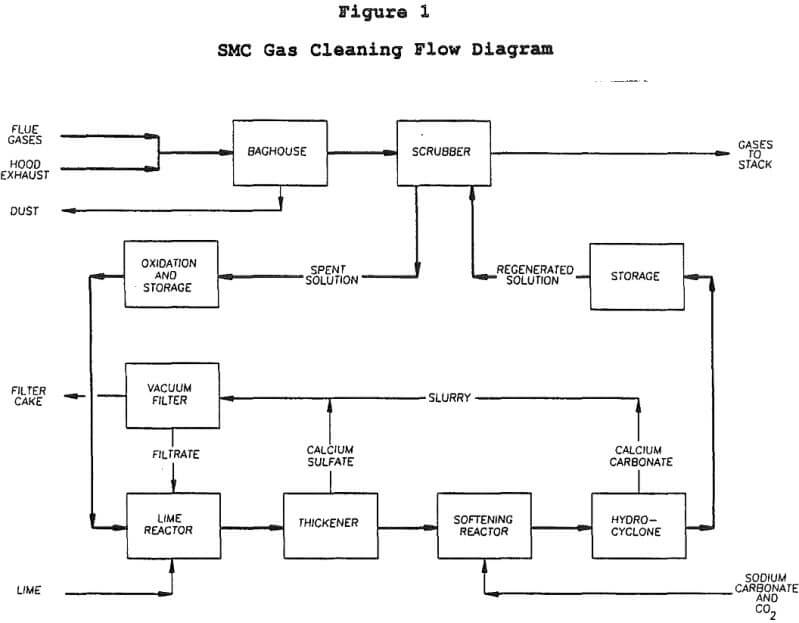

SMC’s smelting process is composed of a submerged-arc electric furnace and a top blown rotary converter (TBRC). The 1.5 MW rated furnace operates continuously while the 0.15 M³ TBRC is operated on a batch basis. Process flue gases are combined with tapping hood exhaust air and ducted to a gas cleaning system prior to release to the atmosphere.

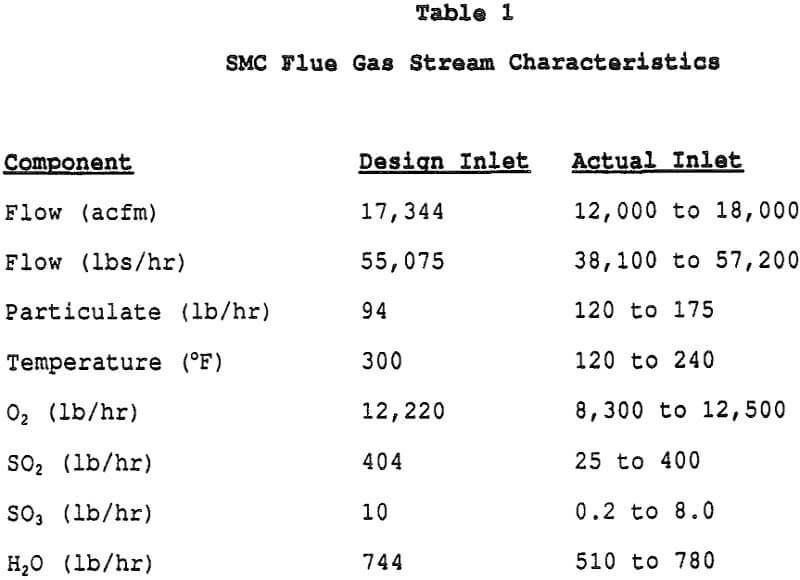

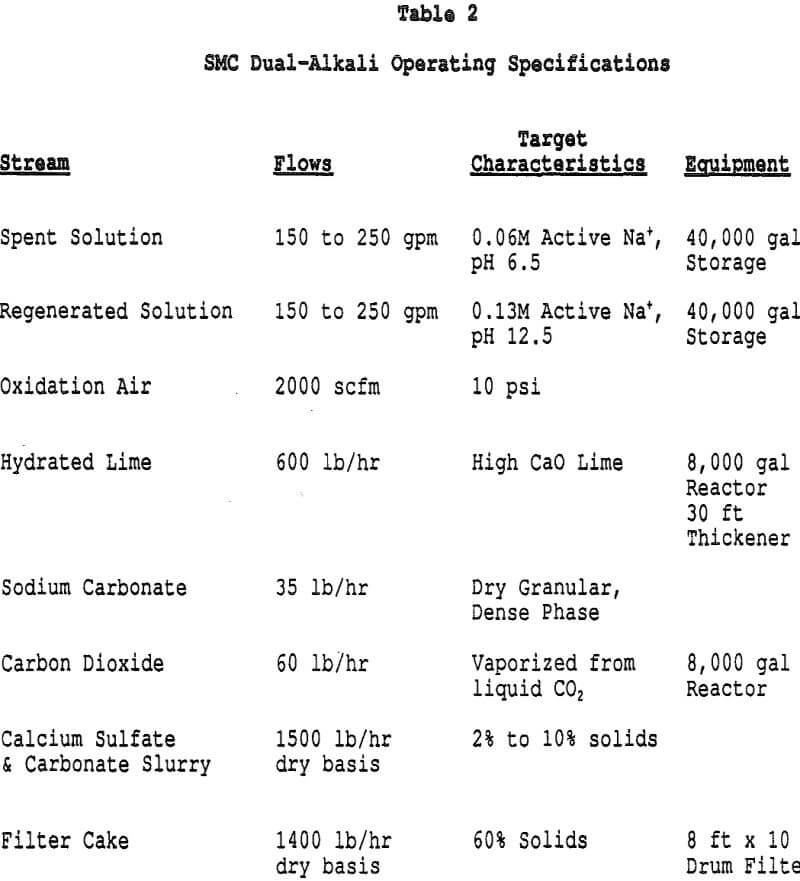

The gas cleaning system is comprised of two sections: a baghouse type dust collector for metals recovery; and a dual-alkali FGD system for SO2 removal. The system was originally constructed without a dust collector. However this resulted in unacceptable loss of PGM values.In a dual-alkali FGD process, sodium alkali is used in the absorber for high scrubbing efficiency and scale-free operation. The spent sodium alkali is regenerated with lime or limestone.

Operation of concentrated mode systems under high oxidation conditions is not feasible because settling and filtering characteristics of the resulting combined sulfate/sulfite sludge are very poor. Additionally, a high potential for scrubber scaling is created, lime utilization is poor, and process control is difficult. In the dilute mode, where virtually all sulfite is converted to sulfate before regeneration, the settling and filtering characteristics of the calcium sulfate are very good.

In response to the very high oxygen concentrations anticipated, the dilute mode dual-alkali system was chosen for the SMC gas cleaning system.

Continuous emission monitors at the scrubber inlet and outlet monitor the efficiency of SO2 removal. Removal efficiency can be increased by raising the pH of the scrubber first stage from its normal setpoint of 6.5 by addition of regenerated scrubbing solution. Air addition to the oxidation tank is maintained at a fixed rate based on average solution flow.

Upon completion of construction, all operators attended classroom training sessions during which they learned the basic theory and control mechanisms of the system. One operator was assigned to each shift with responsibility for the scrubber operation, regeneration circuit, and gypsum filtration/handling.

After installation of the regeneration thickener, cyclone performance was found to be adequate downstream of the softening reactor due to a relatively low solids content.