The flotation process may be considered an interactive system consisting of many chemical, operational, and equipment variables. Changing any one of these variables causes an overall system response change. This study examines the effects of simultaneously changing the operating variables of: (1) frother concentration and air flow rate, and (2) frother concentration and collector concentration. It is part of a comprehensive study to look at how changes in several of the major variables may be used to produce interactions which will allow the rougher flotation process to be optimized.

Experimental Procedure

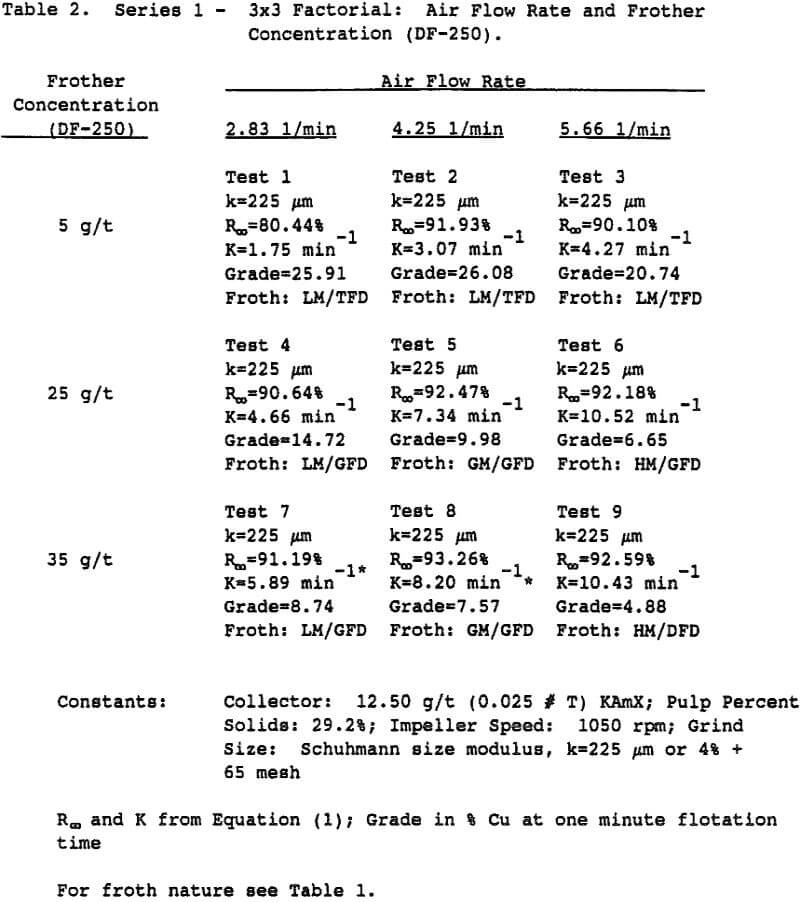

Series 1 – Air Flow Rate and Frother Concentration: A 3×3 factorial experiment was designed to observe the effects of simultaneously changing three levels of air flow rate (range: 2.83 to 5.66 l/min.), and three levels of DF-250 frother (range: 15 to 35 g/t) while holding collector concentration at 12.5 g/t potassium anyl xanthate (KAmX), slurry percent solids at 29%, and grind size at a nominal -225 µm.

Series 2 – Collector Concentration and Frother Concentration: A 4×3 factorial experiment was designed to observe the effects of simultaneously changing four concentration levels of KAmX collector (range: 2.0 to 23.0 g/t), and three levels of DF-250 frother (range: 15.0 to 35.0 g/t) while holding air flow rate constant at 4.25 l/min, slurry percent solids at 29%, and grind size at nominal -225 µm.

Based on the cumulative fractional recoveries, the first order kinetic model with a rectangular distribution of floatabilities was used for the calculation of the ultimate recovery and flotation rate:

r = R∞{1-1/Kt{1-exp(-Kt)]………………………………………………………….(1)

r = recovery of component at time t

R∞ = ultimate recovery of component

K = rate constant (time-¹) for this model

Results and Discussion

As air flow rate increases, recovery increases until a maximum is reached at an air flow rate of -4.25 M/min and then decreases slightly. This is more evident for the lowest level of frother tested (15.0 g/t). This decrease in recovery at a high air rate is to be anticipated since had previously noted that excessive air flow can reduce solids suspension capability, as well as introduce surface geysering in the froth.

Increasing frother (Dowfroth 250) concentration induces higher recoveries. A relatively high frother dosage tends to produce closely-knit froths which are conducive to high recoveries. The increase in frother dosage also leads to an increase in flotation rate but with an accompanying decrease in concentrate grade. These higher frother concentrations cause excessive froth in the flotation cell which increases the froth overflow rate and thus an increase in flotation rate. Alternatively, low frother concentrations produce loosely textured froths with large bubbles which tend to release gangue particles from the froth, resulting in a high concentrate grade (>20.0% Cu).

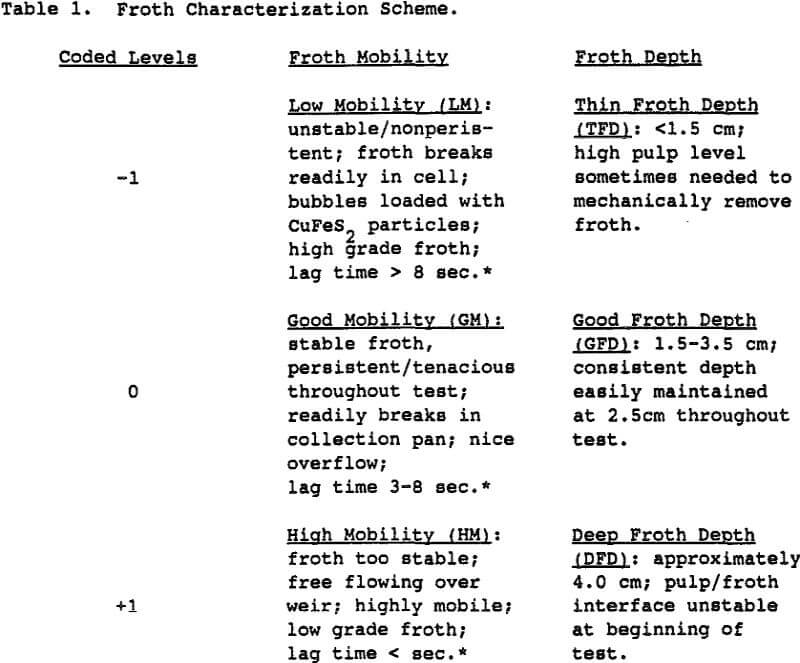

Visual observations indicate that froths with low mobility and thin froth depth (tests involving low frother concentration, i.e., 15 g/t), generally lead to low flotation rates (<5.0 min ) and very high concentrate grades (>20.0% Cu). These froths are “loaded” with chalcopyrite particles, so much so that the bubbles break before they can be removed from the flotation cell. Loose froths with large bubbles, which are low in mobility and thin in depth, tend to release gangue particles from the froth, thus producing a high grade concentrate.

Air flow rate has a greater influence on flotation rate at high frother concentrations than at low concentrations. Since increasing the frother concentration increases the mobility of the froth, increasing the air flow rate will immediately cause an increase in flotation rate.

- Excessive aeration causes entrainment of gangue particles in the froth leading to a lower concentrate grade.

- An increase in recovery is seen as frother dosage increases. High frother dosages create small-bubble, closely-knit froths which lead to high recoveries since they can support heavy mineral loads and prevent the drop-off of particles from the bubbles.

- A high frother concentration produces an excessive amount of froth in the flotation cell. This increases the froth overflow and flotation rate, but, unfortunately it also decreases the concentrate grade.

Collector concentration has a significant effect (either linear or non-linear) on all three quantitative response variables. As collector concentration increases, recovery increases until a maximum is reached (=93%), after which a slight decrease occurs. For all three frother levels, the maximum recovery is found at approximately the same collector concentration range of 10-15 g/t. It appears that within the xanthate concentration range or 10-23 g/t, the recovery is independent of frother concentration for the range of 15-35 g/t.

As the frother concentration increases, recovery typically increases with the effect being much more pronounced at the two lowest collector levels. This same trend was also seen in the first test series where the effect of air flow rate and frother concentration was studied.

Concentrate grade typically decreases as the frother concentration increases except when a starvation quantity (= 2 g/t) of collector is used. The previous test series showed a similar decrease in concentrate grade with an increase in frother concentration. An overabundance of froth leads to excessive entrainment of fine gangue particles in the froth.

The partial substitution of a frother for a collector is a favorable circumstance as the frother typically sells for half the cost of the collector. It must be taken into consideration, however, that if the flotation system is driven with a frother, a decrease in selectivity may occur for all size fractions, whereas if the system is driven with a collector, a decrease in the selectivity of only the finer particles (say <200 mesh) may occur.