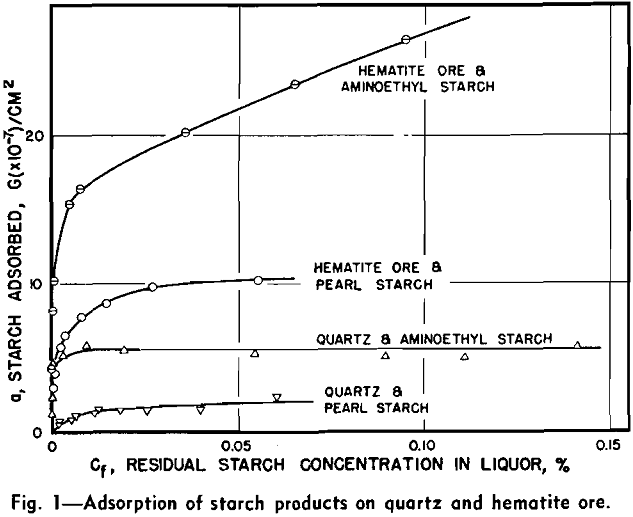

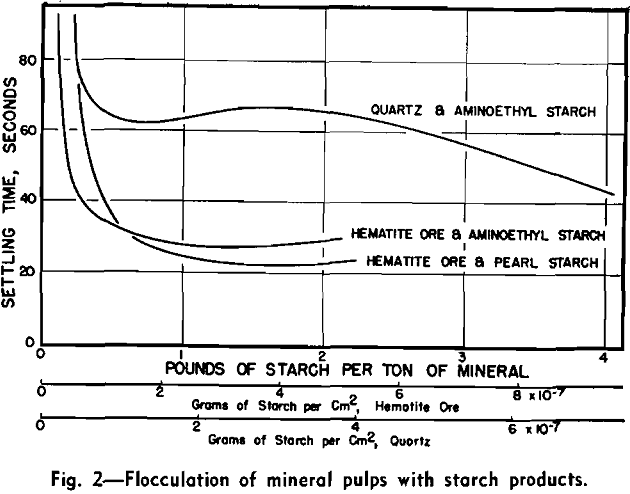

During the course of an investigation of the effects of various starch products on hematite and quartz in regard to their separation by flotation, it was found that whereas most starches flocculated suspensions of hematite in water, they did not flocculate similar suspensions of quartz. However, a derivative of whole corn starch containing approximately one tenth aminoethyl group (—CH2CH2NH2) per glucose unit proved to be an exception.

The degree of flocculation was determined for a given pulp by measuring the time required for the supernatant liquid to reach a certain degree of clarity. This was accomplished by passing a standard light beam through the pulp, contained in a glass settling tube, and measuring the time required after agitation ceased for the intensity of the transmitted beam to reach a predetermined value. Starch re-agent was added to each pulp in small uniform increments, and the settling time was determined after each such addition.

Flotation tests were made on samples of iron wash-ore tails that were prepared by a brief grinding and a thorough desliming operation, using 0.33 lb of quebracho per ton of ore, which removed the particles smaller than 13.5 microns.

Pearl starch markedly improved the iron recovery of the flotation process, when used in quantities up to 1 lb per short ton, by selectively depressing the hematite. With no starch, the iron recovery was 64.1 pct, with 1 lb of starch per ton, 80.6 pct, increasing slowly to 83.5 pct with 10 lb per ton. Grade of concentrate was but little affected, averaging about 53.5 pct Fe for starch additions of from 0 to 10 lb per ton.