Several types of eddy current separators have been developed in recent years. These separators range from slide chutes lined with alternating permanent magnets to electromagnetic circuits that generate a pulsed field when conducting material is sensed. The illustrated rotating permanent magnetic field eddy-current separator has proven to be most effective in view of capital cost, operating cost, and separation efficiency. Unlike a static chute type separator, the frequency of the alternating magnetic field in the rotating permanent magnetic field eddy-current separator is variable to provide optimum repulsive forces. When compared to an electromagnetic circuit, the high energy rare earth permanent magnets rival the electromagnetic field in strength and consumes no power.

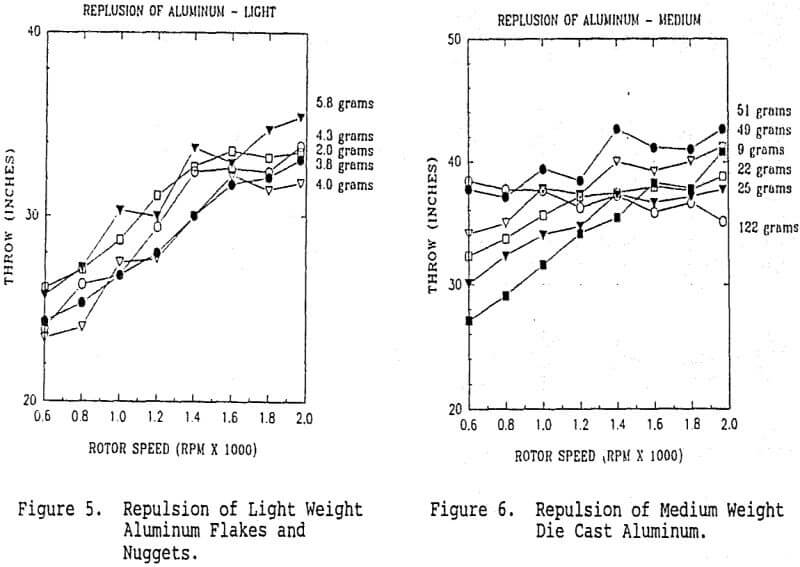

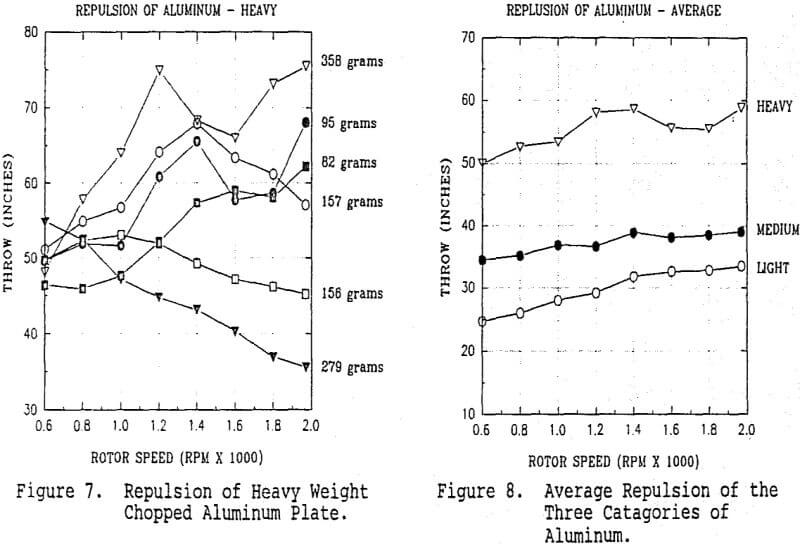

The separator was developed in order to provide processing flexibility. The magnetic rotor is 12 inches in diameter and consists of a series of axial magnetic poles that span the 360 degree circumference. Each magnet extends the width of the rotor and the series is assembled with alternating polarity. The magnetic field strength was maximized employing high energy neodymium-born-iron permanent magnets. A fiber composite drum encloses the rotor. A conveyor belt runs around the drum to deliver feed material to the alternating magnetic field. The speed of the drum and of the rotor are independent and variable. The drum (and conveyor belt) will normally operate at 250 fpm to deliver feed. The speed of the internal magnetic rotor ranges up to 2500 rpm to provide a peak frequency in excess of 450 hertz. The variable rotor speed enables matching the frequency of the alternating magnetic field to the specific conductivity and size range of the conductor to produce an effective separation.

Although eddy-current repulsive forces are generated in ferrous metal, the magnetic attractive force is overwhelming. The high-intensity magnetic field produced by the rotor requires that all ferrous metal be removed prior to the eddy current separation. Pretreatment to remove ferrous metal is accomplished using a standard magnetic drum separator.

A production scale eddy-current separation system is shown in Figure 3. The system consists of a vibratory feeder that delivers the feed to a magnetic drum separator to initially remove the ferrous fraction. The pretreated material is then conveyed with another vibratory feeder to the eddy-current separator which produces a metallic conductor product and a non-conductor product. A splitter segregates the two products. This particular system employs a 12 inch diameter by 24 inch wide eddy-current separator capable of treating up to 5 to 10 TPH of feed.

Brass foundry sand applications are of particular interest for several reasons. After casting, the sand contains residual brass as relatively large flashings and spills as well as fine sized particulates. Hard sand agglomerates termed “core butts” are also formed during the casting process which makes any screen separation difficult at best. The build-up of residual brass in the sand not only makes the sand unuseable for casting, but also renders it a hazardous waste. The selective separation of the residual brass produces a salable brass concentrate, eliminates a hazardous waste, and allows the sand to be reused.

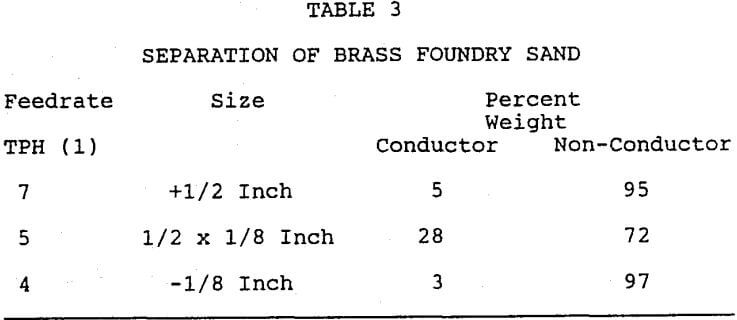

The results of treating brass foundry sand are presented in Table 3. The +½ inch fraction and the -½ by +1/8 inch fraction consisted mainly of large flashings, spills, and core butts. These samples were subjected to an eddy-current separation at a rotor speed of 1900 rpm. The coarser fraction responded with a 99.9 percent brass rejection while the finer fraction responded with a 90+ percent brass rejection. The minus 1/8 inch fraction consisted mainly of sand with fine brass particulates. This fraction responded with an 80+ percent brass rejection.

Throughout the separation test work that was conducted on the various samples, it was observed that the characteristics of the separation generally followed the principles established in equation 4. The factor relating electrical conductivity with specific gravity proved to be a major component in the repulsion of specific metals. Metals with a high factor were successfully separated from metals with a low factor. The mass of any conducting component was also a factor for separation. Generally, larger components were repelled with a greater magnitude.