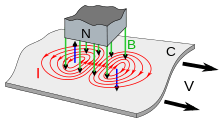

An eddy current is a circulating electric current induced within the body of a conductor when that conductor either moves through a nonuniform magnetic field or is in a region where there is a change in the magnetic flux. Typical currents of this sort resemble in form the eddies in flowing streams of turbulent water, hence, the name eddy currents. Although they can be induced in any electrical conductor, the effect is most pronounced in solid metal conductors. A suitable magnetic field can be genera ted by a coil carrying an alternating current. This magnetic field will interact with a test

ted by a coil carrying an alternating current. This magnetic field will interact with a test

object brought near to the coil causing eddy currents in the test object. These eddy currents in turn create their own electromagnetic field, which may be sensed either through its effects on the primary excitation coil, or by means of an independent sensor.

In nonmagnetic materials, the secondary electromagnetic field depends simply on the eddy currents. With ferromagnetic materials, additional magnetic effects occur that usually are much larger than the direct eddy current fields. These magnetic effects result from the magnetic permeability of the test material.

The main factors in determining the magnitude and direction of eddy currents induced by harmonically varying magnetic fields are as follows:

- The geometrical shape of the applied field.

- The amplitude of the applied field.

- The frequency of the applied field.

- The size and shape of the test object.

- The location and orientation of the test object with respect to the applied field.

- The electrical conductivity of the test object.

- The magnetic permeability of the test object.

A very small change in any one of these can have a marked effect on the eddy current produced. For practical testing purposes, it is usually necessary that all of these parameters be rigorously controlled.

From the point of view of metal identification, the factor of most importance is the effect of electrical conductivity. Since the electrical conductivity of an alloy is sensitive to changes in chemical composition, eddy current techniques can be used to identify metals and alloys. Electrical conductivity is, however, sensitive to changes in the physical nature of the material. This is a complicating factor when this technique is applied to scrap metal identification where a given alloy may be present in different physical forms.

Eddy currently test equipment ranges from simple portable units to complex automatic or console-type apparatus. Regardless of the complexity, however, each system must have at least the following elements:

- A source of magnetic field capable of inducing eddy currents in conductive materials.

- A sensor or transducer, sufficiently sensitive to detect the very small changes in the magnetic field caused by eddy currents.

- A means of interpreting the measured changes in the magnetic field, whether it be by monitoring a meter whose reading is proportional to the magnetic field change or an electronic black box that displays readings proportional to phase magnitude or modulation of the magnetic field.

In simple eddy current instruments, the voltage across the coil may be used as a measure of the eddy current effect and may be manipulated to produce a meter reading indicative of the desired property or feature under investigation. There are many variables active in eddy current testing that affect the results. In application of this technique to alloy sorting and identification, changes in electrical conductivity are usually used as a basis for identification. However, the impedance values observed can be Influenced by heat treatment, grain size and orientation, grain boundary precipitation and geometrical factors, among others. This means that identification of materials may be ambiguous Eddy current testing is rapid, nondestructive, and can be substantially automated. In addition, mechanical contact with the test article is not normally required, although, in most cases, it is necessary to have a fiat surface. On the other hand, the number of variables that may influence the result often make the interpretation of the test results ambiguous.

The method is restricted substantially to surface analysis owing to skin effects, so the presence of coatings, scale, etc presents a problem. When the test articles are ferromagnetic the permeability of the test specimen changes as it is brought near to the coil which may obscure the results.

The eddy current method is best suited to testing large numbers of mass-produced articles. The response of standard article may be stored in the memory unit of the instrument. The response of the test articles is the compared to the stored standard and either accepted c rejected. In this way. the articles may be tested for correct composition and also for flaws on or near the surface. Eddy current testing, at its present state of development, has very limited applicability for identification of mixed scrap material owing to the complicating effects of shape and structure.