Currently, most coal mines rely primarily on two methods for controlling dust. The first utilizes large volumes of outside air to ventilate and dilute the dust (and methane gas) to acceptable concentrations. The second method involves water used in various ways, such as water spray systems. Unfortunately, both techniques have limitations. For example, increasing the quantity of water used for dust control may create discomfort and undesirable operating problems, especially in mines that are already too wet or when certain clay bottoms are encountered. Moreover, recent Bureau research indicates that the best conventional water spray systems only reduce respirable dust concentrations (particles less than 7 micrometers, um) by approximately 50 pct. Increasing the use of air to further dilute dust may increase air velocities beyond comfort or to a point where already deposited dust can be reentrained in the ventilation airstream. Additional air also requires cubic power increases in fan horsepower. Thus, to double the volumetric flow rate, an eightfold increase in fan power is required. For many mines, this can be unacceptably high.

Currently, most coal mines rely primarily on two methods for controlling dust. The first utilizes large volumes of outside air to ventilate and dilute the dust (and methane gas) to acceptable concentrations. The second method involves water used in various ways, such as water spray systems. Unfortunately, both techniques have limitations. For example, increasing the quantity of water used for dust control may create discomfort and undesirable operating problems, especially in mines that are already too wet or when certain clay bottoms are encountered. Moreover, recent Bureau research indicates that the best conventional water spray systems only reduce respirable dust concentrations (particles less than 7 micrometers, um) by approximately 50 pct. Increasing the use of air to further dilute dust may increase air velocities beyond comfort or to a point where already deposited dust can be reentrained in the ventilation airstream. Additional air also requires cubic power increases in fan horsepower. Thus, to double the volumetric flow rate, an eightfold increase in fan power is required. For many mines, this can be unacceptably high.

Recent field and laboratory studies show that mechanical dust collectors (scrubbers) are an increasingly attractive means of reducing coal mine dust concentrations. When installed and used properly, scrubbers can offer many advantages including the following:

- A strong potential for 90-pct plus reductions in face dust concentrations.

- Improved face visibility.

- Reduced rock-dusting requirements in return airways.

Scrubbers also are generally required for sections using blowing ventilations and to control the excessive dust created when rock bands are encountered in the coal seam.

However, safety, size, power, or other utility requirements prohibit the use of most standard industrial scrubbers for coal mine applications. Theoretical equations for predicting the dust collection efficiency of a scrubber appear to be of limited value and there are few reliable data as to the effectiveness of various types of scrubbers in controlling respirable coal mine dust.

To fill this gap, the Bureau initiated a laboratory research program to evaluate prospective scrubbers before their use underground and to expedite the development of new scrubbers.

This report covers the development and testing of prospective scrubbers for operation at air pressure differential levels above 2 inches wc.

In 1969, the Bureau of Mines funded a study to evaluate prospective commercial scrubbers and determine their potential for reducing coal mine face dust concentrations to legal levels. Emphasis was given to scrubbers that were expected to have high collection efficiency for respirable size coal dust. Thirty-five commercial collectors were surveyed and eight were evaluated in detail by laboratory tests. No commercially available dust collector was found that satisfied both the physical constraints of the mine environment and the designated collection criterion. It was also found that a collector based on an inertial mechanism would be most likely to meet this criterion. The venturi-type scrubber appeared the most promising, but no satisfactory venturi scrubber was commercially available.

As a followup to the Garrett contract, five commercially available scrubbers were evaluated at the Pittsburgh Research Center. These were scrubbers that were not available during the Garrett study or were excluded from that study which concentrated on high-efficiency units. Four of these scrubbers, Jeffrey-Donaldson, Gundlach, Joy, and Vortex, were all essentially wetted-fan scrubbers consisting of a centrifugal fan with water sprays on the inlet side and were already being used in underground coal mining operations. The fifth scrubber was the Lambert impaction plate scrubber.

Although some of the wetted-fan scrubbers had size and mechanical problems, the dust collection efficiencies were generally high and peaked near 90 pct on respirable size coal dust. None of the units appeared to have a strong potential for reducing anticipated respirable dust concentrations below 2 mg/m³. With these data, the Bureau initiated a program to determine if any scrubber suitable for coal mine use could achieve the desired efficiency of more than 90 pct.

Based on the Garrett recommendation, the venturi scrubber appeared to offer the best potential, and since no venturi scrubber suitable for underground coal mine use was commercially available, a 3,000-ft³/min venturi scrubber was designed and fabricated at the Pittsburgh Research Center early in 1974. The scrubber was designed for minimum size and cost. Efficiencies in the desired range of 90 to 98 pct on respirable coal dust were readily achieved at pressures between 7 and 20 inches wc and scrubber spray water rates less than 5 gal/min per 1,000 ft³/min. Subsequently, tests with a commercial (E. I. du Pont de Nemours & Co,) flooded-bed scrubber showed efficiencies significantly higher than the venturi.

Other scrubbers including a flooded-bed (Fairchild Corp.) and impaction-plate-venturi (American Air Filter Co., Inc,,) have been tested. The results are reported herein.

Simultaneously, Bureau of Mines work with scale models of typical coal mine face ventilation systems indicated that relatively low volumes of air (2,000 to 3,000 ft³/min) through machine-mounted scrubbers, when properly applied with exhaust ventilation in room-and-pillar mining, could be a surprisingly effective means of dust control at the face. This is somewhat contrary to European practices, where high volume and, therefore, relatively large scrubbers predominate. Based on commercially available hardware and scrubbers that would be suitable for both low coal and machine-mounted applications, the Bureau directed its research toward the development of small, inexpensive, and rugged scrubbers with collection efficiencies of more than 90 pct

Dust Collection Efficiency Requirements

Various Bureau of Mines field investigations indicate that 8-hour average values of respirable dust concentrations up to 20 mg/m³ can be encountered at the face with ripper-type continuous-mining machines. With longwall shearers, dust levels are frequently much higher. Assuming that all of the dust cloud enters the scrubber, a dust collector efficiency of 90 pct would reduce a 20-mg/m³ value to 2 mg/m³ in the scrubber effluent; a dust collection efficiency of up to about 98 pct would provide a desirable safety factor.

Dust collection efficiency requirements vary, depending upon the operation. Lower efficiencies are frequently adequate for full shift dust exposure, especially where the scrubber discharge can be vented to the return of an exhaust ventilation system. Higher efficiencies are normally required where the personnel may be exposed to effluent air from the scrubber, as in blowing face ventilation systems and on longwalls where dust cloud capture efficiency is usually low. More than 98 pct collection efficiency for respirable dust is usually not required and can frequently be prohibitive in terms of fan size, noise, power, and water consumption. A 98-pct scrubber would pass only one-fifth of the dust of the 90-pct scrubber; that is, 2 per against 10 pct of the dust penetrates the scrubber and is present in the scrubber effluent.

In underground applications, it is unlikely that all of the dust cloud will be captured by and pulled through the scrubber. The overall efficiency of the scrubber system in the field is the product of its laboratory efficiency multiplied by its efficiency in capturing the dust cloud. Relatively high (above 80 pct) capture efficiencies can be readily achieved in room-and-pillar development, where the dust cloud is largely contained by the face coal and machinery. Longwall and retreat mining usually presents much more difficult problems in dust cloud capture. To achieve reasonable reduction in overall dust concentrations, the scrubber inlet must be located where the dust concentrations are highest prior to additional dilution by the ventilating air.

Data Analysis

Dust collection efficiency data for these tests follow and are presented in three dust size fractions. Sizes are unit density equivalent volume diameters. All dust measurements were made with the Andersen 1-ft³/min ambient sampler. Details are presented in the Dust Sampling Procedure section of this report.

- At 1.1 µm the effective cut diameter (ECD) is a tight size range (approximately 0.9 to 2.0 µm) taken directly from the sixth stage of the Andersen eight-stage impactor. Although the scatter is large, it can be very valuable in analyzing the performance of most high-efficiency scrubbers.

- Respirable dust ranges from about 1 to 7 µm. This size fraction efficiency is most valuable for scrubbers intended for general mining applications.

- Total dust range has a limited value for most uses. It is completely influenced by the size distribution of the inlet or parent dust cloud. The small difference between the respirable and total collection efficiencies for these tests show that the parent dust cloud size distribution was largely in the respirable range, as measured by the Andersen impactor.

When evaluating any fractional breakdown data on scrubbers, a very rapid analysis can be made by simply checking the fractional efficiency data in the 1- to 2-µm size range for which good scrubbers will show an efficiency well above 80 pct.

All dust collection efficiency numbers are rounded off to the nearest whole number. Efficiencies above and including 99.5 pct are shown as 99+ pct. Note that conditions may vary with different tests on each scrubber.

Venturi Scrubbers

During the period 1972-74, the Bureau of Mines conducted tests of various commercial scrubbers designed for coal mines. Respirable dust collection efficiencies were between 60 and 90 pct; however, the more efficient scrubbers were frequently too large, too complicated, or too fragile for prolonged underground service. For this reason, the Pittsburgh Research Center undertook the the development of several full-scale venturi-scrubber prototypes to determine if reasonably high dust collection efficiency could be achieved with a small practical scrubber designed for in-mine use.

The first Bureau of Mines venturi scrubber consisted of a 1- by 1- by 6-foot lucite duct (fig. 1). An adjustable restriction or throat was formed from sections of lucite connected by piano-type hinges. The rectangular throat opening was adjusted by an outside screw arrangement connected to the top portions of the throat. The inlet to the throat sloped at 45° and the outlet sloped at approximately 12°; the bottom section of the throat was fixed.

The initial maximum opening was designed for a pressure drop of approximately 5 inches wc at an airflow of 3,000 ft³/min. Tests were conducted with the venturi scrubber in a horizontal position with a blade-type water-droplet eliminator positioned approximately 6 feet downstream. In these tests, the fan was remotely located and isokinetic sampling probes were installed about 10 feet upstream and 10 feet downstream of the eliminator.

Water spray outlets ranged from standard 1/8-inch pipe nipples at essentially zero pressure to 4 high-pressure spray nozzles. Spray nozzles were full jet, wide-angle types with 0.070-in diam orifices located approximately 15 inches upstream of the venturi throat.

Following laboratory tests of the first venturi scrubber, two other venturi scrubbers, a long and a short version, were designed, fabricated, and tested. Since minimum size is essential for most underground applications, the purpose was to determine the efficiency trade-off for a short venturi scrubber such as would frequently be required in many mining operations.

The long venturi scrubber was 1- by 1- by 10-feet- and construction was similar to the first venturi scrubber with a 45° slope into the throat and a 7° included angle (3½° from the center line) from the throat; the throat was 4 inches long. For the short venturi scrubber both 3½° sloping plates were removed by disconnecting them from the throat plate, thus reducing the length to approximately 1 foot. A wave-blade water-droplet eliminator, located approximately 7 feet downstream of the throat, was used for the long and short venturi scrubber tests.

Results

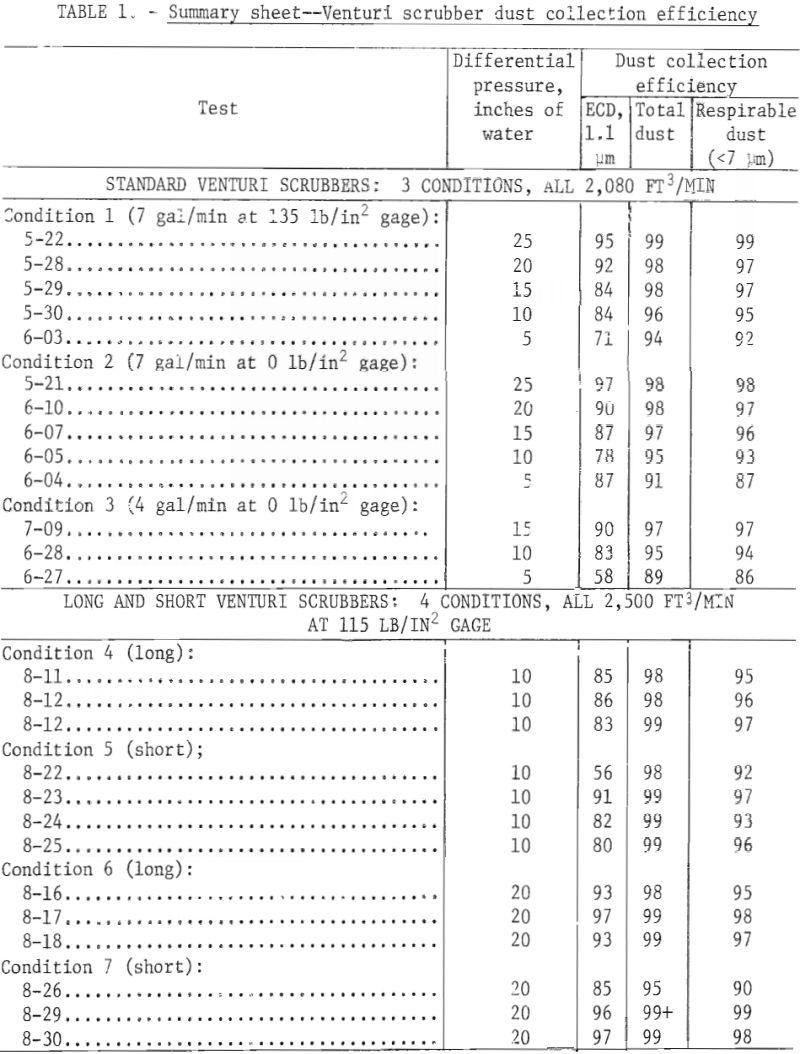

The dust collection efficiency of the three venturi scrubbers was evaluated in 26 tests (table 1) conducted at differential pressures ranging from 5 to 25 inches wc measured across the throat section. Respirable coal dust collection efficiencies ranged from the low to upper nineties. As expected, efficiency increased with increasing air pressure differential drop across the venturi throat, and with increasing spray water flow rate and pressure. Although not tabulated, respirable coal dust collection efficiency exceeding 99 pct normally occurred at throat air differential pressures above 30 inches wc.

The simplicity and relatively high dust collection efficiency of the venturi scrubber made it useful as a standard by which the performance of other scrubbers can be compared. The standard venturi scrubber described earlier was designed for this purpose. Efficiency results reported for conditions 1 through 3 would be useful for these comparisons. Conditions are described on the test summary sheets.

For many mining installations, scrubber size, especially height, can be crucial. The long and short venturi scrubber tests, conditions 4 through 7, were conducted to determine the loss in dust collection efficiency, if any, that would result in drastically reducing the length. Results indicate a slight loss in efficiency for the short venturi scrubber that would probably be acceptable for most mine installations.

In addition to a high dust collection efficiency, the venturi scrubber has most of the other characteristics desirable for a good underground scrubber. The venturi scrubber is—

- Smalls simple, rugged, easily maintained, and low in initial costs.

- Flexible. its dust collection efficiency is limited only by fan pressure and water use. The throat section is easily adjustable to compensate for various air volumes and duct pressure losses.

- Essentially nonclogging and can handle very coarse particulate. The collected dust can be continuously drained. Slurry or slurry water can usually be recycled by the venturi.

- Not affected by machine orientation or tilt, as are scrubbers using a large sump.

- Does not split the airstream (no purge or bleed air).

- Has no inherent permissibility problems.

Because of the relatively high water use and fine mist that it creates, the venturi scrubber usually requires a water-droplet eliminator. For these tests, a new commercial wave blade eliminator was used. The wave-blade eliminator removed over 90 pct of the slurry water at eliminator face velocities near and exceeding 2,000 ft/min, with a low air pressure drop of less than 3 inches wc. All field tests of this eliminator have been especially promising.

It is not known whether a standard venturi scrubber suitable for an underground coal mine is commercially available but one could readily be designed and fabricated by most sheet metal shops. For ease of fabrication and machine-mounting purposes, all of the venturi scrubbers designed by the Bureau had square or rectangular cross sections.

Although the venturi scrubber normally uses more water than other types of scrubbers, these tests indicate good dust collection efficiency at reasonably low water rates. Also, very low pressure water can be readily used by the venturi scrubber without significant dust collection efficiency loss if the throat differential pressure is above 12 or 13 inches wc. Throat pressure drops above 6 or 7 inches wc are required for reasonable dust collection efficiencies, and this requirement somewhat limits the selection of fans for typical mine installations. For most coal mine applications, venturi throat differential air pressures from 10 to 20 inches wc are considered adequate for effective respirable dust control.

American Air Filter Scrubber

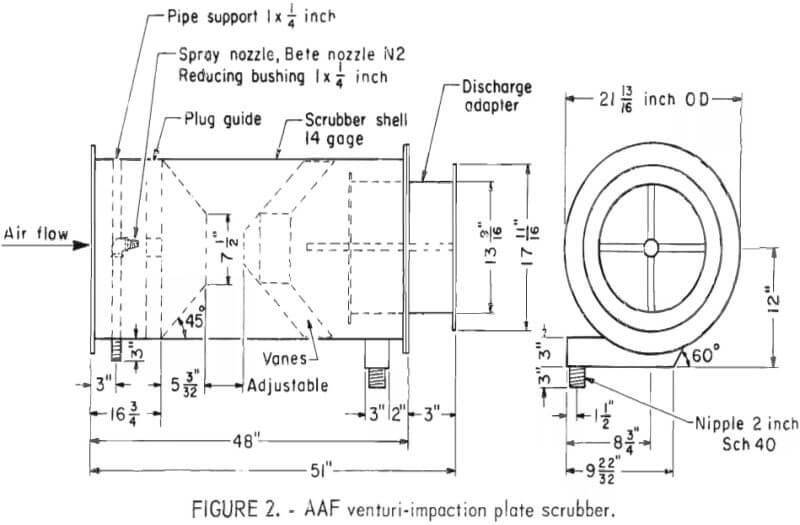

A scrubber developed specifically for coal applications by American Air Filter (AAF) Co., Inc., Louisville, Ky., is essentially a venturi type (fig. 2), The air flowing through the cylindrically shaped scrubber is drawn through a concentric 7½-in-diam venturi orifice. An adjustable plug is moved axially upstream toward the orifice to restrict the open airflow area and thus increase the air pressure differential. Vanes attached behind the plug impact a spinning action to the airstream that whirls the water droplets to the inside wall

of the scrubber where water flows to a drain sump at the exhaust end. A 14-in- diam concentric-collar discharge adapter acts as a water droplet eliminator from which the essentially droplet-free airstream is discharged. A separate fan is required.

Air volumetric flow rates can range up to approximately 3,000 ft³/min and air pressure can drop to 30 inches wc or more. For these tests, air pressure drop was measured immediately upstream and downstream of this scrubber. Water flow is provided by a spray at the scrubber inlet. A single Bete N2-416 fog nozzle was used for all tests.

Results

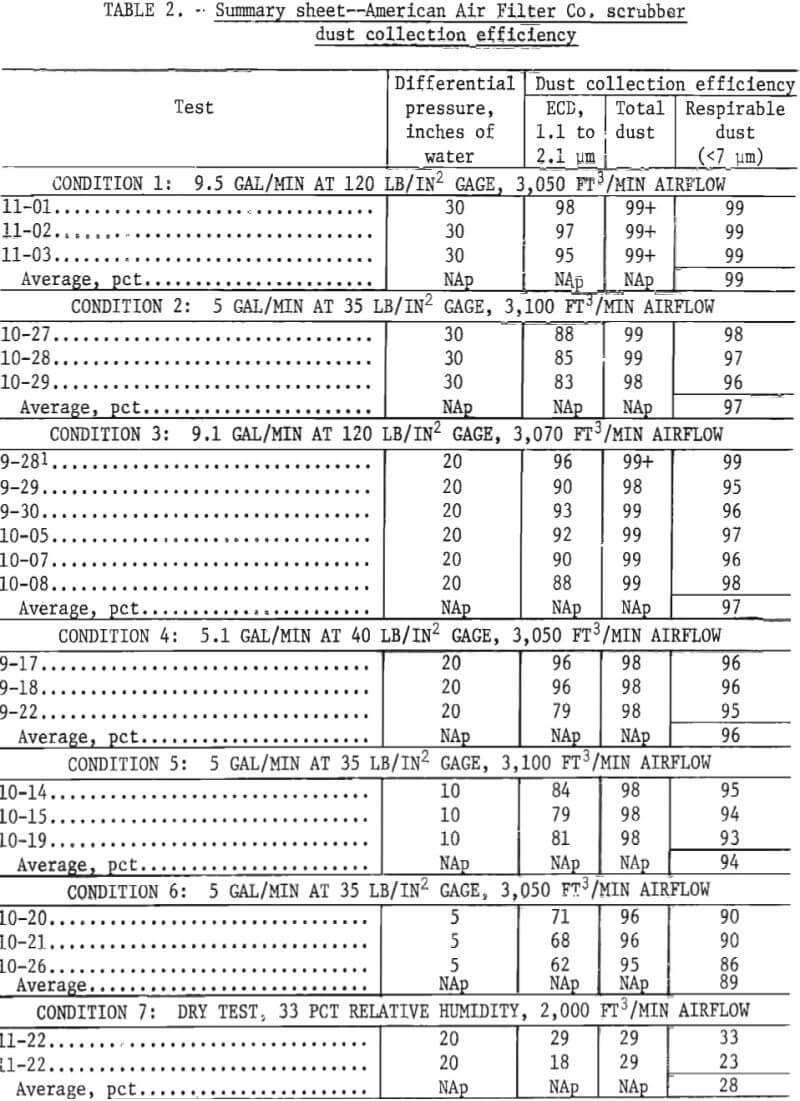

Twenty-three dust collection efficiency tests were conducted in the laboratory at seven different test conditions (table 2). The air volumetric flow rate was maintained at about 3,000 ft³/min. Water flow rates ranged from 1 to 3 gal/min per 1,000 ft³/min.

Maximum respirable dust collection efficiency of 99 pct (condition 1) occurred at maximum air pressure differential and maximum water flow rate, 30 inches wc and 3.1 gal/min per 1,000 ft³/min, respectively. Maintaining the same air pressure drop and volumetric flow, but decreasing the water rate to half by reducing the water pressure (condition 2) caused a marked decrease in efficiency to 97 pct; that is, roughly three times more dust penetration. Bureau test programs show that this reduction is typical of venturi scrubbers when water rates are reduced at this relatively low water-to-air ratio. Continued decrease in air pressure differential and spray water rate and pressure decreased efficiency to 89 pct at 4 inches wc and 5 gal/min.

Two tests were conducted without scrubber spray water and without using steam to increase the ambient relative humidity (condition 7). Respirable dust collection was about 30 pct. This is typical of similar tests on other scrubbers at low relative humidity (35 pct) even though the air pressure differential for this test was much higher than in the other scrubber tests.

Dust collection efficiency of the AAF scrubber was somewhat low when compared with the standard venturi and fibrous-bed scrubbers evaluated in this study.

Previous Bureau of Mines experience with two other scrubbers of similar design, in which the dust also impacts against a large target such as a disk or plug, also indicated low dust collection efficiency. The first was a somewhat revised version of the Lambert inertia separator where the dust-laden airstream was accelerated through a truncated cone and discharged directly into a large impaction plate. The second was a 6,000-ft³/min scrubber developed by Peabody ABC Corp. It featured a high energy radial spray and a single disk-shaped plate centered in a circular machined wash chamber. The relatively poor performance of these scrubbers suggests that scrubber designs relying upon impaction between respirable dust and a large target are misdirected.

Flooded Fibrous Bed Scrubber

The flooded-fibrous-bed scrubber uses a woven stainless steel wire mesh developed by Du Pont for scrubber applications in the chemical industry. Initial laboratory tests indicated that the dust collection efficiency of this type of scrubber would readily equal or exceed that of all other scrubbers previously tested. The design also offered the advantage of minimum size and simplicity.

Following these tests and based on a Bureau of Mines design, Du Pont fabricated two 2,000-ft³/min scrubbers suitable for face operations. These consisted of a commercial 2,000-ft³/min scrubber, a two-stage vane axial fan (Joy Manufacturing Co., Model No. 5112) with a short duct transition at the fan inlet, and a 1- by 1-foot by ¼-inch-thick bed of the Du Pont wire mesh; air pressure drop was 3 inches wc. This complete scrubber, including the fan, are described in an earlier report.

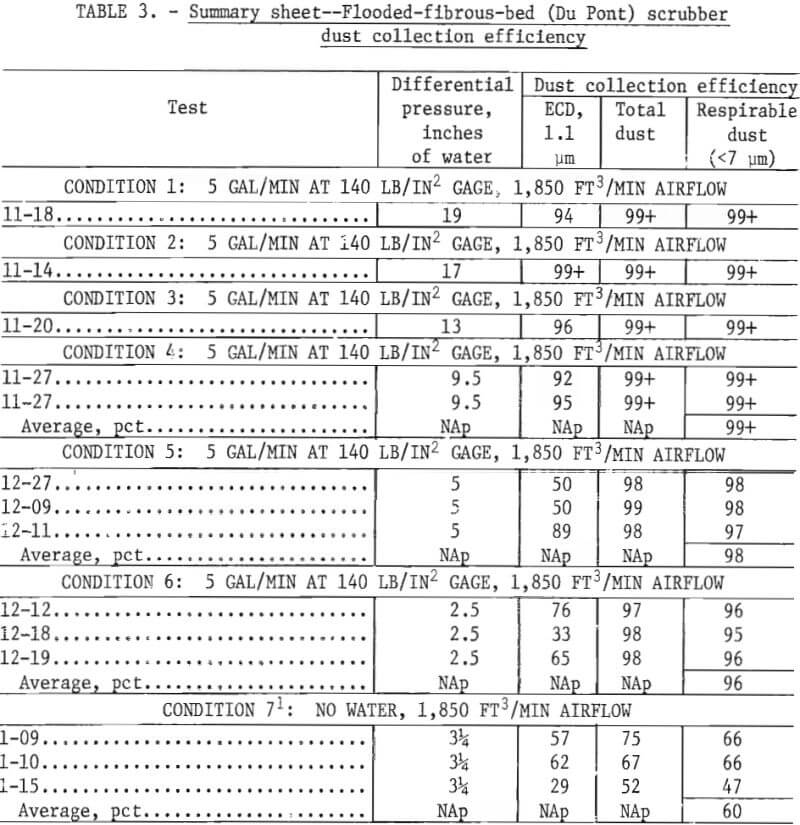

The present test data pertains to the wire mesh only at various pressure differentials and does not include a fan. A 1- by 1-foot wire mesh panel approximately ¼ to 1¼-inches thick was used in the present tests. At a fixed airflow rate of 1,850 ft³/min, pressure increased with panel thickness from 2.5 to 19 inches wc.

For high dust collection efficiency, the dust-laden air must flow through the wire mesh at more than 30 ft/sec (1,800 ft/min); that is, 1 ft² of panel mesh area must handle approximately 2,000 ft³/min of air.

Bete Co. type P solid cone water sprays were placed immediately upstream of the wire mesh to wet its surface completely and uniformly. Water flow rates were 5 gal/min at 140 lb/in² gage. Other tests indicate that a fairly high dust collection efficiency could also be achieved with less than 1 gal/min per 1,000 ft³/min.

The bed was made of loosely woven cardigan or half-cardigan stitch type 430 stainless steel wire. Mesh size was about ¼-inch. In these tests, 0.0035 inch was used, but wire diameters can range up to 0.006 inch without significantly impairing efficiency. However, previous Bureau tests with 0.025- to 0.030-in-diam wire showed greatly reduced dust collection efficiency.

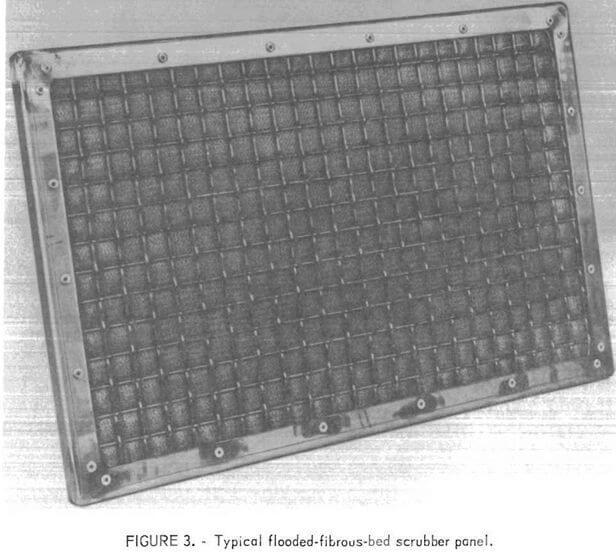

The mesh was supported by a 1/16-in-diam wire grid with 1-inch centers (fig. 3). The grid wire was welded to a stainless steel frame that was seated on a lip in the duct to insure an airtight connection. The lip maintained the mesh in an upright position, perpendicular to the airflow.

Results

Fourteen tests were run under seven different conditions (table 3); the primary variable was the bed thickness. As expected, maximum dust collection efficiency occurred with maximum air pressure differential, 19 inches wc and a maximum bed thickness of about 1¼ inches (condition 1). The cross-section area of the bed was held constant during these tests. Air pressure differential was reduced by removing layers of the steel mesh to make the bed thinner. Minimum respirable dust efficiency, 96 pct (condition 6), occurred with minimum bed thickness of approximately 5/16 inch and a minimum air pressure differential of 2½ inches wc. No air pressure differential buildup occurred during these tests. In several tests run without water (condition 7) efficiencies were about 50 pct.

Respirable dust collection efficiency was essentially 100 pct in all tests above 13 inches wc, making the flooded-fibrous-bed scrubber the most efficient of the scrubbers tested to date at the Pittsburgh Research Center.

Since the flooded-fibrous-bed scrubber offers many advantages, including simplicity and small size, the Bureau of Mines has continued its development. This ongoing effort is directed toward lower maintenance, reduced clogging, further reduction in size by coupling the mesh with a high (2,500 ft/min) velocity water-droplet eliminator, and increased dust collection efficiency. One recent application of the scrubber on a Joy ripper continuous miner has been hailed as a breakthrough in coal mine face dust control and additional successes are anticipated.

Plans have been initiated to resolve problems with mesh clogging that have occurred in some installations. Examination of clogged mesh panels taken from scrubbers at coal mine faces shows particulate in the 1/16- to 1/8-inch size range embedded in the wire mesh. This can lead to a gradual air pressure buildup and loss of fan volumetric flow rate. The problem has been partially solved by installing the panel so that it can be easily replaced when necessary. In coal mines, the clogged panel is placed on the section transformer, dried, and then “banged” clean or flushed with water. Each shift is responsible for maintaining its panel.

In the mine section, where the Joy miner was operating, a rockband in the coal seam created a very severe dust problem with respirable dust concentrations of 15 mg/m³ (8-hour average); the scrubber reduced this to slightly less than 2 mg/m³. According to face personnel, the scrubber installation greatly improved visibility, eliminated the need for respirators, and greatly reduced facial dirt.

Vortex Flooded Fibrous Bed Scrubber

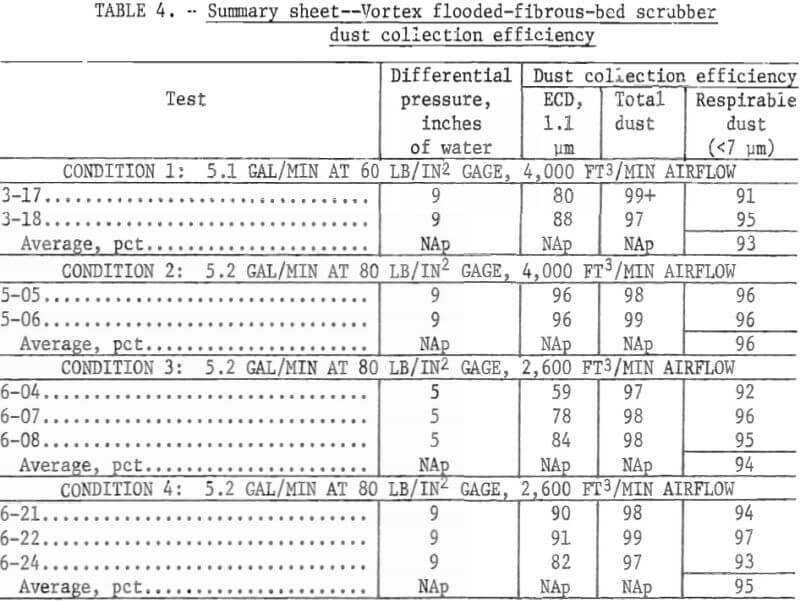

The Bureau of Mines also tested a flooded-fibrous-bed scrubber panel developed by Vortex Air Corp. (Fairchild, Inc.) for use in coal mines. The 18-in-diam, about 2-inch-thick, disk shaped panel consisted of a thick bed of very small stainless steel wire coils. The wire was 0.004-inch in diameter and the coil was approximately 3/16-inch in diameter and 3 to 4 inches long. The bed of interlocking and random-packed coils was contained by an expanded metal grid framed by a steel collar designed to fit inside a round pipe or duct. Three water sprays were located immediately upstream of the panel and directed radially inward. The panel was designed to be placed upstream of a wetted-fan scrubber manufactured by Vortex. Nominal volumetric capacity was 3,000 ft³/min. Only the panel was used for these tests to allow a closer comparison with the Du Pont knitted wire screen.

Results

Ten tests conducted with four different conditions showed a relatively narrow span of respirable dust collection efficiency centered in the mid-nineties (table 4).

The first tests (condition 1) showed a respirable dust collection efficiency of roughly 93 pct. This was slightly lower than anticipated and was attributed to poor distribution of spray water on the bed face. Replacing the original water sprays by four Bete P series fog nozzles (condition 2) resulted in more uniform wetting of the bed face and marked improvement in efficiency (that is, to approximately 96 pct). When air volume through the bed was reduced to 2,600 ft³/min without changing the bed (condition 3) the air pressure dropped to 5 inches wc and the efficiency dropped to about 94 pct. When bed thickness was increased to 2 inches by adding additional springs (condition 4) while maintaining approximately the same air volume, the air differential pressure was 9 inches wc (the same as condition 2) and the efficiency increased to approximately 95 pct.

Previous and subsequent Bureau of Mines tests have shown that with flooded-bed scrubbers, high face velocities of about 2,000 ft/min and more are required to achieve high dust collection efficiency. Bed face area for this scrubber was 2 ft². The low face velocity tests of approximately 1,300 ft/min (conditions 3 and 4) showed a somewhat lower efficiency than the high face velocity of tests of 2,000 ft/min (condition 2). A close comparison of all efficiencies for conditions 2 and 4 shows a higher dust collection efficiency for the high face velocity tests.

Overall, the efficiency is somewhat lower than for the Du Pont panel. This may be due to the difficulty in achieving uniform wire packing density in the thin coil spring beds that clearly show areas of low packing density when held up to a light. This is not a problem with the uniform-knitted wire mesh panels.

A-Par Air Washer

The A-PAR air washer is a commercial mechanical dust collector (scrubber) manufactured by ECAR Products, Inc., A-PAR Div. Wyckoff, N. J. The scrubber was tested at the Bureau of Mines Pittsburgh Research Center to determine its dust collection efficiency for both coal and noncoal (limestone) dusts. It is interesting for mining applications because its water consumption is about 1/10 or less than that of other scrubbers tested to date.

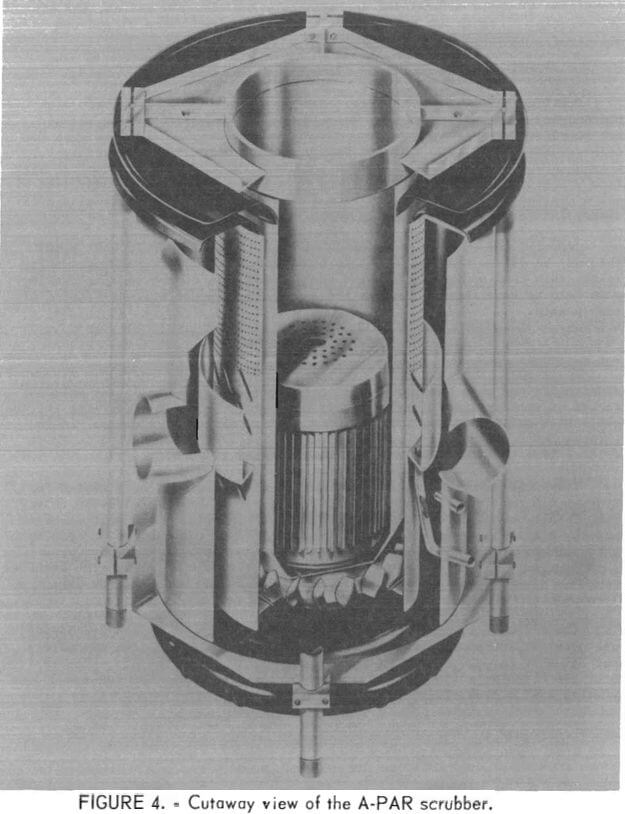

The A-PAR scrubber (fig. 4) can be broadly classified as a wetted-fan type with water directed into the fan impeller. It is powered by an internal, 5-horsepower, direct connected 3,600 rev/min, 230 to 460-volt electric motor. Airflow is nominally rated at 1,300 ft³/min maximum, at or near zero external air pressure load. Water supply to the scrubber, provided by a separate pump, was a very low 4 to 8 gal/hr during these tests. The scrubber contains its own droplet eliminator, described by the manufacturer as a “transpirational wall” type.

The scrubber is cylindrical and roughly the size of a standard 55-gal oil drum, 41 inches high and 30 inches in diameter. Dust-laden air enters the scrubber through four 8-in-diam tangential fittings and air exhausts from a single circular diffuser near the top of the scrubber. The collected dust gravity drains as a slurry from the bottom of the unit.

The internal dust collection mechanism as described by the manufacturer is: “Scrubbing liquid is introduced to the polluted air as it enters the washer and is carried by the airstream down the outer annular space. Most of the liquid is then deposited on the surface of the streamlined base by centrifugal force and ducted to the center of the impeller where it is atomized to extremely small size (submicron) droplets and forced to pass through the airstream. The 2600 g centrifugal separating force created by the impeller forces the liquid (including the pollutants) to the outer wall of the inner annular space (the inside of the intermediate wall) where slots are provided to remove about 99% of the liquid for recycling or effluent collection. The remaining 1% is removed in the demisting region. The slots used for recycling spray the liquid directly into the incoming airstream. Liquid from the effluent collector slots drains into a circular manifold and out the effluent rube. The amount of liquid in recirculation can be controlled by the position of the manifold which determines the number of slots used for recycling.

“The made-up scrubbing liquid is introduced through a tube in the outer wall directly into the airstream. This liquid input is required to make up for the effluent removal and evaporation (typically about 1½ gallons per hour per 1,000 cfm). The rate of liquid input controls the effluent rate and therefore the composition of the recirculating scrubbing liquid.

“A wide variety of scrubbing liquids can be used. Typically, a small amount of additive (e.g. soap) is used with water and is provided by a small dual, adjustable proportioning pump mounted on top of the washer.

“If the pollution is a liquid, aerosol addition of make-up liquid may not be necessary.”

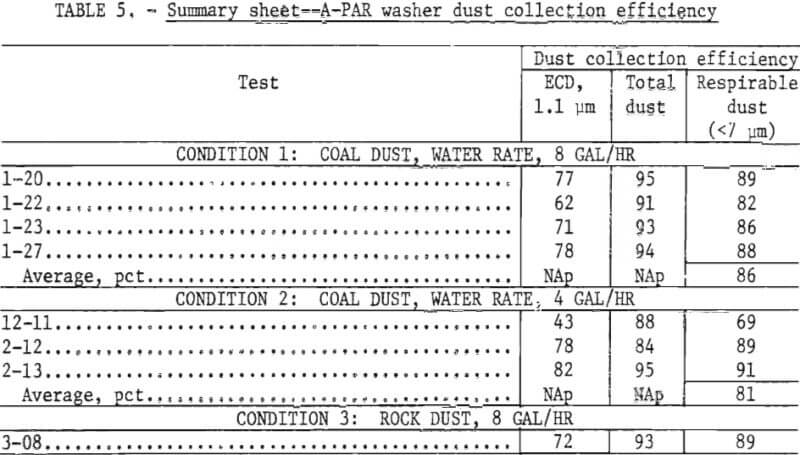

Results

Seven tests were run with coal dust and one test was run with rock dust (table 5). Results of four tests at 8 gal/hr showed collection efficiencies averaging approximately 86 pct on respirable size coal dust. Three tests at 4 gal/hr indicated an efficiency of 81 pct.

One test (No.3-08) was run with rock dust (limestone) to assess the usefulness of the A-PAR scrubber for noncoal applications with a soluble material. The collection efficiency was approximately 88 pct. A second test was conducted while gradually increasing the feed rate of limestone dust to determine the concentration at which the scrubber would clog. After 2 hours, and a final concentration exceeding 10,000 mg/m³, the scrubber was still operating normally, although the effluent was a thickened, “buttermilk-like” slurry. Water flow rate of both limestone rests was 8 gal/hr.

Comments

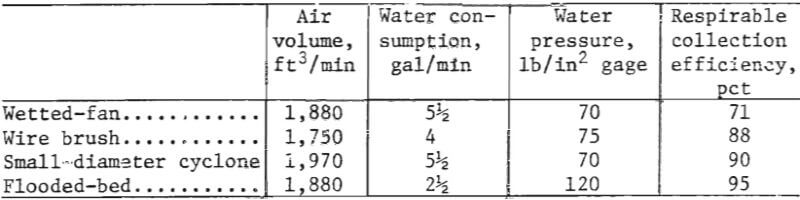

The collection efficiency for respirable coal dust of the A-PAR scrubber was comparable to that of the other scrubbers tested by the Bureau of Mines with roughly the same power requirement (horsepower per 1,000 ft³/min) but these later consumed more than 10 times as much water. These similar tests showed the following results:

The A-PAR scrubber might be useful for dust control at conveyor belt transfer points and other applications where high water use is not desirable. For example, field reports indicate that high water flow rates can reduce belt life because the scrubber slurry water usually drains onto the belt. The scrubber might also be useful for noncoal mining operations with soluble ores, such as potash and trona.

Originally designed to collect airborne ink, carbon, oil, and paper dust particulate from newspaper pressrooms, the A-PAR scrubber has not yet been used in mining operations. The current vertical layout and arrangement of air inlet and outlet connections would make it inconvenient for many mining applications. A horizontal-type layout would be more convenient.

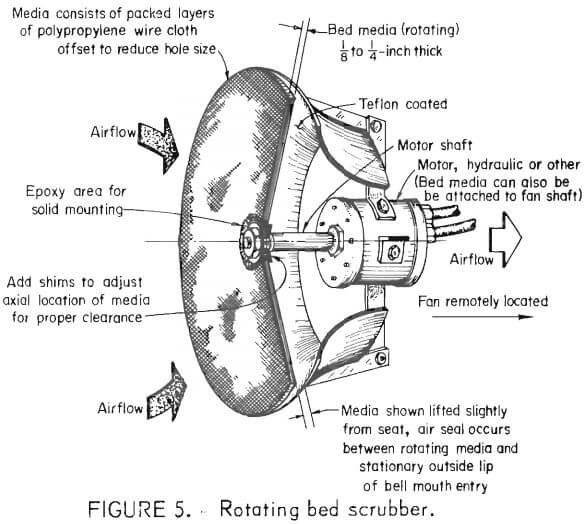

Rotating Flooded Fibrous Bed Scrubber

In 1976, the Bureau of Mines began full-scale testing of a prototype rotating-bed scrubber that was designed and fabricated at the Pittsburgh Research Center. The scrubber (fig. 5), consists of an 18-in-diam by 1/8-inch- thick bed of polypropylene wire, a hydraulic motor, and a sheet metal housing with an 18-in-od bell-mouth entry with supports for the motor. The rotating outside surface of the bed seats lightly against the outside stationary lip of the bell-mouth entry.

The bed is constructed of packed layers of 10-mesh wire cloth, 0.01 inch in diameter. Each layer is slightly offset to reduce or eliminate the possibility of large holes through the bed. A 2-in-diam plastic fill is located in the center of the bed to provide suitable mounting for the drive shaft. Overall size of the bed assembly was 18 inches in diameter by 12 inches long. For underground service, it is apparent that the bed would be damaged by severe impact and would have to be protected by a stationary grid.

The bed was directly attached to a hydraulic motor mounted in the center of a short length of 12-gage duct, 14 inches in diameter. Hydraulic motor power requirements were less than 2 horsepower at 2,700 rev/min. The fan was located approximately 60 feet downstream of the scrubber. Tests were conducted at speeds of 1,750 and 2,750 rev/min, to simulate conditions where standard electric motor drives might be used. Spraying Systems Co. BD-3 and 007 water sprays were located 12 inches upstream (below) and directed toward the rotating bed. The inlet air current convected most of the water droplets to the bed surface.

Air pressure across the rotating bed ranged from 2 to 12 inches wc during the tests. Air volumetric flow rates were 2,000 and 4,000 ft³/min. Airflow was varied by an adjustable vent at the fan inlet. Water flow rates ranged up to 5.2 gal/min and water pressure was 65 lb/in² gage at the spray nozzle. The tests were arranged to determine the effect of air velocity through the bed against rotation on dust collection efficiency.

Air pressure across the rotating bed ranged from 2 to 12 inches wc during the tests. Air volumetric flow rates were 2,000 and 4,000 ft³/min. Airflow was varied by an adjustable vent at the fan inlet. Water flow rates ranged up to 5.2 gal/min and water pressure was 65 lb/in² gage at the spray nozzle. The tests were arranged to determine the effect of air velocity through the bed against rotation on dust collection efficiency.

The tests simulated a scrubber installed in the bottom of the auger support frame (boom) of a ripper- type continuous miner.

The effectiveness of the rotating bed as a water droplet eliminator was checked by placing a large clear lucite window in the duct immediately behind (downstream) the rotating bed. Duct interior walls were painted flat black in this section and a high-intensity spotlight was used to observe the water droplets that might blow through the bed.

With the bed stationary, most of the water droplets were pulled through the bed and into a long, horizontal duct by the high-velocity airstream at over 2,000 ft/min. At bed rotation exceeding 400 rev/min, there was no visual evidence of droplets behind the bed and no water in the horizontal duct leading to the fan. As the bed rotations increased, a large-diameter umbrella of water droplets arced out from the bottom (upstream side) of the rotating bed.

The usual dust sampling procedures were revised to compensate for the layout of the scrubber, with both samples being taken in the same location.

The baseline sample was taken with the sprays off and with the stationary bed slightly lifted from its seat to allow leakage both through and around the bed. The test sample was taken with all components operating normally.

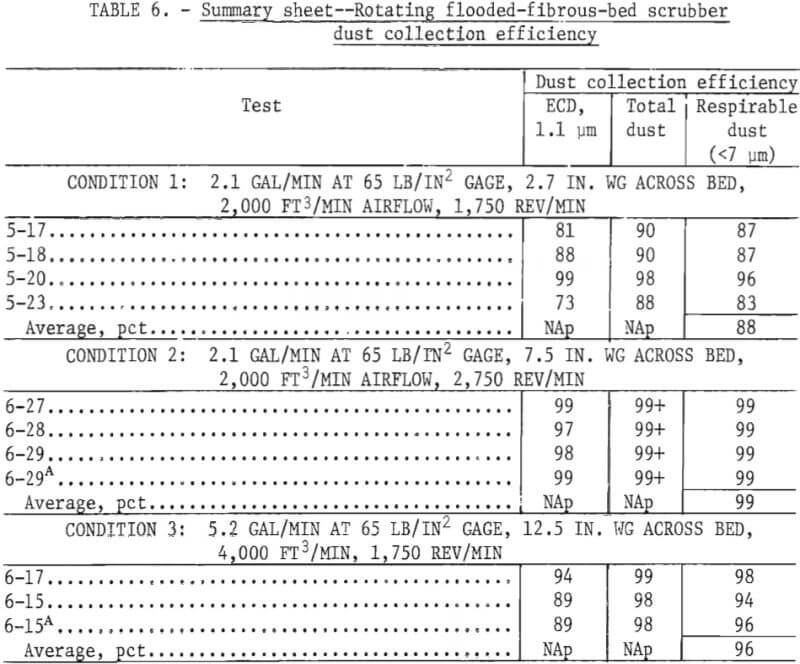

Results

Eleven dust collection efficiency tests were conducted at three different conditions (table 6). Maximum efficiency of over 99 pct on respirable size coal dust and 98 pct on 1.1 µm ECD (condition 2) occurred at the maximum bed rotation of 2,750 rev/min, air volume flow rate of 2,000 ft³/min, and a pressure differential of 7 to 12 inches water gage across the bed. Increasing the volumetric flow rate to 4,000 ft³/min (condition 3) but decreasing the rotations to 1,750 rev/min reduced the efficiency to 98 pct for respirable size coal dust and to 97 pct for 1.1 µm ECD, even with an increase in water flow rate to 5.2 gal/min and an increase in air pressure differential to 12.5 inches water gage.

These tests indicate that at 1,750 rev/min and 2,000 ft³/min, the rotating-bed scrubber is not as efficient as the stationary (Du Pont) flooded- fibrous-bed scrubber (table 3). Increasing the water flow and the air volume to 4,000 ft³/min did not achieve a competitive efficiency. However, the dust collection efficiency was dramatically improved by increasing the bed rotations to 2,750 rev/min (condition 2). The rotating-bed scrubber performance at this speed is especially impressive in the micrometer and submicrometer particle range, exceeding the performance of all other scrubbers previously tested.

The original concept for this scrubber utilized the rotating-bed scrubber for three purposes. The first was to improve dust collection by increasing impaction between the dust particle and the wire target sweeping across its path. The second and third were to use the rotation to sling the water and particulate, especially oversize particulate, from the bed. Tests showed excellent results for these purposes.

Minimum size is essential for the successful application of scrubbers on mobile equipment, especially underground. A scrubber design that features the rotating bed attached directly to the fan shaft appears to be especially attractive. Future Bureau of Mines research work is being oriented in this direction.

Conclusions

Several types of small scrubbers with very high dust collection efficiency are available for coal mine applications. Respirable dust collection efficiency in the high 90-pct range can be readily achieved with the flooded- fibrous-bed, rotating flooded-bed and venturi scrubbers. These high efficiencies are achieved at relatively low power and water consumption, about 10 inches wc and less than 3 gal/min of water.

Laboratory Test Facility

A laboratory test facility was constructed to evaluate prospective scrubbers, determine their maximum potential, and develop new scrubber concepts.

Full-size scrubbers up to 10,000 ft³/min can be tested in this facility. A wide range of respirable dust concentrations and size distributions typical of coal mine face operations can be set up and maintained for long periods, thus reducing the need for the difficult, much more costly, and time consuming underground evaluation of scrubbers.

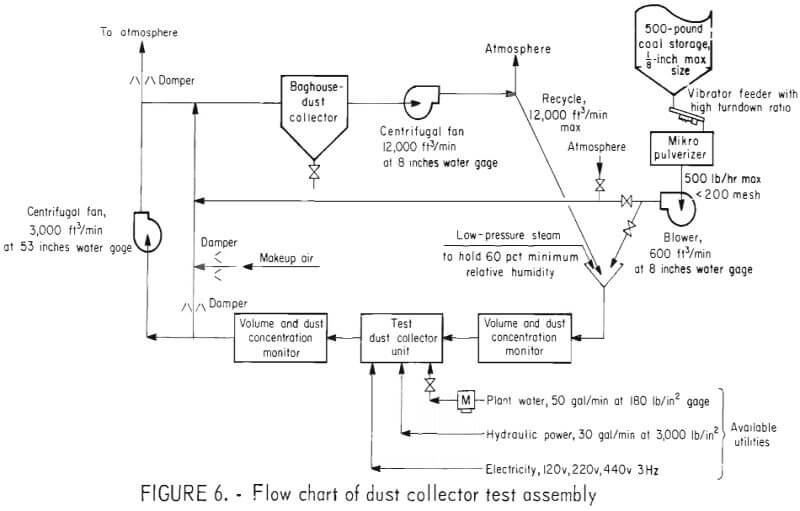

A flow chart of the facility is shown in figure 6. Fine (minus 1/8-inch) Pittsburgh seam coal is fed to a commercial variable-speed pulverizer that breaks the coal into very fine dust and feeds it to a variable 1,000- to 10,000 ft³/min airstream that is ducted through the dust collector being tested (fig. 7). Coal feed rate to the pulverizer is controlled by a high turndown ratio vibrator feeder, thus providing a control on dust concentration. The test assembly is approximately 55 feet long, and the scrubber being tested is placed in the center of a horizontal section of duct approximately 45 feet long. Particulate sampling instrumentation is located 5 to 10 feet upstream of the scrubber and about 20 feet downstream.

A flow chart of the facility is shown in figure 6. Fine (minus 1/8-inch) Pittsburgh seam coal is fed to a commercial variable-speed pulverizer that breaks the coal into very fine dust and feeds it to a variable 1,000- to 10,000 ft³/min airstream that is ducted through the dust collector being tested (fig. 7). Coal feed rate to the pulverizer is controlled by a high turndown ratio vibrator feeder, thus providing a control on dust concentration. The test assembly is approximately 55 feet long, and the scrubber being tested is placed in the center of a horizontal section of duct approximately 45 feet long. Particulate sampling instrumentation is located 5 to 10 feet upstream of the scrubber and about 20 feet downstream.

Duct sections were fabricated from ½- and ¾-inch-thick plywood. Steel, fiberglass, and plywood transitions are used to fit the collector into the test assembly. The plywood duct sections are normally rectangular in cross section and generally designed for air velocities of 2,000 ft/min. Velocity gradients within the duct are probed with pitot tubes and a hot wire anemometer with a special sensor element resistant to damage from airborne particulate matter. Duct splitters were utilized to minimize both velocity and duct concentration gradients. The scrubber effluent was ducted to a baghouse for cleaning prior to being discharged or bypassed to the atmosphere when moisture might affect baghouse operations

Most tests were conducted at dust concentrations between 15 to 30 mg/m³ of respirable coal dust. Dust concentration was constant within ±10 pct for 2 hours. Tests with a special light-scattering dust monitor developed by Stanford Research Institute indicated occasional changes in the dust concentration at the upstream station of ±20 pct for 30-sec periods. Various dust concentrations were achieved by changing the feed rate on the vibrator feeder. The total dust concentration into the scrubber being tested is normally between two and three times the respirable dust concentration, that is, about 75 mg/m³ when measured with the Andersen impactor.

Total material cost for the facility amounted to approximately $32,000 in 1972, exclusive of dust-measuring instrumentation. Labor (design specification, fabrication, and erection) costs amounted to approximately $22,000 and represent about 12 work months. A hydraulic power station, 30 gal/min at 3,000 lb/in² was available.

The length of an existing building housing the test apparatus determined the maximum length of the horizontal test duct connected to the scrubber (about 55 feet) . The use of splitters and low-velocity elbows helped reduce turbulence in the sampling zone. Although no significant problems with velocity or dust concentration gradients were experienced, it is believed that a horizontal test duct of more than 80 feet would have been more desirable.

Dust Sampling Procedure

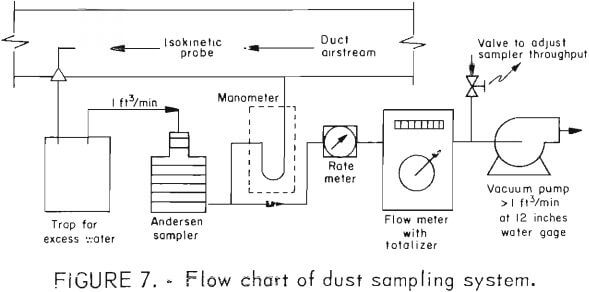

Isokinetic dust sampling probes were located in the center of the duct, 10 feet upstream and approximately 15 feet downstream of the scrubber. The size distribution of the sampled dust cloud was measured with eight-stage Andersen cascade impactor ambient samplers. The airflow rate through the sampler was 1 ft³/min, the manufacturer’s recommended value. This sampler separates the airborne particulate into various size fractions, according to the aerodynamic behavior of the dust particles. Dust particles in specific size ranges are deposited on various stages (plates) of the sampler and groups of particles are deposited as agglomerates.

A 1-quart glass jar was used as a water trap upstream of each impactor with both air connections terminating approximately 1 inch below the sealed lid.

A preweighed, 80-mm-diam, glass fiber Gelman filter was used to cover each plate of the Andersen sampler to increase the ratio of dust weight to tare weight and reduce dust blowoff from overloaded plates. The filters were desiccated for 30 min immediately before weighing.

Due to the large reduction in dust concentration downstream of the scrubber, the sampling time was extended to achieve reasonable dust sample weights. Upstream sampling time usually was about 12 min, and downstream sampling time was about 120 min. The upstream sampling time was divided into three intervals—at the beginning, middle, and end of the total 120-min sampling time—to help compensate for possible long-term concentration drift.

Dust Sampling Analysis

Federal health regulations pertaining to coal mine dust are based only on the respirable fraction of the airborne dust cloud, which is defined as the percentage of particles of a given aerodynamic size that penetrates into and deposits in the human lung. To determine the respirable fraction of a dust cloud, coal mine dust samplers have an initial or first-stage separator that passes only the respirable fraction of the total dust sample The respirable fraction of coal mine dust can be determined by an MRE sampler that uses a parallel-plate elutriator as the separator. The MRE penetration curve can be readily described by the formula

Percent MRE = [1 – [(equivalent diameter, µm)²/50] x 100

The dust collection efficiency for the respirable fraction of the dust cloud can then be determined from the fractional breakdown data as measured by the cascade impactor by appropriate application of the MRE curve. The ECD for unit-density spheres on each stage is obtained by multiplying the weight by the percent MRE penetration factor for each stage. The respirable concentration in milligrams per cubic meter corresponding to each stage is calculated by

35.31/sampling time (minutes) x respirable weight

where 35.31 converts cubic feet to cubic meters. The respirable concentration of the dust cloud is the sum of the respirable concentrations corresponding with each stage and the collection efficiency of the test scrubber is

![]()

It should be noted that the overall dust collection efficiency of the scrubber given by this procedure is still dependent upon the size distribution of the test dust within the respirable range.

Experimental Problems

Air Leaks

Air leaks into the test duct between the dust sampling locations were a common problem, especially when scrubbers were evaluated at high negative pressures with a remotely located fan. The use of metal flanged and gasket joints did reduce this leakage to minimum values, but the additional time and expense of fabricating and fitting metal transitions to various scrubbers normally prohibited their use. For most tests, duct sections were made from ½- to ¾-inch plywood with glued, screwed, and caulked seams and joints. This kept air leakage between the sampling points to a minimum.

The plywood duct sections were usually rectangular in cross section and generally designed for air velocities of 2,000 ft/min. These medium velocities helped to avoid sampling problems, especially by reducing the use of small inside diameter isokinetic probes

Dust Loss

It was determined that the relative humidity of the ambient air in the building that housed the test assembly affected respirable-size coal dust and was investigated to determine the impact on typical testing conditions.

Two conditions were tested with both Andersen samplers operating simultaneously on a straight section of plywood duct with no dust collector installed.

Condition 1

Ambient relative humidities ranged from 25 to 30 pct at 70° F, a common indoor wintertime condition. Respirable dust concentrations ranged from 10 to 50 mg/m³ and the distance between the sampling locations was set at 5 and 25 feet (three tests at each distance). Airflows were maintained at

2,000 ft/min in a 1-ft² duct.

Broadly interpreted, all the fractional efficiency curves showed a decrease in respirable dust concentrations as the air moved down the duct. This decrease was dependent upon upstream concentration and distances between sampling points, both as expected. Somewhat unexpectedly, the same curves tended to “bottom out” at approximately 20 pct loss of efficiency at a particle size of about 4 µm and then start to show increasing efficiency with particulate smaller than 4 µm.

Condition 2

Low pressure steam was added to the duct inlet approximately 30 feet upstream of the first sampling point to increase the relative humidity to 60 pct minimum. Subsequent fractional efficiency tests with the Andersen sampler now showed continuously decreasing efficiency with decreasing particle size (about 10 pct at 4 µm) and continued to drop with particulate below 4 µm.

The sampling now showed the sampling scatter and occasional negative weights expected under these conditions.

These tests may explain the respirable efficiency bottoming out frequently experienced at low humidities with low-efficiency scrubbers. This would include scrubbers purposely tested at very low water rates and resultant low efficiency.

It might be assumed from the above that duct wall deposition cannot explain the bottoming out under the low humidity conditions. Deposition would be a function of particle size. Only the tests above 60 pct relative humidity showed an anticipated deposition curve. With low humidity, airborne impaction, electrostatic attraction, and subsequent agglomeration of the small particulate could explain this loss to the plates of the Andersen sampler that would otherwise accumulate this size fraction.

Fractional efficiency tests on scrubbers operating in the efficiency range expected for prospective underground use (90 to 98 pct on respirable coal dust) showed that humidity had little or no discernible effect on efficiency. However, low-pressure steam was used on all tests to maintain relative humidities above 60 pct, representative of operating conditions in underground coal mines, where humidity rarely falls below 55 pct.

Drift in Dust Concentrations

Very close attention was paid to prevent any unreasonable variance in the dust feed. This is especially critical when testing high-efficiency scrubbers where valid and representative sampling weights sometimes require large time differences between the upstream (dirty) and downstream (clean) airflow due to the great difference in dust concentration. Long-term drifts in concentration during the sampling time could seriously affect results.

The vibrator dust feeder used in the test assembly was located so that the operator could visually observe the dust feed to the pulverizer. Although visual observation indicated no rapid shifts in dust feed, the rapid response SRI monitor did indicate short-term (generally less than 30 sec concentration shifts at the scrubber inlet. The extreme range of this shift at a normal concentration of 25 mg/m³ of respirable dust was ±10 pct. This shift could conceivably affect the Andersen sampler when testing high-efficiency scrubbers where long-term (up to 2 hours) sampling is required on the clean side, and short-term (6 min, spread in three intervals of 2 min each through total sampling time) on the dust-laden inlet side. The Andersen sampling results did not indicate a significant problem from this dust feed variance.

This Bureau of Mines report describes the results of a program to develop small, rugged scrubbers with high dust collection efficiency for use in underground coal mines. The Bureau’s Pittsburgh (Pa.) Research Center has developed and assisted in the development of several types of improved scrubbers that are especially suitable for various underground mining applications. Research efforts concentrated on reducing the size, power, and water consumption of these scrubbers, while optimizing their dust collection efficiency. Fractional dust collection efficiency, air volumetric range, size, power, water consumption, and application guidelines for each type are described. Air pressure differentials ranged between 2- and 30-inches water column (wc).

The dust collection efficiency of six scrubbers—a venturi, two flooded- fibrous-bed, a venturi-impaction plate, a wetted-fan, and a rotating flooded-bed—were compared. The rotating flooded-fibrous-bed and the stationary flooded-fibrous-bed scrubbers showed the highest coal dust collection efficiency. Test results show that these scrubbers can generally achieve respirable size coal dust collection efficiencies in the high 90-pct range required to reduce both long- (8-hour) and short-term coal mine dust concentrations below Federal requirements.