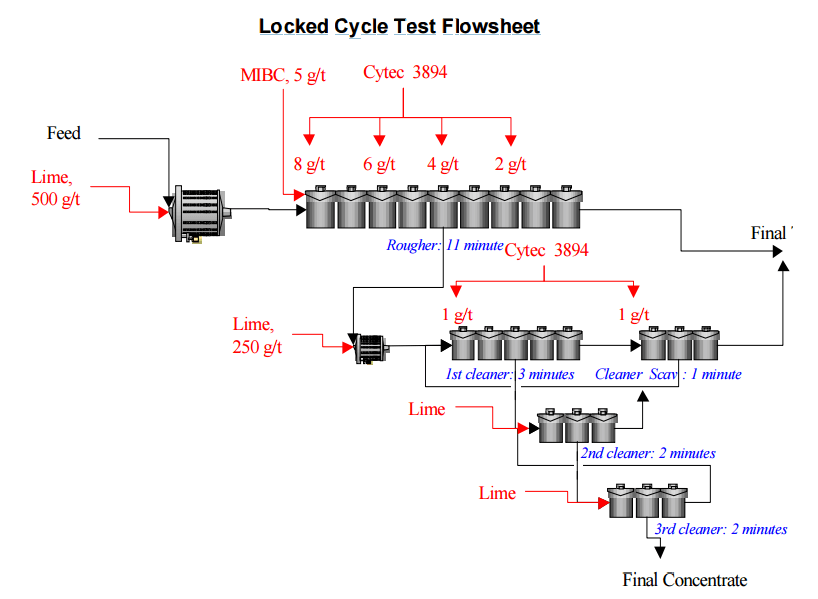

Locked cycle tests were conducted on each of the super composites, using the flowsheet shown below. The flowsheet consisted of a primary grind to a P80 of 150 µm, followed by rougher flotation at pH 9.5 to produce a bulk sulphide concentrate. The rougher concentrate was reground to a P80 of ~30 µm prior to three stages of cleaning at pH 11.0, 11.5, and 12.0, respectively. The 2nd and 3 rd cleaner tails were recycled to the feed of the previous stage, while the 1 st cleaner tails went to a scavenger float. The scavenger concentrate was returned to the first cleaner feed, and the scavenger tail to the final tails. Reagent additions consisted of lime to control pH, Aero 3894 as collector, and MIBC as frother. Collector and frother additions were held constant between tests, whereas lime addition fluctuated in order to maintain the setpoint pH.

The tests exhibited minor scatter through the cycles, though reaching acceptable mass equilibrium after 2 to 3 cycles, and copper equilibrium after 4 cycles. Steady gold balancing was impeded by the low gold content in the ore and possibly, the presence of small amounts of coarser gold affecting assay reproducibility. The results from locked cycle confirmation tests on each composite are shown in Table 5-8. On average, copper recovery was 90%, while the copper concentrate grade averaged 31%. Gold recovery was 49%. These results are consistent with the performance expected from batch testing and mineralogy. Copper losses were primarily incurred in roughing (6%), while a further 3% to 4% were lost to the first cleaner scavenger tails. Gold losses were also mainly to the rougher tails, and probably consisted of gold occurring as ultra-fine inclusions in silicates. The gold lost in the cleaner tails were probably associated, primarily, with pyrite.