The primary metals sector was particularly hard hit early on, to develop the technology, acquire the equipment, and implement the programs to eliminate or reduce the by-products of metal making. To this end, through a combination of technological innovation and extensive capital expenditures, the metals industry has net, and in many cases, exceeded the minimum standards.

Recognizing the challenge of total waste management, we are unique, in that, our primary objective is to limit our clients exposure to hazardous waste liabilities now and in the future.

In addition to simplifying the logistics of waste handling, by this elimination of over-the-road transportation, our clients are further insulated from future increased taxation for the purpose of funding “Hazardous Waste Spill” clean-up and landfill reclamation projects.

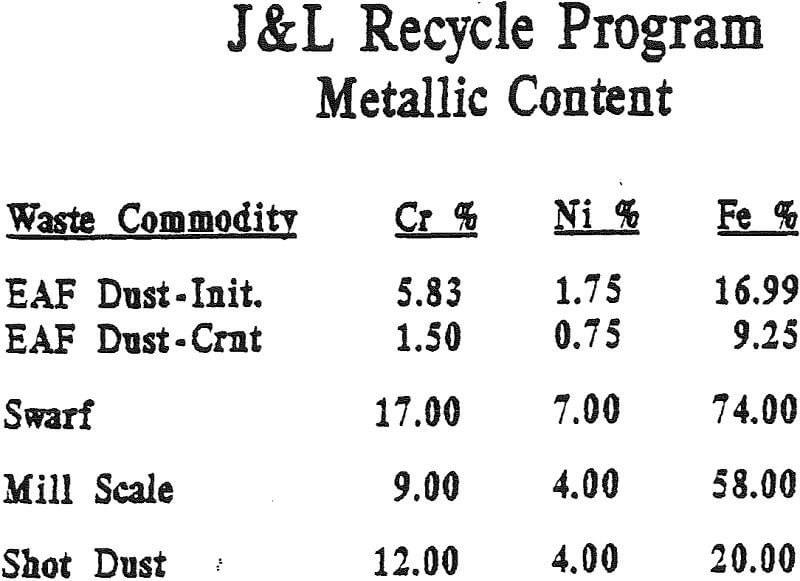

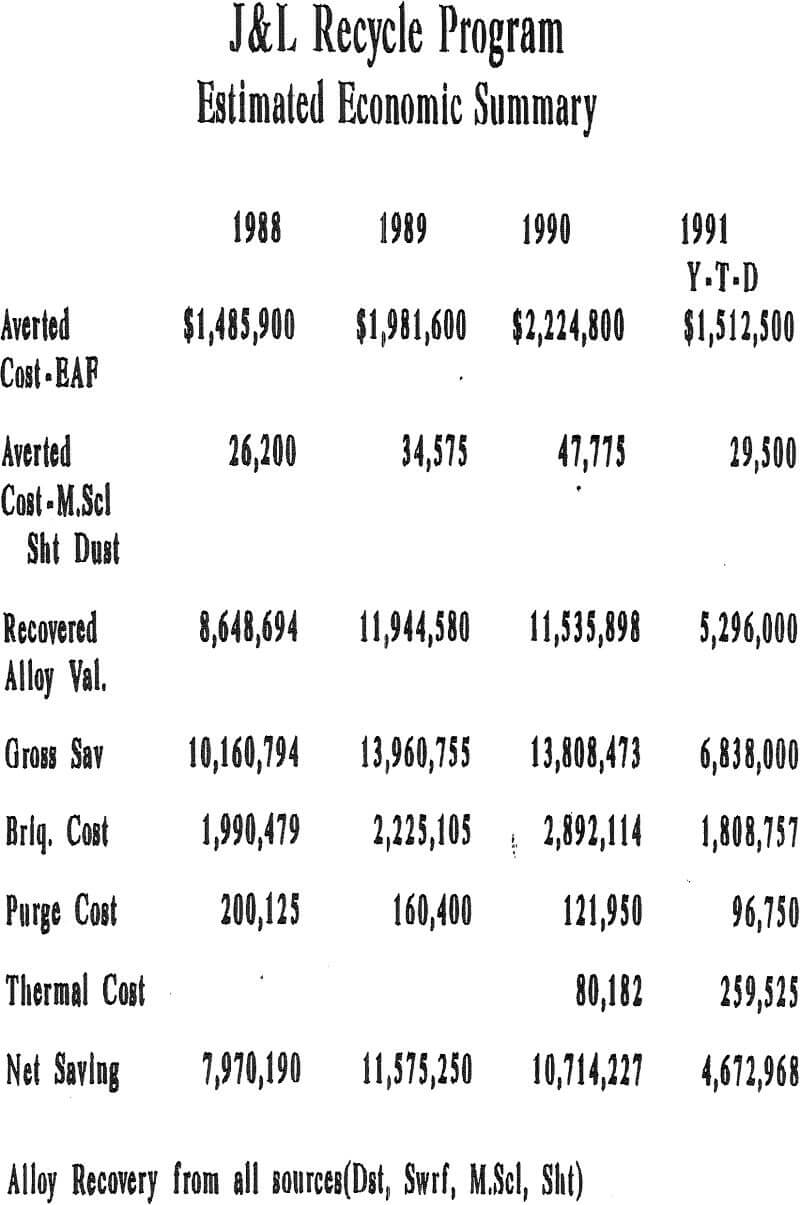

After this initial evaluation, several formulations were recommended which took into account metallurgical restrictions and economic viability. As a part of this process, potential metal recoveries are calculated and an optimum charge rate arrived at.

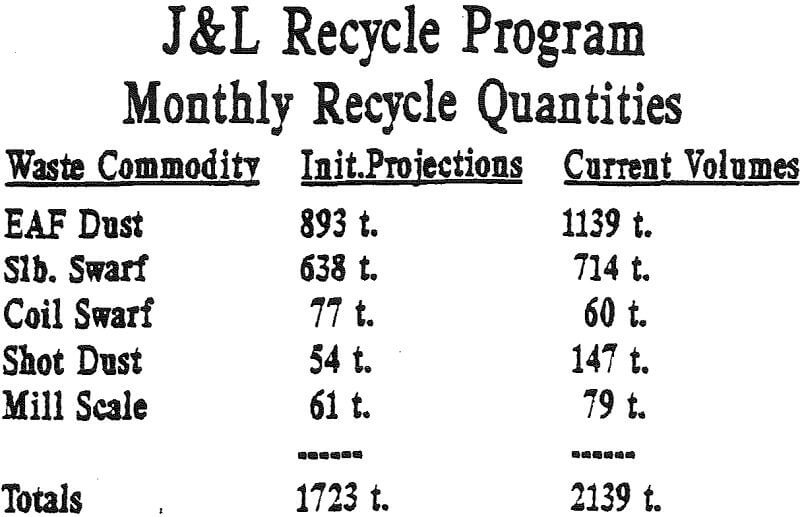

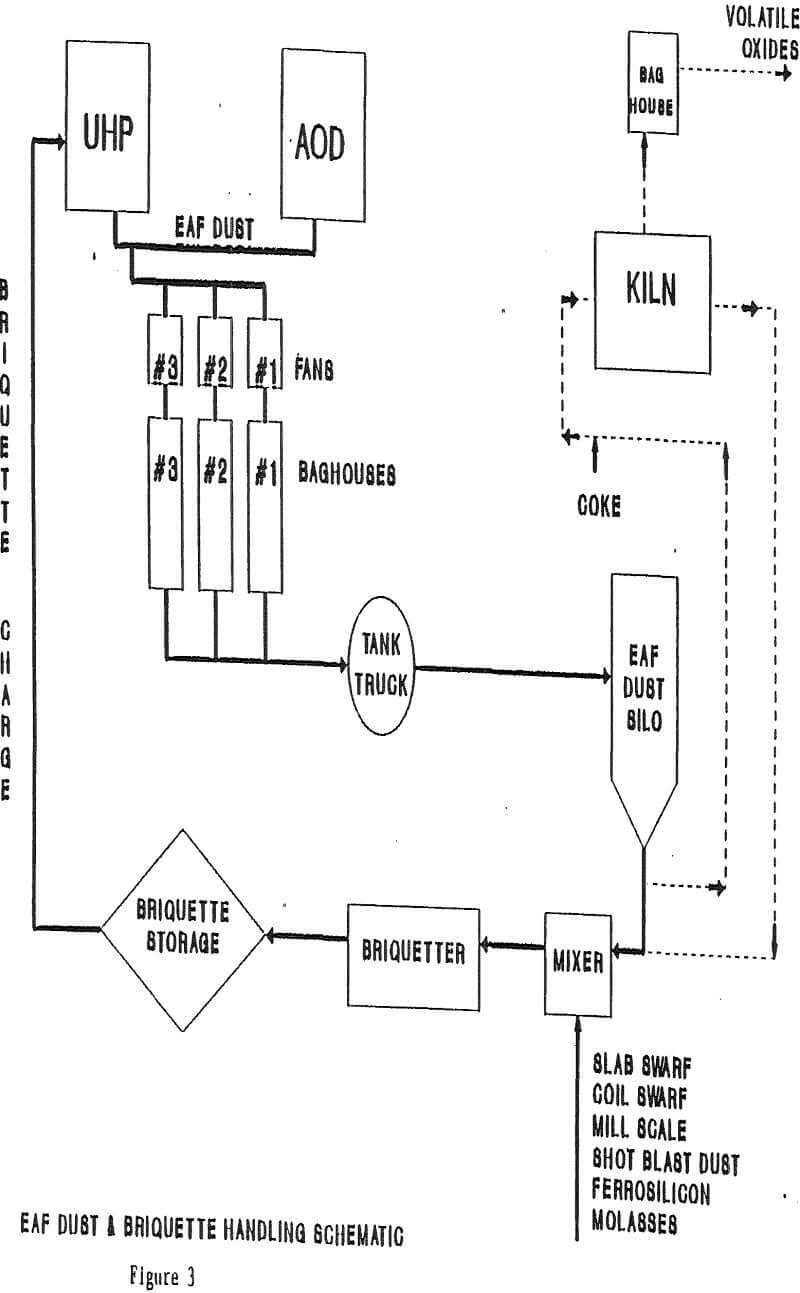

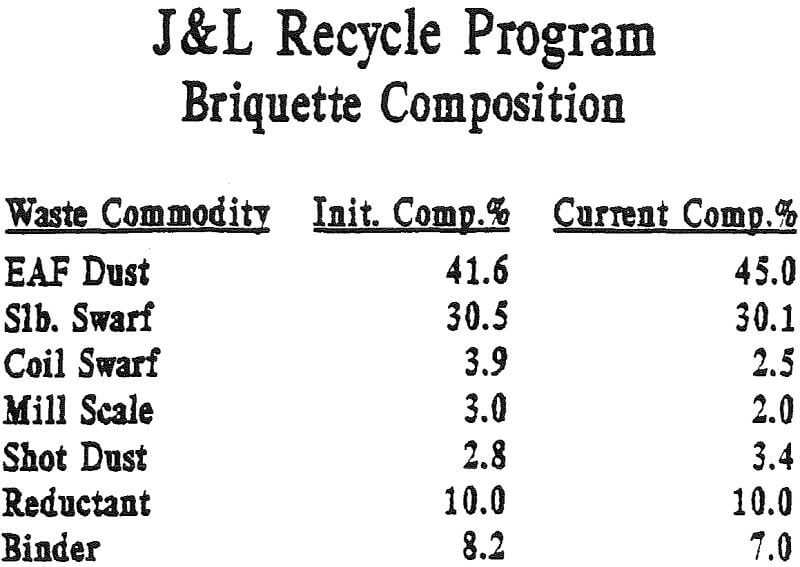

Based on the projected generations for the remaining 4 waste commodities, and allowing for adequate reductant and binder, it was found that virtually all of these wastes could be utilized by a 121 substitution for scrap in the charge make-up. Though the original formulation utilized carbon as the reductant, a change to Ferro Silicon was implemented for more aggressive chrome recoveries. This charge ratio has been maintained throughout 4 ¼ years at J & L.

Having decided on a formulation and charge percentage, a program was devised for determining the optimum placement of the briquettes in the charging sequence. It was determined that for optimum recovery, the full 12% portion of briquettes be charged in the second pan along with the balance of the scrap charge & alloy.

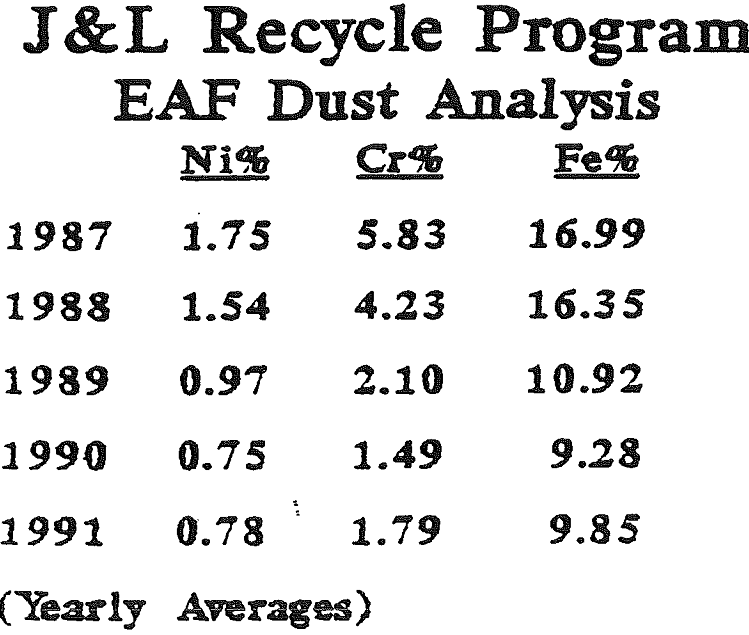

As part of the overall performance study, the increased recovery from swarf due to its inclusion in the briquettes was examined, Though a large portion of the swarfs were being used as charge make-up, no formal system was in place. Dust chemistries prior to our start-up in 1987 were higher than expected in Ni and Cr content, suggesting an inefficiency in getting the swarf into the liquid metal bath where the best recovery would occur.

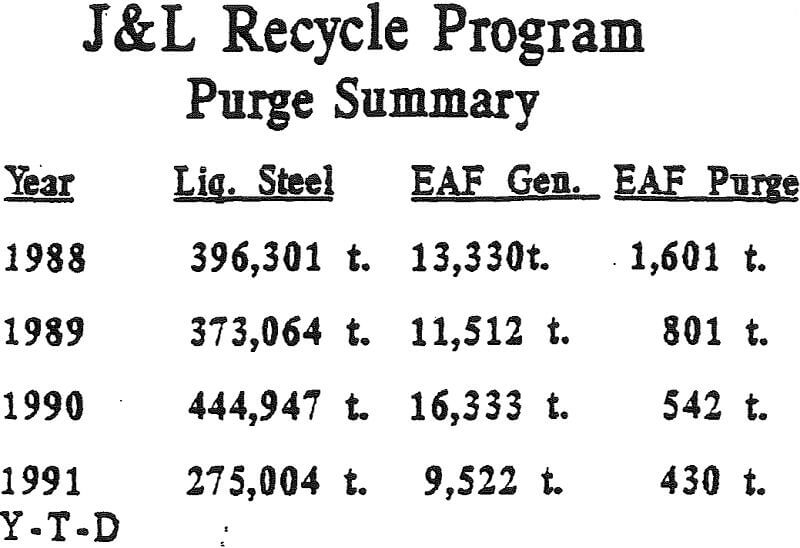

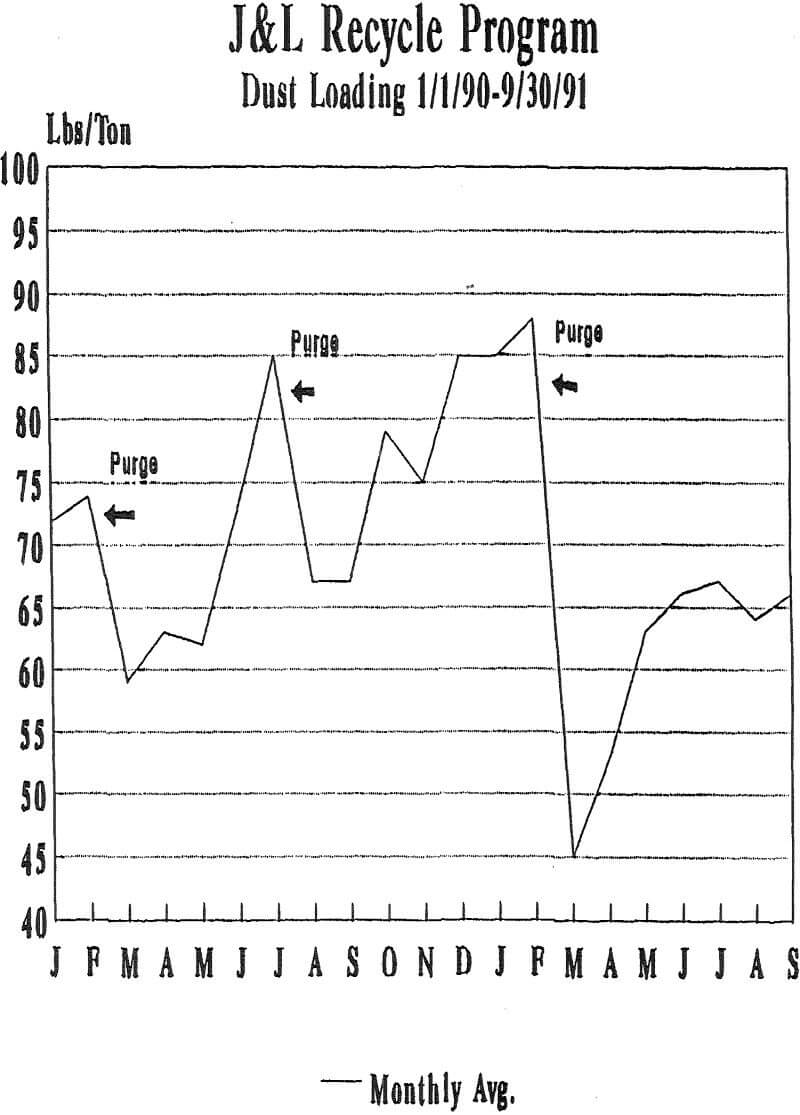

In reality 93.5% of the dust generated over the last 4¼ years has been re-absorbed by the steelmaking process. The current absorption exceeds 95%.

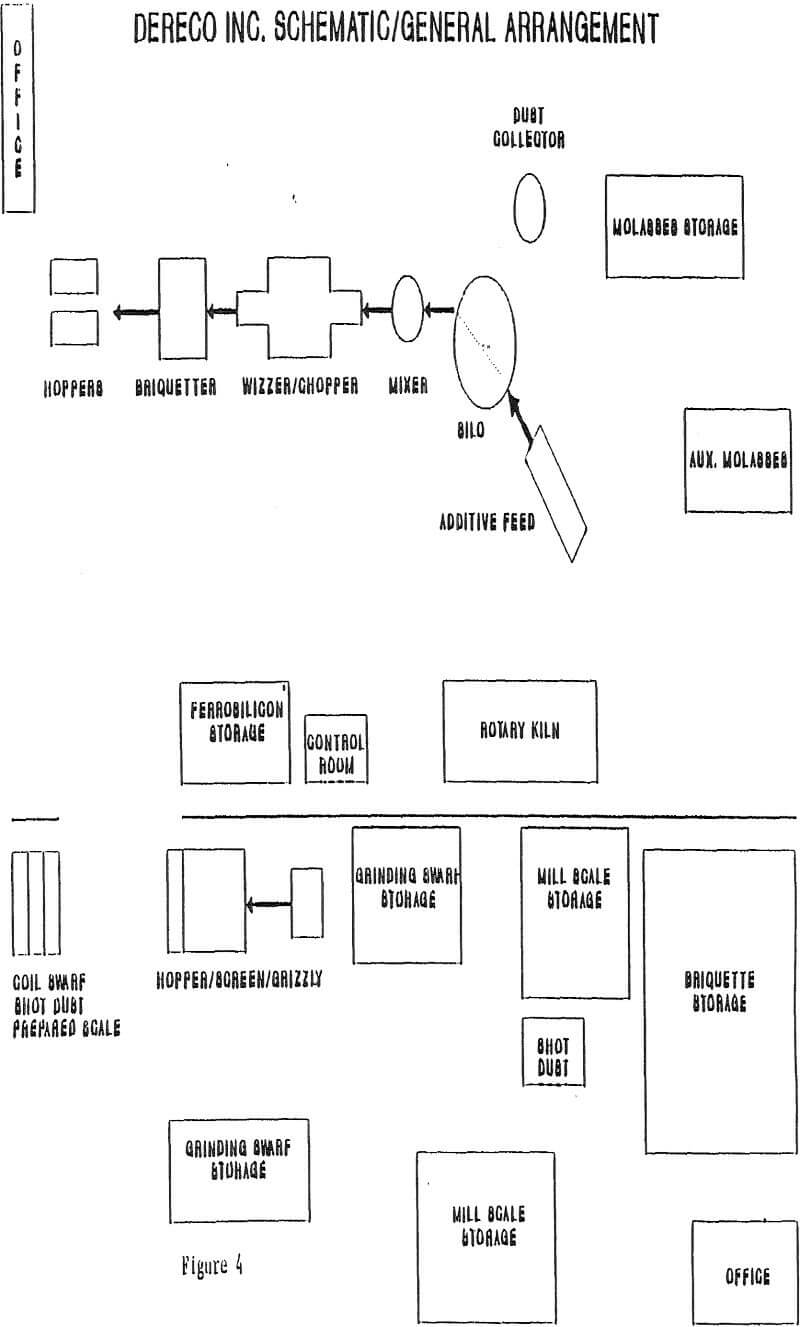

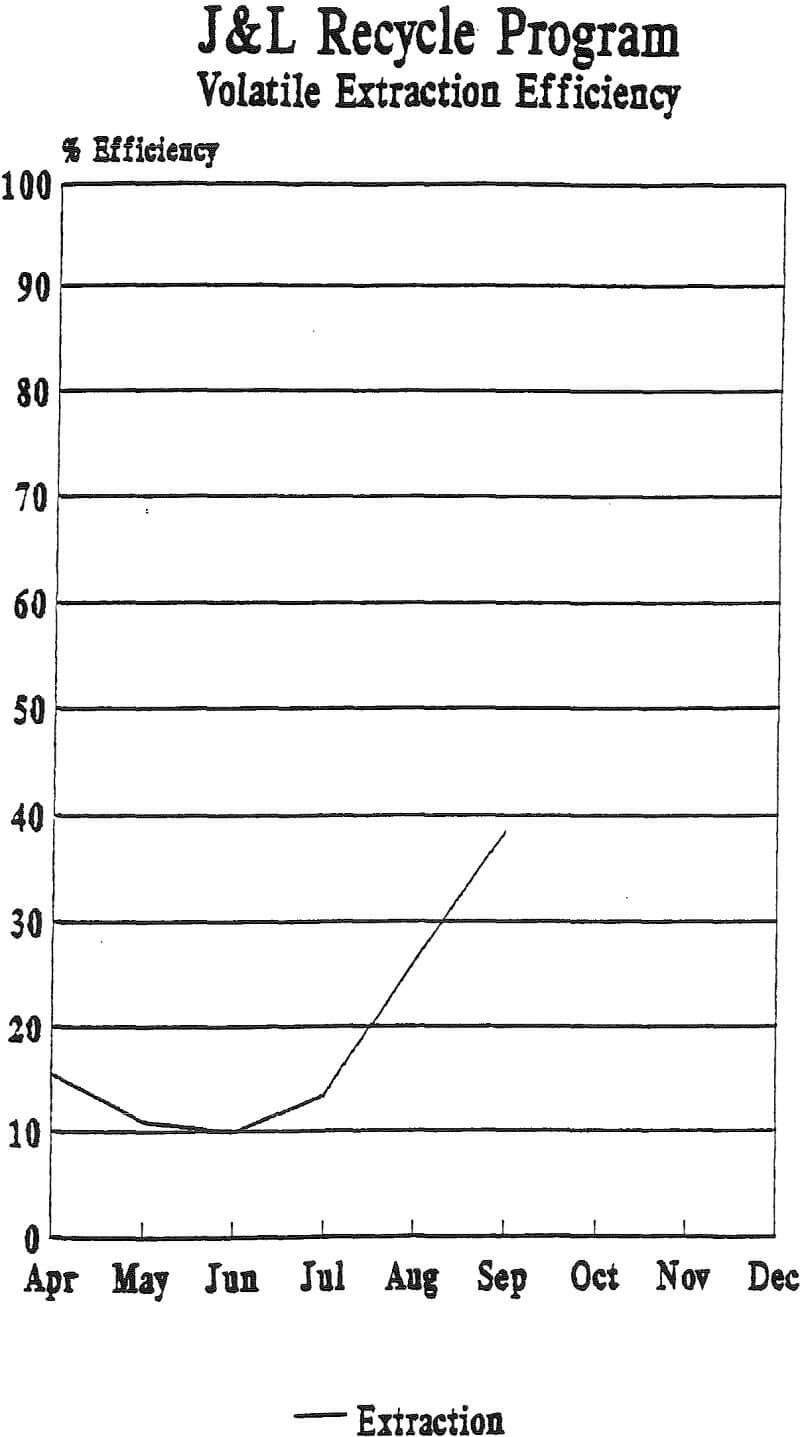

During the last quarter of 1990, the necessary equipment for a thermal separation process was installed at our J & L site. During the start-up program a number of design problems were encountered which necessitated some months of retro-fitting.

The basic principle of the process involves diverting a portion of the current dust generation for treatment. The feed dust is sized with carbon and processed through an indirect – fired kiln. The zinc, cadmium and lead are reduced by the carbon and captured in a carrying gas composed of combustion gas and nitrogen. These volatiles are re-oxidized as they pass through a heat exchanger and are captured in a baghouse. These oxides are then marketed to a secondary non- ferrous market for further refinement. On-site processing of these volatiles is also possible. At present, the economics favor off-site refinement.

In summary, the system can offer the steel industry:

- The opportunity for metallic recovery from all waste streams currently being generated.

- Elimination of all “over the road” liabilities for K061 transportation and the associated administration costs.

- Provide for the least amount of liability exposure both now and in the future.