Since man began beneficiating ores, a limited number of factors influenced the type of treatment. The ore itself has always been a factor. The first form of concentration was probably hand sorting, and the grade of concentrate and recovery had to be considered from the start.

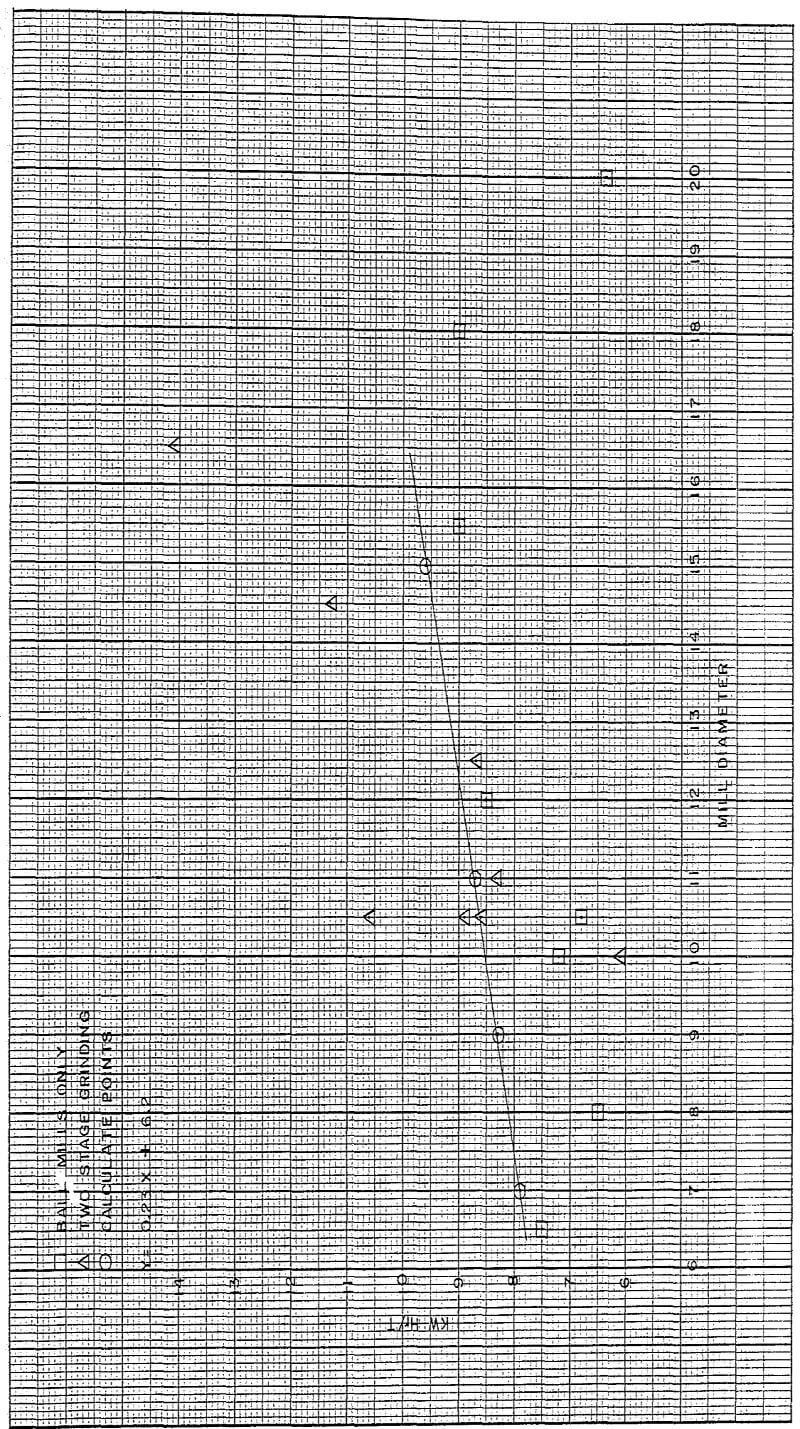

Five of the principal factors having an effect on the power consumption per unit of capacity are:

- Hardness of the ore.

- Fineness of the grind.

- Circulating load.

- Diameter of the ball mills.

- Number of grinding stages.

Comparing 8 single stage grinding circuits with an equal number of multistage plants show a saving of approximately 1 KWHr/ton for the former. This figure is based on the combined crushing and grinding power consumption. Another advantage of the single stage grinding circuit is a reduced number of pumps and other auxiliaries.

It should again be emphasized that this work concentrates on power saving. Therefore there could be valid reasons for installing large diameter, or multistage grinding mills. But the advantages must be sufficient to overcome a continuing and increasing cost of power. Regrinding consumes between 5% and 10% of the power in the primary grinding circuits in a number of the mills studied.

The third area in a concentrator where significant power savings are possible is in the flotation section. The larger cells, 300 cubic feet or more, can save up to 1 KWHr/ton. Based on reports from 17 operations, a power consumption varying from 1.0 to 2.0 KWHr/ton is normal. More than half fell in this range.

A substantial majority of the operations reported between 12 and 15 KWHr/ton treated. This held true despite wide variations in pumping, conveying and other operating conditions. The above figure may serve as a guide for feasibility studies, but every effort should be made to maximize the efficient use of energy.