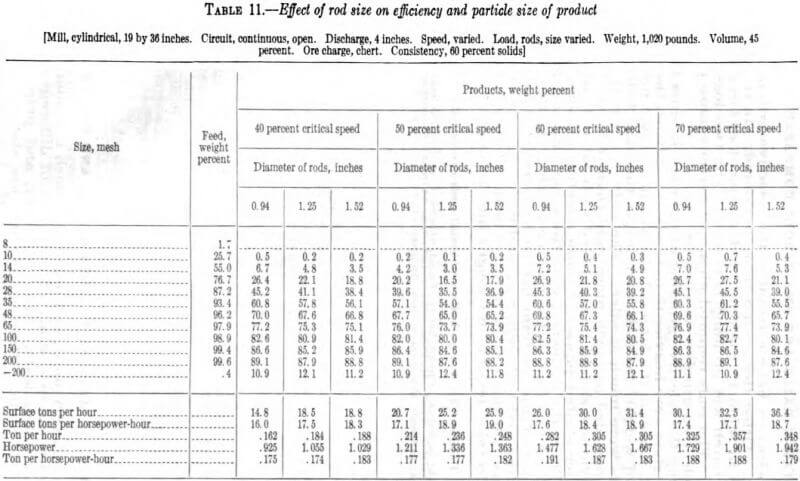

In a study of rod-mill discharge openings of different sizes, four pairs of tests were made at speeds of 40, 50, 60, and 70 percent of critical. In each pair the discharge openings were 8.0 and 4.5 inches, respectively. The tests were conducted so that the tons per horsepower-hour were nearly the same. This manner of conducting the tests gave about the same amount of sub-sieve size in each. The results are shown in table 8. The similarity of the sizing analyses is notable. At 70-percent speed and with the 8-inch discharge the capacity was less than in the analogous test at 60-percent, speed, and the power was increased so much that efficiency was noticeably impaired. A similar comparison of the work with the 4.5-inch discharge at 70-percent speed shows some advance in capacity over 60-percent speed; but again, the power was increased so much that efficiency declined. A general examination leads to the conclusion that 70-percent speed is too high.

With the large discharge the power was higher. This principle is well known but here the measure of the difference in power is given. It was only about 2 percent. The best capacity and efficiency was with the large discharge.

A similar test of discharge openings of the ball mill was given in a former paper. There the results of the ball-mill tests at 80-percent speed showed about the same degree of failure in efficiency as the present rod-mill tests at 70-percent speed. At very slow speeds the ball mill seemed to function better than the rod mill at similarly slow speeds. The rod mill, like the ball mill, gave higher capacities when the discharge openings were large. The range of satisfactory speeds of the rod mill was more limited than that of the ball mill.

The rod-mill work shown in table 8 was best with the large discharge because less ore was retained in the mill. In regular mills the large opening required to facilitate the addition and removal of rods seems to have been an advantage not recognized when the first mills were built. The observation about the amount of ore in the rod mill will come up again in the next discussion.

Effect of Rod Mills Ore Charges & Speeds

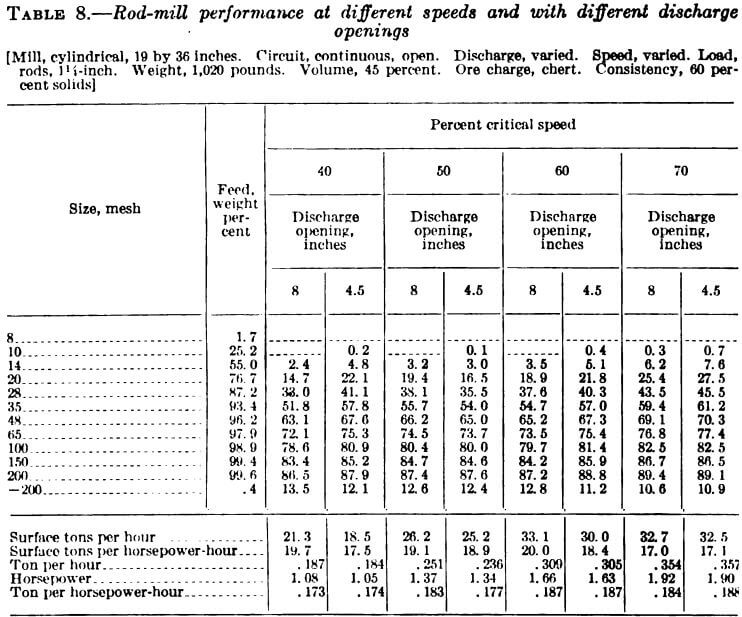

The continuous rod-mill tests just shown were supplemented by batch grinding. Although 40- and 70-percent speeds have been found not to be the most desirable, they were used in tests to illustrate the

effect of varying the ore charge. The results are shown in table 9. In each of the two groups of tests the capacities and efficiencies increased progressively with decreased amounts of ore charge and were maximum at about 25 pounds. By actual tests, 39 pounds of dry ore was required to fill the interstices at rest. The small amount required for best work indicates again that a large discharge on a rod mill is desirable.

The observation that the wet rod milling was the best with a very small amount of ore is analogous to the dry ball milling to be shown later in table 14. A different trend will be shown in the wet ball milling in table 13.

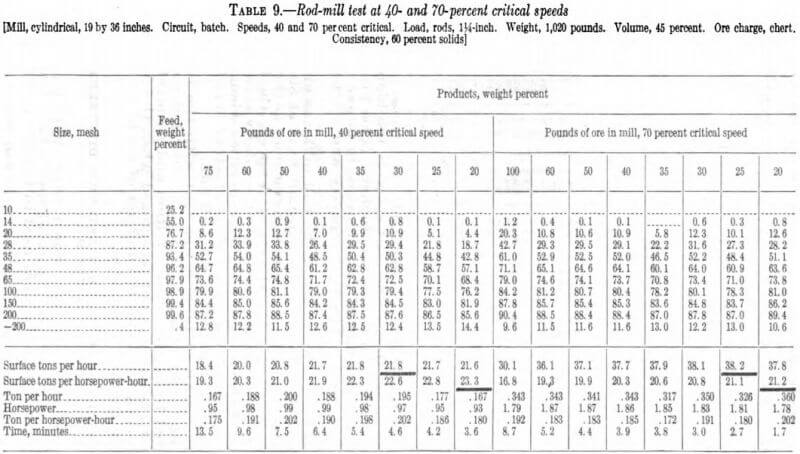

Effect of Rods Sizes & Speeds

Rods of three sizes were tried in the open circuit at four speeds. The results are given in table 11. The feed rate was adjusted as near as possible for a constant ratio with power. (Such adjustments are tedious, but they are worth the trouble.) It followed that the amounts of the subsieve material were about the same, and thus a comparison of sizing analyses and surface calculations is justified. As was expected, the largest rods gave the greatest capacity and efficiency and better selective grinding. Even the largest rods used might be too small for a large mill, because of the tendency of small long rods to become bent and subsequently entangled. Rods larger than 1.52 inches in diameter were not available.

Although the rods were sized closer than is done in practice, a comparison of the work of rods and balls will be made. This may be done by taking the results of 60 percent speed and 45 percent rod volume from table 11 and the same speed in the upper part of table 13. The former is continuous and the latter is batch grinding, but that status need not vitiate the comparisons. In the rod mill with the 1.52-inch rods, the tons per horsepower-hour were nearly the same as in the ball mill. The efficiency, that is, the surface tons per horsepower-hour, of the rod mill was a little below that of the ball mill.

These citations must not be taken to indicate that there is no difference between a rod mill and a ball mill. The former required more power than the latter when loaded with the same volume of media, and accordingly did more grinding. At 60 percent speed the 1.52-inch rods gave a capacity of 31.4 surface tons per hour, whereas the best capacity in the ball mill at the same speed (table 13) was 30.3 surface tons per hour.

If an operator withdraws a ball charge and replaces it with the same volume of rods and then, upon starting again, maintains the same feed rate, he will find that the effluent has a much smaller amount of coarse particles. Then, if he fails to take into account that he is doing more work on a unit weight of ore he will become an unduly ardent supporter of the rod mill. A just comparison cannot be made without taking power and feed rate into account.