The (Edwards Type) Mechanical Roaster was first developed in Australia for the roasting of gold and silver ores and concentrates. It can be built in units to handle from 20 to 200 tons per 24 hours. The overall height of this type of unit is low, an important advantage in installation. Dusting is eliminated because the material being treated is not dropped from one hearth to another. Instead, material being roasted passes continuously on the one hearth from the feed end to the discharge.

Temperature can be closely regulated and heat properly applied. Ordinarily two fire boxes are used on each side; however, this is governed by the character of the material being roasted. Arrangements can be made for using pulverized fuel or oil, or other fuels may be used which require hand firing methods.

Rabbling arms and shafts can be arranged for the circulation of cooling water where materials being treated require

temperatures high enough to warrant such an arrangement.

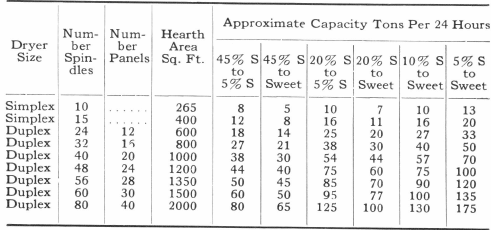

For a sweet roast approximately 200 to 225 pounds of 10,000 BTU coal is used per ton of ore roasted. The horsepower per spindle is from 0.2 to 0.3. Width of the simplex unit is 6.6 ft. and the duplex unit has a width of 13 ft. The length of each panel is approximately 4 ft. The costs of materials and construction will vary widely with location and local prices, but the following is approximate cost of a 54 spindle furnace.