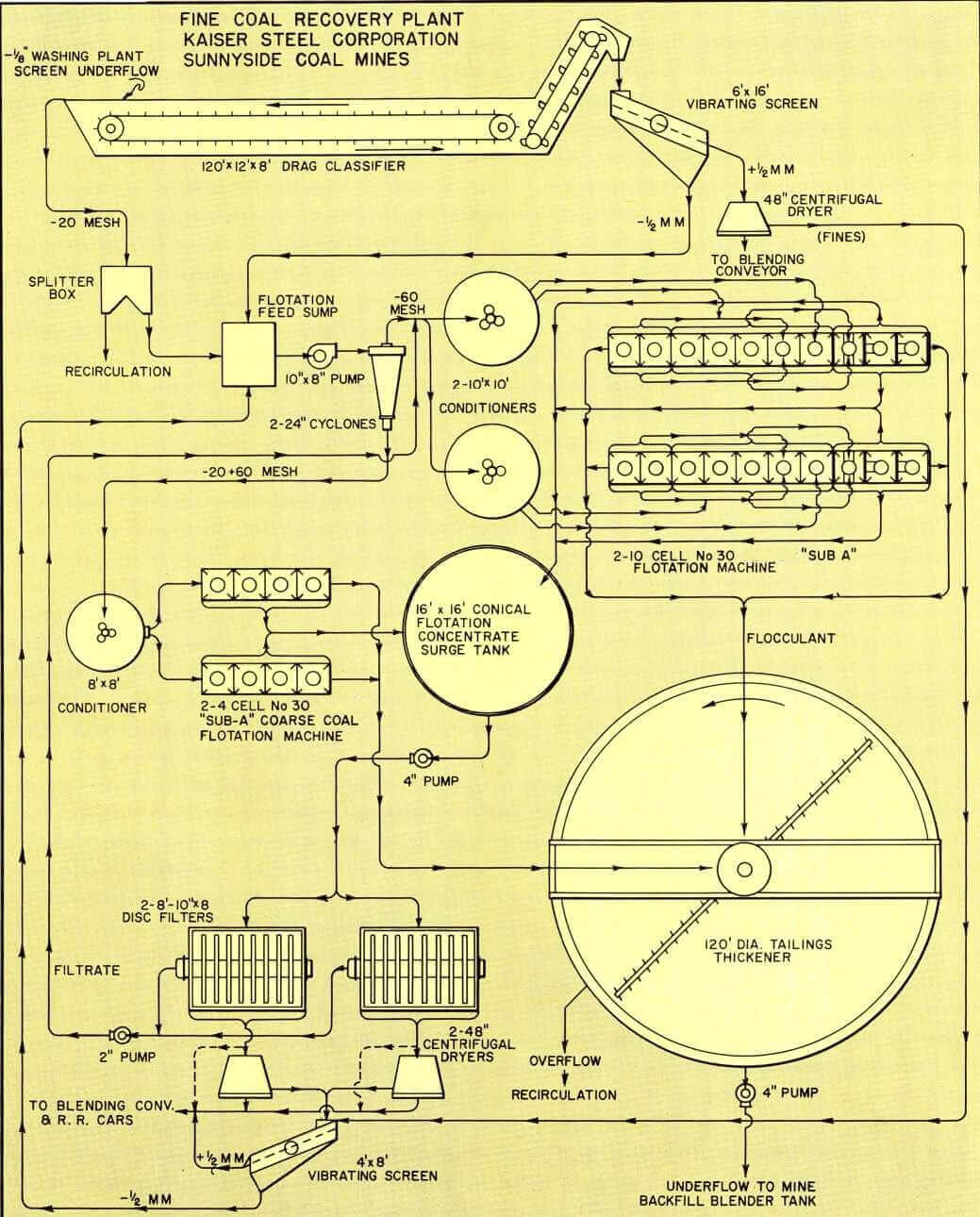

The minus ½” coal underflow from the reciprocating coarse coal screen flows by gravity to two 5’x 12′ vibrating screens with 1/8″ wedge bar screen decks. The plus 1/8″ coal fraction goes to the 48″ blending drag conveyor and railroad cars, while the minus 1/8″ material goes to a 120′ long x 12′ wide x 8′ deep drag classifier. The coarse rake return from the drag classifier is elevated by a screen type bucket drain elevator (buckets 36″x 14″) to one 6’x 16′ vibrating screen equipped with ½ mm wedge bar screen deck. The plus ½ mm coal fraction discharges to a 26′ drag conveyor feeding three 48″ centrifugal dryers. The solids from the centrifuges go to the 48″ blending drag conveyor and cars. Minus ½ mm screen underflow is sent to the flotation feed sump.

The overflow pulp from the 120′ drag classifier consists of approximately 12,000 g.p.m., containing 6% to 8% solids. The solids are essentially minus 20 mesh coal containing 13% to 15% ash. The flow is divided into 2000 g.p.m. to flotation feed sump and 10,000 g.p.m. to main plant sumps for recirculation.

Main sumps are three 12′ wide x 20′ long x 12′ deep concrete tanks feeding two 14″x 12″ and one 12″x 10″ pumps for plant recirculation to jigs, screens, etc. The flotation feed sump is a 12′ wide x 20′ long x 10′ deep concrete tank. The 2000 g.p.m. flotation feed containing 6% to 8% solids of minus 20 mesh fines assaying 12% to 15% ash) is pumped by a 10″x 8″ pump to two 24″ cyclones which produce a 60 mesh separation.

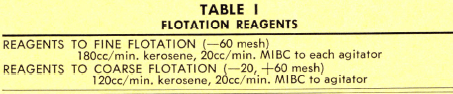

The overflow from the cyclones containing the minus 60 mesh material and amounting to approximately 1250 g.p.m. is split to two 10’x 10′ Super Agitators where kerosene and methyl isobutyl carbinol are added by four Wet Reagent Feeders. The discharge from agitators is sent by gravity to two 10-cell No. 30 “Sub-A” Flotation Machines by an 8″ line to the number 4 cell and a 6″ line to the number 5 cell of each bank. Flotation banks are arranged with 5 freeflow rougher cells, 2 freeflow scavenger cells and 3 cell-to-cell cleaner cells. Scavenger concentrate is returned to the second rougher cell and rougher concentrate is returned to the first cleaner cell, for one stage of cleaning using three cells. All cells are double overflow, with four froth paddles on each side of the cell. Paddles are driven by separate variable speed drives.

The underflows from the cyclones containing the 20 mesh by 60 mesh material and representing approximately 750 g.p.m. is sent to one 8’x 8′ Super-Agitator, where kerosene and methyl isobutyl carbinol are added.

The conditioner discharge is split and sent by gravity to two 4-cell No. 30 “Sub-A” Flotation Machines. Flotation is by one pass through the flotation machines with no cleaning of the froth concentrate. The Flotation Machines are single overflow with multi-bladed chain driven froth paddles.

The average operating life of the Flotation Machine’s neoprene multibladed impeller and diffuser plates on the fine coal (— 60 mesh x 0) float is approximately 24 months, and the average operating life on the coarse (—28 mesh +60 mesh) float is also approximately 24 months.

The tailings from the fine flotation scavenger cells, fine flotation cleaners, and coarse float roughers, are sent to a 120′ diameter thickener where Cyanamid S-3171 is added for flocculation. Clear thickener overflow is sent to main sump for recirculation and thickener underflow is pumped directly to the backfill blending tank as backfill material.

Concentrates from both fine and coarse flotation circuits are sent by gravity to a 16’x 16′ cone shaped surge tank and then by 4″ pump to two 8′-10″ x 8-disc.

Automatic sampling is used at Kaiser’s Sunnyside plant on the final product blending conveyor. Secondary sampling is then used to reduce the bulk of the final sample.

filters. Filtrate from filters is pumped by 2″ pump to the fine flotation circuit. Filter cake goes by gravity to the 48″ blending conveyor and railroad cars.

Production of flotation coal is approximately 75 t.p.h. with a 6% to 7% ash content and representing a 92% to 95% extraction of the coal in flotation feed.

Final Product Sampling

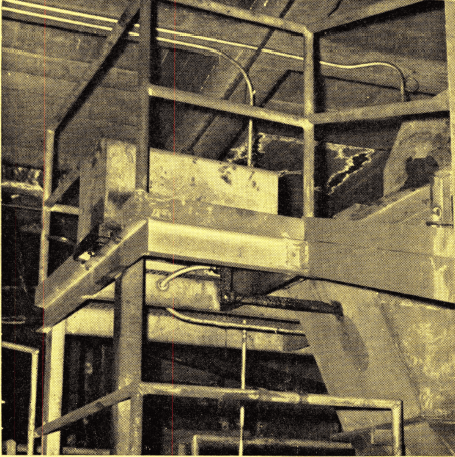

The 48″ blending conveyor discharges to either of two chutes to railroad cars. The discharge stream from either chute is cut at five minute intervals by one of two 72″ automatic samplers with chute-plate front track cutters, taking 1000 pounds per cut from 650 t.p.h. flow of blended coal. The sample is delivered by a 24″ conveyor, to a hopper and 24″x12″ hammer mill. The hammer mill discharge is then sampled by a 26″ automatic sampler with chute-plate cutter on an end track carriage. This sample falls by gravity to a 15″x9″ hammer mill and then through a second 26″ automatic sampler with chute-plate cutter on an end track carriage. Rejects from both secondary and tertiary samplers fall onto an 18″ conveyor discharging to cars. A final sample of 200 pounds per shift is collected.

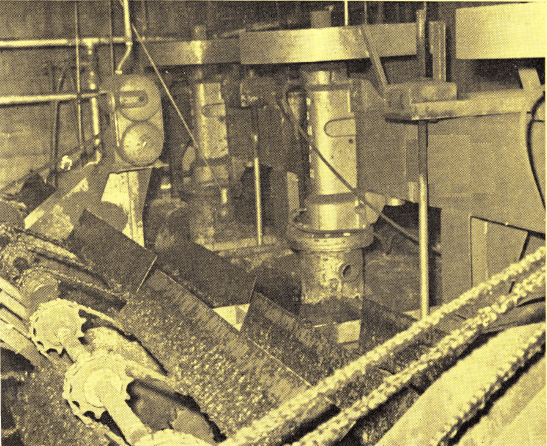

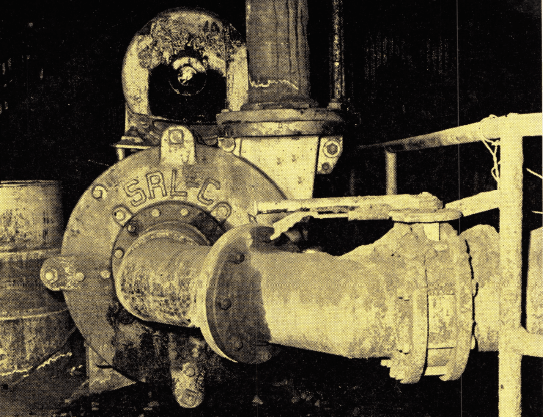

Big 10″x8″ SRL-C Pump handles — ½” rod mill discharge from 7’x 13′ Center-Peripheral Discharge Mill. Rod mill discharge is returned to screens for sizing. Pump has 75 HP motor. Wearing part life is 500-600 hours.