Table of Contents

For the past decade, the Bureau of Mines has addressed the problem of using low-grade scrap, such as the ferrous fraction of municipal refuse, to produce steels of acceptable quality. The investigations are a part of the Bureau’s 65- year commitment to minimize the requirements for mineral commodities by devising new technologies for the recovery of metal values from waste resources. Early work focused on methods to remove deleterious elements, such as Cu, Pb, and Zn, from wastes, so that the wastes could be used as melting stock to produce predictable and acceptable quality steels. Later and concurrent research emphasized the use of as-received waste materials and the determination of the effects of tramp elements such as copper and tin on the quality of the steel produced. Finally, different types of scrap were evaluated to determine the feasibility of using a variety of materials to produce acceptable steel. New analytical techniques also have been developed to determine accurately the level of tramp elements in steels produced from low-grade scrap.

The production of steel requires a variety of raw materials, and scrap is the major one. Computer models were generated in 1973 to predict scrap requirements. They indicated that domestic scrap consumption would reach 79 million tons per year by 1980, and 99 million tons per year by 1990. A decrease in the net available supply of scrap in the United States has also been forecast. Accordingly, it is imperative to determine whether the ferrous fractions of waste materials can be substituted for some of the higher grade scrap to produce acceptable quality steels. It has recently been reported that 179 waste processing units are either under construction or in the planning stage. At the present time, 17 installations are in operation, and 6 are operable but temporarily shut down. The plants recover ferrous metals, aluminum, glass, and energy (as combustibles).

The Bureau of Mines has conducted extensive research specifically on the ferrous fractions of urban refuse. Earlier investigations involved melting ferrous scrap (mostly cans) from Chicago incinerator residues and unburned tin coated steel cans, together with appropriate ferroalloys, in an induction furnace to produce 55-pound steel ingots. Combined copper and tin contents ranged from 0.35 to 1.97 wt-pct in the steels produced. Dilution with purchased scrap lowered the levels to ranges of 0.14 to 0.44 wt-pct Cu and 0.005 to 0.16 wt-pct Sn, compared with values averaging 0.11 wt-pct Cu and 0.006 wt-pct Sn when purchased steel scrap alone was used. The ingots were forged and rolled without difficulty; and tensile, hardness, and impact tests were performed on the plates. In some steels, high copper levels (0.60 to 2.0 wt-pct) caused edge cracking, but tin contents up to 0.12 wt- pct had little effect on cracking. The data showed that copper and/or tin can have a strengthening effect, although tin levels up to 0.16 wt-pct appeared to have very little effect on the tensile strength of medium carbon steels.

Another series of steel heats was made in a 1-ton electric-arc furnace, from which 55-pound and 870-pound ingots were produced. In general, the 55-pound ingots were forged and rolled successfully, and mechanical properties were obtained from the rolled plates. Copper and tin contents in plates derived from the incinerated scrap averaged 0.23 wt-pct and 0.19 wt-pct, respectively. Plates made from the unburned steel cans averaged 0.07 wt-pct Cu and ranged from 0.06 (detinned cans) to 0.37 wt-pct Sn. Tensile and yield strengths generally exceeded specified minimum values for plain carbon steels, and ductility values ranged upward from slightly below the minimum values.

This report covers a continuation of the Bureau’s efforts to evaluate the use of raw refuse scrap in steel of noncritical quality. The steels produced using this material are compared with steels produced from other types of scrap, such as turnings, No. 2 bundles, auto scrap, and heavy melting scrap.

Materials

The ferrous materials used in this research included the following:

gray iron in pig form

Navy destroyer anchor chain

fragmented automobile scrap

No. 2 bundles

magnetic fraction of municipal refuse

borings and turnings

Gray iron was used primarily as a source of carbon when necessary; it was produced during ongoing cupola ironmelting research. The chemistry determined (in weight-percent) was typically 3.5 C, 2.3 Si, 0.8 Mn, 0.05 S, and 0.02 P. This iron was clean, and the surface was virtually free of sand from the pigging operation. The pigs ranged in weight from 20 to 30 pounds.

The chain was obtained from Navy surplus and is considered to be high-quality scrap, equal to or better than No. 1 heavy-melting scrap. Each link, including the crosspiece, weighed about 11 pounds. The link itself was mild steel at about 0.1 wt-pct C, and the crosspiece was gray iron at about 3.3 wt- pct C. The crosspiece, inserted during forming the chain to minimize elongation of the links, weighed about 0.75 pound. The average carbon into the furnace from this material was about 0.3 wt-pct; the meltdown carbon was less than 0.3 wt- pct.

Fragmented automobile scrap is a commercial product that has gained wide acceptance in the steel industry, The material for this study was obtained from a local processor, and it contained typical amounts of wire, fabric, and other foreign materials. This type of scrap normally melts in at about 0.25 wt-pct C, and it typically contains from 95 to 97 wt-pct recoverable iron.

Number 2 bundles are intended to provide somewhat of a catchall for miscellaneous scrap materials from the scrap processing trade that can be bailed or bundled. These bundles can contain sheet metal, some enameled sheet, galvanized steels, strapping, large and small containers, and the like, and are made to weigh about 3,000 pounds. The material for this study was taken from a pile being accumulated by a local processor for bundling. Efforts were made to select representative pieces for melting, although the overall composition of bundled scrap is obviously variable.

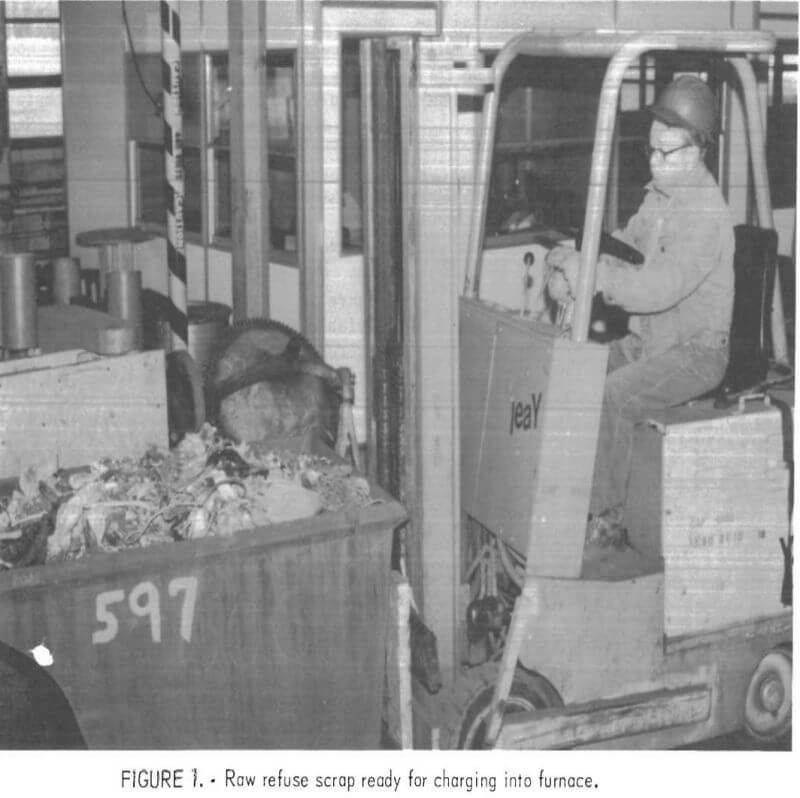

The magnetic fraction of municipal refuse, or refuse scrap, was obtained from a waste reduction plant in Madison, Wis. The material consisted largely of food and beverage containers, including some bimetallic cans. Since the plant was being operated primarily for the fuel value, this scrap also contained bits of plastic bags, paper, some glass, and other foreign materials. As a result, the carbon content of the refuse scrap was estimated to be from 1 to 2 wt-pct, with the carbon being in several forms. The aluminum content was estimated to be from 1 to 2 wt-pct. Tin and lead from sealing and joining and/or from plating were also significants Zinc from miscellaneous galvanized materials might also have been present. The recoverable iron content was estimated to be between 88 and 90 wt-pct. A hopper of this scrap is shown in figure 1.

The borings and turnings, obtained from a local scrap dealer, were typically oily and were of the short-shoveling variety. Several spot samples of the material showed about 0.50 wt-pct C, so they probably contained only a small percentage of cast iron (borings).

Silicon and manganese added as ferroalloys for deoxidation and alloying contained 48 wt-pct Si and 65 wt-pct Mn, respectively. High-calcium lime for slag formation contained about 97 wt-pct CaO, and fluorspar was used as required for fluidizing. Iron oxide pellets for decarburization contained about 93 wt-pct Fe2O3.

All heats were made on a magnesite lining, and patching was done with the same magnesite refractory.

Equipment

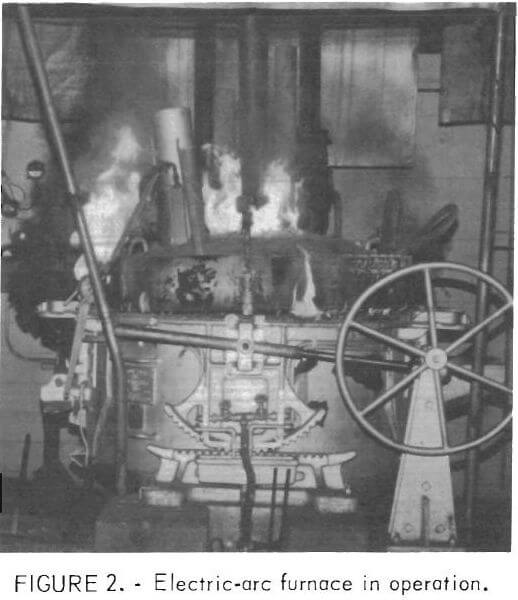

All of the heats for this research were made in the three-phase, 1-ton-capacity, electric-arc furnace shown in figure 2. This is a roof-swing, top-charging furnace with a transformer of 500-kva rating. This unit was designed primarily for melting with 4-inch-diam electrodes, and the furnace transformer provides four secondary voltage taps, which are changed manually. All of the furnace fumes are drawn from the hood overhead and passed through a high-pressure drop venturi scrubber before they are exhausted into a stack. Sampling of scrubber water containing particulates is done at the scrubber discharge.

Rolling of the steel specimens into rods was done using the mill shown in figure 3. This is a reversing mill with variable speed control. The specimens for rolling were small because the reheat furnace could not accommodate rods over 15 inches long.

Procedure

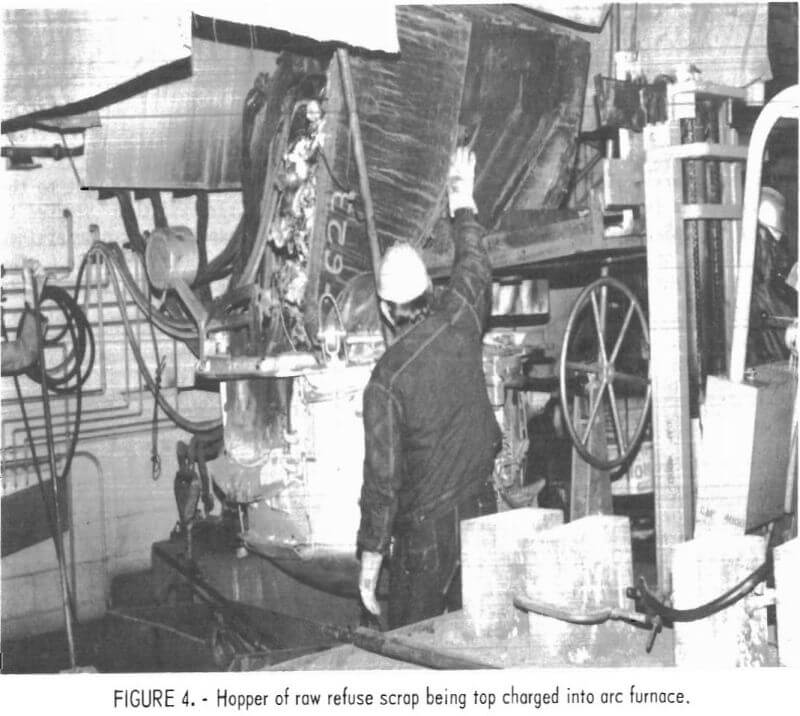

The roof of the furnace was lifted and swung off to permit top charging with a hopper and forklift truck, as shown in figure 4. The hopper was modified slightly to facilitate charging, and experience showed the appropriate volumes of the various scrap materials that could be charged at one time. When scraps of low bulk density, such as refuse scrap, were melted, several backcharges were required.

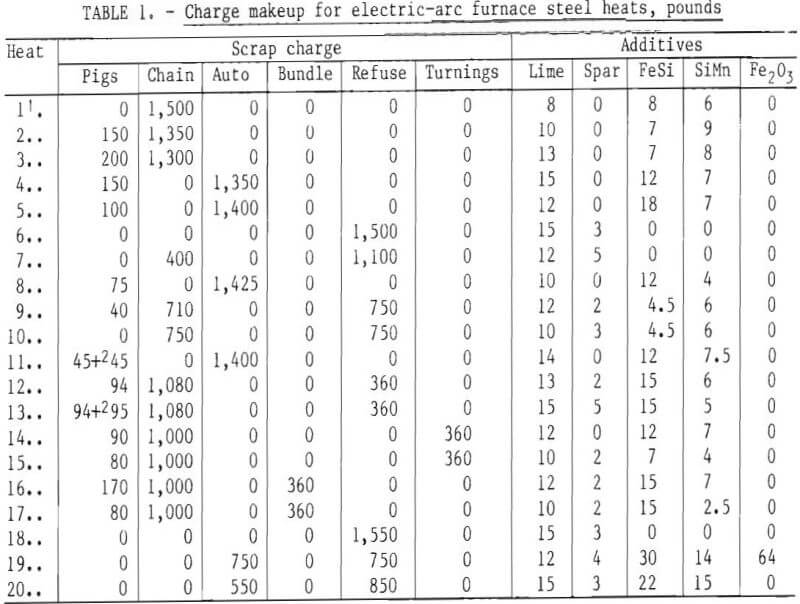

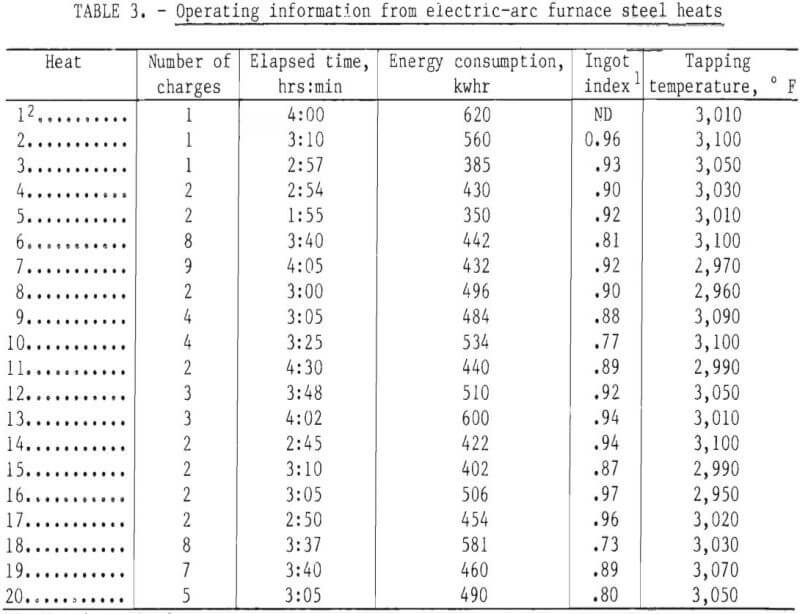

All melting was done with the appropriate secondary voltages dependent on the conditions in the furnace. Lime for fluxing the slag and fluorspar for fluidizing were added as necessary. After the entire heat was melted, preliminary samples were taken, and the partial chemistry was determined and adjusted as necessary. The heat was brought to the desired temperature and then blocked in the furnace. Temperature was determined and the heat tapped into a ladle. The materials used for each heat are given in table 1.

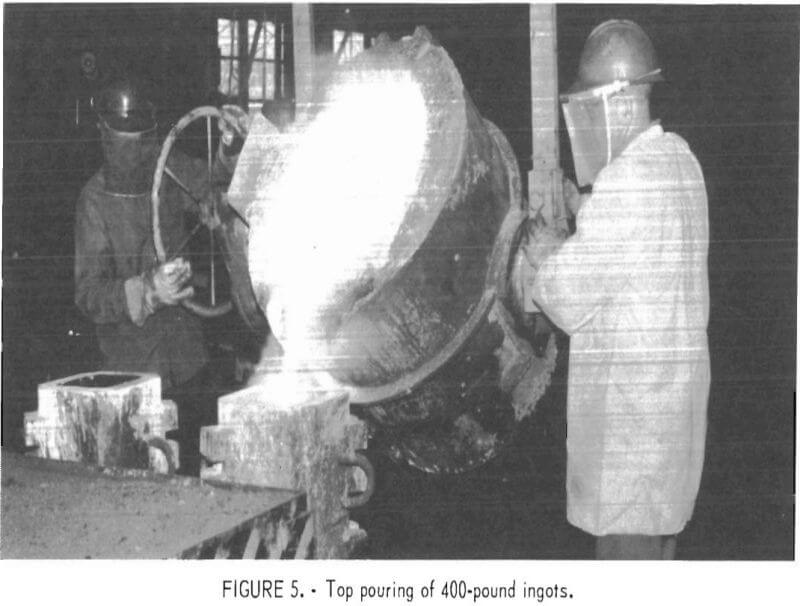

All of the steel was top poured into ingots of various sizes. Some of the smaller ingot molds may be seen in the lower right corner of figure 4. The pouring operation into the larger ingot molds is shown in figure 5.

All samples for steel chemistry analyses were taken out of the furnace. Specimens that were rolled into rods were sectioned from the ingots produced. Metallographic samples were taken before and after rolling. The rods were tested in tension by a local steel mill. Some of the rods are shown in figure 6.

Results and Discussion

Several preliminary small-scale (100-pound) heats were made in an induction furnace, combining various low-quality scraps to determine if desired carbon contents could be met. Although some variability in carbon was evident, no serious problems arose in achieving a particular content by appropriate blending of materials. This preliminary work was the basis for larger heats of at least 1,500 pounds in the arc furnace.

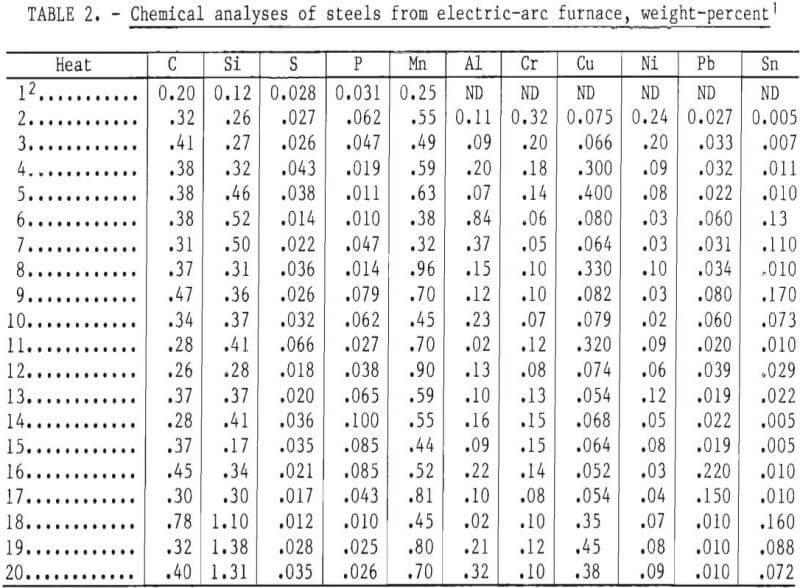

The chemical composition of the steels is given in table 2. The first heat was made to condition the new furnace lining and was not processed further. Efforts were made on the other heats to produce either 0.30 or 0.40 pct C. These carbon contents provide grade 40 or grade 60 steels, respectively, with appropriate refining and alloying. These grades (ASTM 6155) correspond to tensile strengths of 40,000 and 60,000 psi. Other specifications include about 0.60 to 0.90 pct Mn, maximum 0.07 pct S, and maximum 0.06 pct P. The only exception to the carbon specifications was 0.78 pct C in heat 18, which was made from 100 pct refuse scrap that contained high levels of paper, plastic, and other carbon

contributors. It should be noted that heats 6, 7, and 18, made with 70 pct refuse scrap or more, required no blocking or alloying, probably owing to the aluminum content of the scrap. The tin in steels made from 50 pct or more refuse (heats 6, 7, 9, 10, 18, 19, 20) reflect the tin content of this material. Some of the other heats were slightly out of specification with respect to manganese and phosphorus. These are not serious problems, however, since these elements are readily controllable through additions and/or furnace practice. Most of these steels met the strength requirements.

The information obtained from the records of furnace operation is given in table 3. Of particular interest is the number of charges required to complete a heat. The initial charge is included, and the number of charges reflects on the bulk density of the scrap. Backcharges obviously contribute to lost time and energy; therefore, serious consideration must be given to compaction of light-gage scrap if such scrap is to be used commercially. The quality of the scrap may be judged by the “ingot index,” which is the weight of the steel in ingot form divided by the weight of the scrap.

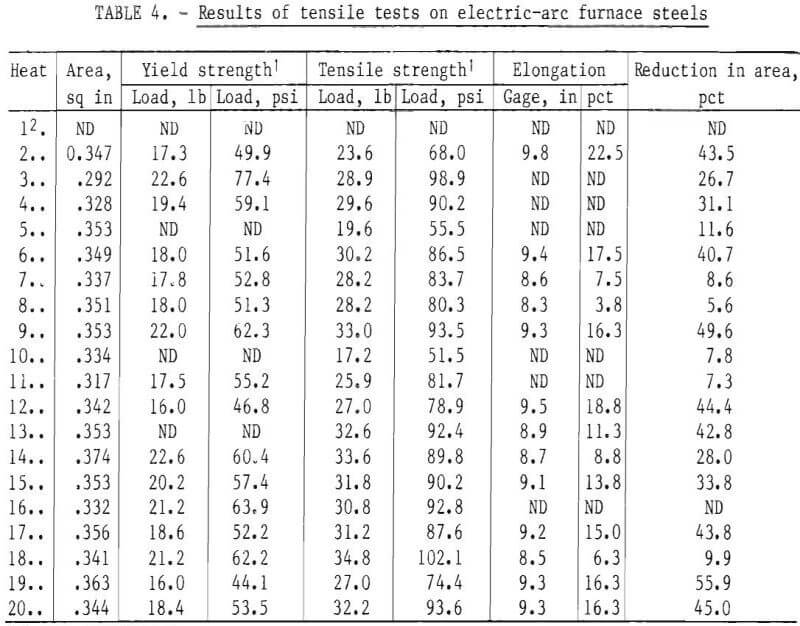

The ingots poured from these heats were sectioned to provide a coupon about 1.5 inches in diameter by 3 inches long. These were rolled into rods about five-eights inch in diameter and some 12 to 15 inches long. The rods were tested in tension by a local steel (mini) mill.

The results are shown in table 4. Although steels met tensile strength specifications, in some the ductility was low. This was probably due to the chemistry of the steel and perhaps somewhat to the processing.

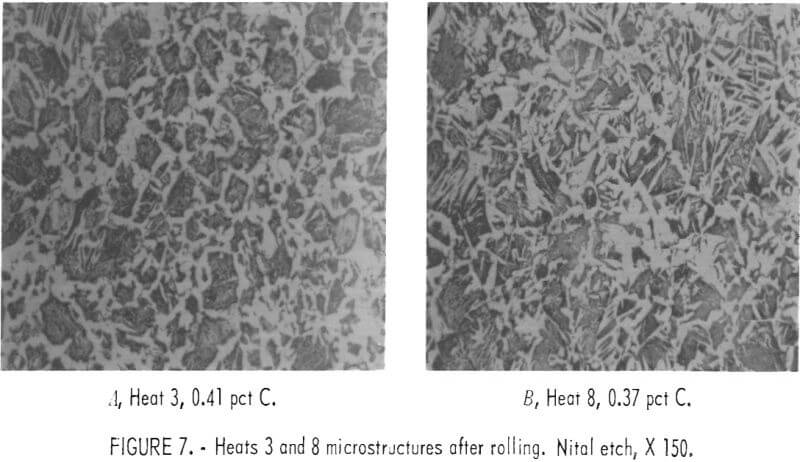

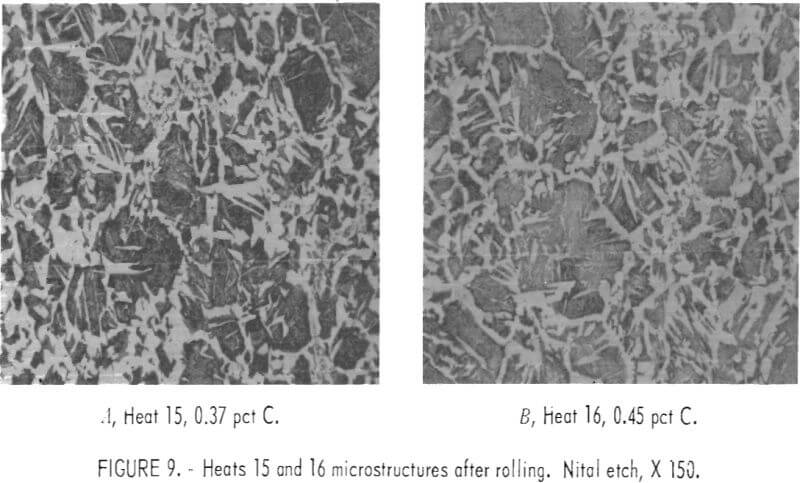

Specimens were taken from the steel rods as cross sections and were prepared for microscopic examination. Figures 7 through 9 are photomicrographs showing typical as-rolled structures. Figure 7 shows typical structures of high-quality steel made with heavy-melting and fragmented scrap. The photomicrographs show iron carbide (dark) as either massive carbides or in pearlite, in a ferrite (light) matrix. Ferrite side bands into the carbide are clearly evident. These structures are normal for unalloyed carbon steel with the indicated carbon content.

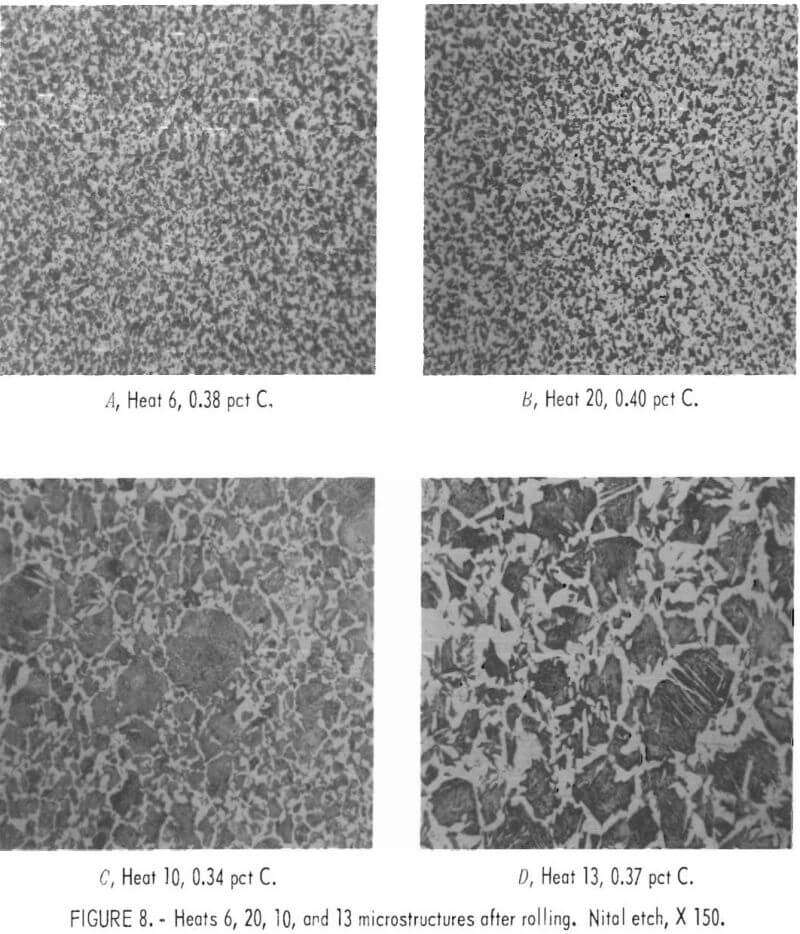

The structures of steels made from decreasing levels of raw refuse scrap are in figure 8. Figure 8A shows a steel made from 100 pct refuse scrap, which apparently produced an extremely fine-grained structure. The steel made from about 60 pct refuse scrap is shown in figure 8B. The structure is also fine grained, although the grains are slightly larger than in the steel made from 100 pct refuse scrap. The steel shown in figure 8C was made from 50 pct refuse scrap, melted with chain. This provided a grain size among the carbides and pearlite, which were just discernible at the magnification used. The matrix of ferrite also tends to be widely dispersed and less predominant. The steel shown in figure 8D, made with about 25 pct refuse scrap, with chain, has structures similar to steels shown in figure 7.

Figures 9A and 9B show the structures obtained from steels made with about 25 pct short-shoveling turnings and 25 pct No. 2 bundle (type) scrap, respectively. These structures appear normal for the carbon content. Those scraps are used commercially, particularly the No. 2 bundle (type) scrap. Turnings should be free of borings (cast iron) because the borings have a high carbon level.

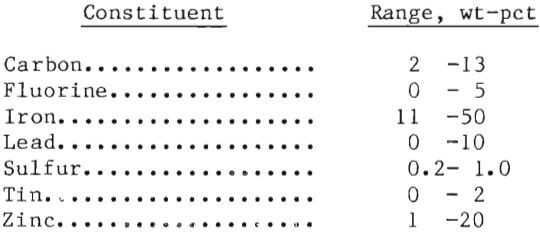

Water samples containing particulates were taken from the scrubber discharge at various times during a heat. (The dust load was between 0.1 and 3.0 grams per liter of scrubber water.) The composition of the particulates varied widely depending on the type and amount of each scrap being melted and on the sampling time. The range of composition of particular elements in the dust; derived from the chemistry of all the samples taken, was as follows:

Conclusions

Based on steelmaking research in a pilot-scale electric-arc furnace, the following were concluded:

- Most of the steel produced met chemical specifications (ASTM 615) of grades 40 and 60, containing 0.30 or 0.40 pct C.

- All of the steels could be rolled without difficulty and most met tensile strength requirements of minimum yield strengths of 40,000 or 60,000 psi, respectively. The ductility of some steels produced from certain combinations of scrap was not satisfactory, and this area should be studied.

- Refuse scrap in the charge at levels up to 50 to 55 pct, in combination with higher quality scrap, produced acceptable steel. At levels above 50 to 55 pct, refuse scrap apparently provides steels of finer grain size than steels produced from higher quality.

- Steelmaking dusts can be rich in Pb, Sn, and Zn and should be recovered. Although research has been done, additional study would be appropriate.

- Refuse scrap in the charge at levels above 70 pct eliminates the need for blocking or alloying with silicon and manganese ferroalloys because of the aluminum from bimetallic cans.

- The tin contents of the steels produced from charges containing over 50 pct of raw refuse scrap can range from about 0.07 to 0.17 pct.